Influence of pre-stress on elastic precursor of LY12 aluminum

-

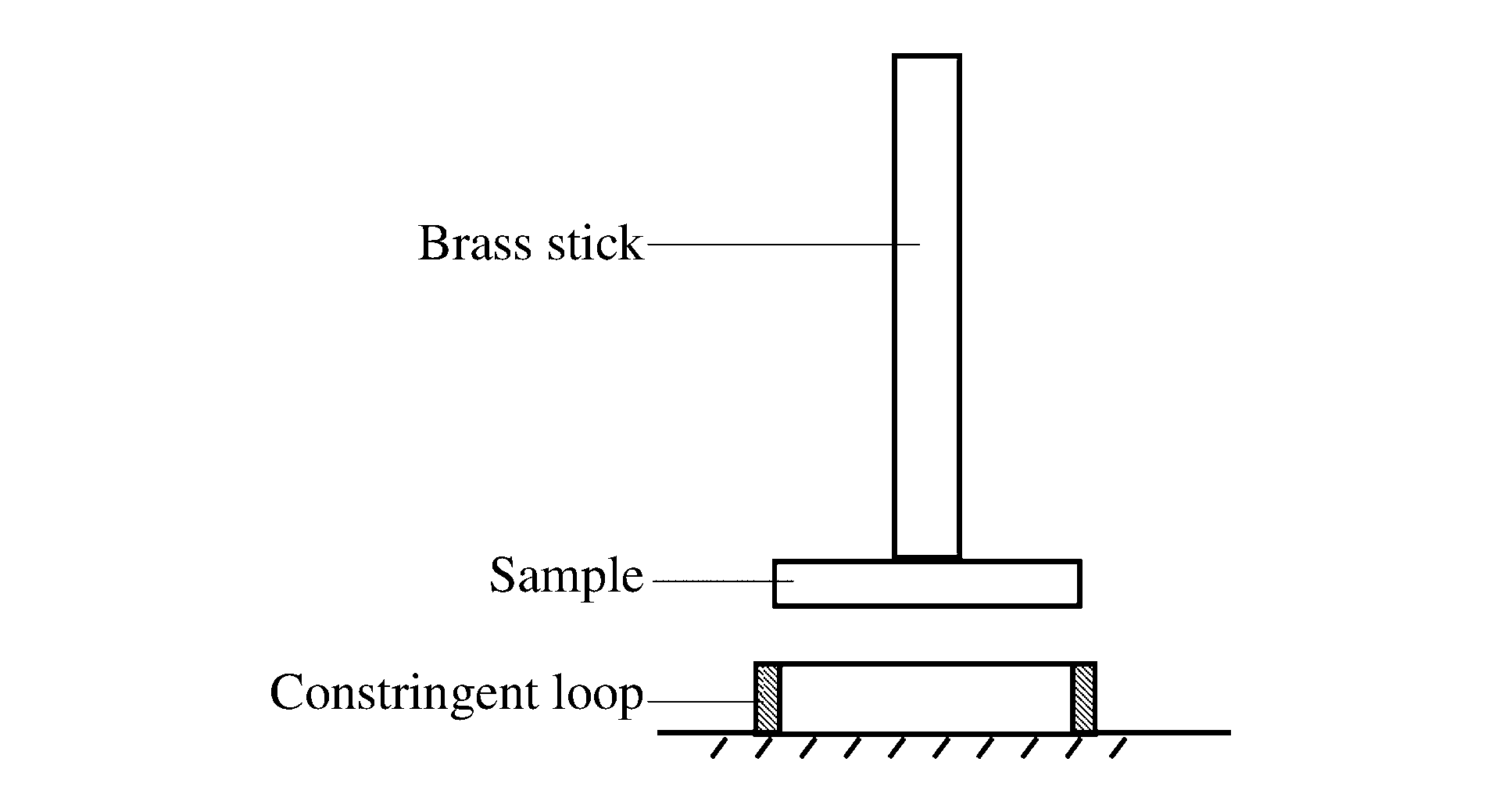

摘要: 通过过盈配合的热装配方法对LY12铝合金平面样品施加了径向预应力,采用平面飞片撞击方法获得了预应力对弹性前驱波的影响。结果表明:当飞片均以500 m/s的速度撞击样品时,压缩预应变为0(无预应变)、964.5×10-6和1 886.0×10-6时,弹性前驱波幅值分别为87.56、95.24、121.03 m/s,压缩预应力(变)提高了LY12铝弹性前驱波幅值。结合实验的特点,探讨了对样品施加静态径向预应力的数值模拟方法,结果表明,上升沿(100 μs)较为缓慢的加载可以达到与准静态加载应力分布一样的结果。采用该数值模拟方法给出和验证了弹性前驱波随压缩预应力增加而上升的计算结果,与实验结果较为吻合。Abstract: The effect of pre-stress on elastic precursor of disk-shaped LY12 aluminum samples was studied, and the radial pre-stress (or pre-strain) state was achieved by using an excessively-conjugated heat assembly device. In the experiment, the LY12 samples were impacted by flyer plates driven by a one-stage light-gas gun, and elastic precursor signals of the samples in several pre-strain states were measured by VISAR. The experimental results show that the elastic precursors are 87.56, 95.24 and 121.03 m/s respectively corresponding to the pre-strains of 0, 964.5×10-6 and 1 886.0×10-6 when the samples are impacted by the flyer plates with almost the same velocity. This clearly indicates that the pre-stress (pre-strain) increases the elastic precursor of LY12 aluminum. According to these experiments, we discussed how to apply static loading on the sample in the radial direction. The result shows that the loading with rising edge time 100 μs can produce the same stress distribution as that of static loading. Using this technology, the simulation results show that by increasing pre-stress we can enhance the elastic precursor velocity on the free surface of the samples. The simulated results are in good agreement with those from the experiments.

-

Key words:

- mechanics of explosion /

- pre-stress /

- impact /

- elastic precursor

-

表 1 不同径向预应力下实验结果

Table 1. Experimental results of samples under different pre-strains

ε0, r/10-6 σ0, r/MPa v/(m·s-1) ue*/(m·s-1) 0 0 497.82 87.56 964.5 99.2 497.06 95.24 1 886.0 194.0 499.60 121.03 -

[1] 唐光普, 张晓敏, 张培源.初应力位形上附加变形线性理论的局限性及二次理论[J].工程力学, 2003, 20(2): 91-94. http://www.cqvip.com/Main/Detail.aspx?id=7781045Tang Guang-pu, Zhang Xiao-min, Zhang Pei-yuan. The limitations of linear theory and improved quadratic theory for superposing additional deformation upon the configuration with initial stresses[J]. Engineering Mechanics, 2003, 20(2): 91-94. http://www.cqvip.com/Main/Detail.aspx?id=7781045 [2] 张晓敏, 盛天文, 张培源.初应力拱侧向振动的固有频率[J].工程力学, 2004, 21(2): 178-182. http://www.cnki.com.cn/Article/CJFDTotal-GCLX200402029.htmZhang Xiao-min, Shen Tian-wen, Zhang Pei-yuan. Natural frequencies of initially stressed arches in lateral vibration[J]. Engineering Mechanics, 2004, 21(2): 178-182. http://www.cnki.com.cn/Article/CJFDTotal-GCLX200402029.htm [3] 张世文, 刘仓理, 李庆忠, 等.预应力对LY12铝层裂强度的影响[J].爆炸与冲击, 2009, 29(1): 85-89. doi: 10.11883/1001-1455(2009)01-0085-05Zhang Shi-wen, Liu Cang-li, Li Qing-zhong, et al. Influence of pre-stress on spall strength of LY12 aluminum[J]. Explosion and Shock Waves, 2009, 29(1): 85-89. doi: 10.11883/1001-1455(2009)01-0085-05 [4] 刘建秀, 韩长生, 张祖根, 等.摩擦材料在无围压和加围压条件下的形变比较[J].爆炸与冲击, 2004, 24(2): 151-157. http://www.bzycj.cn/article/id/9935Liu Jian-xiu, Han Chang-sheng, Zhang Zu-gen, et al. Deformation comparison between confined pressure and non-confined pressure for friction material[J]. Explosion and Shock Waves, 2004, 24(2): 151-157. http://www.bzycj.cn/article/id/9935 [5] Candappa D P, Setunge S, Sanjayan J G. Stress versus strain relation of high strength concrete under high lateral confinement[J]. Cement and Concrete Research, 1999(29): 1977-1982. http://www.sciencedirect.com/science/article/pii/S0008884699002197 [6] Ravichandran G, Subhash G. Critical appraisal of limiting strain rates for compression testing of ceramics in a split Hopkinson pressure bar[J]. Journal of American Ceramic Society, 1994, 77(1): 263-267. doi: 10.1111/j.1151-2916.1994.tb06987.x [7] Binici B. An analytical model for stress-strain behavior of confined concrete[J]. Engineering Structures, 2005, 27(7): 1040-1051. doi: 10.1016/j.engstruct.2005.03.002 [8] 薛志刚, 胡时胜.水泥砂浆在主动围压下的动态力学性能[J].爆炸与冲击, 2008, 28(6): 561-564. doi: 10.11883/1001-1455(2008)06-0561-04Xue Zhi-gang, Hu Shi-sheng. Dynamic behavior of cementmortar under active confinement[J]. Explosion and Shock Waves, 2008, 28(6): 561-564. doi: 10.11883/1001-1455(2008)06-0561-04 [9] 吕晓聪, 许金余, 郭洪海, 等.围压对砂岩动态力学性能的影响[J].岩石力学与工程学报, 2010, 29(1): 193-201.Lü Xiao-cong, Xu Jin-yu, Ge Hong-hai, et al. Effects of confining pressure on mechanical behaviors of sandstone under dynamic impact loads[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(1): 193-201. [10] Chen W, Ravichandran G. Static and dynamic compressive behavior of aluminum nitride under moderate confinement[J]. Journal of American Ceramic Society, 1996, 79(3): 579-584. doi: 10.1111/j.1151-2916.1996.tb07913.x [11] Chen W, Ravichandran G. Failure mode transition in ceramics under dynamic multiaxial compression[J]. International Journal of Fracture, 2001, 101(1): 141-159. doi: 10.1023/A:1007672422700 [12] 张世文.复杂应力状态对材料层裂特性影响的探索性研究[D].绵阳: 中国工程物理研究院, 2009. [13] 董杰, 李永池, 陈学东.一种新型微孔洞损伤模型[J].高压物理学报, 2007, 21(4): 414-418. http://www.cqvip.com/QK/96553X/200704/26403270.htmlDong Jie, Li Yong-chi, Chen Xue-dong. A new damage model of microvoid[J]. Chinese Journal of High Pressure Physics, 2007, 21(4): 414-418. http://www.cqvip.com/QK/96553X/200704/26403270.html [14] Livermore Software Technology Corporation. LS-DYNA keyword user'S manual, volume Ⅱ[M]. version 960, Livermore LSTC, MARCH, 2001. [15] 张世文, 刘仓理, 李庆忠, 等.初始应力状态对材料层裂破坏特性影响研究[J].力学学报, 2008, 40(4): 535-542.Zhang Shi-wen, Liu Cang-li, Li Qing-zhong, et al. Study on spalling response of materials under pre-stress[J]. Chinese Journal of Theoretical and Applied Mechanics, 2008, 40(4): 535-542. [16] Li Q M, Meng H. About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test[J]. International Journal of Solids and Structures, 2003, 40(4): 343-360. http://www.sciencedirect.com/science/article/pii/S0020768302005267 [17] Lu Y B, Li Q M. Dynamic behavior of polymers at high strain-rates based on split Hopkinson pressure bar tests[J]. International Journalof Impact Engineering, 2011, 38(1): 41-50. doi: 10.1016/j.ijimpeng.2010.08.001 -

下载:

下载: