Resonance and energy-absorption capability of polyurethane foam in high-shock launching for scout-robot

-

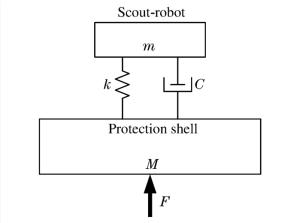

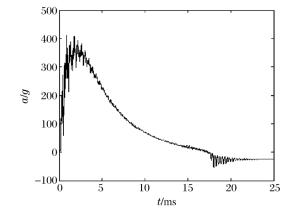

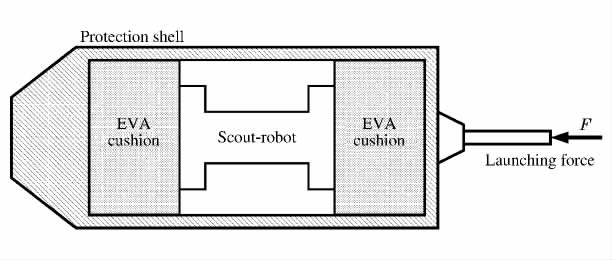

摘要: 针对抛投式机器人弹射过程中存在的高过载问题,使用缓冲材料对机器人进行减过载处理。讨论了缓冲材料在高过载情况下的吸能特性,根据抛投式机器人缓冲保护壳的结构和缓冲材料的性质,建立了单自由度支座激励系统数学模型,并对其系统固有频率和放大系数进行了分析。利用弹射器内弹道加速度测量系统测量了弹射器的激励曲线和机器人在缓冲材料作用下的响应。实验结果表明,当缓冲系统的固有频率与弹射器的激励频率接近时,系统产生共振,机器人所受过载增加。通过调整缓冲系统的参数,改变其固有频率,使系统放大系数小于1,避免产生共振。Abstract: For solving the high-overload problem existing during launching the scout-robot, the polyurethane foam was used as cushion material to reduce the overloads endured by the scout-robot.The energy-absorption capability of the polyurethane foam in the high-shock launching was discussed.Based on the structure of the robot protection shell and the properties of the cushion material, a mathematical model was established for the base-excited system with single degree of freedom.And the natural frequency of this system was analyzed as well as its amplification coefficient.An interior ballistics measurement system was developed to measure the acceleration curves of the scout-robot with and without cushion.The experimental results show that the system can produce resonance to make its acceleration increase when the natural frequency of the system is close to the excitation frequency of the launching device.And the natural frequency of the cushion system can be changed by adjusting the system parameters to reduce the amplification coefficient to less than 1and thus the cushion system can avoid resonance.

-

表 1 抛投机器人缓冲系统实验数据

Table 1. Experimental data of robot cushioning system

h/mm fn/Hz a/g β 0 55.50 380 50 58.12 1 200 3.150 70 49.07 480 1.260 90 43.31 410 1.070 110 30.33 314 0.826 -

[1] 袁应龙, 卢子兴.复合泡沫塑料的缓冲特性研究[J].北京航空航天大学学报, 2004, 30(2): 135-138. doi: 10.3969/j.issn.1001-5965.2004.02.010Yuan Ying-long, Lu Zi-xing. Cushioning properties of polyurethane syntactic foam[J]. Journal of Beijing University of Aeronautics and Astronautics, 2004, 30(2): 135-138. doi: 10.3969/j.issn.1001-5965.2004.02.010 [2] 姜锡权, 陶杰, 王玉志.改进的霍普金森杆技术在聚氨脂泡沫塑料动态力学性能研究中的应用[J].爆炸与冲击, 2007, 27(4): 358-363. doi: 10.3321/j.issn:1001-1455.2007.04.011Jiang Xi-quan, Tao Jie, Wang Yu-zhi. Application of modified split Hopkinson pressure bar technique in the study of dynamic behavior of a polyurethane foam[J]. Explosion and Shock Waves, 2007, 27(4): 358-363. doi: 10.3321/j.issn:1001-1455.2007.04.011 [3] 张海波, 孙金坤, 谭立伟, 等.聚氨酯泡沫塑料吸能特性研究[J].材料科学与工程学报, 2004, 22(1): 117-120. doi: 10.3969/j.issn.1673-2812.2004.01.031Zhang Hai-bo, Sun Jin-kun, Tan Li-wei, et al. Study of energy-absorbing properties of polyurethane plastic foam[J]. Journal of Materials Science and Engineering, 2004, 22(1): 117-120. doi: 10.3969/j.issn.1673-2812.2004.01.031 [4] 胡时胜, 刘剑飞, 王悟.硬质聚氨酯泡沫塑料的缓冲吸能特性评估[J].爆炸与冲击, 1998, 18(1): 42-47. http://www.cnki.com.cn/Article/CJFDTotal-BZCJ801.006.htmHu Shi-sheng, Liu Jian-fei, Wang Wu. Evaluation of cushioning properties and energy-absorption capability of rigid polyurethane foam[J]. Explosion and Shock Waves, 1998, 18(1): 42-47. http://www.cnki.com.cn/Article/CJFDTotal-BZCJ801.006.htm [5] 文丰, 任勇峰, 王强.高冲击随弹测试固态记录器的设计与应用[J].爆炸与冲击, 2009, 29(2): 221-224. doi: 10.3321/j.issn:1001-1455.2009.02.021Wen Feng, Ren Yong-feng, Wang Qiang. Design of bomb-borne solid-state recorder for high-shock test and its application[J]. Explosion and Shock Waves, 2009, 29(2): 221-224. doi: 10.3321/j.issn:1001-1455.2009.02.021 [6] 苏远, 汤伯森.缓冲包装理论基础与应用[M].北京: 化学工业出版社, 2006: 11-15. [7] Li Zhi-bin, Yu Ji-lin, Guo Liu-wei. Deformation and energy absorption of aluminum foam-filled tubes subjected to oblique loading[J]. International Journal of Mechanical Sciences, 2012, 54(1): 48-56. doi: 10.1016/j.ijmecsci.2011.09.006 [8] Mohammad R S, Russel E, Glynn R. Effects of temperature on the material characteristics of midsole and insole footwear foams subject to quasi-static compressive and shear force loading[J]. Materials and Design, 2012, 37: 543-559. doi: 10.1016/j.matdes.2011.10.045 [9] Li Bin-chao, Zhao Gui-ping, Lu Tian-jian. Low strain rate compressive behavior of high porosity closed-cell aluminum foams[J]. Science China Technological Sciences, 2012, 55(2): 451-463. doi: 10.1007/s11431-011-4685-5 -

下载:

下载: