Explosion of gasoline/air mixture in confined space with weakly constrained structure at the top

-

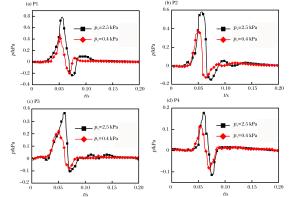

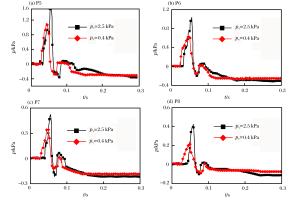

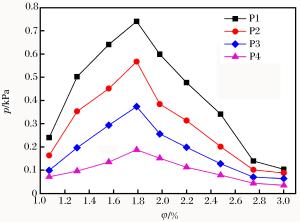

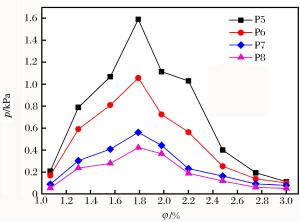

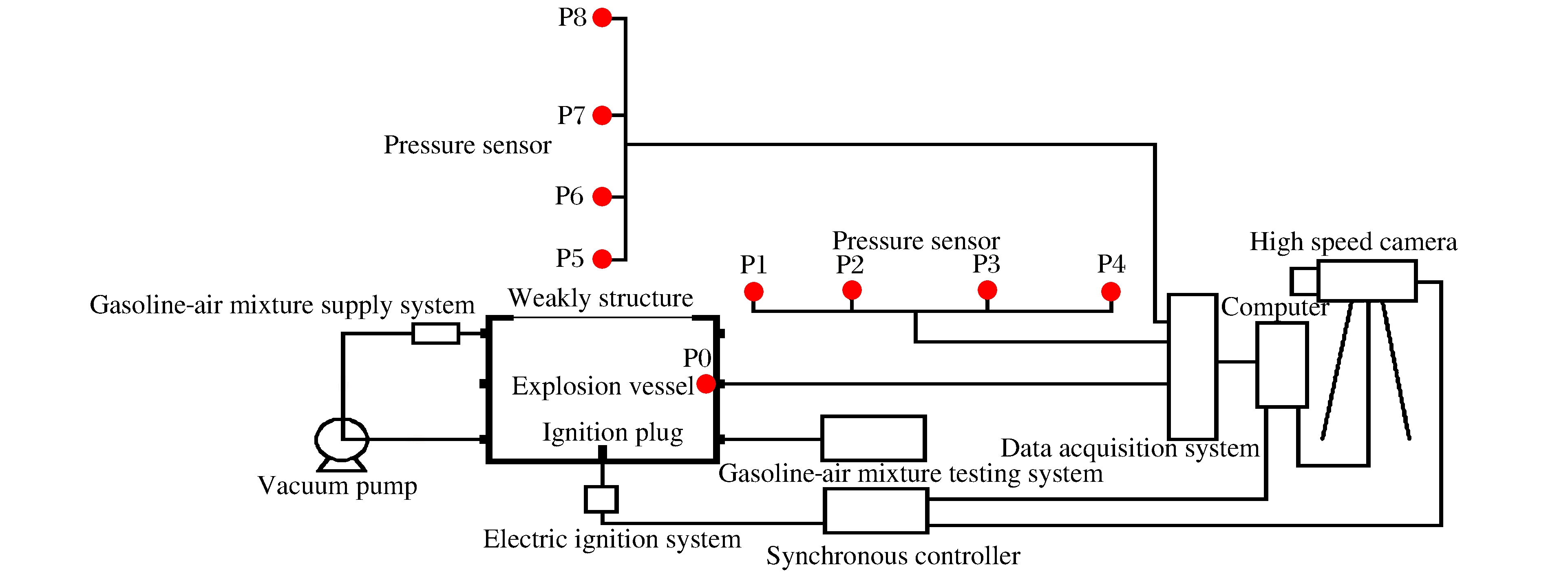

摘要: 建立了顶部含有弱约束结构的受限空间油气爆炸实验系统,并对含有弱约束的受限空间中油气爆炸特性进行实验研究,获得超压变化规律及火焰发展特征。结果表明:(1)容器内部超压受泄流、外部爆炸、火焰扩张等因素的影响,出现多个峰值,并伴以强烈的振荡;容器外部超压随着距离的增大而减小,且竖直方向超压大于水平方向超压。(2)与无约束爆炸相比,弱约束结构对爆炸的影响主要体现在对爆炸超压的增强效应和对爆炸发展速率的滞后效应。(3)爆炸超压随着油气体积分数的增加先增大后减小,最大超压所对应的初始油气体积分数为1.79%。(4)容器外火焰发展过程分为初级燃烧阶段、过渡燃烧阶段、次级燃烧阶段,由于受Rayleigh-Talor不稳定、Helmholtz不稳定、斜压效应的影响,火焰出现褶皱和卷曲,最大火焰高度和直径分别为0.8和0.55 m。Abstract: An experimental system of a confined space with a weakly constrained structure at the top was established. A series of gasoline/air mixture explosion experiments were conducted, and overpressure characteristics as well as flame behaviors were obtained. The results show that the internal overpressure exhibited a phenomenon of multi-peaks and pressure oscillations, induced by such factors as venting, external explosion, flame extension, etc. The value of the external overpressure decreased obviously with the increase of the distance from the weakly constrained structure, and the value along the vertical direction was larger than that along the horizontal direction. The impact of the weakly constrained structure was mainly reflected in the enhancement effect on the overpressure value and the lagging effect on the development rate of the explosion. The overpressure value showed the tendency to increase at first and then to decrease with the increase of the volume fraction of the gasoline/air vapor volume corresponding to the maximum overpressure, which is 1.79%. The flame propagation process involves three stages, i.e. stages of primary combustion, transitional combustion and secondary combustion. Affected by the Rayleigh instability, the Helmholtz instability and the baroclinic effect, the flame front was twisted and wrinkled, and the maximum height and maximum diameter were 0.80 and 0.55 m, respectively.

-

Key words:

- mechanics of explosion /

- fuel/air mixture explosion /

- confined space /

- weak constraint /

- overpressure /

- flame

-

表 1 容器内部爆炸特性对比

Table 1. Comparison of internal explosion characteristics

约束条件 泄流超压峰值 外部爆炸超压峰值 火焰扩展超压峰值 T/s Δt/s pfv/kPa t/s pfv/kPa t/s pfv/kPa t/s 2.5 kPa 2.58 0.025 3.96 0.051 0.59 0.096 0.008 0.039 0.4 kPa 0.59 0.021 2.45 0.046 0.39 0.093 0.008 0.040 表 2 外部爆炸超压对比

Table 2. Comparison of external explosion overpressure

传感器 p1/kPa t/s p2/kPa t/s (Δp/p1)/% pv=0.4 kPa pv=2.5 kPa P1 0.49 0.051 0.79 0.055 61.2 P2 0.37 0.051 0.58 0.055 56.7 P3 0.23 0.052 0.38 0.058 65.2 P4 0.11 0.054 0.19 0.059 72.7 P5 1.10 0.048 1.59 0.055 44.5 P6 0.63 0.049 1.07 0.055 69.8 P7 0.33 0.049 0.52 0.055 57.5 P8 0.23 0.050 0.42 0.057 78.2 -

[1] 曹凤霞.爆炸综合毁伤效应研究[D].南京: 南京理工大学, 2008. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1366795 [2] 赵衡阳, 王廷增, 卢晓勇.贮油罐的爆炸模拟试验[J].北京理工大学学报, 1990, 10(3):16-21. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000001094666Zhao Hengyang, Wang Tingzeng, Lu Xiaoyong.Laboratory simulation of the explosion of large oil storage vessels[J].Journal of Beijing Institute of Technology, 1990, 10(3):16-21. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000001094666 [3] 杜扬, 蒋新生, 钱海兵, 等.地下轻质油料储存库火灾模拟实验研究[J].油气储运, 2002, 21(4):47-49. doi: 10.3969/j.issn.1000-8241-D.2002.04.015Du Yang, Jiang Xinsheng, Qian Haibing, et al.The simulative experiment study on the fire of underground light oil storage[J].Oil & Gas Storage and Transportation, 2002, 21(4):47-49. doi: 10.3969/j.issn.1000-8241-D.2002.04.015 [4] 陈思维, 杜杨, 王博.油罐中油气爆炸规律研究[J].安全与环境学报, 2007, 7(3):102-104. http://d.old.wanfangdata.com.cn/Periodical/aqyhjxb200703026Chen Siwei, Du Yang, Wang Bo.On regularity of likely explosion of oil-gas mixture in a simulated fuel tank[J].Journal of Safety and Environment, 2007, 21(3):7-9. http://d.old.wanfangdata.com.cn/Periodical/aqyhjxb200703026 [5] 杜扬, 杨小凤, 蒋新生, 等.基于多种控制机理的湍流爆炸燃烧模型研究[J].工程热物理学报, 2006, 27(6):1045-1047. doi: 10.3321/j.issn:0253-231X.2006.06.046Du Yang, Yang Xiaofeng, Jiang Xinsheng, et al.Turbulence explosion combustion model study based multi-control mechanisms[J].Journal of Engineering Thermophysics, 2006, 27(6):1045-1047. doi: 10.3321/j.issn:0253-231X.2006.06.046 [6] Molkov V, Makarov D.LES modelling of an unconfined large-scale hydrogen-air deflagration[J].Journal of Physics D:Applied Physics, 2006, 39(18):4366-4376. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e144bbf0c6ca569002fc48a69e70243c [7] Qiao A, Zhang S.Advanced CFD modeling on vapor dispersion and vapor cloud explosion[J].Journal of Loss Prevention in the Process Industries, 2010, 23(6):843-848. doi: 10.1016/j.jlp.2010.06.006 [8] Dadashzadeh M, Khan F, Hawboldt K, et al.An integrated approach for fire and explosion consequence modelling[J].Fire Safety Journal, 2013, 61(5):324-337. http://www.sciencedirect.com/science/article/pii/S0379711213001586 [9] Pedersen H H, Tomlin G, Middha P, et al.Modelling large-scale vented gas explosions in a twin-compartment enclosure[J].Journal of Loss Prevention in the Process Industries, 2013, 26(6):1604-1615. doi: 10.1016/j.jlp.2013.08.001 [10] 丁宇奇, 沙金成, 刘巨保, 等.储罐内可燃气体燃烧引起的瞬时超压机理分析与动力学仿真计算[J].压力容器, 2014, 31(3):20-27. doi: 10.3969/j.issn.1001-4837.2014.03.004Ding Yuqi, Sha Jincheng, Liu Jubao, et al.Mechanism analysis of instantaneous overpressure caused by the combustion of combustible gas in tank and dynamics simulation[J].Pressure Vessel Technology, 2014, 31(3):20-27. doi: 10.3969/j.issn.1001-4837.2014.03.004 [11] 刘文辉, 蒋新生, 周建忠, 等.不同环境条件油气爆炸极限测试模拟实验系统[J].后勤工程学院学报, 2013(06):24-29. doi: 10.3969/j.issn.1672-7843.2013.06.005Liu Wenhui, Jiang Xinsheng, Zhou Jianzhong, et al.Simulation experimental system for explosion limit measurement of gasoline-air mixture under different environmental conditions[J].Journal of Logistical Engineering University, 2013, 29(6), 24-29. doi: 10.3969/j.issn.1672-7843.2013.06.005 [12] Guo J, Li Q, Chen D, et al.Effect of burst pressure on vented hydrogen-air explosion in a cylindrical vessel[J].International Journal of Hydrogen Energy, 2015, 40(19):6478-6486. doi: 10.1016/j.ijhydene.2015.03.059 [13] Kasmani R M, Andrews G E, Phylaktou H N.Experimental study on vented gas explosion in a cylindrical vessel with a vent duct[J].Process Safety and Environmental Protection, 2013, 91(4):245-252. doi: 10.1016/j.psep.2012.05.006 [14] Fakandu B M, Andrews G E, Phylaktou H N.Vent burst pressure effects on vented gas explosion reduced pressure[J].Journal of Loss Prevention in the Process Industries, 2015, 36(7):1-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3047865161e6ba69c455a6af5eb57118 [15] Chao J, Bauwens C R, Dorofeev S B.An analysis of peak overpressures in vented gaseous explosions[J].Proceedings of the Combustion Institute, 2011, 33(2):2367-2374. doi: 10.1016/j.proci.2010.06.144 [16] 姜孝海.泄爆外流场的动力学机理研究[D].南京: 南京理工大学, 2004. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y683280 [17] Bai Chunhua, Gong Guangdong, Liu Qingming, et al.The explosion overpressure field and flame propagation of methane/air and methane/coal dust/air mixtures[J].Safety Science, 2011, 10(49):1349-1354. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=38acaa050fe1409a5fbd8426bf93046d -

下载:

下载: