Penetration process of screw/seat ejection life-saving system through canopy:Numerical simulation

-

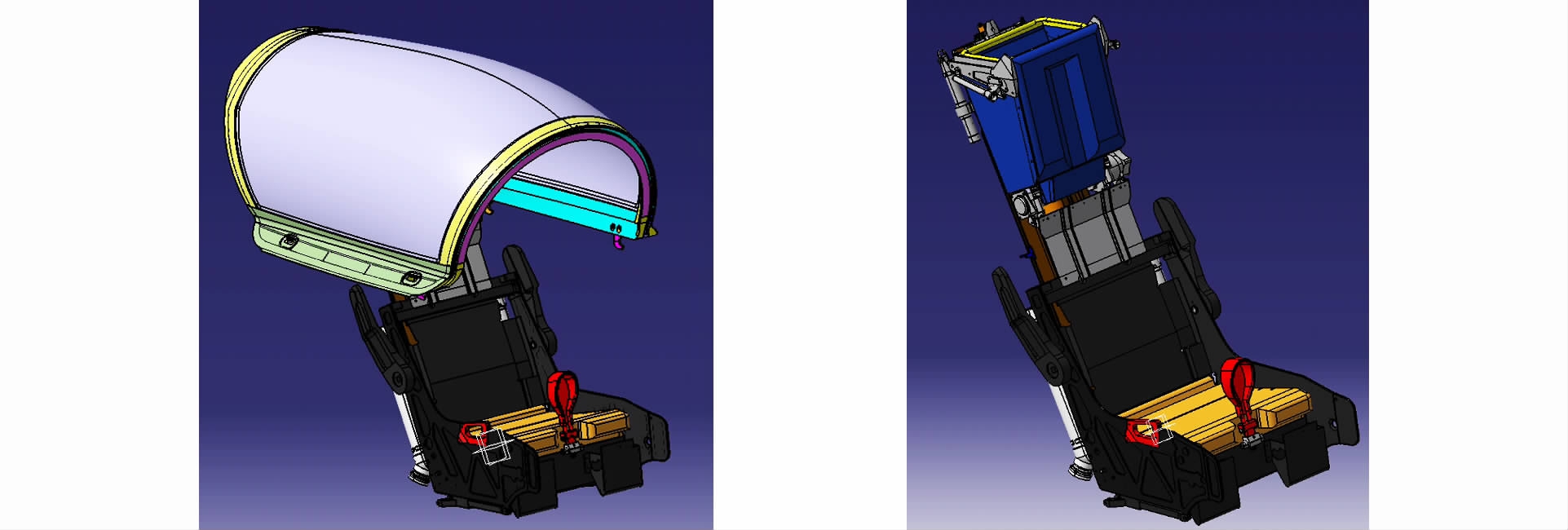

摘要: 拟针对战斗机微爆索预破碎座舱盖弹射救生系统中人/椅系统穿盖过程中弹射通道的畅通性,座舱盖的破坏模式以及人体重要部位的冲击损伤程度。考虑微爆索在舱盖内表面沿中央和四周2种不同的切割布局,建立人/椅系统撞击舱盖的解耦模型,采用非线性动态显式算法对穿盖过程进行了数值模拟。模拟结果表明:第2种布局较第1种布局更有利于形成畅通的弹射通道,也有助于减轻人体的损伤,同时给出2种布局切割槽深度的临界值。研究结果可为弹射救生系统的优化设计和安全生产提供可靠依据。Abstract: Aimed to an ejection life-saving system in combat aircraft with a canopy pre-damaged by miniature detonation cord, the followings were investigated as the accessibility of the ejection passageway, the damage modes of the canopy, and the impact injury degrees of the key human-body parts.The decoupled models were proposed for describing the impact of the aircrew/seat system into the canopy.In the proposed models, the two different layouts of the miniature detonation cord in the canopy were considered, i.e.Along the center of the canopy(the first layout)and around it(the second layout).Based on the above models, the process of the aircrew/seat system penetrating through the canopy was numerically simulated by using the nonlinear dynamics explicit algorithm.And the critical depths of the cutting slots were obtained for the two layouts.The simulated results indicate that the second layout is more helpful for generating an unobstructed passageway and relieving human impact injury than the first layout.

-

表 1 Hybrid Ⅲ假人颈部材料模型及参数

Table 1. Material models and parameters of neck for HybridⅢ dummy

部位 材料模型 ρ/(kg·m-3) K/GPa E/GPa ν G0/GPa G∞/GPa β 颈椎肌肉 黏弹性 1 250 0.002 3 - - 0.007 5 0.002 1.0 颈椎 刚性 2 700 - 70.00 0.31 - - - 颈部皮肤 2 700 7.000 0 0.31 - - - - 气管 线弹性 1 250 - 4.30 0.31 - - - -

[1] Sandstedt P. Experience of rocket seat ejection in the swedish air force: 1967-1987[J]. Aviation, Space, and Environmental Medicine, 1989, 60(6): 367-373. http://europepmc.org/abstract/MED/2705973 [2] Milanov L. Aircrew ejection on the republic of bulgaria, 1953-1993[J]. Aviation, space, and environmental medicine, 1996, 67(4): 364-368. http://europepmc.org/abstract/MED/8900991 [3] Moreno Vazquez J M, Duran Tededa M R, Garcia Alcon J L. Report of ejections in the spanish air force, 1979-1995: An epidemiological and comparative study[J]. Aviation, Space, and Environmental Medicine, 1999, 70(3): 686-691. http://europepmc.org/abstract/MED/10417005 [4] Miller B A. Unassisted through canopy ejection experience[C]//Proceedings of the 20th SAFE annual symposium. 1982: 146-149. [5] 丛红, 徐建仁, 刘力, 等.穿盖弹射对人体头、肩、膝部的损伤程度[J].航空军医, 1997, 25(5): 259-261.Cong Hong, Xu Jian-ren, Liu Li, et al. Human head and knee tolerance to impact produced by through-the-canopy ejection[J]. Chinese Journal of Aerospace Medicine, 1997, 25(5): 259-261. [6] Patrick L M, Lissner H R, Gurdjian E S. Survival by design head protection[C]//Proceedings of the 7th Stapp Car Crash Conference. 1963. [7] 赵一明, 杨春信, 韩海鹰, 等.弹射救生过程数值计算及损伤风险评估[J].空气动力学学报, 2006, 24(3): 314-318. http://www.cnki.com.cn/Article/CJFDTotal-KQDX200603007.htmZhao Yi-ming, Yang Chun-xin, Han Hai-ying, et al. Numerical calculation of ejection process and injury crisis evaluation[J]. Acta Aerodynamica Sinica, 2006, 24(3): 314-318. http://www.cnki.com.cn/Article/CJFDTotal-KQDX200603007.htm [8] Brinkley J W, Mosher S E. Development of acceleration exposure limits to advanced escape systems, implications of advanced technologies for air and spacecraft escape[R]. GARD-CP-472, 1989: 24-28. [9] 李志强, 刘晓明, 赵勇刚, 等.微爆索线性切割航空有机玻璃的实验研究和有限元分析[J].爆炸与冲击, 2007, 27(5): 385-389. http://www.cnki.com.cn/Article/CJFDTotal-BZCJ200705001.htmLi Zhi-qiang, Liu Xiao-ming, Zhao Yong-gang, et al. Experimental study and finite element analysis of linear cutting aerial PMMA using micro detonation cord[J]. Explosion and Shock Waves, 2007, 27(5): 385-389. http://www.cnki.com.cn/Article/CJFDTotal-BZCJ200705001.htm [10] 李志强, 赵隆茂, 刘晓明, 等.微爆索线型切割某战斗机舱盖的研究[J].航空学报, 2008, 29, (4): 1049-1054. http://d.wanfangdata.com.cn/Periodical/hkxb200804046Li Zhi-qiang, Zhao Long-mao, Liu Xiao-ming, et al. Study on the linear shape cutting canopy of a warcraft with miniature detonating cord[J]. Acta Aeronautica Et Astronautica Sinica, 2008, 29, (4): 1049-1054. http://d.wanfangdata.com.cn/Periodical/hkxb200804046 [11] 李志强, 赵隆茂, 刘晓明, 等.微爆索布局对战斗机舱盖破裂影响的数值模拟[J].北京理工大学学报, 2009, 29(增刊): 170-173.Li Zhi-qiang, Zhao Long-mao, Liu Xiao-ming, et al. Numerical simulation of the influence of miniature detonating cord layout on fracturing warcraft[J]. Journal of Beijing Institute of Technology Natural Science Edition, 2009, 29(suppl): 170-173. [12] Li Zhi-qiang, Yao Xiao-hu, Zhao Long-mao. A computer simulation on human injury during the aircrew/seat through-the-canopy-ejection[J]. Applied Mechanics and Materials, 2011(55/56/57): 179-182. http://www.scientific.net/AMM.55-57.179 [13] Berstad T, Hopperstad O S, Lademo O G, et al. Computational model of ductile damage and fracture in shell analysis[C]//The Second European LS-DYNA Conference. Gothenburg, Sweden, 1999. [14] Shalak R, Chinen S. Handbook of bioengineering[M]. New York: MeGraw-Hill, 1987. [15] MeElhaney J H. Dynamics response of bone and muscle tissue[J]. Journal of Applied Physiology, 1966, 21: 1231-1236. http://europepmc.org/abstract/med/5916656 [16] LS-DYNA971keyword user's manual[M]. Livermore Software Technology, 2007. -

下载:

下载: