Deviation research on internal electronic pressure gauge and copper cylinder pressure gauge in artillery chamber pressure test

-

摘要: 火炮膛压作为火炮和弹药的内弹道重要参数,在研制、生产、交付、存储校验等环节都需要测量。针对当前同时采用放入式铜柱测压器和电子测压器测量某一批弹药时,电子测压器峰值出现散布较大,而铜柱测压法一致性好的问题,在分析两种测压法测压原理的基础上,利用铜柱动态校准数据作用到其ANSYS模型上修正了铜柱的Johnson-Cook模型参数;分析发现出现差异时电子测压器测量的压力变化率时程曲线不同,铜柱实际测试形变量与施加压力时程曲线作用于模型得到的形变量一致。研究表明:同时测量某一批弹药时,电子测压器比铜柱测压器出现压力峰值散布大的原因是由膛压上升过程变化率不同导致铜柱的应变率不同造成的。

-

关键词:

- 火炮膛压 /

- 电子测压器 /

- 铜柱测压器 /

- Johnson-Cook模型参数

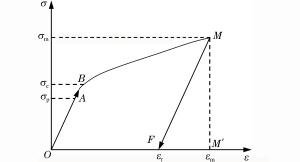

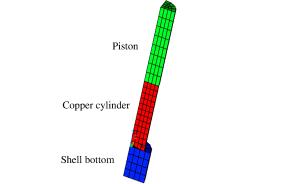

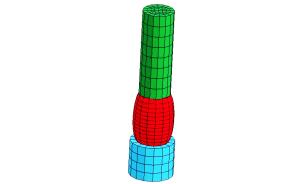

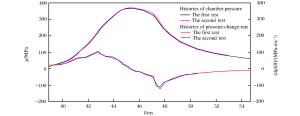

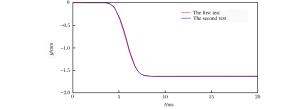

Abstract: The artillery chamber pressure is so important a parameter for interior ballistic performance that it has to be measured repeatedly in the course of artillery development, production, acceptance, storage check. When a batch of ammunitions are measured by internal electronic pressure gauge (IEPG) and copper cylinder pressure gauge (CCPG) at the same time, the distribution of IEPG peak values is found to be much larger than that of CCPG ones. The ANSYS model of CCPG was proposed based on the CCPG working principle, and the Johnson-Cook model parameters were optimized according to the dynamic calibration data. The results shows that when discrepancy occurred with respect to the peak pressures measured respectively by IEPG and CCPG, the pressure-change-rate histories of IEPG were different, and the test pressure exerted on the CCPG model was consistent with the copper cylinder deformation obtained in the copper test. The results also show that the difference in peak pressure, captured by IEPG and CCPG in a batch of ammunition chamber pressure measurement at the same time, is due to the influence of different copper cylinder strain rates as a result of different rising rates of the chamber pressure. -

表 1 实验数据与数值模拟结果对比

Table 1. Comparison of experimental with simulation data

标定点 pm/MPa τ/ms y/mm ε/% 实验 数值模拟 1 270.35 6.49 0.226 8 0.226 5 -0.132 2 310.18 6.45 0.483 0 0.483 6 0.124 3 356.66 6.44 0.783 0 0.780 2 -0.359 4 396.78 6.38 1.045 0 1.042 0 -0.288 5 452.44 6.37 1.361 0 1.356 6 -0.324 6 516.23 6.35 1.749 0 1.751 1 0.120 表 2 不同传感器实测压力峰值对比

Table 2. Comparison of peak pressures measured by different sensors

发次 pm/MPa 电子测压器 铜柱测压器 1 368.52 371.90 2 371.02 372.60 -

[1] 金志明, 翁春生, 宋明.高等内弹道学[M].北京:高等教育出版社, 2003:1. [2] 李新娥, 祖静, 徐鹏.新型应变式高膛压测试系统研制[J].高压物理学报, 2011, 25(4):310-316. http://www.gywlxb.cn/CN/abstract/abstract1375.shtmlLi Xin'e, Zu Jing, Xu Peng. A novel strain type high chamber pressure test system[J]. Chinese Journal of High Pressure Physics, 2011, 25(4):310-316. http://www.gywlxb.cn/CN/abstract/abstract1375.shtml [3] 刘林林, 马忠亮, 萧忠良.变燃速发射药膛内燃烧与内弹道过程研究[J].兵工学报, 2010, 31(4):409-413. http://d.old.wanfangdata.com.cn/Periodical/bgxb201004002Liu Linlin, Ma Zhongliang, Xiao Zhongliang. Research on the actual combustion and interior ballistics process of the variable-burning rate propellant in cannon[J]. Acta Armamentarii, 2010, 31(4):409-413. http://d.old.wanfangdata.com.cn/Periodical/bgxb201004002 [4] Walton W S. Electrical measurement of weapon chamber pressure: ADP002684[S]. Aberdeen Proving Ground MD Materiel Testing Directorate, 1995. [5] 中国人民解放军总装备部测量通信总体研究所. 火炮内弹道试验方法: GJB 2973A-2008[S]. 北京: 总装备部军标出版发行部, 2008. [6] Li Xin'e, Zu Jing, Ma Tiehua, et al. Research on a novel capacitive pressure sensor to measure chamber pressures of different caliber artilleries[J]. IEEE Sensors Journal, 2011, 11(4):862-868. doi: 10.1109/JSEN.2010.2070793 [7] 尤文斌, 马铁华, 丁永红, 等.铜柱测压器膛压测试产生误差的机理研究[J].仪器仪表技术, 2015, 36(10):2290-2296. http://d.old.wanfangdata.com.cn/Periodical/yqyb201510017You Wenbin, Ma Tiehua, Ding Yonghong, et al. Deviation mechanism research for copper cylinder pressure gage in the artillery chamber pressure test[J]. Chinese Journal of Scientific Instrument, 2015, 36(10):2290-2296. http://d.old.wanfangdata.com.cn/Periodical/yqyb201510017 [8] Carson J A, Dimeff J, Charters A C. Piston type strain gauge for measuring pressures in interior ballistics research[J]. Review of Scientific Instruments, 1955, 26(9):879-883. doi: 10.1063/1.1715334 [9] 孔德仁. 塑性测压器材准动态校准技术及实验研究[D]. 南京: 南京理工大学, 2003. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y530001 [10] 张淑宁. 准动态校准技术实验研究[D]. 南京: 南京理工大学, 2003. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y531564 [11] 边义祥, 杨成.基于压电材料的振动能量回收技术现状综述[J].压电与声光, 2011, 33(4):612-622. doi: 10.3969/j.issn.1004-2474.2011.04.029Bian Yixiang, Yang Chenghua. A review of current research for energy harvesting based on vibration of piezoelectric materials[J]. Piezoelectrics and Acoustooptics, 2011, 33(4):612-622. doi: 10.3969/j.issn.1004-2474.2011.04.029 [12] Johnson G R, Inc H, William H C. A constitutive model and data for metals subjected to large st rains, high tempreture[C]//Proceedings of 7th International Symposium on Ball. The Hague, Netherlands: International Ballistics Committee, 1983: 541-547. [13] 吕剑, 何颖波, 田常津, 等.泰勒杆实验对材料动态本构参数的确认和优化确定[J].爆炸与冲击, 2006, 26(4):339-344. doi: 10.3321/j.issn:1001-1455.2006.04.009Lü Jian, He Yingbo, Tian Changjin, et al. Validation and optimization of dynamic constitutive model constants with Taylor test[J]. Explosion and Shock Waves, 2006, 26(4):339-344. doi: 10.3321/j.issn:1001-1455.2006.04.009 [14] 孔德仁, 朱明武.铜柱、铜球准动态校准的机理[J].南京理工大学学报(自然科学版), 2004, 28(4):375-379. doi: 10.3969/j.issn.1005-9830.2004.04.009Kong Deren, Zhu Mingwu. Mechanism of quasi-dynamic calibration for copper cylinder and copper ball[J]. Journal of Nanjing University of Science and Technology (Natural Science Edition), 2004, 28(4):375-379. doi: 10.3969/j.issn.1005-9830.2004.04.009 -

下载:

下载: