| [1] |

Deshpande V S, Fleck N A. High strain rate compressive behaviour of aluminum alloy foams[J]. International Journal of Impact Engineering, 2000, 24(3): 277-298. http://www.researchgate.net/publication/222567169_High_strain_rate_compressive_behaviour_of_aluminum_alloy_foams

|

| [2] |

Dannemann K A, James Lankford Jr. High strain rate compression of closed-cell aluminum foams[J]. Materials Science and Engineering, 2000, 293(1/2): 157-164. http://www.sciencedirect.com/science/article/pii/S0921509300012193

|

| [3] |

Mukai T, Kanahashi H, Miyoshi T, et al. Experimental study of energy absorption in a closed-celled aluminium foam under dynamic loading[J]. Scripta Materialia, 1999, 40(8): 921-927. http://www.sciencedirect.com/science/article/pii/S135964629900038X

|

| [4] |

Montanini R. Measurement of strain rate sensitivity of aluminum foams for energy dissipation[J]. International Journal of Mechanical Sciences, 2005, 47(1): 26-42. http://www.sciencedirect.com/science/article/pii/S0020740304002942

|

| [5] |

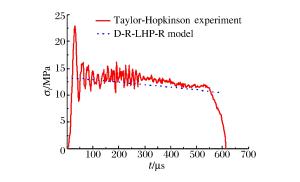

Lopatnikov S L, Gama B A, Haque Md J, et al. Dynamics of metal foam deformation during Taylor cylinder-Hopkinson impact experiment[J]. Composite Structure, 2003(61): 61-71. http://www.sciencedirect.com/science/article/pii/S0263822303000394

|

| [6] |

Shim V P W, Tay B Y, Stronge W J. Dynamic crushing of strain-softening cellular structures-A one-dimensional analysis[J]. Journal of Engineering Materials and Technology, 1990, 112(4): 398-405. http://jxb.oxfordjournals.org/external-ref?access_num=10.1115/1.2903349&link_type=DOI

|

| [7] |

Li Q M, Meng H. Attenuation or enhancement-A one-dimensional analysis on shock transmission in the solid phase of cellular material[J]. International Journal of Impact Engineering, 2002(27): 1049-1065. http://www.sciencedirect.com/science/article/pii/S0734743X02000167

|

| [8] |

Harrigan J J, Reid S R, Yaghoubi A S. The correct analysis of shocks in a cellular material[J]. International Journal of Impact Engineering, 2010, 37(8): 918-927. http://www.sciencedirect.com/science/article/pii/S0734743X0900061X

|

| [9] |

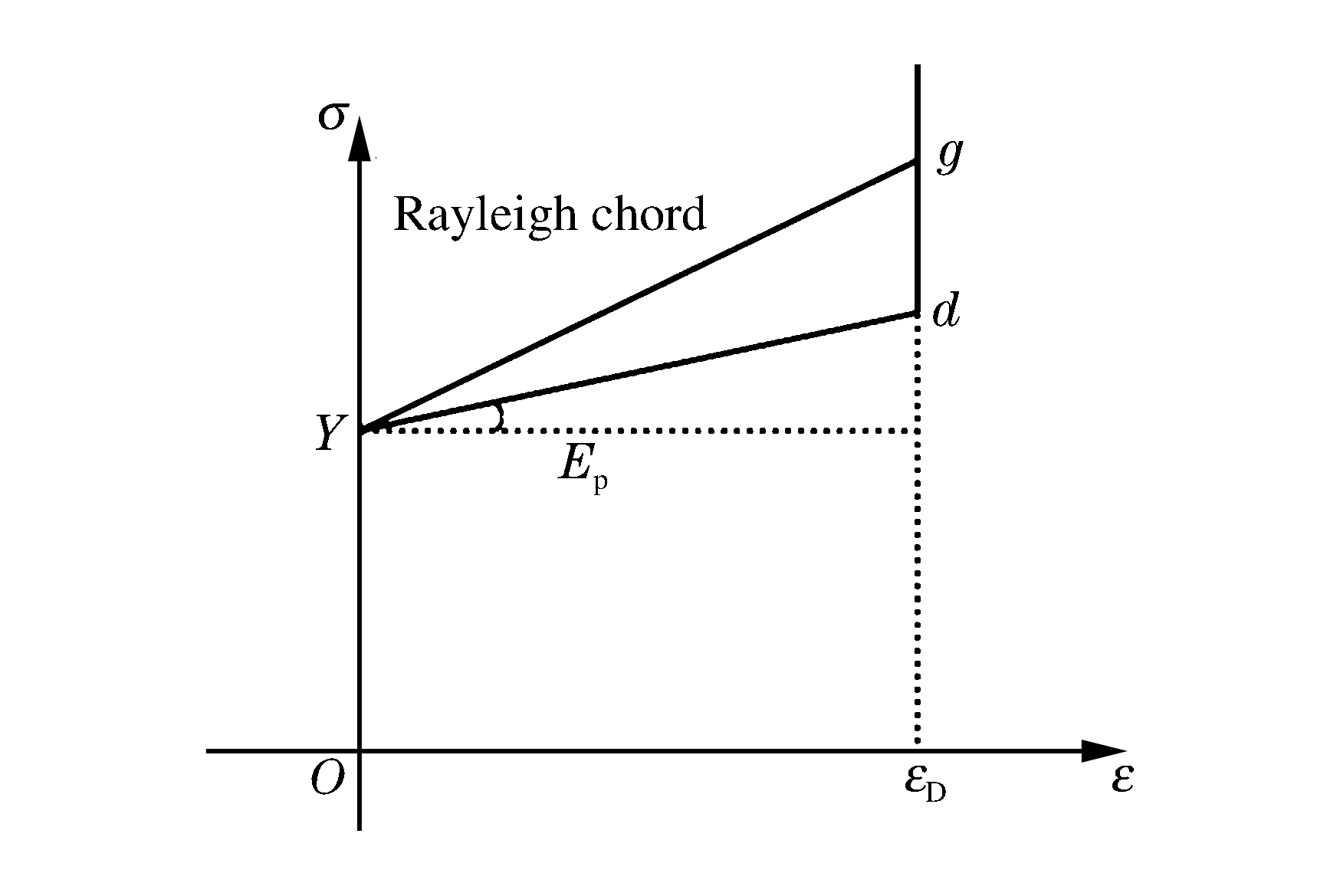

Reid S R, Peng C. Dynamic uniaxial crushing of wood[J]. International Journal of Impact Engineering, 1997, 19(5/6): 531-570. http://www.sciencedirect.com/science/article/pii/S0734743X9700016X

|

| [10] |

Lopatnikov S L, Gama B A, Haque M J, et al. High-velocity plate impact of metal foams[J]. International Journal of Impact Engineering, 2004, 30(4): 421-445. http://www.sciencedirect.com/science/article/pii/S0734743X03000666

|

| [11] |

Harrigan J J, Reid S R, Tan P J, et al. High rate crushing of wood along the grain[J]. International Journal of Mechanical Sciences, 2005, 47(4/5): 521-544. http://www.sciencedirect.com/science/article/pii/S0020740305000421

|

| [12] |

Tan P J, Reid S R, Harrigan J J, et al. Dynamic compressive strength properties of aluminum foams. Part Ⅱ-'shock' theory and comparison with experimental data and numerical models[J]. Journal of the Mechanics and Physics of Solids, 2005, 53(10): 2206-2230. http://www.ingentaconnect.com/content/el/00225096/2005/00000053/00000010/art00002

|

| [13] |

胡时胜, 王悟, 潘艺, 等.泡沫材料的应变率效应[J].爆炸与冲击, 2003, 23(1): 13-18.Hu Shi-sheng, Wang Wu, Pan Yi, et al. Strain rate effect on the properties foam materials[J]. Explosion and Shock Waves, 2003, 23(1): 13-18.

|

| [14] |

王永刚, 施绍裘, 王礼立.采用改进的SHPB方法对泡沫铝动态力学性能的研究[J].实验力学, 2003, 18(2): 257-264.Wang Yong-gang, Shi Shao-qiu, Wang Li-li. An improved SHPB method and its application in the study of dynamic mechanical behavior of aluminum foams[J]. Journal of Experimental Mechanics, 2003, 18(2): 257-264.

|

| [15] |

Wang Zhi-hua, Jing Lin, Zhao Long-mao. Elasto-plastic constitutive model of aluminum alloy foam subjected to impact loading[J]. Transactions of Nonferrous Metals Society of China, 2011(21): 449-454. http://www.sciencedirect.com/science/article/pii/S1003632611607358

|

| [16] |

Zheng Zhi-jun, Liu Yao-dong, Yu Ji-lin, et al. Dynamic crushing of cellular materials: Continuum-based wave models for the transitional and shock modes[J]. International Journal of Impact Engineering, 2012, 42: 66-79. http://www.sciencedirect.com/science/article/pii/S0734743X11001497

|

| [17] |

Wang Li-li, Yang Li-ming, Ding Yuan-yuan. On the energy conservation and critical velocities for the propagation of a "steady-shock" wave in a bar made of cellular material[J]. Acta Mechanica Sinica, 2013, 29(3): 420-428. http://www.cqvip.com/QK/86601X/20133/47712318.html

|

| [18] |

王礼立.应力波基础[M]. 2版.北京: 国防工业出版社, 2005.

|

| [19] |

Gibson L J, Ashby M F. Cellular solids: Structure and properties[M]. Oxford: Pergamon Press, 1997.

|

下载:

下载: