Interior ballistic optimal design of detonation powerplant

-

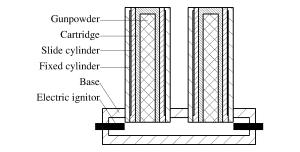

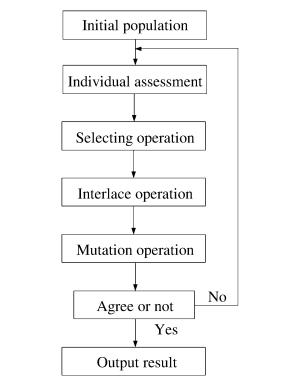

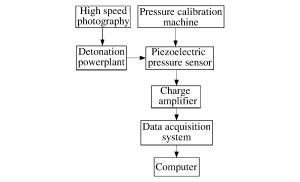

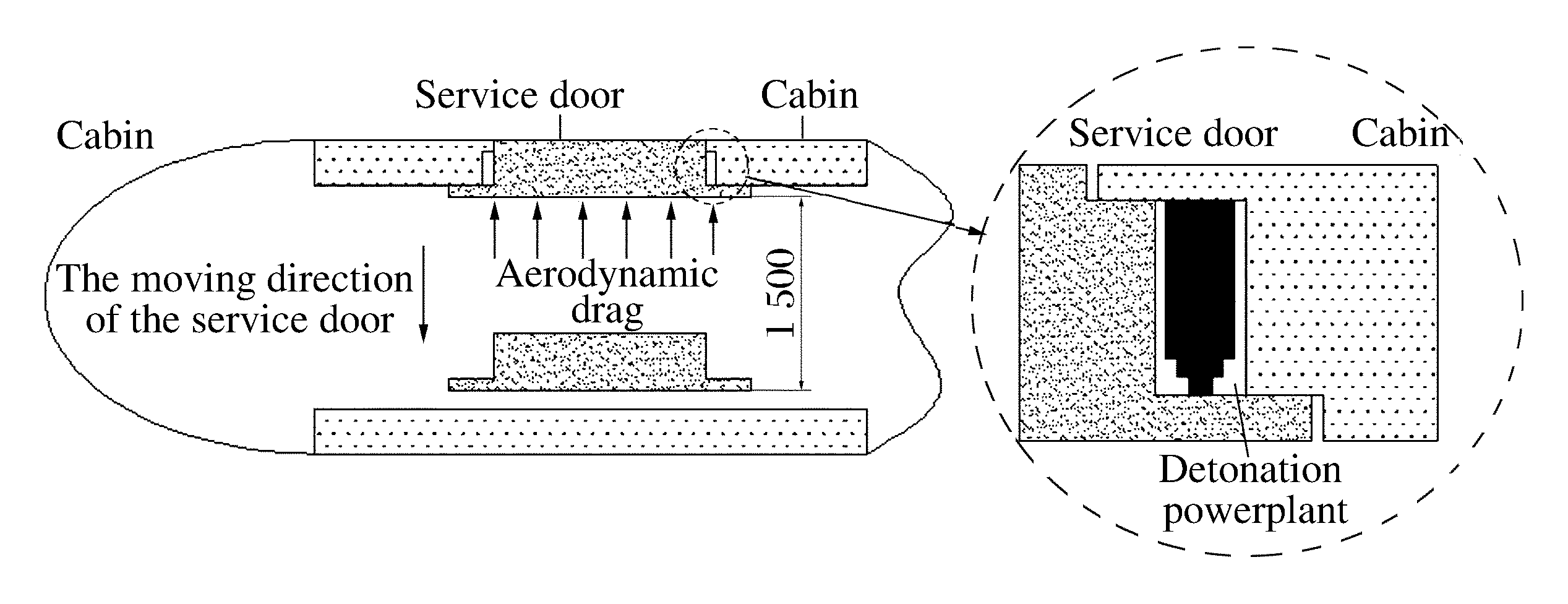

摘要: 为了研制一种具有特殊功能的爆燃动力装置,并确保该爆燃动力装置做功能力的精确化,涉及一种爆燃动力装置的内弹道数值模拟、优化设计及实验验证技术。在建立爆燃动力装置内弹道物理模型、分析装置做功过程的基础上,应用经典内弹道理论,获得了爆燃动力装置内弹道数学模型,并开展内弹道数值模拟;依据爆燃动力装置评价指标,确定了遗传算法的目标函数、优化设计变量及约束条件,获得了爆燃动力装置内弹道设计的优化解;依据相似理论原理,开展了爆燃动力装置推门模拟实验。实验表明,建立的爆燃动力装置内弹道数学模型合理,爆燃动力装置内弹道优化设计结果较理想。Abstract: In order to develop a special detonation powerplant and ensure the accuracy of the work capacity of the detonation powerplant, the interior ballistic numerical simulation, optimal design and corresponding experimental verification technology of detonation powerplant were investigated. On the basis of getting physical model and analyzing working process of detonation powerplant, the interior ballistic mathematical model was established and calculated. According to the interior ballistic evaluation index of detonation powerplant, the objective function, the optimized interior ballistic design variables, and the constraint condition were obtained with the genetic algorithm. According to the similarity theory, the simulation test of pushing airliner door was carried out. It shows that the calculated results coincide with the test results, the interior ballistic mathematical model is reasonable, and the optimized interior ballistic result is acceptable.

-

表 1 爆燃动力装置内弹道实验与计算结果

Table 1. The interior ballistic results of the detonation powerplant

方法 pmax/MPa t/ms v/(m·s-1) 理论 117.1 4.97 8.9 实验 112.6 5.28 8.4 ε/% 3.84 6.23 5.62 -

[1] 江坤, 王浩, 郭锦炎, 等.拉杆活塞式发射装置内弹道建模与仿真[J].弹道学报, 2011, 23(1):13-17. http://www.cnki.com.cn/Article/CJFDTotal-DDXB201101005.htmJiang Kun, Wang Hao, Guo Jin-yan, et al. Modeling and simulation of interior ballistics of slide rod piston launching device[J]. Journal of Ballistics, 2011, 23(1):13-17 http://www.cnki.com.cn/Article/CJFDTotal-DDXB201101005.htm [2] 侯健, 魏平, 李金新.锥膛炮内弹道建模与仿真计算[J].兵工学报, 2010, 31(4):419-422. http://d.wanfangdata.com.cn/Periodical/bgxb201004004Hou Jian, Wei Ping, Li Jin-xin. Interior ballistics modeling and simulation of conic-chamber gun system[J]. Acta Armamentar, 2010, 31(4):419-422. http://d.wanfangdata.com.cn/Periodical/bgxb201004004 [3] 金志明.枪炮内弹道学[M].北京:北京理工大学出版社, 2007:53-94. [4] 李建良, 蒋勇, 汪先光.计算机数值方法[M].江苏:东南大学出版社, 2000:72-102. [5] David D, 王国荣.数值分析[M].北京:机械工业出版社, 2005:127-149. [6] Gambardella L M, Mastrololli M, Rizzoli A E. An optimization methodlogy for intermodal terminal management[J]. Journal of Intelligent Manufacturing, 2001, 12(5):521-634. doi: 10.1023/A:1012208605758 [7] 刑文训, 谢金星.现代优化计算方法[M].北京:清华大学出版社, 2005:13-17. [8] 汪定伟.智能优化算法[M].北京:高等教育出版社, 2007:24-36. [9] 赵博文.随行装药内弹道优化设计及数值模拟[D].南京: 南京理工大学, 2010. [10] Goldberg D E. Genetic algorithms in search, optimization and machine learning[M]. Massachusetts: Addison-Wesley Publishing Company, 1989:47-52. -

下载:

下载: