Stress-testing method by PVDF gauge and its application in explosive test of porous material

-

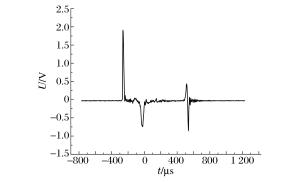

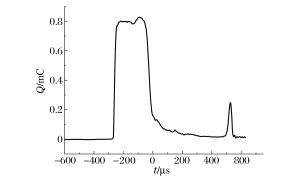

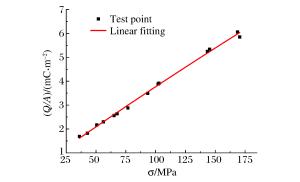

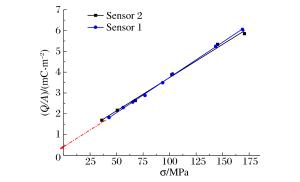

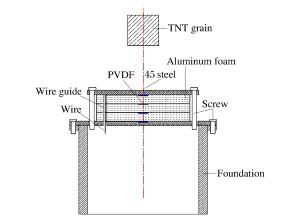

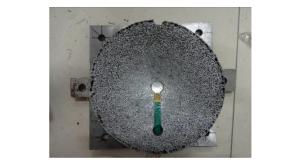

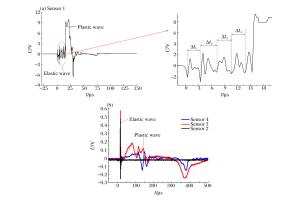

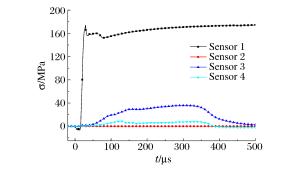

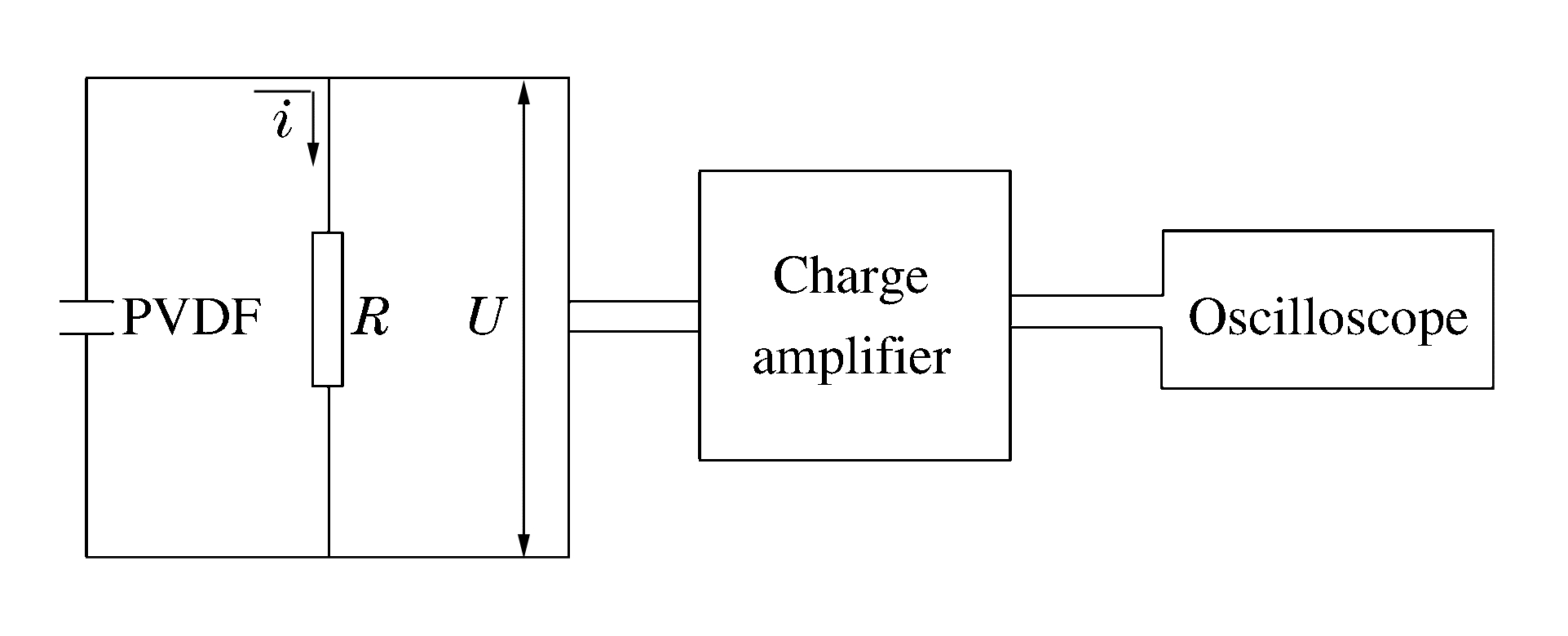

摘要: 通过精确测量Hopkinson杆子弹速度,实现了对PVDF压力传感器的动态标定,测试数据线性度良好,误差不超过1.9%,得到动态灵敏度系数K=32.83 pC/N,采用500 g TNT对“钢板-泡沫铝-钢板”复合结构进行爆炸冲击加载,测量结构间应力波的传播情况。研究结果表明:电压测试信号可以较为准确地反映弹性波与塑性波的加载时间和传播速度,PVDF对弹性应力波段高频信号的动态响应灵敏准确,与理论数据的相对误差为3.5%。测得泡沫铝材料中塑性波的传播速度为590 m/s,A1-B1界面塑性波透射系数达到了0.53,远高于弹性波透射系数。从机理上对应力时程曲线中出现的特殊现象进行了阐述,为相关爆炸测试提供参考。Abstract: In this work, by accurately measuring the bullet speed of the Hopkinson bar, we succeeded in the dynamic calibration of the PVDF pressure sensor. The test data obtained have a good linearity and a deviation below 1.9%. The coefficient value K of dynamic sensitivity is 32.83 pC/N. By applying a blast loading of 500 g TNT to the composite structure of "steel-aluminum foam-steel", the propagation of the stress wave between its components was measured. The results show that the voltage signal can accurately represent the loading time and the propagation velocity of the elastic wave and plastic wave and the PVDF dynamic response of elastic stress wave with high-frequency signal is sensitive and accurate, with only a relative deviation of less than 3.5% from the theoretical data. The measured propagation velocity of the plastic wave in the aluminum foam is 590 m/s, the transmission coefficient of the plastic wave in A1-B1 interface is 0.53, which is much higher than that of the elastic wave. Special remarks were made concerning the unusual phenomena observed in the stress curve based upon our understanding of the mechanism, providing a reference for relevant explosion tests.

-

Key words:

- mechanics of explosion /

- explosion test /

- aluminum foam /

- PVDF sensor

-

表 1 Hopkinson杆冲击测试数据

Table 1. Measurement data of Hopkinson bar impacting

传感器1 传感器2 v/(m·s-1) σ/MPa Ωmax/pC v/(m·s-1) σ/MPa Ωmax/pC 8.03 56 2 300 9.67 68 2 640 6.12 43 1 820 7.24 51 2 170 9.31 65 2 560 5.16 36 1 690 10.97 77 2 880 14.60 102 3 880 13.35 93 3 490 20.76 145 5 340 14.69 103 3 910 24.38 171 5 850 20.50 143 5 240 24.11 169 6 060 表 2 实验相关参数(炸高15 cm)

Table 2. Related parameters(blasting height: 15 cm)

泡沫铝 δ/% ρ/(g·cm-3) d/mm 传感器 布设位置 R/Ω B1 84.5 0.418 5 2.5 1 A1-B1 42.68 B2 80.8 0.518 4 2.0 2 B1-B2 43.02 B3 77.6 0.604 8 2.0 3 B2-B3 42.28 -

[1] Kawai H. The piezoelectricity of polyvinyldene fluoride[J]. Journal of Applied Physics, 1969, 8(7):975-976. doi: 10.1143/JJAP.8.975 [2] Graham R A, Anderson M U, Bauer F, et al. Piezoelectric polarization of the ferroelectric polymer PVDF from 10 MPa to 10 GPa: Studies of loading-path dependence[C]//Shock Compression of Condensed Matter-1991. Williamsburg, Virginia, 1992: 883-886. https://www.sciencedirect.com/science/article/pii/B978044489732950203X [3] Bauer F. Advances in piezoelectric PVDF shock compression sensors[C]//10th International Symposium on Electrets. Greece: IEEE Stands Office, 1999: 647-650. http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=832129 [4] Bauer F. PVDF shock sensors: Applications to polar materials and high explosives[J]. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2000, 47(6):1448-1454. doi: 10.1109/58.883534 [5] Sokhanvar S, Dargahi J, Packirisamy M. Influence of friction on piezoelectric sensors[J]. Sensors & Actuators A Physical, 2008, 141(1):120-128. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e7e4fd12958a1a28042606d90f80f6c4 [6] Shirinov A V, Schomburg W K. Pressure sensor from a PVDF film[J]. Sensors & Actuators A Physical, 2008, 142(1):48-55. doi: 10.1007-s10725-010-9536-z/ [7] 席道瑛, 郑永来.PVDF压电计在动态应力利测量中的应用[J].爆炸与冲击, 1995, 15(2):174-179. http://www.bzycj.cn/article/id/10573Xi Daoying, Zheng Yonglai. Application of PVDF gauges to dynamical stress measurements[J]. Explosion and Shock Waves, 1995, 15(2):174-179. http://www.bzycj.cn/article/id/10573 [8] 李焰, 张向荣, 谭红梅, 等.国产PVDF压电薄膜的冲击加载及卸载响应研究[J].高压物理学报, 2004, 18(3):261-266. doi: 10.3969/j.issn.1000-5773.2004.03.011Li Yan, Zhang Xiangrong, Tan Hongmei, et al. Response of homemade PVDF piezofilm under shock loading and unloading[J]. Chinese Journal of High Pressure Physics, 2004, 18(3):261-266. doi: 10.3969/j.issn.1000-5773.2004.03.011 [9] 赵继波, 谭多望, 张远平, 等.PVDF计在水中爆炸近场压力测试中的应用[J].火炸药学报, 2009, 32(3):1-4. doi: 10.3969/j.issn.1007-7812.2009.03.001Zhao Jibo, Tan Duowang, Zhang Yuanping, et al. Application of PVDF sensor in underwater explosive shock wave measurement at near-field[J]. Chinese Journal of Explosives & Propellants, 2009, 32(3):1-4. doi: 10.3969/j.issn.1007-7812.2009.03.001 [10] 王伟, 李小春.不耦合装药下爆炸应力波传播规律的试验研究[J].岩土力学, 2010, 31(6):1723-1729. doi: 10.3969/j.issn.1000-7598.2010.06.008Wang Wei, Li Xiaochun. Experimental study of propagation law of explosive stress wave under condition of decouple charge[J]. Rock and Soil Mechanics, 2010, 31(6):1723-1729. doi: 10.3969/j.issn.1000-7598.2010.06.008 [11] 任新见, 陈虎林.PVDF传感器在爆炸近区超压测量中的应用研究[J].振动与冲击, 2012, 31(12):146-149. http://d.old.wanfangdata.com.cn/Periodical/zdycj201212029Ren Xinjian, Chen Hulin. Application of PVDF sensor in shock wave measurement of near zone of explosion[J]. Journal of Vibration and Shock, 2012, 31(12):146-149. http://d.old.wanfangdata.com.cn/Periodical/zdycj201212029 [12] 王永刚, 胡时胜, 王礼立.爆炸荷载下泡沫铝材料中冲击波衰减特性的实验和数值模拟研究[J].爆炸与冲击, 2003, 32(6):516-523. doi: 10.3321/j.issn:1001-1455.2003.06.006Wang Yonggang, Hu Shisheng, Wang Lili. Shock attenuation in aluminum foams under explosion loading[J]. Explosion and Shock Waves, 2003, 32(6):516-523. doi: 10.3321/j.issn:1001-1455.2003.06.006 [13] 田杰.泡沫铝的冲击波衰减和抗爆震特性研究[D].合肥: 中国科学技术大学, 2006: 50-66. http://cdmd.cnki.com.cn/Article/CDMD-10358-2006102746.htm [14] 王礼立.应力波基础[M].北京:国防工业出版社, 1985. [15] 胡亚峰, 顾文彬, 刘建青, 等.应力波在泡沫铝夹层三明治板中传播规律的数值研究[J].爆破器材, 2014, 43(5):15-23. doi: 10.3969/j.issn.1001-8352.2014.05.004Hu Yafeng, Gu Wenbin, Liu Jianqing, et al. Numerical study of stress wave propagation rules in aluminum foam sandwich plates[J]. Explosive Materials, 2014, 43(5):15-23. doi: 10.3969/j.issn.1001-8352.2014.05.004 -

下载:

下载: