-

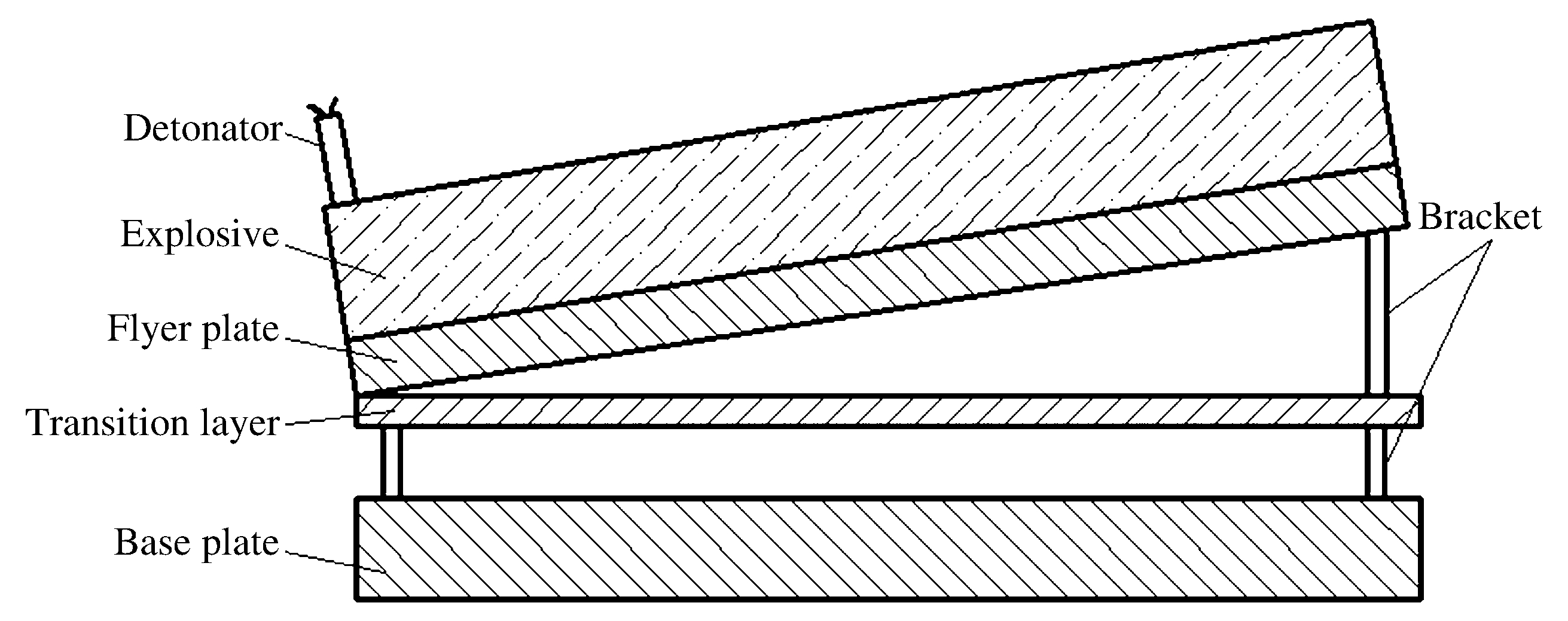

摘要: 为了考察钛作为过渡层提高锆/钢复合板结合强度的有效性,同时给出合理的爆炸焊接碰撞参数,对双层锆/钢和三层锆/钛/钢进行了小倾角法爆炸焊接实验研究。借助金相显微技术测量了复合板结合界面的波形参数,采用光滑粒子动力学法模拟得到了不同位置的碰撞速度和碰撞角,并按照国家标准(GB/T 6396-2008)测量了复合板结合界面的爆炸态及退火态的剪切强度。结果表明:钛作为过渡层能够显著提高锆/钢界面的剪切强度;退火消除加工应力后,锆/钢及钛/钢结合面的剪切强度会有所降低;当锆/钛界面的碰撞速度为734~805 m/s,碰撞角为19.8°~20.8°,钛/钢界面的碰撞速度为803~904m/s,碰撞角为19.5°~20.5°时,锆/钛/钢三层复合板的锆/钛和钛/钢界面的剪切强度都能高于140 MPa。Abstract: In order to investigate the influence of the transition layer on the shear strength of the Zr/steel explosive clad plate and obtain the rational impact parameters of explosive welding, the difference of the Zr/steel and Zr/Ti/steel clad plates was compared by the explosive welding experiments at small angles.The interfacial wave parameters were measured by a metallographic microscope, and the impact velocities and impact angles were calculated by the smoothed particle hydrodynamics meshfree method.The shear strengths of the explosive and the annealed samples from the clad plates were measured according to the national standard (GBT 6396-2008).The results indicate that titanium as the transition layer can increase the shear strength of the Zr/steel interface and annealing treatment can decrease the shear strength.When the impact velocity is 734-805 m/s and the impact angle is 19.8°-20.8°, the shear strength of the Zr/Ti interface can be higher than 140 MPa.When the impact velocity is 803-904 m/s and the impact angle is 19.5°-20.5°, the shear strength of the Ti/steel interface can also be higher than 140 MPa.

-

Key words:

- mechanics of explosion /

- shear strength /

- explosve welding /

- Zr/steel cald plate /

- transition layer

-

表 1 复合板的波形参数

Table 1. The interfacial wave parameters of the clad plates

试样编号 s/mm h/mm s/h s/mm h/mm s/h s/mm h/mm s/h 锆/钢界面 锆/钛界面 钛/钢界面 1 0.189 0.011 17.18 0 0 0 0.500 0.111 4.50 2 0.511 0.133 3.84 0.120 0.110 1.09 0.889 0.200 4.45 3 1.056 0.278 3.80 0.222 0.167 1.33 0.833 0.189 4.41 4 1.444 0.411 3.51 0.389 0.278 1.40 1.111 0.222 5.00 5 1.944 0.711 2.73 0.445 0.333 1.34 1.278 0.278 4.60 6 2.111 0.833 2.53 0.556 0.389 1.43 1.444 0.333 4.34 7 2.333 0.722 2.23 0.611 0.444 1.38 1.611 0.333 4.84 8 2.444 0.822 2.97 0.667 0.500 1.33 1.667 0.333 5.00 9 2.833 0.777 3.64 0.844 0.510 1.65 1.889 0.333 5.67 表 2 复合板结合界面的剪切强度

Table 2. The interfacial shear strength of clad plate

试样编号 σs/MPa 锆/钛界面 钛/钢界面 锆/钢界面 爆炸态 退火态 爆炸态 退火态 爆炸态 退火态 1 57 41 63 185 47 160 2 77 68 124 180 110 160 3 103 94 150 193 138 166 4 115 101 163 163 147 132 5 142 121 155 191 144 157 6 155 131 164 217 148 179 7 124 110 158 183 143 165 8 84 78 166 156 146 131 9 51 46 133 131 115 112 表 3 锆/钛/钢界面的碰撞参数

Table 3. Impact parameters for Zr/Ti/steel interface

试样 v/(m·s-1) β/(°) v/(m·s-1) β/(°) 锆/钛界面 钛/钢界面 1 325 5.2 485 3.3 2 501 10.1 554 8.5 3 602 13.5 684 14.2 4 680 17.0 755 16.8 5 734 19.8 803 19.5 6 774 20.4 871 20.2 7 805 20.8 904 20.5 8 823 21.2 923 20.9 9 850 21.5 939 21.3 -

[1] 王应植, 袁彪, 张林贤, 等.锆-钢复合板压力容器制造技术研究[J].石油机械, 2008, 36(6): 28-31.Wang Ying-zhi, Yuan Biao, Zhang Lin-xian, et al. Study of manufacturing technology of zirconium-steel clad plate paressure vessel[J]. China Petroleum Machinery, 2008, 36(6): 28-31. [2] 孙万仓, 贺旭明, 孙胜奇.锆/钢复合板设备结构设计分析[J].钛工业进展, 2012, 29(1): 39-41.Sun Wan-cang, He Xu-ming, Sun Sheng-qi. A brief introduction on the structure design of Zr-steel clad plate equipments[J]. Titanium, 2012, 29(1): 39-41. [3] Findik F. Recent developments in explosive welding[J]. Materials and Design, 2011, 32(3): 1081-1093. [4] Crossland B. Explosive welding of metals and its application[M]. Oxford: Oxford University Press, 1982: 35-38. [5] Wronka B. Testing of explosive welding and welded joints: Wavy character of process and joint quality[J]. International Journal of Impact Engineering, 2011, 38(5): 309-313. [6] 郑远谋.爆炸焊接和爆炸复合材料的原理及应用[M].长沙: 中南大学出版社, 2007: 286-287. [7] 邵丙璜, 张凯.爆炸焊接原理及其工程应用[M].大连: 大连工学院出版社, 1987: 301-305. [8] 中国国家标准化管理委员会.复合钢板力学及工艺性能实验方法[S].北京: 中国标准出版社, 2008. [9] 中国工业和信息化部.锆-钢复合板[S].北京: 中国标准出版社, 2011. [10] Liu M B, Liu G R, Lam K Y, et al. Meshfree particle simulation of the detonation process for high explosive in shaped charge unlined cavity configurations[J]. Shock Waves, 2003, 12(6): 509-520. [11] Liu G R, Liu M B. Smoothed particle hydrodynamics: A meshfree particle method[M]. Singapore: World Scientific, 2003: 20-23. [12] 李晓杰, 莫非, 闫鸿浩, 等.爆炸焊接界面波的数值模拟[J].爆炸与冲击, 2011, 31(6): 653-657.Li Xiao-jie, Mo Fei, Yan Hong-hao, et al. Numerical simulation of interface waves in steel explosive welding[J]. Explosion and Shock Waves, 2011, 31(6): 653-657. [13] Wang Xiao, Zheng Yuan-yuan, Liu Hui-xia, et al. Numerical study of the mechanism of explosive/impact welding using smoothed particle hydrodynamics method[J]. Materials and Design, 2012, 35: 210-219. -

下载:

下载: