Ballistic resistance capabilities of explosive reactive armors encapsulated by ceramic layers

-

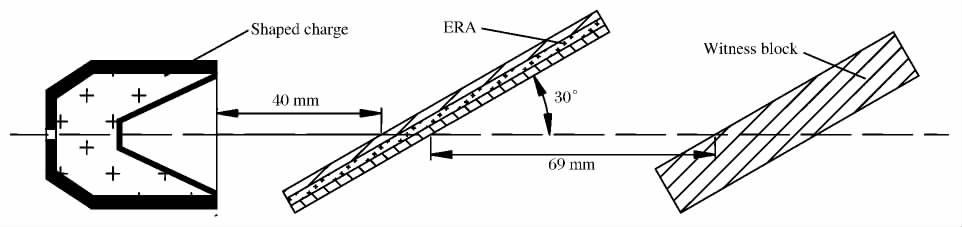

摘要: 运用口径36mm的精密成型装药实验,研究了等效厚度相同的碳化硅和氧化铝陶瓷平板装药的防护性能,并与包覆材料为钢的平板装药进行了对比。运用LS-DYNA3D软件,对平板装药与聚能装药的作用过程进行了三维数值模拟。实验结果显示,对于此结构的平板装药,碳化硅和氧化铝陶瓷平板装药使聚能装药侵彻能力分别下降了88%和82%,优于钢板的防护性能。数值模拟结果显示,陶瓷包覆板从边缘至中心依次出现断裂和粉碎现象,钢板与射流后部作用为断续干扰,而陶瓷板为连续干扰。Abstract: By using the precision shaped charge warheads with the caliber of 36mm, anti-penetration experiments were conducted on the explosive reactive armors(ERAs)encapsulated by three different material layers with the same equivalent thickness, respectively.And the encapsulation layers were made of alumina, silicon carbide and steel plates, respectively.The experimental results show that for this armor configuration, after passing the ERAs with alumina and silicon carbide plates, the penetration depths of the shaped-charge jets decrease 82%and 88%, respectively, which are comparable to those in the cases of steel plates.And the interactions of the jets with the ceramic and steel plates were simulated by applying the finite-element code LS-DYNA3D.The simulation results display that after interaction with the jets, the ceramic plates shatter and break into pieces from the edge to the center.And the interaction mechanism between the shaped-charge jet back and the steel plate is an intermittent disturbance, whereas it is a continuous disturbance with the ceramic plates.

-

Key words:

- mechanics of explosion /

- protection performance /

- LS-DYNA3D /

- explosive reactive armour /

- alumina /

- silicon carbide /

- shaped charge

-

表 1 不同包覆板材料平板装药的防护性能

Table 1. Protection performance of ERA with different plate materials

包覆板材料 a/mm b/mm c/mm l/mm SiC 15 10 6 麻点 45 steel 25 10 10 2~3 Al2O3 25 11 9 麻点 表 2 紫铜和45钢的计算参数

Table 2. Calculating parameters for the copper and 45 steel

材料 ρ/(g·cm-3) A/GPa B/GPa n C m Tm/K Tr/K Fe 7.85 0.792 0.510 0.26 0.014 1.03 1 793 294 Cu 8.96 0.090 0.292 0.31 0.025 1.09 1 356 294 表 3 陶瓷的计算参数[10]

Table 3. Calculating parameters for SiC and AL2O3

材料 G/GPa A B C M N T σc/GPa σHEL/GPa pHEL/GPa K1 K2 K3 β D1 D2 σf, max/GPa SiC 183.00 0.96 0.35 0 1.0 0.65 0.37 14.57 13 5.90 204.8 0 0 1.0 0.480 0.480 1.0 Al2O3 90.16 0.35 0.31 0 0.6 0.60 0.20 2.79 2 2.79 131.0 0 0 1.0 0.005 1.00 1.0 -

[1] Held M. Protection device against projectiles, especially shaped charges: Deutsches, 2358277[P]. 1973. [2] Held M. Stopping power of explosive reactive armors against different shaped charge diameters or at different angles[J]. Propellants, Explosives, Pyrotechnics, 2001, 26: 97-104. doi: 10.1002/1521-4087(200104)26:2<97::AID-PREP97>3.0.CO;2-A [3] Held M. Momentum theory of explosive reactive armours[J]. Propellants, Explosives, Pyrotechnics, 2001, 26: 91-96. doi: 10.1002/1521-4087(200104)26:2<91::AID-PREP91>3.0.CO;2-9 [4] Held M. Disturbance of shaped charge jets by bulging armour[J]. Propellants, Explosives, Pyrotechnics, 2001, 26: 191-195. doi: 10.1002/1521-4087(200110)26:4<191::AID-PREP191>3.0.CO;2-C [5] 毛东方, 李向东, 宋柳丽. V型夹层炸药对射流干扰的数值模拟[J].爆炸与冲击, 2008, 28(1): 86-91. doi: 10.3321/j.issn:1001-1455.2008.01.015Mao Dong-fang, Li Xiang-dong, Song Liu-li. Numeriacal simulation of disturbance by sandwich explosive on jet[J]. Explosion and Shock Waves, 2008, 28(1): 86-91. doi: 10.3321/j.issn:1001-1455.2008.01.015 [6] Kaufmann H, Koch A. Terminal ballistic effects of low density materials used as confinement plates for explosive reactive armor[C]//Proceedings of the 22nd International Symposium on Ballistics. Vancouver, Canada, 2005: 405-412. [7] Hazell P J, Lawrence T, Stennett C. The defeat of shaped charge jets by explosively driven ceramic and glass plates[J]. International Journal of Applied Ceramic Technology, 2012, 9(2): 382-392. doi: 10.1111/j.1744-7402.2011.02656.x [8] 王玲, 郑威, 辛培训, 等.纤维增强复合材料的制备及防护性能研究[J].工程塑料应用, 2010, 38(10): 27-30. doi: 10.3969/j.issn.1001-3539.2010.10.006Wang Ling, Zheng Wei, Xin Pei-xun, et al. Study on preparation and ballistic resistance of fiber reinforced composite[J]. Engineering Plastics Application, 2010, 38(10): 27-30. doi: 10.3969/j.issn.1001-3539.2010.10.006 [9] Lee E L, Tarver C M. Phenomenological model of initiation in heterogeneous explosives[J]. Physics of Fluids, 1980, 23(12): 2362-2369. doi: 10.1063/1.862940 [10] Livermore Software Technology Corporation. LS-DYNA keyword user's manual[M]. California: Livermore Software Technology Corporation, 2001. -

下载:

下载: