Energy absorption of pre-folded origami under low speed impact

-

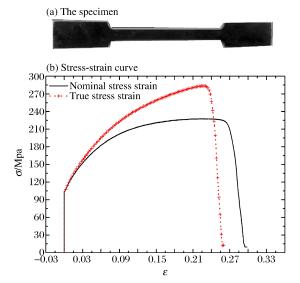

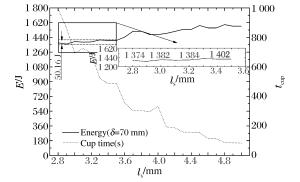

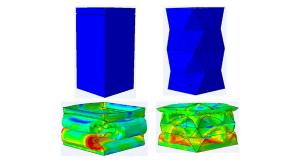

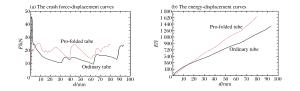

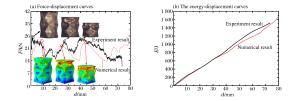

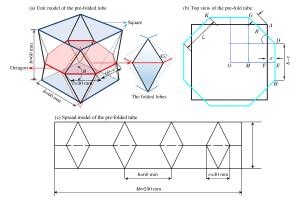

摘要: 为了降低结构的初始载荷、增加有效塑性变形面积,进而提高其吸能效率,研究一种以新型的预折纹管,在普通管的管壁上引入特别设计的折角。基于有限元软件ABAQUS/EXPLICIT的数值分析验证了预折纹在低速冲击载荷作用下可以引导预期的大变形模式,预折纹管的这种大变形模式相较于普通方管的对称变形模式有更低峰值载荷和更高的平均载荷。通过低速落锤实验获得了与有限元模拟结果相似的载荷-位移曲线和变形模式,验证了数值结果的可信性和预折纹方管的高效吸能特点。Abstract: A new type of creased square tube specifically designed with some folded lobes added at the wall of ordinary square tube is studied inorder not only to reduce the initial loading, but also to enhance the effective plastic area distortion which leads to a higher energy absorption efficiency. The numerical results based on the FEM package ABAQUS /EXPLICIT verify that the pre-folds could lead the pre-folded origami to the expected large deformation mode under low speed impact, which effectively reduce the peak load and also improve the average load of load-displacement curve compared with ordinary square tubes. The load-displacement curve obtained by FEM is identical to the results of low droped hammer test, which verifies the credibility of the numerical results as well as the high energy absorption characteristics of the tube.

-

表 1 普通方管和预折纹管的比较结果

Table 1. Comparison result between the pre-folded origami and the ordinary square tube

结构 Fp/kN S2/kN2 Fm/kN ηCFE 普通方管(数值) 45.99 24.63 14.47 0.31 普通方管(实验) 88.86 46.78 15.41 0.17 预折纹管(数值) 25.40 12.25 19.85 0.78 预折纹管(实验) 27.77 14.61 20.83 0.75 -

[1] Olabi A G, Morrisa E, Hashmi M S J. Metallic tube type energy absorbers: A synopsis[J]. Thin-walled Structures, 2006, 45(7/8): 706-726. [2] Stein E, Borst R, Huges T J R. Encyclopedia of computational mechanics[M]. New York, USA: John Wiley & Sons, 2004: 25-46. [3] Zhong Z H, Zhang W G, Cao L B. Automotive crash safety technology[M]. Beijing: China Machine Press, 2003: 112-152. [4] Airoldi A, Janszen G. A design solution for a crashworthy landing gear with a new triggering mechanism for the plastic collapse of metallic tubes[J]. Aerospace Science and Technology, 2005, 9(5): 445-455. doi: 10.1016/j.ast.2005.04.001 [5] Tyrell D, Jacobsen K, Martinez E, et al. A train-to-train impact test of crash energy management passenger rail equipment: Structural results[C]∥Proceedings of IMECE2006. Chicargo, Illiois, USA, 2006. [6] Hu Z Q, Cui W C. Review of the researches on the ship collision mechanisms and the structural designs against collision[J]. Journal of Ship Mechanics, 2005, 9(2): 131-142. [7] 杨嘉陵, 吴卫华, 刘旭红, 等.直升机整体机坠毁设计的简化力学模型[J].机械工程学报, 2003, 39(12): 109-113.Yang Jia-ling, Wu Wei-hua, Liu Xu-hong, et al. The simplified mechanics model of helicopter design when crashed[J]. Chinese Journal of Mechanical Engineering, 2003, 39(12): 109-113. [8] 李玉龙, 石霄鹏.民用飞机鸟撞研究现状[J].航空学报, 2012, 33(2): 189-198.Li Yu-long, Shi Xiao-peng. Research status of bird strike civilian aircraft[J]. Acta Aeronautica et Astronautica Sinica, 2012, 33(2): 189-198. [9] Zhang L L, Gao F. Researches development on the crashworthiness about metal: thin-walled structures[J]. Metal Forming, 2006, 32(5): 76-78. [10] Lu G X, Yu T X. Energy absorption of structures and materials[M]. Woodhead, Florida, USA: CRC Press, 2003: 12-18. [11] Du X W, Song H W. Impact dynamics and crashworthiness design of cylindrical shell[M]. Beijing: Science Press, 2004: 16-30. [12] Yu T X. Impact energy absorbing devices based upon the plastic deformation of metallic elements[J]. Advances in Mechanics, 1986, 16(1): 28-39. [13] Yuen S C K, Nurick G N. The energy-absorbing characteristics of tubular structures with geometric and material modifications: an overview[J]. Applied Mechanics Review, 2008, 62(2): 0208021-02080215. [14] Abramowicz W. Thin-walled structures as impact energy absorbers[J]. Thin-walled Structures, 2003, 41(2/3): 91-107.DOI: 10.1016/S0263-8231(02)00082-4. [15] Liu Y C. Crashworthiness design of multi-corner thin-walled columns[J]. Thin-walled Structures, 2008, 46(12): 1329-1337.DOI: 10.1016/j.tws.2008.04.003. [16] Yamazaki K, Han J. Maximization of the crushing energy absorption of cylindrical shells[J]. Advances in Engineering Software, 2000, 31(6): 25-434.DOI: 10.1016/S0965-9978(00)00004-1. [17] Gibson L J, Ashby M F. Cellular solids[M]. Cambridge, UK: Cambridge University Press, 1999, 51: 48-57. [18] Song J, Chen Y, Lu G. Axial crushing of thin-walled structures with origami patterns[J]. Thin-Walled Structures, 2012, 54: 65-71. doi: 10.1016/j.tws.2012.02.007 [19] Ma J, You Z. Energy absorption of thin-walled square tubes with a prefolded origami pattern: Part Ⅰ: geometry and numerical simulation[J]. Journal of Applied Mechanics, 81(1): 011003-1-011003-11. [20] Ma J, You Z. Energy absorption of thin-walled beams with a pre-folded origami pattern[J]. Thin-Walled Structures, 2013, 73(1): 198-206. http://adsabs.harvard.edu/abs/2013jam....81a1003m [21] Wierzbicki T, Abramowicz W. On the crushing mechanics of thin-walled structures[J]. Journal of applied Mechanics, 1983, 50(4a): 727-734.DOI: 10.1115/1.3167137. [22] Hsu S S, Jones N. Quasi-static and dynamic axial crushing of thin-walled circular stainless steel, mild steel and aluminum alloy tubes[J]. International Journal of Crashworthiness, 2010, 9(2): 195-217. [23] SIMULIA. ABAQUS Analysis User's Manual[M]. Documentation Version 6.10. Providence, RI, USA: Dassault Systems Simulia Corp, 2007: 32.5.2.1-32.5.2.6. [24] Meng Q, Al-Hassani S T S, Soden P D. Axial crushing of square tubes[J]. International Journal of Mechanical Sciences, 1983, 25(9/10): 747-773. -

下载:

下载: