Perforation characteristics of cylindrical shell free beamunder high-speed impact

-

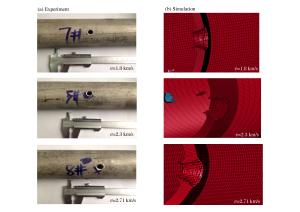

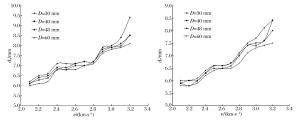

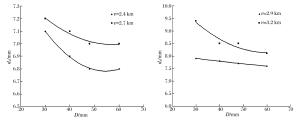

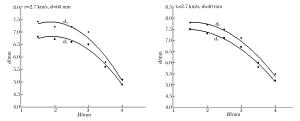

摘要: 利用二级轻气炮加载,进行了球状2A12铝弹丸垂直撞击圆柱壳自由梁实验。并进行了弹丸速度、圆柱壳直径和壁厚等因素对穿孔直径影响的数值模拟,数值模拟结果和实验结果基本吻合。通过量纲分析和数值模拟结合,推导了穿孔直径与相关影响参数的经验关系式。研究结果表明:当圆柱壳直径和厚度不变时,高速撞击产生的穿孔直径在径向和轴向都随着弹丸速度增大而增大;当弹丸速度和圆柱壳厚度不变时,高速撞击产生的穿孔直径随着圆柱壳自由梁直径的增大而减小;当弹丸速度和圆柱壳直径不变时,穿孔直径随着圆柱壳厚度的增大而减小。Abstract: In order to study the perforation characteristics generated by a spherical 2A12 aluminum projectile impacting cylindrical shell steel free beams at high-speed, the experiments of a spherical projectile loaded by a two-stage light gas gun impacting cylindrical shell free beams were performed. Simulations were carried out to study different factors such as projectile speed, cylindrical shell diameter and thickness that influence the perforation diameter. Our simulation and experimental results are basically consistent. An empirical correlation of perforation diameter and related parameters was deduced combining dimension analysis and simulation. The results show that the radial and axial perforation diameters increase with the increase of the impact velocity when the thickness and diameter of the cylindrical shell remains unchanged; the radial and axial perforation diameter decreases with the increase of the diameter of the cylindrical shell when the projectile velocity and thickness are remain unchanged; the radial and axial perforation diameters decrease with the increase of the cylindrical shell thickness when the projectile velocity and cylindrical shell diameter remain unchanged.

-

表 1 材料参数

Table 1. Material parameters

材料 ρ/(kg·m-3) G/GPa A/MPa B/MPa n C m s c0/(km·s-1) γ0 2A12铝 2 780 27.6 265 426 0.34 0.015 1.0 1.34 5.330 2.0 304钢 7 830 77.0 332 245 0.36 0.022 1.0 1.92 3.570 1.67 表 2 数值模拟结果

Table 2. Simulation results

No. D/mm H/mm v/(km·s-1) da/mm dr/mm 1 30 3 2.2 6.5 6.0 3 30 3 3.2 9.4 8.4 4 40 3 2.2 6.4 6.0 5 40 3 3.2 8.5 8.4 6 40 2 2.7 7.7 7.3 7 48 3 2.2 6.3 5.8 9 48 3 3.2 8.5 8.0 10 60 3 2.2 6.0 5.8 12 60 3 3.2 8.1 7.5 表 3 实验与数值模拟结果的比较

Table 3. Comparison of simulation and experiment results

D/mm v/(km·s-1) da/mm dr/mm 实验 模拟 实验 模拟 30 2.10 7.9 6.2 7.4 6.0 40 2.06 7.5 6.1 7.4 5.9 48 2.10 7.3 6.1 6.7 5.9 60 2.06 7.2 6.0 6.5 5.8 60 1.80 7.2 6.0 6.5 5.0 60 2.30 7.2 6.2 7.0 5.9 60 2.58 8.4 6.8 7.5 6.5 60 2.71 8.4 7.0 7.8 6.5 60 3.30 8.9 8.6 7.9 7.7 -

[1] Lee E H, Symonds P S, Providence R I. Large plastic deformations of beams under transverse impact[J]. Journal of Applied Mechanics, 1952, 19(3):308-314. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=J-STAGE_1018680 [2] Jones N, Wierzbicki T. Dynamic plastic failure of a free-free beam[J]. International Journal Impact Engineering, 1987, 6(3):225-240. doi: 10.1016/0734-743X(87)90022-4 [3] Yang J L, Xi F. Experiment and theoretical study of free-free beam subjected to impact at any cross-section along its span[J]. International Journal of Impact Engineering, 2003, 28(7):761-781. doi: 10.1016/S0734-743X(02)00123-9 [4] Yu T X, Yang J L, Reid S R. Dynamic behaviour of elastic-plastic free-free beams subjected to impulsive loading[J]. International Journal of Solids Structures, 1996, 33(18):2659-2680. doi: 10.1016/0020-7683(95)00169-7 [5] 穆建春, 张铁光.刚塑性自由梁中部在横向冲击下的初始变形模式[J].爆炸与冲击, 2000, 20(1):7-12. doi: 10.3321/j.issn:1001-1455.2000.01.002Mu Jianchun, Zhang Tieguang. Initial deformation modes of rigid-plastic free-free beams under transversal impact[J]. Explosion and Shock Waves, 2000, 20(1):7-12. doi: 10.3321/j.issn:1001-1455.2000.01.002 [6] 穆建春, 乔志宏, 张依芬, 等.自由梁中部在平头子弹横向正冲击下的穿透及变形[J].爆炸与冲击, 2000, 20(3):200-207. doi: 10.3321/j.issn:1001-1455.2000.03.002Mu Jianchun, Qiao Zhihong, Zhang Yifen, et al. Perforation and deformation of free-free beam by transverse impact of flat nosed missile at the middle of its span[J]. Explosion and Shock Waves, 2000, 20(3):200-207. doi: 10.3321/j.issn:1001-1455.2000.03.002 [7] 席丰, 杨嘉陵, 郑晓宁, 等.自由梁受集中质量横向撞击的刚-塑性动力响应[J].爆炸与冲击, 1998, 18(1):55-62. http://www.bzycj.cn/article/id/10381Xi Feng, Yang Jialing, Zheng Xiaoning, et al. Dynamic response of a rigid, perfectly plastic free-free beam subjected to impulsive loading[J]. Explosion and Shock Waves, 1998, 18(1):55-62. http://www.bzycj.cn/article/id/10381 [8] 尚晓江, 苏建宇, 王化锋.ANSYS LS-DYNA动力分析方法与工程实例[M]. 2版.北京:中国水利水电出版社, 2008:140. [9] 周劲松, 甄良, 杨德庄.几种金属材料在2.6~7 km/s弹丸撞击下的损伤行为[J].宇航学报, 2000, 21(2):75-81. doi: 10.3321/j.issn:1000-1328.2000.02.012Zhou Jinsong, Zhen Liang, Yang Dezhuang. Damage behaviors of several metal materials under impacts of projectiles with hypervelocities of 2.6-7 km/s[J]. Journal of Astronautics, 2000, 21(2):75-81. doi: 10.3321/j.issn:1000-1328.2000.02.012 -

下载:

下载: