Improved calculation model for the size of crushed zone around blasthole

-

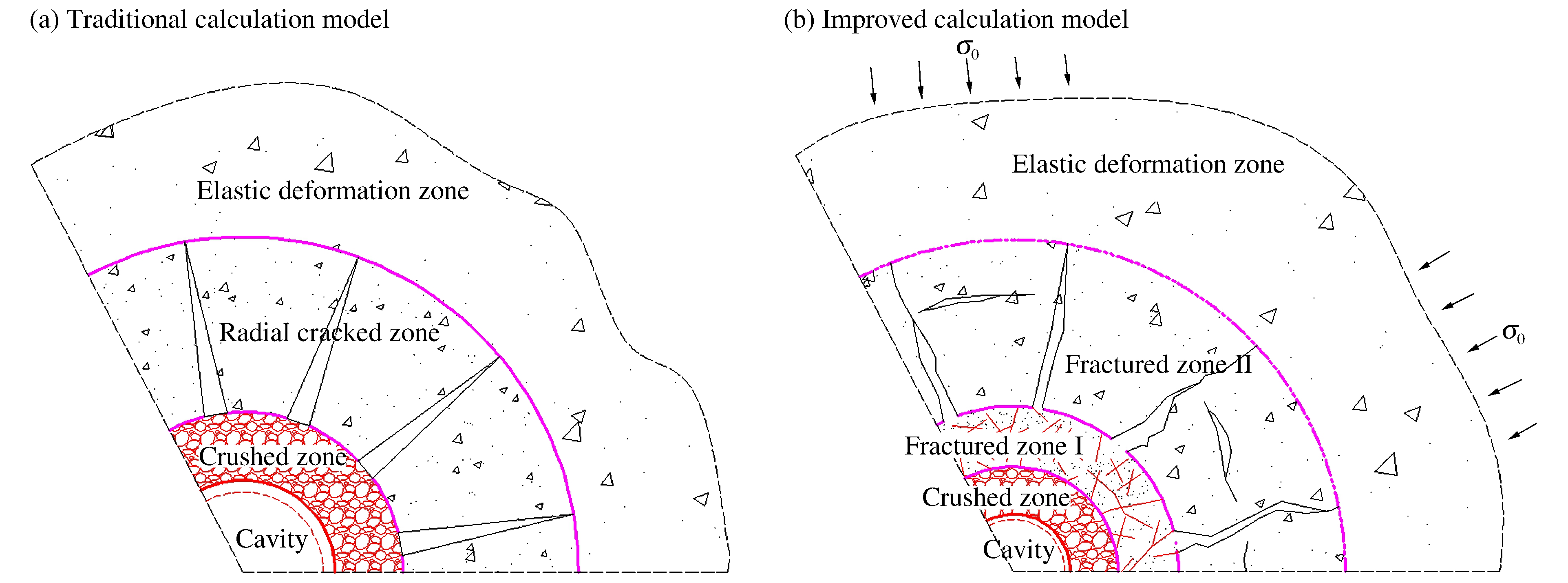

摘要: 为了研究炮孔周围岩石的破坏机理,准确预测粉碎区的范围,提出了一种计算钻孔爆破粉碎区范围的改进模型。该四分区模型考虑了破裂区内侧的环向压应力和炮孔空腔膨胀的影响,假定粉碎区为丧失了内聚力但仍具有内摩擦力的散体介质。采用弹塑性力学理论推导了柱状装药起爆条件下的岩石钻孔爆破粉碎区半径公式。计算结果表明,岩石钻孔爆破粉碎区范围通常为1.2~5.0倍炮孔半径,不同种类岩石的粉碎区范围差别很大。与其他计算模型相比,本模型的计算结果与实验数据更吻合。Abstract: To explore the breakage mechanism of rocks around the blasthole and to accurately predict the size of the crushed zone in drilling and blasting, an improved calculation model for calculation the size of the crushed zone was presented. The four-region model was established with hoop compressive stress in the inner part of fractured zone and cavity expansion effect taken into account. The material in the crushed zone is assumed to be granular medium without cohesion but with internal friction. On this basis, the formula for the crushed zone radius in drilling blasting is derived by elastic-plastic mechanics theory. The analysis shows that the size of the crushed zone ranges from 1.2 to 5.0 times of the blasthole radius, and there are notable discrepancies among rock types. Compared with other models, the improved model is in better agreement with the experiment data.

-

Key words:

- mechanics of explosion /

- calculation model /

- hoop stress /

- crushed zone /

- improvement /

- cavity expansion

-

表 1 各种岩石的物理力学参数

Table 1. Physico-mechnical properties of different rocks

岩石类型 [σc]/MPa [σt]/MPa E/GPa θ/(°) ρm/(kg·m-3) ν 石英岩 250 20 70 48 2 670 0.26 花岗岩 150 15 50 50 2 670 0.24 石灰岩 60 6 35 43 2 500 0.23 粉砂岩 40 3 30 41 2 600 0.22 表 2 不同粉碎区范围计算模型的计算结果对比

Table 2. Comparison of crushing zone models in full scale blasting conditions

岩石

类型装药

结构炸药

类型b*m/rb Il’yushin

模型Szuladzinski

模型Djordjevic

模型Kanchibotla

模型Esen

模型戴俊

模型改进

模型石英岩 耦合 铵油 5.08 1.68 1.74 3.42 1.00 1.54 1.16 乳化 5.45 1.81 2.14 4.20 1.04 1.79 1.31 花岗岩 耦合 铵油 5.81 2.17 2.01 4.41 1.06 1.79 1.36 乳化 6.22 2.34 2.48 5.42 1.39 2.08 1.55 K=3 Gurit 2.91 1.79 1.00 1.76 1.00 1.00 1.00 石灰岩 耦合 铵油 9.04 3.43 3.18 6.97 1.71 2.71 2.18 乳化 9.69 3.70 3.91 8.58 2.25 3.12 2.52 粉砂岩 耦合 铵油 10.76 4.20 4.50 8.54 2.11 3.19 2.76 乳化 11.53 4.53 5.54 10.50 2.77 3.67 2.95 注:K为径向不耦合系数,K=炮孔直径\装药直径。 -

[1] Melnikov N V. Influence of explosive charge design on results of blasting[C]//International Symposium on Mining Research. Clark G B. London, Pergamon, 1962: 147-155. [2] 朱红兵, 卢文波, 吴亮.空气间隔装药爆破机理研究[J].岩土力学, 2007, 28(5): 986-989. http://d.wanfangdata.com.cn/Periodical/ytlx200705025Zhu Hong-bing, Lu Wen-bo, Wu Liang. Research on mechanism of air-decking technique in bench blasting[J]. Chinese Journal of Rock and Soil Mechanics, 2007, 28(5): 986-989. http://d.wanfangdata.com.cn/Periodical/ytlx200705025 [3] 王明洋, 邓宏见, 钱七虎.岩石中侵彻与爆炸作用的近区问题研究[J].岩石力学与工程学报, 2005, 24(16): 2859-2863. http://www.cnki.com.cn/Article/CJFDTotal-YSLX200516009.htmWang Ming-yang, Deng Hong-jian, Qian Qi-hu. Study on problems of near cavity of penetration and explosion in rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2859-2863. http://www.cnki.com.cn/Article/CJFDTotal-YSLX200516009.htm [4] Jimeno E L, Carcedo F J A. Drilling and blasting of rocks[M]. Taylor & Francis Group, 1995. [5] Ouchterlony F, Moser P. On the branching-merging mechanism during dynamic crack growth as a major source of fines in rock blasting[C]//The 10th International Symposium on Rock Fragmentation by Blasting. New Delhi, India, 2012: 65-75. [6] 钱七虎.岩石爆炸动力学的若干进展[J].岩石力学与工程学报, 2009, 28(10): 1945-1968. http://d.wanfangdata.com.cn/Periodical/yslxygcxb200910001Qian Qi-hu. Some advances in rock blasting dynamics[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(10): 1945-1968. http://d.wanfangdata.com.cn/Periodical/yslxygcxb200910001 [7] Szuladzinski G. Response of rock medium to explosive borehole pressure[C]//Proceedings of the Fourth International Symposium on Rock Fragmentation by Blasting-Fragblast-4. Vienna, Austria, 1993: 17-23. [8] Djordjevic N. A two-component of blast fragmentation[C]//Proceedings of the Sixth International Symposium on Rock Fragmentation by Blasting-Fragblast. Johannesburg, South Africa, 1999: 213-222. [9] Hustrulid W A. Blasting principles for open pit mining-Theoretical foundations[M]. Rotterdam: Balkema, 1999. [10] Vovk A A, Mikhalyuk A V, Belinskii I V. Development of fracture zones in rocks during camouflet blasting[J]. Journal of Mining Science, 1973, 9(4): 383-387. doi: 10.1007/BF02501169 [11] Kanchibotla S S, Valery W, Morrell S. Modelling fines in blast fragmentation and its impact on crushing and grinding[C]//Proceedings of Explo'99-A Conference on Rock Breaking. Kalgoorlie, Australia, 1999: 137-181. [12] Esen S, Onederra I, Bilgin H A. Modelling the size of the crushed zone around a blast hole[J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(4): 485-495. http://www.sciencedirect.com/science/article/pii/S1365160903000182 [13] 戴俊.岩石动力学特性与爆破理论[M].北京: 冶金工业出版社, 2002. [14] Hagan T N, Gibson I M. Lower blasthole pressures: A means of reducing costs when blasting rocks of low to moderate strength[J]. International Journal of Mining and Geological Engineering, 1988, 6(1): 1-13. doi: 10.1007/BF00881023 [15] Ghosh A. Fractal and numerical models of explosive rock fragmentation[D]. Tucson: The University of Arizona, 1990. [16] Rakishev B, Rakisheva Z B. Basic characteristics of the stages of rock massif destruction by explosive crushing[C]//Asia-Pacific Symposium on Blasting Techniques. Kunming, China, 2011: 65-69. [17] 亨利奇.爆炸动力学及其应用[M].熊建国, 等, 译.北京: 科学出版社, 1987. [18] 杨善元.岩石爆破动力学基础[M].北京: 煤炭工业出版社, 1991. [19] Olsson M, Bergqvist I. Crack lengths from explosives in multiple hole blasting[C]//The Fifth International Symposium on Rock Fragmentation by Blasting. Montreal, Quebec, Canada, 1996: 187-191. [20] Slaughter S. Investigation of coal fines[R]. Internal Report, Julius Kruttschnitt Mineral Research Centre(JKMRC), Australia, 1991. -

下载:

下载:

*m对比

*m对比