Damage characteristics of sandwich bulkhead under the impact of shock and high-velocity fragments

-

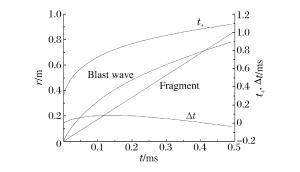

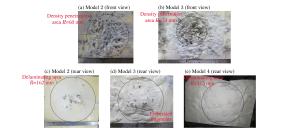

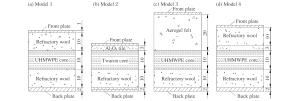

摘要: 为探讨导弹战斗部近炸下舰船夹芯复合舱壁结构设计方法,采用TNT和预制破片近炸实验研究了典型夹芯复合舱壁结构在冲击波与高速破片联合作用下的破坏效应,分析了冲击波和破片联合毁伤载荷,指出了钢质面板和抗弹层的破坏模式,阐述了夹芯复合舱壁结构的防护机理。结果表明:预制破片装药近炸下,破片能远大于冲击波能,是防护结构的主要设计载荷;前面板主要是抵御冲击波,其变形破坏整体为挠曲大变形,局部为集团破片冲塞破口、破片穿孔和撞击凹坑;背板以挠曲大变形吸能为主;陶瓷材料碎裂严重,部分陶瓷碎片反向飞溅撞击前面板;纤维增强复合材料发生了纤维断裂、基体开裂、整体弯曲大变形及分层等破坏,抗弹层应避免产生穿透性破坏。Abstract: In order to explore the design method of sandwich bulkhead subjected to the close blast load of missile-warhead, experiments were carried out to investigate the damage effect of sandwich bulkhead subjected to combined impact of shock and fragments using cast TNT and prefabricated fragments. The combined impact load of the shock and high-velocity fragments were analyzed. The failure modes of surface plate and sandwich core of the bulkhead were pointed out, and the protective mechanism of sandwich bulkhead were analyzed. Results show that the impact energy acted on the structure by the prefabricated fragments is far larger than that of shock under the close blast of cast TNT and prefabricated fragments, and should be the main load in the design of the bulkhead. Under combined impact of close-impact waves and high-velocity fragments, the deformation and failure modes of the front plate is large deformation, combined with large amounts of perforation holes, including large shearing plug caused by the dense fragments, perforation and craters caused by individual fragments. Large deformation is the main failure modes of back plate. Al2O3 tiles are badly fragmented. Part of the tile fragments splashed reversely and impact on the front plate. Fiber-reinforced composite laminates will generate large deformation including damage like fibers fracture and matrix cracking. In the design of sandwich bulkhead, the front plate should avoid transverse shearing failure and collision on the bullet-resistant core, the bullet-resistant core should avoid perforation failure, and the back plate should have enough strength to absorb the residual impact energy.

-

Key words:

- mechanics of explosion /

- damage characteristics /

- shock /

- fragments /

- sandwich bulkhead

-

表 1 模型芯层结构组成

Table 1. Core structures of experimental models

模型 前隔温层 抗弹层 后隔温层 ρA/(kg·m-2) 1 10 mm陶瓷棉 10 mm高强聚乙烯纤维(UMWPE)增强层合板 10 mm陶瓷棉 15.75 2 3 mm Al2O3陶瓷,9.4 mm芳纶纤维(Twaron)增强层合板 10 mm陶瓷棉 25.45 3 20 mm气凝胶毡 10 mm高强聚乙烯纤维(UMWPE)增强层合板 10 mm陶瓷棉 17.08 4 10 mm陶瓷棉 3 mm Al2O3陶瓷,高强聚乙烯纤维(UMWPE)增强层合板 10 mm陶瓷棉 27.42 -

[1] 何翔, 庞伟宾, 曲建波, 等.防护门在空气冲击波和破片作用下的破坏[J].爆炸与冲击, 2004, 24(5): 475-479.He Xiang, Pang Wei-bin, Qu Jian-bo, et al. Protective door damaged by air shock wave and fragment arisen from explosion in prototype tunnel[J]. Explosion and Shock Waves, 2004, 24(5): 475-479. [2] Rudrapatna N S, Vaziri R, Olson M D. Deformation and failure of blast-loaded square plates[J]. International Journal of Impact Engineering, 1999, 22(4): 449-67. https://www.sciencedirect.com/science/article/pii/S0734743X98000463 [3] Chung Kim Yuen S, Nurick G N. Experimental and numerical studies on the response of quadrangular stiffened plates. Part I: Subjected to uniform blast load[J]. International Journal of Impact Engineering, 2005, 31(1): 55-83. https://www.sciencedirect.com/science/article/pii/S0734743X03001076 [4] Langdon G S, Chung Kim Yuen S, Nurick G N. Experimental and numerical studies on the response of quadrangular stiffened plates. Part II: Localized blast loading[J]. International Journal of Impact Engineering, 2005, 31(2): 85-111. https://www.sciencedirect.com/science/article/pii/S0734743X03001088 [5] 侯海量.大型舰艇水上舷侧结构抗毁伤机理研究[D].武汉: 海军工程大学, 2006. [6] 李伟, 朱锡, 梅志远, 等.战斗部舱内爆炸对舱室结构毁伤的试验研究[J].舰船科学技术, 2009, 31(3): 34-37.Li Wei, Zhu Xi, Mei Zhi-yuan, et al. Experimental studies on damage effect of missile warhead on cabin's structure under internal explosion[J]. Ship Science and Technology, 2009, 31(3): 34-37. [7] Qian L, Qu M, Feng G.Study on terminal effects of dense fragment cluster impact on armor plate.Part I:Analytical model[J].International Journal of Impact Engineering, 2005, 31(6):755-767. [8] Qian L, Qu M, Feng G. Study on terminal effects of dense fragment cluster impact on armor plate. Part II: Numerical simulations[J]. International Journal of Impact Engineering, 2005, 31(6): 769-780. [9] 陈长海, 朱锡, 侯海量, 等.近距空爆载荷作用下双层防爆舱壁结构抗爆性能仿真分析[J].海军工程大学学报, 2012, 24(3): 26-33.Chen Chang-hai, Zhu Xi, Hou Hai-liang, et al. Numerical analysis of blast resistance of double-layer bulkhead structures subjected to close-range air blast[J]. Journal of Naval University of Engineering, 2012, 24(3): 26-33. [10] Nurick G N, Langdon G S, Chi Y, et al. Behaviour of sandwich panels subjected to intense air blast-Part 1: Experiments[J]. Composite Structures, 2009, 91(4): 433-441. https://www.sciencedirect.com/science/article/pii/S0263822309001093 [11] Karagiozov D, Nurick G N, Langdon G S. Behavior of sandwich panels subject to intense air blasts-Part 2: Numerical simulation[J]. Composite Structures, 2009, 91(4): 442-450. [12] 王晓强, 朱锡, 梅志远, 等.超高分子量聚乙烯纤维增强层合厚板抗弹性能试验研究[J].爆炸与冲击, 2009, 29(1): 29-34.Wang Xiao-qiang, Zhu Xi, Mei Zhi-yuan, et al. Ballistic performances of ultra-high molecular weight polyethylene fiber-reinforced thick laminated plates[J]. Explosion and Shock Waves, 2009, 29(1): 29-34. [13] 梅志远, 朱锡, 张立军.FRC层合板抗高速冲击机理研究[J].复合材料学报, 2006, 23(2):143-149.Mei Zhi-yuan, Zhu Xi, Zhang Li-jun. Ballistic protective mechanism of FRC laminates[J]. Acta Material Composite Sinic, 2006, 23(2): 143-149. [14] 侯海量, 朱锡, 阚于龙.轻型陶瓷复合装甲结构抗弹性能研究进展[J].兵工学报, 2008, 29(2): 208-216.Hou Hai-liang, Zhu Xi, Kan Yu-long. Advance of ballistic performance of light ceramic composite armour under the impact of projectile[J]. Acta Armamentarii, 2008, 29(2): 208-216. [15] 张成亮, 朱锡, 侯海量, 等.近距空爆载荷下抗爆舱壁变形破坏模式实验研究[J].振动与冲击, 2014, 33(11): 33-37.Zhang Cheng-liang, Zhu Xi, Hou Hai-liang, et al. Model tests for deformation and destruction modes of a blast-resistant bulkhead under near distance explosion[J]. Journal of Vibration and Shock, 2014, 33(11): 33-37. [16] 孙业斌.爆炸作用与装药设计[M].北京: 国防工业出版社, 1987. [17] 吴有生, 彭兴宁, 赵本立.爆炸载荷作用下舰船板架的变形与破损[J].中国造船, 1995(4): 55-61.Wu You-sheng, Peng Xing-ning, Zhao Ben-li. Plastic deformation and damage of naval panels subjected to explosion loading[J]. Shipbuilding of China, 1995(4): 55-61. [18] 侯海量, 朱锡, 李伟.轻型陶瓷/金属复合装甲抗弹机理研究[J].兵工学报, 2013, 34(1): 105-114.Hou Hai-liang, Zhu Xi, Li Wei. Investigation on bullet proof mechanism of light ceramic/steel armor[J]. Acta Armamentarii, 2013, 34(1): 105-114. -

下载:

下载: