-

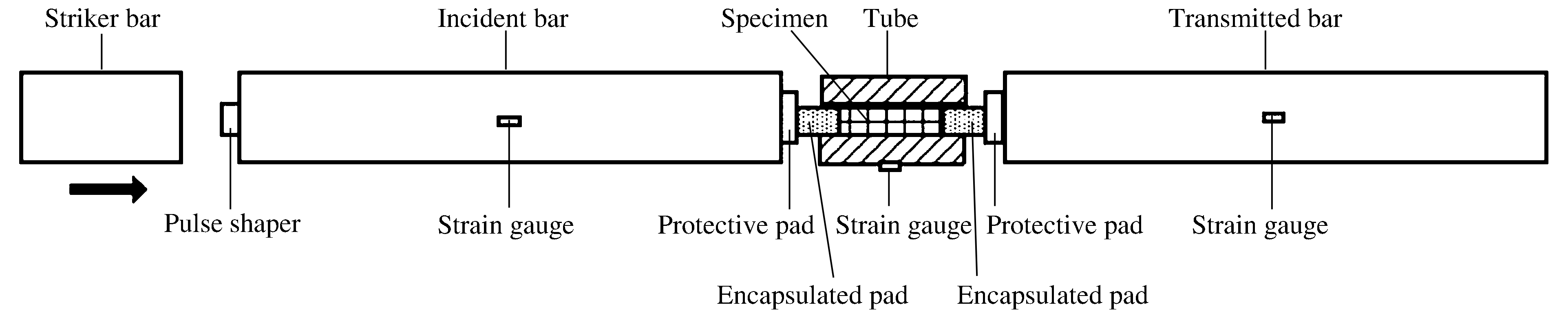

摘要: 基于动态三轴被动加载实验技术,建立了一种可测量吉帕量级及以下低体模量材料压强-体应变关系的被动围压SHPB实验设计方法。在该实验设计中确定了样品、封装垫块、围压套管的尺寸以及尺寸间的匹配,并对实验压强进行了限制。通过比较传统SHPB实验和被动围压SHPB实验测量LC4铝合金等效应力的方式,验证了被动围压SHPB实验压强测量的有效性;通过实验和数值模拟分析,验证了体应变测量的有效性。将设计的被动围压SHPB实验方法应用于铈,得到了铈在伽马→阿尔法相变区间完整显示的压强-体应变演化信息,且相变起始和终止压强、相变体积变化量均与静高压实验结果基本一致。这说明设计的被动围压SHPB实验方法适用于测量低体模量材料的压强-体应变关系。Abstract: Based on dynamic triaxial passive loading techniques, a new passive confined SHPB experiment technique was designed for measuring the responses of pressure and volume strain of materials with bulk modulus of giga pascal or less.In the experiment design, the dimensions of the specimens, encapsulated pads and confinement tube were determined as well as their matching.And the upper limit of pressure load was given.The pressure result from this design was validated by the deviation of equivalent pressure of LC4 aluminum alloy measured by the passive confined SHPB experiment and SHPB experiment.The volume strain result from this design is approximately equal to the axial strain measured by the SHPB experiment.And based on the analysis of experiment and numerical simulation, the radial strain can be omitted compared with the volume strain.Cerium was tested by the designed passive confined SHPB setup.The result shows the entire response of pressure and volume strain during the phase transition of gamma to alpha.The variety of volume strain during phase transition and the pressures of the beginning and ending of phase transition are similar to those by hydrostatic-pressure experiments.So the designed passive confined SHPB technique is feasible for measuring the pressure-volume strain relation of materials with low bulk modulus.

-

-

[1] Singh A K, Kennedy G C. Compressions of Si, MgO, and ZrSiO4 to 8 GPa as measured with a WC-anvil x-ray apparatus and epoxy pressure medium[J]. Journal of Applied Physics, 1977, 48(8): 3362-3367. [2] Mao H K, Bell P M, Shaner J W, et al. Specific volume measurement of Cu, Mo, Pd, and Ag and calibration of the ruby R1 fluorescence pressure gauge from 0.06 to 1 Mbar[J]. Journal of Applied Physics, 1978, 49(6): 3276-3283. [3] Kabir M E, Chen W. Measurement of specimen dimensions and dynamic pressure in dynamic triaxial experiments[J]. Review of Scientific Instruments, 2009, 80(12): 125111-125117. [4] Forquin P, Gray G, Gatuingt F. A testing technique for concrete under confinement at high rates of strain[J]. International Journal of Impact Engineering, 2008, 35(6): 425-446. [5] 李英华, 李英雷, 张祖根, 等.侧限SHPB实验中软材料体压缩特性的测量方法[J].爆炸与冲击, 2010, 30(1): 109-112.Li Ying-hua, Li Ying-lei, Zhang Zu-gen, et al. Approach to pressure and volume measurement of soft materials by an SHPB with lateral confinement[J]. Explosion and Shock Waves, 2010, 30(1): 109-112. [6] Nemat-NassarJ, IsaacJ, RomeJ. Triaxial Hopkinsontechniques[M]∥Kuln H, Medlin D. ASM Handbook: Volume8. Materials Park, Ohio, USA: ASMInernational, 2000: 516-518. [7] Lipp M J, Jackson D, Cynn H, et al. Thermal signatures of the Kondo volume collapse in cerium[J]. Physical Review Letters, 2008, 101(16): 165703-1-4. [8] 胡时胜.霍普金森压杆技术[J].兵器材料科学与工程, 1991(11): 40-47. [9] Wu Z, Wu H, Han F. Elasticity[D]. Beijing: Beijing Insitute of Technology Press, 2006: 98. [10] Malvern L E. Introduction to the mechanics of a continuous medium[D]. New Jersey: Prentice-Hall, Inc, 1969: 90-274. -

下载:

下载: