Simulation analysis of mine refuge chamber performance in different loading modes

-

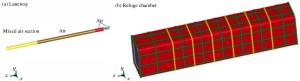

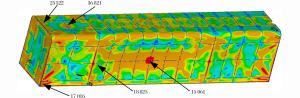

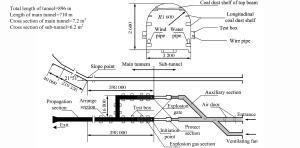

摘要: 针对某煤矿井下救生舱,利用ANSYS和LS-DYNA软件建立救生舱、瓦斯/瓦斯煤尘和巷道三维有限元模型。分别进行了真实内瓦斯/瓦斯煤尘爆炸作用下救生舱流固耦合数值分析,等效三角波爆炸冲击荷载作用下救生舱动态模拟和静水压力荷载作用下救生舱的极限承载力和极限变形的数值计算,确定救生舱动/静态承载能力变化规律和变形模式,给出瓦斯/瓦斯煤尘爆炸超压与救生舱承载能力和变形模式的变化规律。研究结果表明,等效三角波爆炸冲击荷载作用下该救生舱整体结构的极限超压明显比流固耦合计算分析结果大,流固耦合计算分析结果更接近于实验结果。该救生舱满足爆炸冲击波荷载下的变形要求时,其在静水压荷载作用下的变形也能满足。Abstract: In this work, by using the ANSYS and LS-DYNA softwares, we established the three-dimensional finite element model of the refuge chamber, the gas/gas and grime and the laneway. The ultimate strength and deformation of the refuge chamber were simulated under the action of three kinds of loads, mainly including the fluid-solid interaction numerical analysis of the real gas/gas and grime explosion effect, the equivalent triangle wave explosion numerical dynamic simulation and the hydrostatic pressure load calculations. Through the above three forms of numerical simulations of loading, we determined the dynamic/static load capacities of the refuge chamber as well as the deformation rules with the given gas/gas and coal dust explosion overpressure variation. The simulation results indicate that the limit overpressure of the refuge chamber under the equivalent triangle wave explosion is bigger than the fluid-solid interaction numerical analysis results, which approaches more closely to the experimental results. If the refuge chamber can meet the demand of transformation under explosion loading, it can also satisfy the transformation requirement under hydrostatic pressure load.

-

Key words:

- mechanics of explosion /

- finite elements models /

- blast impact /

- gas and grim /

- refuge chamber /

- laneway

-

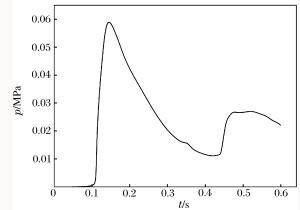

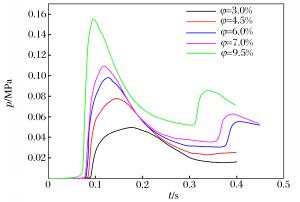

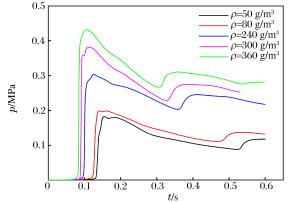

表 1 不同工况下瓦斯/瓦斯煤尘的参数设置

Table 1. Parameters of gas/gas and grime in different cases

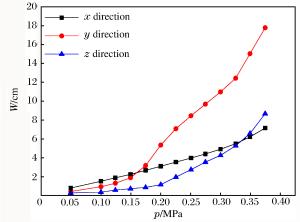

Case d/m φ/% ρ/(g·m-3) L/m V/m3 p/MPa τ/ms 1 40 4.5 0 7 50 0.060 0 600 2 40 3.0 0 14 100 0.050 0 400 2 40 4.5 0 14 100 0.078 5 400 2 40 6.0 0 14 100 0.095 5 500 2 40 7.0 0 14 100 0.111 0 500 2 40 9.5 0 14 100 0.156 0 400 3 80 9.5 50 28 200 0.184 0 600 3 80 9.5 80 28 200 0.205 0 600 3 80 9.5 240 28 200 0.311 0 600 3 80 9.5 300 28 200 0.385 0 600 3 80 9.5 360 28 200 0.435 0 600 表 2 瓦斯/瓦斯煤尘作用下救生舱动态响应

Table 2. Dynamic response of refuge chamber under the action of gas/gas and grime

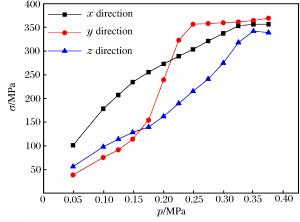

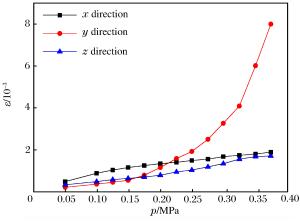

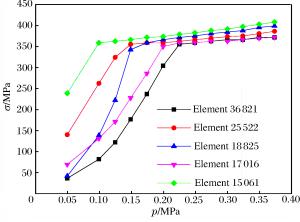

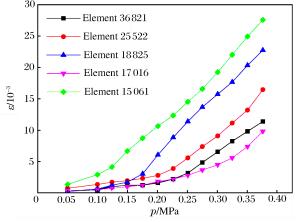

Case $\sigma _{{\text{max}}}^{(1)}$/MPa $\sigma _{{\text{max}}}^{(2)}$/MPa $\varepsilon _{{\text{max}}}^{(1)}$ $\varepsilon _{{\text{max}}}^{(2)}$ $W_x^{(1)}$/mm $W_x^{(2)}$/mm Wy/mm Wz/mm 1 537.0 372.0 0.033 0.056 57 41 0 10.0 2 520.5 346.0 0.020 0.045 70 19 51 19.0 2 536.8 415.0 0.071 0.155 78 66 60 8.4 2 540.5 408.4 0.075 0.150 87 80 63 2 539.0 359.4 0.051 0.070 119 73 70 2 569.5 406.0 0.097 0.150 166 43 82 3 540.0 408.0 0.040 0.150 160 43 87 3 559.5 405.0 0.050 0.150 160 83 82 30.0 3 540.5 396.0 0.040 0.151 160 43 194 3 540.5 401.0 0.040 0.155 170 30 202 3 547.5 406.0 0.047 0.158 132 66 199 表 3 不同等效三角波荷载作用下工况及响应

Table 3. Loading cases and dynamic responses of structures under different equivalent triangular wave loads

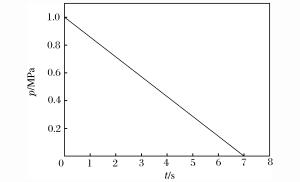

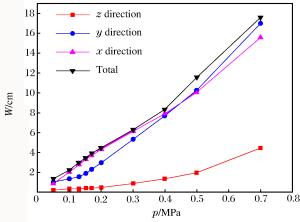

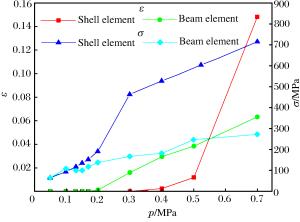

Loading case p/MPa τ/ms W/cm 变形情况 1 5.00 7 - - 2 1.50 7 >50.0 全部塑性变形, 大于20% 3 1.00 7 45.0 全部塑性变形, 最大20% 4 0.70 7 17.6 全部塑性变形, 大部分百分之几, 最大17% 5 0.50 7 11.6 全部塑性变形, 大部分千分之几, 最大10% 6 0.40 7 8.3 全部塑性变形, 大部分千分之几, 最大4%, 有弹性振动 7 0.30 7 6.3 大部分塑性应变很小, 最大1%, 有弹性振动 8 0.20 7 4.5 部分处于弹性状态, 最大0.5%, 有弹性振动 9 0.17 7 3.9 大部分处于弹性状态, 塑性变形区域很小, 最大0.4% 10 0.15 7 3.5 大部分处于弹性状态, 少部分发生小的塑性变形, 最大0.3%, 有弹性振动 11 0.13 7 3.0 大部分处于弹性状态, 少部分发生小的塑性变形, 最大0.2%, 有弹性振动 12 0.10 7 2.2 大部分处于弹性状态, 少部分发生小的塑性变形, 最大万分之几, 有弹性振动 13 0.10 70 4.0 大部分处于弹性状态,极少部分发生小的塑性变形, 最大0.3%, 有弹性振动 14 0.10 350 4.5 大部分处于弹性状态, 极少部分发生小的塑性变形, 最大0.4%, 振荡剧烈 15 0.05 7 1.3 结构全部处于弹性状态 -

[1] 杨俊玲, 马跃征, 杨鲁伟, 等.煤矿救生舱防爆性能分析[J].煤炭学报, 2013, 38(增1):159-163. http://d.old.wanfangdata.com.cn/Periodical/mtxb2013z1028Yang Junling, Ma Yuezheng, Yang Luwei, et al. Explosion-proof performance analysis of mine refuge chamber[J]. Journal of China Coal Society, 2013, 38(Suppl 1):159-163. http://d.old.wanfangdata.com.cn/Periodical/mtxb2013z1028 [2] 姚文亮.中国矿难的政府规制研究[D].西安: 西北大学, 2011. http://cdmd.cnki.com.cn/Article/CDMD-10697-1011087106.htm [3] 梅瑞斌, 李长生, 蔡般, 等.爆炸冲击下救生舱抗爆能力有限元分析[J].东北大学学报(自然科学版), 2013, 34(1):85-94. doi: 10.3969/j.issn.1005-3026.2013.01.020Mei Ruibin, Li Changsheng, Cai Ban, et al. FEM analysis of anti-deformation capability for coal mine refuge chamber suffered to gas explosion[J]. Journal of Northeastern University (Natural Science), 2013, 34(1):85-94. doi: 10.3969/j.issn.1005-3026.2013.01.020 [4] Bjerketvedt D, Bakke J R, Wingerden K V. Gas explosion handbook[J]. Journal of Hazardous Materials, 1997, 52(1):1-150. doi: 10.1016/S0304-3894(97)81620-2 [5] Grillo A, Slack M W. Shock tube study of ignition delay times in methane oxygen nitrogen argon mixtures[J]. Combustion & Flame, 1976, 27(3):377-381. http://www.sciencedirect.com/science/article/pii/0010218076900420 [6] Benedetto A D, Sarli V D, Salzano E, et al. Explosion behavior of CH4/O2/N2/CO2, and H2/O2/N2/CO2, mixtures[J]. International Journal of Hydrogen Energy, 2009, 34(16):6970-6978. doi: 10.1016/j.ijhydene.2009.05.120 [7] Zhu Y J, Chao J, Lee J H S. An experimental investigation of the propagation mechanism of critical deflagration waves that lead to the onset of detonation[J]. Proceedings of the Combustion Institute, 2007, 31(2):2455-2462. doi: 10.1016/j.proci.2006.07.209 [8] Inaba Y, Nishihara T, Groethe M A, et al. Study on explosion characteristics of natural gas and methane in semi-open space for the HTTR hydrogen production system[J]. Nuclear Engineering & Design, 2004, 232(1):111-119. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=55ffec91b6fa5486dd62c4d2300af7a8 [9] Kobiera A, Kindracki J, Zydak P, et al. A new phenomenological model of gas explosion based on characteristics of flame surface[J]. Journal of Loss Prevention in the Process Industries, 2007, 20(3):271-280. doi: 10.1016/j.jlp.2007.04.023 [10] 王志荣.受限空间气体爆炸传播及其动力学过程研究[D].南京: 南京工业大学, 2005. http://cdmd.cnki.com.cn/article/cdmd-10291-2005129007.htm [11] 李江涛.微型圆管结构对火焰传播抑制作用的数值模拟[D].大连: 大连理工大学, 2006. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y865639 [12] 胡春明.预混火焰在平板狭缝中传播与淬熄的研究[D].大连: 大连理工大学, 2006. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y865090 [13] Jiang Bingyou, Lin Baiquan, Shi Shulei, et al. Numerical simulation on the influences of initial temperature and initial pressure on attenuation characteristics and safety distance of gas explosion[J]. Combustion Science and Technology, 2012, 184(2):135-150. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f4845ca22a42555ac4438cd23450f256 [14] 江丙友, 林柏泉, 朱传杰, 等.瓦斯爆炸冲击波在并联巷道中传播特性的数值模拟[J].燃烧科学与技术, 2011, 17(3):250-254. http://www.cnki.com.cn/Article/CJFDTotal-RSKX201103012.htmJiang Bingyou, Lin Baiquan, Zhu Chuanjie, et al. Numerical simulation on shock wave propagation characteristics of gas explosion in parallel roadway[J]. Journal of Combustion Science & Technology, 2011, 17(3):250-254. http://www.cnki.com.cn/Article/CJFDTotal-RSKX201103012.htm [15] 李志强, 白博, 谢青海, 等.冲击载荷下矿用移动式救生舱动态响应的数值模拟[J].振动与冲击, 2013, 32(16):146-151. doi: 10.3969/j.issn.1000-3835.2013.16.026Li Zhiqiang, Bai Bo, Xie Qinghai, et al. Numerical simulation on the dynamic response of movable mine rescue chamber subjected to impact loading[J]. Journal of Vibration & Shock, 2013, 32(16):146-151. doi: 10.3969/j.issn.1000-3835.2013.16.026 [16] 常德功, 王吉利, 李国星.基于LS-DYNA的矿用救生舱壳结构爆炸冲击分析[J].矿山机械, 2013, 41(11):130-134. http://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201311034.htmChang Degong, Wang Jili, Li Guoxing. Explosion impact analysis on shell of mine refuge chamber based on LS-DYNA[J]. Mining & Processing Equipment, 2013, 41(11):130-134. http://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201311034.htm [17] 曾一鑫, 白春华, 李建平, 等.巷道救生舱抗冲击数值仿真[J].煤炭学报, 2012, 37(10):1705-1708. http://d.old.wanfangdata.com.cn/Periodical/mtxb201210022Ceng Yixin, Bai Chunhua, Li Jianping, et al. Numerical simulation of rescue cabin under blasting in the tunnel[J]. Journal of the China Coal Society, 2012, 37(10):1705-1708. http://d.old.wanfangdata.com.cn/Periodical/mtxb201210022 [18] 刘超, 鲍久圣.救生舱抗爆炸冲击载荷数值模拟[J].金属矿山, 2014, 43(1):141-144. http://d.old.wanfangdata.com.cn/Periodical/jsks201401034Liu Chao, Bao Jiusheng. Numerical Simulation of explosion impact load on refuge chamber[J]. Metal Mine, 2014, 43(1):141-144. http://d.old.wanfangdata.com.cn/Periodical/jsks201401034 [19] 王磊, 范世平, 龚建宇, 等.矿井KJYF-96/8型救生舱抗爆有限元分析[J].煤炭科学技术, 2014, 42(3):69-72. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtkxjs201403019Wang Lei, Fan Shiping, Gong Jianyu, et al. Finite element analysis of antiknock performance for KJYF-96/8 refuge chamber[J]. Coal Science & Technology, 2014, 42(3):69-72. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtkxjs201403019 [20] 王云艳, 何宁.基于AUTODYN、LS-DYNA的救生舱抗爆仿真试验[J].安全与环境学报, 2014, 14(2):9-12. http://d.old.wanfangdata.com.cn/Periodical/aqyhjxb201402003Wang Yunyan, He Ning. Simulation test of rescue chamber under the explosive load based on the AUTODYN and LS-DYNA model[J]. Journal of Safety & Environment, 2014, 14(2):9-12. http://d.old.wanfangdata.com.cn/Periodical/aqyhjxb201402003 [21] 白博, 李志强, 王志华, 等.矿用救生舱抗爆炸TNT当量与冲击载荷研究[J].科学技术与工程, 2014, 14(17):1-5. doi: 10.3969/j.issn.1671-1815.2014.17.001Bai Bo, Li Zhiqiang, Wang Zhihua, et al. Research on the TNT equivalent and impact load in anti-explosion of mine rescue capsule[J]. Science Technology & Engineering, 2014, 14(17):1-5. doi: 10.3969/j.issn.1671-1815.2014.17.001 [22] 徐景德, 徐胜利, 杨庚宇.矿井瓦斯爆炸传播的试验研究[J].煤炭科学技术, 2004, 33(7):55-57. doi: 10.3969/j.issn.0253-2336.2004.07.019Xu Jingde, Xu Shengli, Yang Gengyu. Experimental study on mine gas explosion diffusion[J]. Coal Science & Technology, 2004, 33(7):55-57. doi: 10.3969/j.issn.0253-2336.2004.07.019 [23] 焦宇, 周心权, 段玉龙, 等.瓦斯爆炸烟流浓度和温度的扩散规律[J].煤炭学报, 2011, 36(2):293-297. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201100120681Jiao Yu, Zhou Xinquan, Duan Yulong, et al. Concentration and temperature diffusion laws of smoke plume after methane explosions[J]. Journal of the China Coal Society, 2011, 36(2):293-297. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201100120681 [24] 司荣军.矿井瓦斯煤尘爆炸传播规律研究[D].济南: 山东科技大学, 2007. http://cdmd.cnki.com.cn/article/cdmd-10424-2008013280.htm [25] Lebecki K, Sliz J, Cybulski K, et al. Efficiency of triggered barriers in dust explosion suppression in galleries[J]. Journal of Loss Prevention in the Process Industries, 2001, 14(6):489-494. doi: 10.1016/S0950-4230(01)00056-0 [26] Boh J W, Louca L A, Choo Y S. Numerical assessment of explosion resistant profiled barriers[J]. Marine Structures, 2004, 17(2):139-160. doi: 10.1016/j.marstruc.2004.04.002 [27] Moore P E, Spring D J. Design of Explosion Isolation Barriers[J]. Process Safety & Environmental Protection, 2005, 83(2):161-170. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=85643369284901341c6b84dc6654eea8 [28] Houf W, Schefer R, Evans G, et al. Evaluation of barrier walls for mitigation of unintended releases of hydrogen[J]. International Journal of Hydrogen Energy, 2011, 36(36):2520-2529. http://www.sciencedirect.com/science/article/pii/S0360319910003861 [29] 浦以康, 胡山.粉尘火焰加速现象的实验研究[J].爆炸与冲击, 1995, 15(2):97-106. http://www.bzycj.cn/CN/Y1995/V15/I2/97Pu Yikang, Hu Shan. Experimental studies on the phenomena of dust flame acceleration[J]. Explosion and Shock Waves, 1995, 15(2):97-106. http://www.bzycj.cn/CN/Y1995/V15/I2/97 [30] 董磊.障碍物体形对爆炸波传播的影响[D].天津: 天津大学, 2008. http://cdmd.cnki.com.cn/Article/CDMD-10056-2009072930.htm [31] 樊小涛.矿用救生舱抗爆性能试验研究[J].矿业安全与环保, 2010, 37(3):25-30. doi: 10.3969/j.issn.1008-4495.2010.03.008Fan Xiaotao. Experiment study on the explosion-proof performance of mine refuge chamber[J]. Mining Safety and Environmental Protection, 2010, 37(3):25-30. doi: 10.3969/j.issn.1008-4495.2010.03.008 -

下载:

下载: