Calculation method and influencing factors of the fragmental radial velocities of PELE after penetrating thin target

-

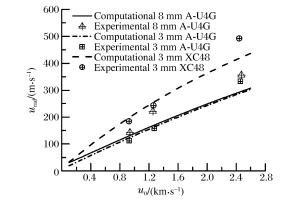

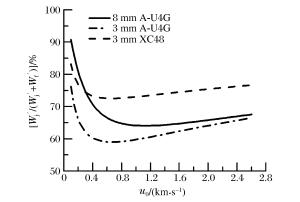

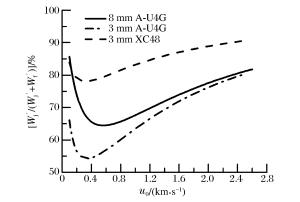

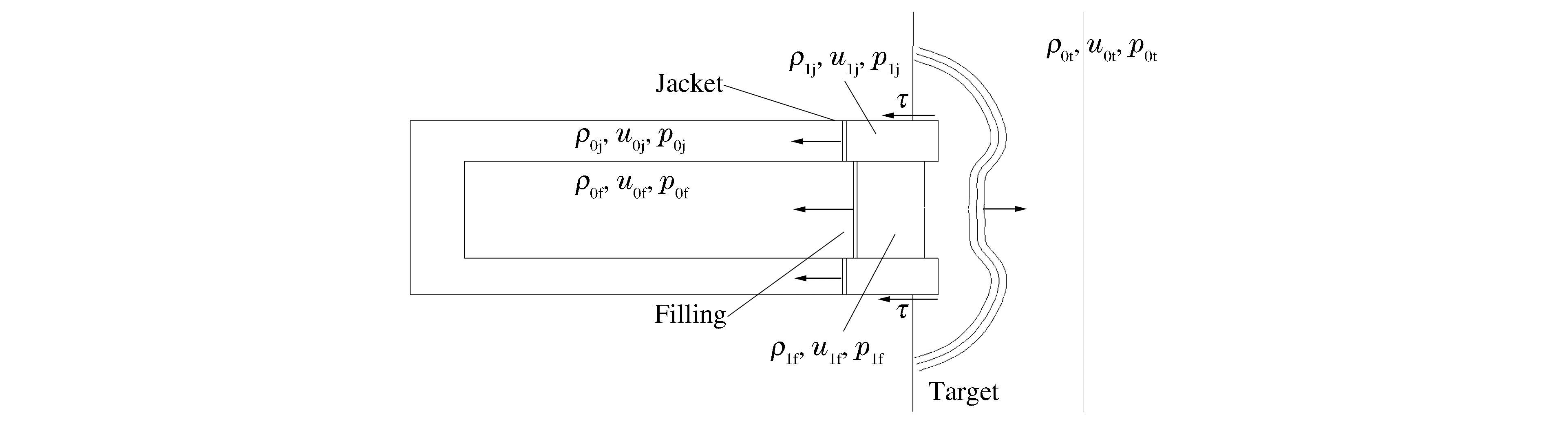

摘要: 基于横向效应增强型弹丸(PELE)侵彻金属薄靶板过程分析,将弹体前端在撞击作用下的变形过程分解为轴向一维压缩和径向自由膨胀两个变形阶段;依据冲击波理论,给出了弹体前端的冲击波压缩势能,由功能转化原理,给出了PELE前端外壳在靶后形成破片的最大径向飞散速度计算公式。计算结果在多种工况下均与文献的实验结果较为一致。计算结果表明:PELE靶后外壳破片的最大径向飞散速度与外壳和内芯材料的体积模量和泊松比有关,且随二者的增大而增大;PELE外壳破片的最大径向飞散速度是壳体和内芯在冲击波压缩作用下共同径向膨胀的结果,且外壳膨胀能在弹体整体膨胀能中所占比例较大,计算中应当同时考虑弹体外壳和内芯材料的横向膨胀效应对弹体破片径向飞散速度的影响。Abstract: Based on an analysis of the PELE (penetrator with enhanced lateral efficiency) penetrating thin metal targets, the deformation process of the front-end projectile was divided into two distinct phases: one-dimensional decomposition in the axial direction and the free conversion in the radial direction, for experimental study. Based on the shock wave theory, we obtained the shock wave compression energy of the front end of the projectile and, on the basis of the conservation of energy and the assumption of two-stage deformation, presented a method for determining the scattered radial velocity of the PELE jacket fragments behind the target. The calculated results in a variety of conditions are fairly consistent with the experimental results. The theoretical analysis showed that the maximum radial velocity of the PELE jacket fragments depends on the radial expansion of both the jacket and the filling part under the shock compression, the former playing a major role in the overall expansion of the projectile whereas the maximum radial velocity of the PELE jacket fragments increasing with the bulk modulus and the Poisson's ratio of the jacket and the filling part. The results suggest that the lateral expansion of both the jacket and the filling part should be taken into account when calculating the radial velocity of the PELE fragments.

-

弹/靶 材料 ρ/(g·cm-3) c0/(m·s-1) s K/GPa μ σy/GPa 弹体 D180K 18.0 4029 1.237 292 0.28 A-G3 2.65 5176 1.35 71 0.33 PE 0.92 2187 1.48 4.4 0.44 靶板 A-U4G 2.80 5106 1.35 0.43 XC48 7.823 4797 1.49 0.72 表 2 A-G3内芯PELE穿靶后弹体破片的最大径向飞散速度

Table 2. Maximum radial velocity of the jacket fragments of PELE with A-G3 as filling material

表 3 PE内芯PELE穿靶后弹体破片的最大径向飞散速度

Table 3. Maximum radial velocity of the jacket fragments of PELE with PE as filling material

-

[1] Paulus G, Chanteret P Y, Wollmann E. PELE: A new penetrator concept for generating lateral effects[C]//21st International Symposium on Ballistics. Adelaide, Australia, 2004: 104-110. [2] Kesberg G, Schirm V, Kerk S. PELE: The future ammunition concept[C]//21st International Symposium on Ballistics. Adelaide, Australia, 2004: 1134-1144. [3] 汤铁钢, 谷岩, 李庆忠, 等.爆轰加载下金属柱壳膨胀破裂过程研究[J].爆炸与冲击, 2003, 23(6):529-533. doi: 10.3321/j.issn:1001-1455.2003.06.008Tang Tiegang, Gu Yan, Li Qingzhong, et al. Expanding fracture of steel cylinder shell by detonation driving[J]. Explosion and Shock Waves, 2003, 23(6):529-533. doi: 10.3321/j.issn:1001-1455.2003.06.008 [4] Wesenberg D L, Sagartz M J. Dynamic fracture of 6061-T6 aluminum cylinders[J]. Journal of Applied Mechanics, 1977, 44(4):643-646. doi: 10.1115/1.3424150 [5] 胡八一.金属圆筒在内部爆轰加载下的膨胀断裂机理研究[D].绵阳: 中国工程物理研究院, 1992. [6] Meyers M A. Dynamic behavior of materials[M]. New York: Wiley-Interscience Publication, 1994:229-242. [7] Gold V M, Baker E L. A model for fracture of explosively driven metal shells[J]. Engineering Fracture Mechanics, 2008, 75(2):275-289. doi: 10.1016/j.engfracmech.2007.02.025 [8] Børvik T, Hopperstad O S, Langseth M, et al. Effect of target thickness in blunt projectile penetration of Weldox 460 E steel plates[J]. International Journal of Impact Engineering, 2003, 28(4):413-464. doi: 10.1016/S0734-743X(02)00072-6 [9] 朱建生, 赵国志, 杜忠华, 等.靶板厚度对横向效应增强型侵彻体作用效果的影响[J].南京理工大学学报(自然科学版), 2009, 33(4):474-479. doi: 10.3969/j.issn.1005-9830.2009.04.014Zhu Jiansheng, Zhao Guozhi, Du Zhonghua, et al. Influence of target thickness on lateral effect of PELE[J]. Journal of Nanjing University of Science and Technology (Natural Science), 2009, 33(4):474-479. doi: 10.3969/j.issn.1005-9830.2009.04.014 [10] 凃胜元, 沈晓军, 王军波, 等.着速和靶厚对钢弹体PELE侵彻后效影响的实验研究[J].弹箭与制导学报, 2010, 30(3):69-71. doi: 10.3969/j.issn.1673-9728.2010.03.020Tu Shengyuan, Shen Xiaojun, Wang Junbo, et al. Research on the influence of impact velocity and thickness of RHA on the penetration aftereffect of steel shell PELE by experiment[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2010, 30(3):69-71. doi: 10.3969/j.issn.1673-9728.2010.03.020 [11] Tu S, Wang J, An Z, et al. Influence of thickness of armor on the burst-effect of steel shell PELE[C]//International Conference on Electronic Measurement & Instruments. IEEE, 2009(4): 926-929. [12] 蒋建伟, 张谋, 门建兵, 等.PELE弹侵彻过程壳体膨胀破裂的数值模拟[J].计算力学学报, 2009, 26(4):568-572. http://d.old.wanfangdata.com.cn/Conference/7079543Jiang Jianwei, Zhang Mou, Men Jianbing, et al. Numerical simulation of penetration process for PELE projectile against target[J]. Chinese Journal of Computational Mechanics, 2009, 26(4):568-572. http://d.old.wanfangdata.com.cn/Conference/7079543 [13] Paulus G, Schirm V. Impact behaviour of PELE projectiles perforating thin target plates[J]. International Journal of Impact Engineering, 2006, 33:566-579. doi: 10.1016/j.ijimpeng.2006.09.026 [14] 朱建生, 赵国志, 杜忠华, 等.PELE垂直侵彻薄靶的机理分析[J].爆炸与冲击, 2009, 29(3):281-288. doi: 10.3321/j.issn:1001-1455.2009.03.010Zhu Jiansheng, Zhao Guozhi, Du Zhonghua, et al. Mechanism of PELE projectiles perpendicularly impacting on thin target plates[J]. Explosion and Shock Waves, 2009, 29(3):281-288. doi: 10.3321/j.issn:1001-1455.2009.03.010 [15] 杜忠华, 宋丽丽.横向效应增强型侵彻体撞击金属薄板理论模型[J].南京理工大学学报, 2011, 35(6):822-826. doi: 10.3969/j.issn.1005-9830.2011.06.018Du Zhonghua, Song Lili. Theoretical model of penetrator with enhanced lateral effect impacting thin metal target[J]. Journal of Nanjing University of Science and Technology, 2011, 35(6):822-826. doi: 10.3969/j.issn.1005-9830.2011.06.018 [16] Verreault J, van Hinsberg N, Abadjieva E. PELE fragmentation dynamics[C]//Wickert M, Salk M. International Symposium on Ballistics. DLR, 2013: 1289-1300. [17] Verreault J. Modelling of the PELE fragmentation dynamics[J]. Journal of Physics: Conference Series, 2014, 500(15):152015. doi: 10.1088/1742-6596/500/15/152015 [18] Verreault J. Analytical and numerical description of the PELE fragmentation upon impact with thin target plates[J]. International Journal of Impact Engineering, 2015, 76:196-206. doi: 10.1016/j.ijimpeng.2014.09.012 [19] 樊自建, 冉宪文, 汤文辉, 等.PELE正侵穿金属薄靶轴向剩余速度近似计算与分析[J].国防科技大学学报, 2015(5):84-90. http://d.old.wanfangdata.com.cn/Periodical/gfkjdxxb201505013Fan Zijian, Ran Xianwen, Tang Wenhui, et al. Approximate calculation on the axial residual velocity of the PELE penetrate thin metal target plate[J]. Journal of National University of Defense Technology, 2015(5):84-90. http://d.old.wanfangdata.com.cn/Periodical/gfkjdxxb201505013 [20] 汤文辉.冲击波物理[M].北京:科学出版社, 2011:180-192. [21] 钱伟长.穿甲力学[M].北京:国防工业出版社, 1984:327-328. -

下载:

下载: