Influence of detonation velocity on interface and combination performances of Al/316L composite tube by explosive welding

-

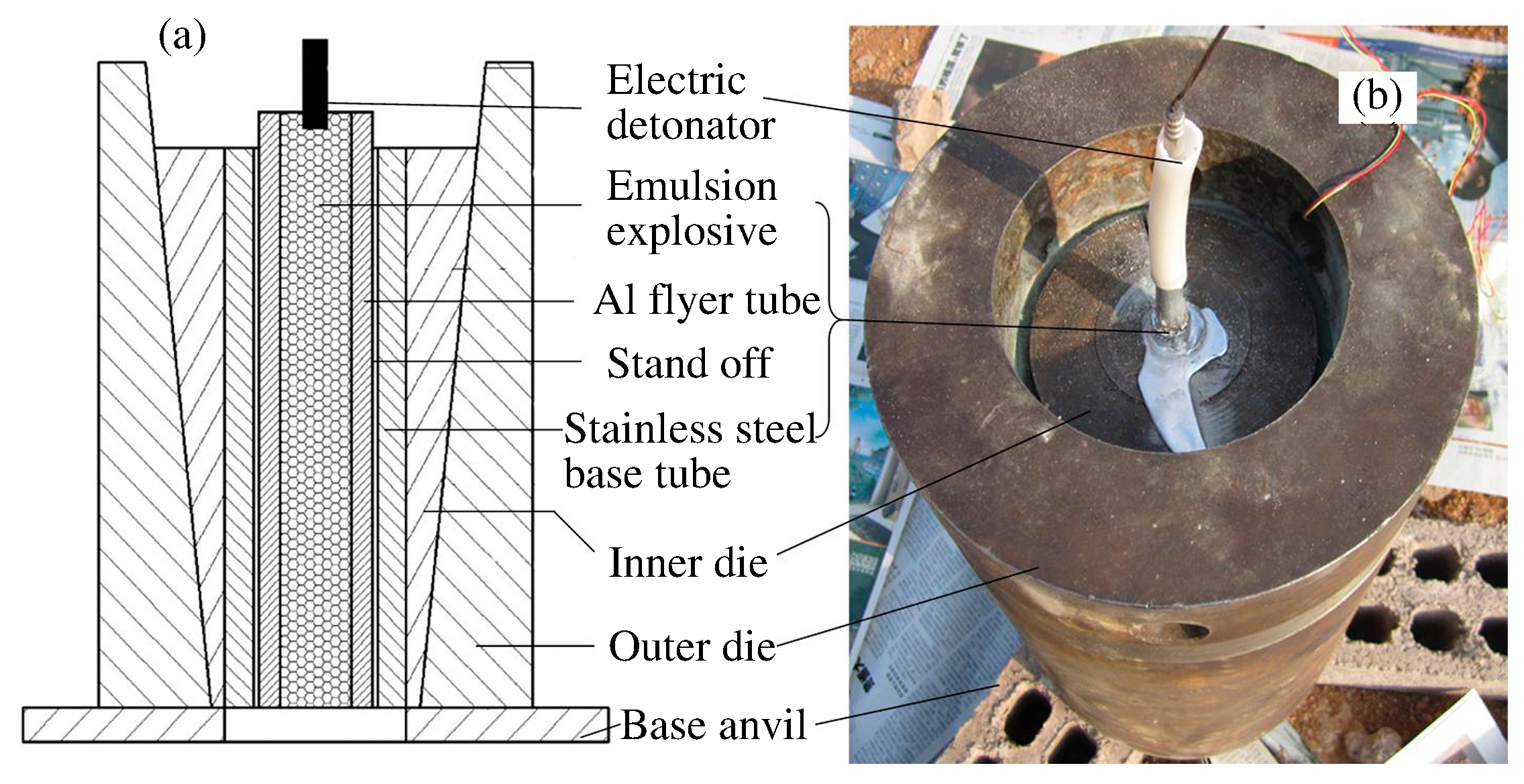

摘要: 通过在粉状乳化炸药中添加不同比例的密度调节剂,配制了爆速范围为1 450~2 550 m/s的低爆速炸药;采用该爆速炸药进行了铝/不锈钢复合管爆炸焊接实验,结合最小碰撞速度理论,对实验结果及其界面微观结构和结合强度进行了测试和分析,确定该复合管爆炸焊接的合适爆速约为1 950~2 150 m/s,其结合质量能够满足后续加工要求;同时发现界面由介于直线与波形之间的波状形态组成,且呈现不太规则的扁平波状结合,经分析,炸药爆速、复合管的爆炸焊接环境和爆炸产物飞散条件对界面结合波形及熔化层厚度有很大影响。Abstract: To obtain low detonation velocity explosive, commercial attenuant was blended into the emulsion explosive. The detonation velocity of compound explosive changes from 2 550 m/s to 1 450 m/s. Through analyzing the result of mechanical properties test and microstructure test of the Al/316L composite tubes which were fabricated by explosive welding of compound explosives, the appropriate detonation velocity (1 950~2 150 m/s) for the explosive welding of composite tube is obtained, and the combination quality of the composite tubes meet the subsequent processing requirement. The shape of the interface waveform is between line and wave. Interfacial wave also has poor rule of periodic variation. The reasons are that detonation velocity is important to the process, the explosion product does not scatter in the direction of tube diameter and the time that detonation products inside the tube affect to the flyer tube is longer than the flyer plate in the explosive welding process.

-

表 1 不同配比的粉状乳化炸药爆速测试结果

Table 1. Experimental results of detonation velocity of emulsion explosive

炸药序号 Re/mm ϕ(NaCl)/% v/(m·s-1) va/(m·s-1) 1 11 5 257 4,255 4,254 1 255 0 2 11 10 229 4,233 5,243 0 235 0 3 11 20 219 0,212 3,222 1 215 0 4 11 30 193 0,186 5,195 6 195 0 5 11 40 148 0,144 1,142 0 145 0 6 11 46 炸药未起爆 表 2 铝复管和不锈钢基管的基本力学性能及尺寸

Table 2. Basic performance parameters of the Al flyer tube and stainless steel base tube

材料 ρ/(g·cm-3) σs/MPa σb/MPa μ Hv/MPa r/mm l/mm s/mm 不锈钢316L 7.98 170 480 0.30 1 862.0 15 400 2 纯铝1060 2.71 100 143 0.33 707.5 11 400 1 表 3 与表 1对应的不同序号炸药计算得到的铝复管碰撞速度

Table 3. Collision speed of Al tube by calculated from different explosives in table 1

炸药序号 R vd/(m·s-1) vp/(m·s-1) 1 0.745 0 2 550 470 2 0.707 8 2 350 422 3 0.670 0 2 150 380 4 0.630 0 1 950 321 5 0.596 0 1 450 228 -

[1] 刘红兵, 陶杰, 张平则, 等.防氚渗透层制备技术的研究进展[J].材料导报, 2006, 20(9): 47-48.Liu Hong-bing, Tao Jie, Zhang Ping-ze, et al. Review on preparation technique of tritium penetration barrier[J]. Materials Review, 2006, 20(9): 47-48. [2] 王耀华.金属板材爆炸焊接研究与实践[M].北京: 国防工业出版社, 2007. [3] 付艳恕, 孙宇新, 陈志华, 等.铝-铝爆炸焊接界面的实验研究[J].实验力学, 2011, 26(1): 49-53.Fu Yan-shu, Sun Yu-xin, Chen Zhi-hua, et al. An experimental investigation on Al-Al explosive welding interfaces[J]. Journal of Experimental Mechanics, 2011, 26(1): 49-53. [4] 张越举, 杨旭升, 李晓杰, 等.钛/钢复合板爆炸焊接实验[J].爆炸与冲击, 2012, 32(1): 103-107. doi: 10.11883/1001-1455(2012)01-0103-05Zhang Yue-ju, Yang Xu-sheng, Li Xiao-jie, et al. An experimental research on explosive welding of titanium/steel clad plate[J]. Explosion and Shock Waves, 2012, 32(1): 103-107. doi: 10.11883/1001-1455(2012)01-0103-05 [5] Wang Jian-min, Zhang Yan, Wang Yan-fang. Explosive mass-bonding property in aluminum alloy-steel explosive welding[J]. Journal of Materials Eugineering, 2009, 2: 443-447. [6] 王伟力, 陈生玉.内装药管动态特性的理论计算[J].稀有金属材料与工程, 1993, 22(5): 138-144.Wang Wei-li, Chen Sheng-yu. Theoretical computation for moving characteristics of an inner tube with explosive[J]. Rare Metal Materials and Engineering, 1993, 22(5): 138-144. [7] 史长根, 郭宏新, 刘丰.高压换热器钛管-管板爆炸焊接模拟与试验[J].压力容器, 2011, 28(11): 21-24.Shi Chang-gen, Guo Hong-xin, Liu Feng. Simulation and experiment of explosive welding on Ti tube and plate of high pressure heat exchanger[J]. Pressure Vessel Technology, 2011, 28(11): 21-24. [8] Sun Xian-jun, Tao Jie, Guo Xun-zhong. Bonding properties of interface in Fe/Al clad tube prepared by explosive welding[J]. Transacation of Nonferrous Metals Society of China, 2011, 21: 2175-2180. https://www.sciencedirect.com/science/article/pii/S1003632611609916 [9] 郭训忠, 陶杰, 袁正, 等.爆炸焊接TA1/Al复合管的界面及性能研究[J].稀有金属材料与工程, 2012, 41(1): 143-146.Guo Xun-zhong, Tao Jie, Yuan Zheng, et al. Interface and properties of explosive welded TA1/Al clad tube[J]. Rare Metal Materials and Engineering, 2012, 41(1): 143-146. [10] 隋国发, 李金山, 马贝, 等.炸药量对双层圆管爆炸焊接影响的数值模拟[J].材料科学与工艺, 2010, 18(6): 741-745.Sui Guo-fa, Li Jin-shan, Ma Bei, et al. Simulation for the influences of explosive amount on explosive welding of two-layer tubes[J]. Material Science & Technology, 2010, 18(6): 741-745. [11] 袁胜芳, 李亚, 陈秋宇, 等.低爆速爆炸焊接炸药的实验研究[J].煤矿爆破, 2010, 2: 1-3.Yuan Sheng-fang, Li Ya, Chen Qiu-yu, et al. Experimental research on low detonation velocity explosives for explosive welding[J]. Coal Mine Blasting, 2010, 2: 1-3. [12] 黄钦, 陆明, 刘鹏, 等.铝/不锈钢复合管的爆炸焊接试验[J].焊接技术, 2010, 39(9): 15-18.Huang Qin, Lu Ming, Liu Peng, et al. An experimental research on explosive welding of Al/titanium composite tube[J]. Welding Technology, 2010, 39(9): 15-18. [13] 郑哲敏, 杨振声.爆炸加工[M].北京: 国防工业出版社, 1981. -

下载:

下载: