Dimensional effects of hat-shaped specimen in Hopkinson bar test

-

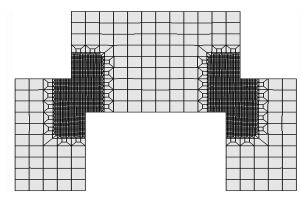

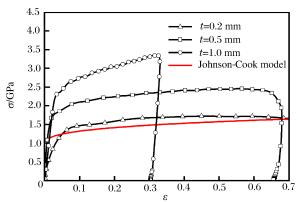

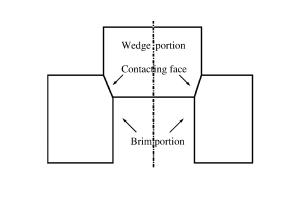

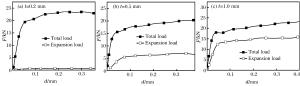

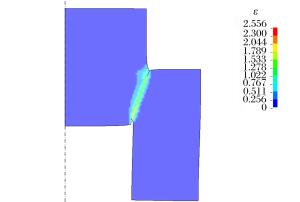

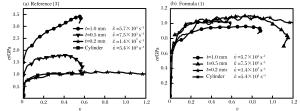

摘要: 利用ANSYS/LS-DYNA软件开展不同尺寸帽形试样的SHPB数值模拟,研究帽形试样的尺寸效应。结果表明,当帽形试样剪切变形区域宽度大于0.2 mm时,根据经典公式处理得到的应力值将随t的增大而显著增大, 严重偏离理论值,当t=1.0 mm时,计算得到的应力值甚至接近理论值的2倍。采用分体模型进行的进一步计算表明,数据处理结果中应力偏差主要来源于帽形试样中环状部位的膨胀变形。提出改进的数据处理方法,并采用圆柱样与几种不同尺寸帽形试样开展了验证实验,结果与计算结果基本一致。

-

关键词:

- 固体力学 /

- 尺寸效应 /

- ANSYS/LS-DYNA软件 /

- 帽形试样 /

- SHPB

Abstract: Numerical Hopkinson bar experiments of hat-shaped specimens with different geometries were carried out using ANSYS/LS-DYNA to investigate the effects resulting from varying the geometrical dimensions of specimens. Results show that the stress value calculated by the classic formula deviated drastically from the theoretical value, when the width t the of shear zone was larger than 0.2 mm. When the width t was 1.0 mm, the calculated stress value would even rise up to twice as much as close to the theoretical value. Further research with the split model revealed that the deviation of the stress mainly occurred as a result from the expansion deformation of the brim portion of the hat-shaped specimen. An improved method of data processing for the hat-shaped specimen was also presented based on the numerical simulation results. Finally, the method was also validated by SHPB experiments with cylinder specimens and hat-shaped specimens with different dimensions.-

Key words:

- solid mechanics /

- geometry effect /

- ANSYS/LS-DYNA /

- hat-shaped specimen /

- SHPB

-

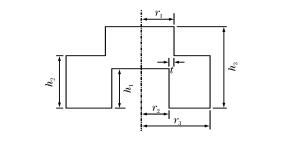

表 1 帽形试样几何尺寸

Table 1. Physical dimensions of the hat-shaped specimens

r1/mm r2/mm r3/mm h1/mm h2/mm h3/mm t/mm 3.0 2.8 5.0 3.5 5.0 8.0 0.2 3.0 2.5 5.0 3.5 5.0 8.0 0.5 3.0 2.0 5.0 3.5 5.0 8.0 1.0 表 2 应力、应变表达式形状相关参数

Table 2. The geometry-related parameters in stress and strain expressions

k1 k2 k3 k1 k2 k3 t=0.5 mm t=1.0 mm 1.224 0 0.868 0.767 0.198 0.657 -

[1] Zukas J A, Nicholas T, Swift H F, et al. Impact dynamics[M]. Malabar, Florida: Krieger Publishing Company, 1992. [2] 肖大武, 李英雷, 蔡灵仓.绝热剪切研究进展[J].实验力学, 2010, 25(4):463-475. http://d.old.wanfangdata.com.cn/Periodical/sylx201004015Xiao Dawu, Li Yinglei, Cai Lingcang. Progress in research on adiabatic shearing[J]. Journal of Experimental Mechanics, 2010, 25(4):463-475. http://d.old.wanfangdata.com.cn/Periodical/sylx201004015 [3] Andrade U, Meyers M A, Vecchio K S, et al. Dynamic recrystallization in high-strain, high-strain-rate plastic deformation of copper[J]. Acta Metallurgica et Materialia, 1994, 42(9):3183-3195. doi: 10.1016/0956-7151(94)90417-0 [4] Rittel D, Dorogoy A. Numerical validation of the shear compression specimen. Part I: Quasi-static large strain testing[J]. Experimental Mechanics, 2005, 45(2):167-177. http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.612.7957 [5] 刘新芹, 谭成文, 张静, 等.应力状态对Ti-6Al-4V绝热剪切敏感性的影响[J].稀有金属材料与工程, 2008, 37(9):1522-1525. doi: 10.3321/j.issn:1002-185X.2008.09.004Liu Xinqin, Tan Chengwen, Zhang Jing, et al. Influence of stress-state on adiabatic shear sensitivity of Ti-6Al-4V[J]. Rare Metal Materials and Engineering, 2008, 37(9):1522-1525. doi: 10.3321/j.issn:1002-185X.2008.09.004 [6] 陈思颖, 黄晨光, 孔卫国, 等.结构钢中绝热剪切带形成与扩展的光学观测与数值模拟响[J].高压物理学报, 2010, 24(1):31-36. doi: 10.3969/j.issn.1000-5773.2010.01.006Chen Siying, Huang Chenguang, Kong Weiguo, et al. Optical observation and numerical simulation on the evolution of adiabatic shear band in structural steel[J]. Chinese Journal of High Pressure Physics, 2010, 24(1):31-36. doi: 10.3969/j.issn.1000-5773.2010.01.006 [7] Wang B F, Yang Y. Microstructure evolution in adiabatic shear band in fine-grain-sized Ti-3Al-5Mo-4.5V alloy[J]. Materials Science and Engineering: A, 2008, 473(1/2):306-311. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=8c0d94d452ec6180419dec4a572a15e1 -

下载:

下载: