Energy-absorbing structure design and crashworthiness analysis of high-speed trains

-

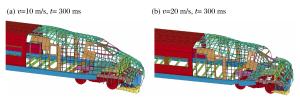

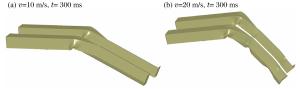

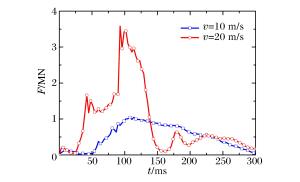

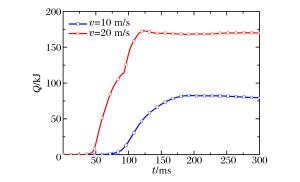

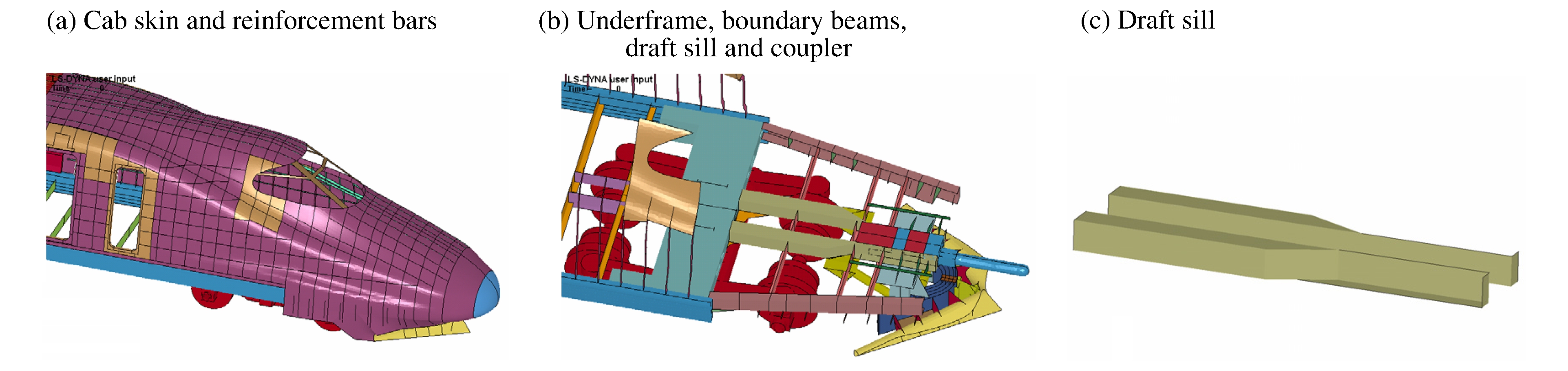

摘要: 建立了高速列车头车的有限元模型,运用有限元软件LS-DYNA模拟了头车碰撞刚性墙的冲击过程。在碰撞发生时,原有设计方案的牵引梁主体的变形以整体屈曲为主,不利于缓冲吸能。在对原设计的耐撞性分析的基础上,建议对原有牵引梁结构加以改进,并在前端增加两组不同尺寸和厚度的带圆角的方管作为缓冲吸能管,考虑了在缓冲管中填充泡沫铝与否,形成了4种设计方案。数值模拟结果表明,与原设计方案相比,新方案的整个头车的吸能量有大幅度提高,刚性墙反力的峰值也有一定程度的降低,采用大的圆角半径的厚管并填充泡沫铝的方案的改进效果最明显。Abstract: A finite element model was established for the head car of a high-speed train and its crashing progresses with a rigid wall at different speeds, simulated by using LS-DYNA software. It is found that when a crash occurs the draft sill deforms mainly in the Euler bending mode, which is harmful to buffering and energy absorption. Based on the understanding from the crashworthiness analysis of the original design, we propose to redesign the structure of the draft sill through adding square tubes with round corners as energy-absorbing tubes, which are either filled with aluminum foam or not. Two different sizes are chosen, thus four schemes are formed. The results of numerical simulation show that, compared to the original design, the energy absorption capacity in all of the new schemes has greatly improved, and the peak force on the rigid wall decreases in a certain extend. The scheme with the tubes having large radius of round corner, thick thickness and aluminum foam filler has the most obvious improvement.

-

表 1 材料参数

Table 1. Material properties

材料 E/GPa ν σy/MPa G/MPa ρ/(kg·m-3) Q235钢 210 0.3 235 2 100 7 800 A6N01铝合金 70 0.3 250 573 2 700 A5083铝合金 62 0.3 150 1 610 2 700 A7N01铝合金 66 0.3 290 1 232 2 700 表 2 改进方案

Table 2. Improvement schemes

方案 c/mm r/mm d/mm 填充泡沫铝 1 7 20 5 否 2 7 20 5 是 3 8 35 5 否 4 8 35 5 是 -

[1] 张振淼, 逢增帧.轨道车辆碰撞能量吸收装置原理及结构设计(待续)[J].国外铁道车辆, 2001, 38(3): 13-19. http://d.wanfangdata.com.cn/Periodical/gwtdcl200103004Zhang Zhen-miao, Feng Zeng-zhen. Principles and structure design of collision energy absorption equipment for rail cars(to be continued)[J]. Foreign Rolling Stock, 2001, 38(3): 13-19. http://d.wanfangdata.com.cn/Periodical/gwtdcl200103004 [2] Lu G. Energy absorption requirement for crashworthy vechicles[J]. Journal of Rail and Rapid Transit, 2002, 216(F3): 31-39. http://en.cnki.com.cn/Article_en/CJFDTOTAL-GWTD200603002.htm [3] Tyrell D, Severson K, Marquis B. Crashworthiness of passenger trains: Safety of high-speed ground transportation systems[R]. Washington DC: US Department of Transportation, 1998. [4] 畑弘敏, 刘克鲜.运用碰撞仿真技术进行提高铁道车辆安全性的研究[J].国外铁道车辆, 2004, 41(6): 22-31. http://www.cnki.com.cn/Article/CJFDTotal-GWTD200406008.htmTian Hong-min, Liu Ke-xian. Research on improvement of rolling stock safety with the collision simulation technology[J]. Foreign Rolling Stock, 2004, 41(6): 22-31. http://www.cnki.com.cn/Article/CJFDTotal-GWTD200406008.htm [5] 陆冠东.铁道车辆的耐碰撞性设计[J].铁道车辆, 2007, 45(10): 1-5. http://d.wanfangdata.com.cn/Periodical/tdcl200710001Lu Guan-dong. The bumping resistance design for rolling stock[J]. Rolling Stock, 2007, 45(10): 1-5. http://d.wanfangdata.com.cn/Periodical/tdcl200710001 [6] 杨俊杰, 王立杰, 李幸人.机车车体碰撞吸能装置结构设计与仿真分析[J].铁道机车车辆, 2011, 31(1): 72-75. http://d.wanfangdata.com.cn/Periodical/tdjccl201101020Yang Jun-jie, Wang Li-jie, Li Xing-ren. Development and simulation of crashworthniess device for locomotive body[J]. Railway Locomotive & Car, 2011, 31(1): 72-75. http://d.wanfangdata.com.cn/Periodical/tdjccl201101020 [7] 余同希.利用金属塑性变形原理的碰撞能量吸收装置[J].力学进展, 1986, 16(1): 28-38. http://www.cnki.com.cn/Article/CJFDTotal-LXJZ198601002.htmYu Tong-xi. Impact energy absorbing devices based upon the plastic deformation of metallic element[J]. Advances in Mechanics, 1986, 16(1): 28-38. http://www.cnki.com.cn/Article/CJFDTotal-LXJZ198601002.htm [8] 田红旗.客运列车耐冲击吸能车体设计方法[J].交通运输工程学报, 2001, 1(1): 110-114. http://www.cnki.com.cn/Article/CJFDTotal-JYGC200101027.htmTian Hong-qi. Crashworthy energy absorbing car-body design method for passenger train[J]. Journal of Traffic and Transportation Engineering, 2001, 1(1): 110-114. http://www.cnki.com.cn/Article/CJFDTotal-JYGC200101027.htm [9] 蒋家桥, 黄西成, 胡时胜.泡沫金属缓冲器的设计新方法及应用[J].爆炸与冲击, 2004, 24(6): 519-523. http://www.bzycj.cn/article/id/10673Jiang Jia-qiao, Huang Xi-cheng, Hu Shi-sheng. Application and design of the foam matalic buffer[J]. Explosion and Shock Waves, 2004, 24(6): 519-523. http://www.bzycj.cn/article/id/10673 [10] 丁晨, 赵洪伦.高速列车头车吸能排障器设计与仿真研究[J].铁道车辆, 2011, 49(1): 1-4. http://www.cqvip.com/Main/Detail.aspx?id=36401328Ding Chen, Zhao Hong-lun. Design and simulation research on energy absorption fender on the head car of a high speed train[J]. Rolling Stock, 2011, 49(1): 1-4. http://www.cqvip.com/Main/Detail.aspx?id=36401328 [11] 雷成, 肖守讷, 罗世辉.基于显式有限元的高速列车吸能装置吸能原理研究[J].铁道机车车辆, 2012, 32(2): 7-11. http://d.wanfangdata.com.cn/Periodical/tdjccl201202001Lei Cheng, Xiao Shou-ne, Luo Shi-hui. Research on the energy-absorbing theory of high speed train energy-absorbing component based on the explicit finite element[J]. Railway Locomotive & Car, 2012, 32(2): 7-11. http://d.wanfangdata.com.cn/Periodical/tdjccl201202001 [12] 宋宏伟, 虞钢, 范子杰, 等.多孔材料填充薄壁结构吸能的相互作用效应[J].力学学报, 2005, 37(6): 697-703. http://www.cnki.com.cn/Article/CJFDTotal-LXXB200506004.htmSong Hong-wei, Yu Gang, Fan Zi-jie, et al. Interaction effect in energy absorption of porous material filled thin-walled structure[J]. Acta Mechanica Sinica, 2005, 37(6): 697-703. http://www.cnki.com.cn/Article/CJFDTotal-LXXB200506004.htm [13] 王蕊, 秦庆华, 程国强, 等.壁厚对金属圆管撕裂卷曲耗能影响的研究[J].力学学报, 2005, 37(2): 244-248. http://www.cqvip.com/Main/Detail.aspx?id=15603645Wang Rui, Qin Qing-hua, Cheng Guo-qiang, et al. Research for the influence of thickness on the energy distribution of splitting and curling circular steel tube[J]. Acta Mechanica Sinica, 2005, 37(2): 244-248. http://www.cqvip.com/Main/Detail.aspx?id=15603645 [14] EN 15227: 2008+A1: 2010, Railway applications: Crashworthiness requirements for railway vehicle bodies[S]. European Committee for Standardization, 2010. -

下载:

下载: