The ballistic performance of Q235 metal plates subjected to impact by hemispherically-nosed projectiles

-

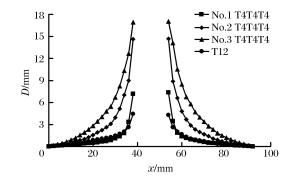

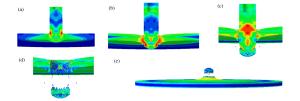

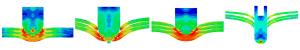

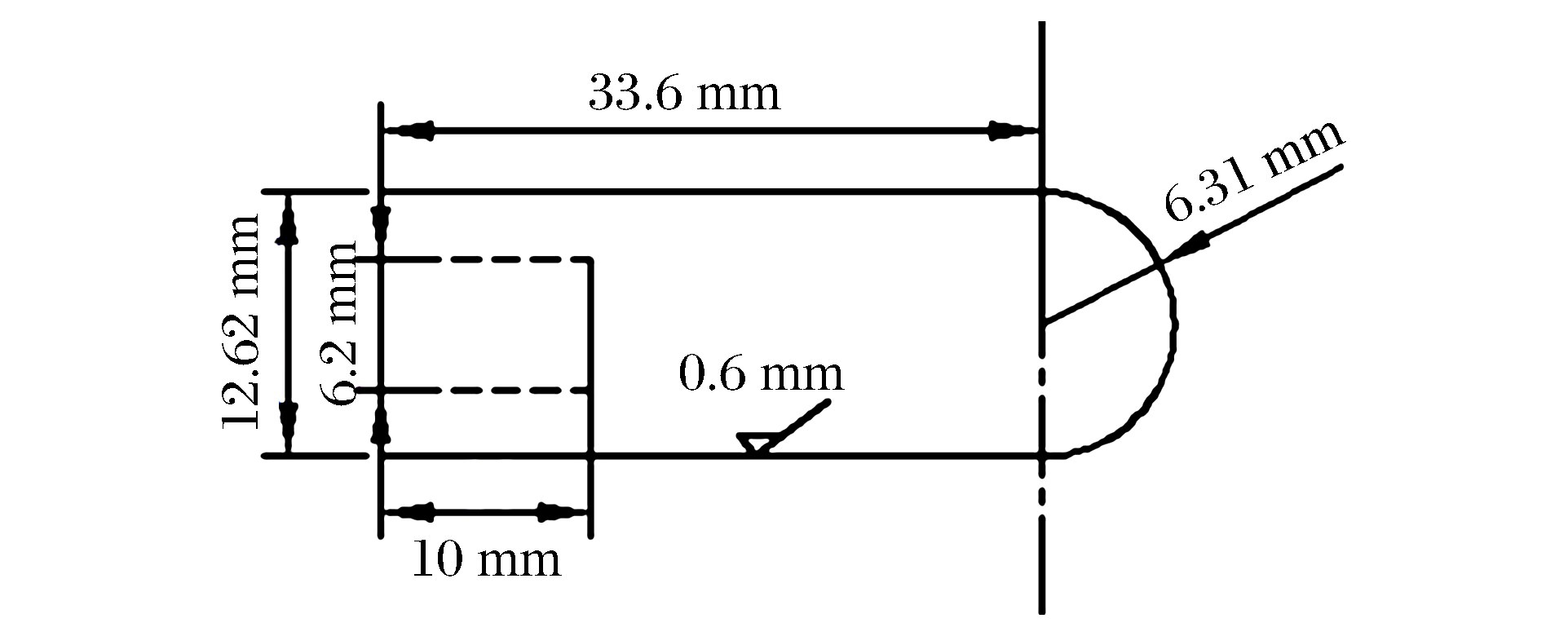

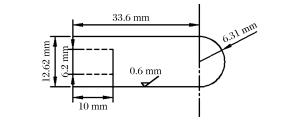

摘要: 利用轻气炮进行了半球形头杆弹正撞击单层板和等厚接触式三层板的实验, 得到了这两种结构靶体的初始-剩余速度曲线以及弹道极限。采用ABAQUS/EXPLICIT数值模拟软件对杆弹撞击金属板的过程进行了数值模拟研究, 通过对比数值模拟和实验结果, 验证了数值模拟材料模型和参数的有效性。研究了靶体结构对抗侵彻特性的影响, 并分析了弹体对靶体的撞击过程。研究结果表明:多层板的弹道极限高于等厚单层板。单层板主要失效模式为剪切, 而多层板的主要失效模式为整体的蝶形变形和局部的盘式隆起。对于多层板, 靶板具体的失效模式与其在靶中位置相关。Abstract: Monolithic and three-layered plates were normally impacted by hemispherically-nosed projectiles.The residual velocity-the initial velocity curves of the projectiles and ballisitic limit velocities were constructed.The penetration process of metal plates impacted by rod projectiles has been studied with numerical simulation code ABAQUS/EXPLICIT.The validation of models and parameters of materials has been proved by comparing the experiment results with numerical simulations.We investigated the influence of combination configuration of target on the ballistic characteristic, including the ballistic resistance and failure models.Furthermore, the impact process was also analyzed.The results indicated that the ballistic limit velocity of multi-layered plate was higher than that of monolithic plate.The dominant failure model of monolithic plate was shearing, but the dominant failure models of multi-layered plate were global dishing and local bulging.Moreover, the failure models of plates of multi-layered plates were in relation to their order in targets.

-

Key words:

- mechanics of explosion /

- ballistic performance /

- ABAQUS/EXPLICIT /

- projectile /

- target /

- ballistic limit

-

表 1 Q235钢靶T12侵彻实验结果

Table 1. Penetration test result of the Q235 steel target T12

vi/(m·s-1) vr/(m·s-1) 254.60 0 272.70 59.90 289.5 109.10 308.05 162.60 335.66 224.60 371.90 270.50 373.20 268.90 422.70 327.30 表 2 Q235钢靶T4T4T4侵彻实验结果

Table 2. Penetration test result of the Q235 steel target T4T4T4

vi/(m·s-1) vr/(m·s-1) 270.6 0 318.2 188.1 323.2 187.5 340.3 218.2 383.2 283.6 415.6 308.3 434.9 337.7 表 3 钢靶的弹道极限及模型参数

Table 3. Ballistic limit velocityies and model constants of targets

靶 a p vbl/(m·s-1) 实验 模拟 实验 模拟 实验 模拟 T12 0.93 0.94 2.35 2.15 268.5 282.5 T4T4T4 0.93 0.89 2.30 2.40 275.5 262.5 -

[1] Marom I, Bodner S R. Projectile perforation of multi-layered beams[J]. International Journal of Mechanical Sciences, 1979, 21: 489-504. [2] 邓云飞, 张伟, 曹宗胜, 等.分层数对Q235钢薄板抗侵彻性能的影响[J].高压物理学报, 2013, 27(4): 550-555.Deng Yun-fei, Zhang Wei, Cao Zong-sheng, et al. Influence of the number of layers on the ballistic resistance oflayered thin Q235 steel plates[J]. Chinese Journal of High Pressure Physics, 2013, 27(4): 550-555. [3] Dey S, Bϕrvik T, Teng X, et al. On the ballistic resistance of double-layered steel plates: An experimental and numerical investigation[J]. International Journal of Solids and Structures, 2007, 44(20): 6701-6723. [4] Børvik T, Dey S, Clausen A H. A preliminary study on the perforation resistance of high-strength steel plates[J]. Journal de Physique IV France, 2006, 134: 1053-1059. [5] Gupta N K, Iqbal M A, Sekhon G S. Effect of projectile nose shape, impact velocity and target thickness on the deformation behavior of layered plates[J]. International Journal of Impact Engineering, 2008, 35(1): 37-60. [6] Alavi Nia A, Hoseini G R. Experimental study of perforation of multi-layered targets by hemispherical-nosed projectiles[J]. Material and Design, 2011, 32(2): 1057-1065. [7] 郭子涛.弹体入水特性及不同介质条件金属靶的抗侵彻性能研究[D].哈尔滨: 哈尔滨工业大学, 2012. [8] 邓云飞, 张伟, 曹宗胜.间隙对A3钢薄板抗卵形头弹侵彻性能影响的实验研究[J].振动与冲击, 2013, 32(12): 95-99.Deng Yun-fei, Zhang Wei, Cao Zong-sheng. Effect of gap on the ballistic performance of double-layered A3 steel shields against ogival rigid projectiles[J]. Journal of Vibration and Shock, 2013, 32(12): 95-99. [9] Recht R F, Ipson T W. Ballistic perforation dynamics[J]. Journal of Applied Mechanics, 1963, 30(3): 384-390. [10] Chen X W, Li Q M. Shear plugging and perforation of ductile circular plates struck by a blunt projectile[J]. International Journal of Impact Engineering, 2003, 28(5): 513-536. [11] Dey S, Børvik T, Teng X, et al. On the ballistic resistance of double-layered steel plates: An experimental and numerical investigation[J]. International Journal of Solids and Structures, 2007, 44(20): 6701-6723. [12] Corran R S J, Shadbolt P J, Ruiz C. Impact loading of plates: An experimental investigation[J]. International Journal of Impact Engineering, 1983, 1(1): 3-22. [13] Tiwari G, Iqbal M A, Gupta P K, et al. The ballistic resistance of thin aluminium plates with varying degrees of fixity along the circumference[J]. International Journal of Impact Engineering, 2014, 74: 46-56. -

下载:

下载: