| [1] |

Chen X, Asay J R, Dwivedi S K, et al. Spall behavior of aluminum with varying microstructures[J]. Journal of Applied Physics, 2006, 99(2):023528. doi: 10.1063/1.2165409

|

| [2] |

Trivedi P B, Asay J R, Gupta Y M, et al. Influence of grain size on the tensile response of aluminum under plate-impact loading[J]. Journal of Applied Physics, 2007, 102(8):083513. doi: 10.1063/1.2798497

|

| [3] |

Escobedo J P, Dennis-Koller D, Cerreta E K, et al. Grain size and boundary structure on the dynamic tensile response of copper[J]. Journal of Applied Physics, 2011, 110(3):033513. doi: 10.1063/1.3607294

|

| [4] |

张凤国, 周洪强.晶粒尺度对延性金属材料层裂损伤的影响[J].物理学报, 2013, 62(16):164601. doi: 10.7498/aps.62.164601Zhang Fengguo, Zhou Hongqiang. Effects of grain size on the dynamic tensile damage of ductile polycrystalline metall[J]. Acta Physica Sinica, 2013, 62(16):164601. doi: 10.7498/aps.62.164601

|

| [5] |

Trinkaus H, Singh B N. Helium accumulation in metals during irradiation-where do we stand?[J].Journal of Nuclear Materials, 2003, 323(2/3):229-242. http://www.sciencedirect.com/science/article/pii/S0022311503004033

|

| [6] |

Marian J, Wirth B D, Perlado M. Mechanism of formation and growth of 〈100〉 interstitial loops in ferritic materials[J]. Physics Review Letters, 2002, 88(25):255507. doi: 10.1103/PhysRevLett.88.255507

|

| [7] |

Moreno D, Eliezer D. Structural changes in a copper alloy due to helium implantation[J]. Scripta Materialia, 1996, 35(12):1385-1389. doi: 10.1016/S1359-6462(96)00314-4

|

| [8] |

Singh B N, Leffers T. Implications of the variation in microstructure caused by changes in helium generation rate and other irradiation parameters[J]. Radiation Effects and Defects in Solids, 1987, 101(1):73-90. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1080/00337578708224737

|

| [9] |

Kubota A, Reisman D B, Wolfer W G. Dynamic strength of metals in shock deformation[J]. Applied Physics Letters, 2006, 88(24):241924. doi: 10.1063/1.2210799

|

| [10] |

Glam B, Eliezer S, Moreno D, et al. Dynamic fracture and spall in aluminum with helium bubbles[J]. International Journal of Fracture, 2010, 163(1/2):217-224. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ce303b4124937f5f94fc151f79eb1df1

|

| [11] |

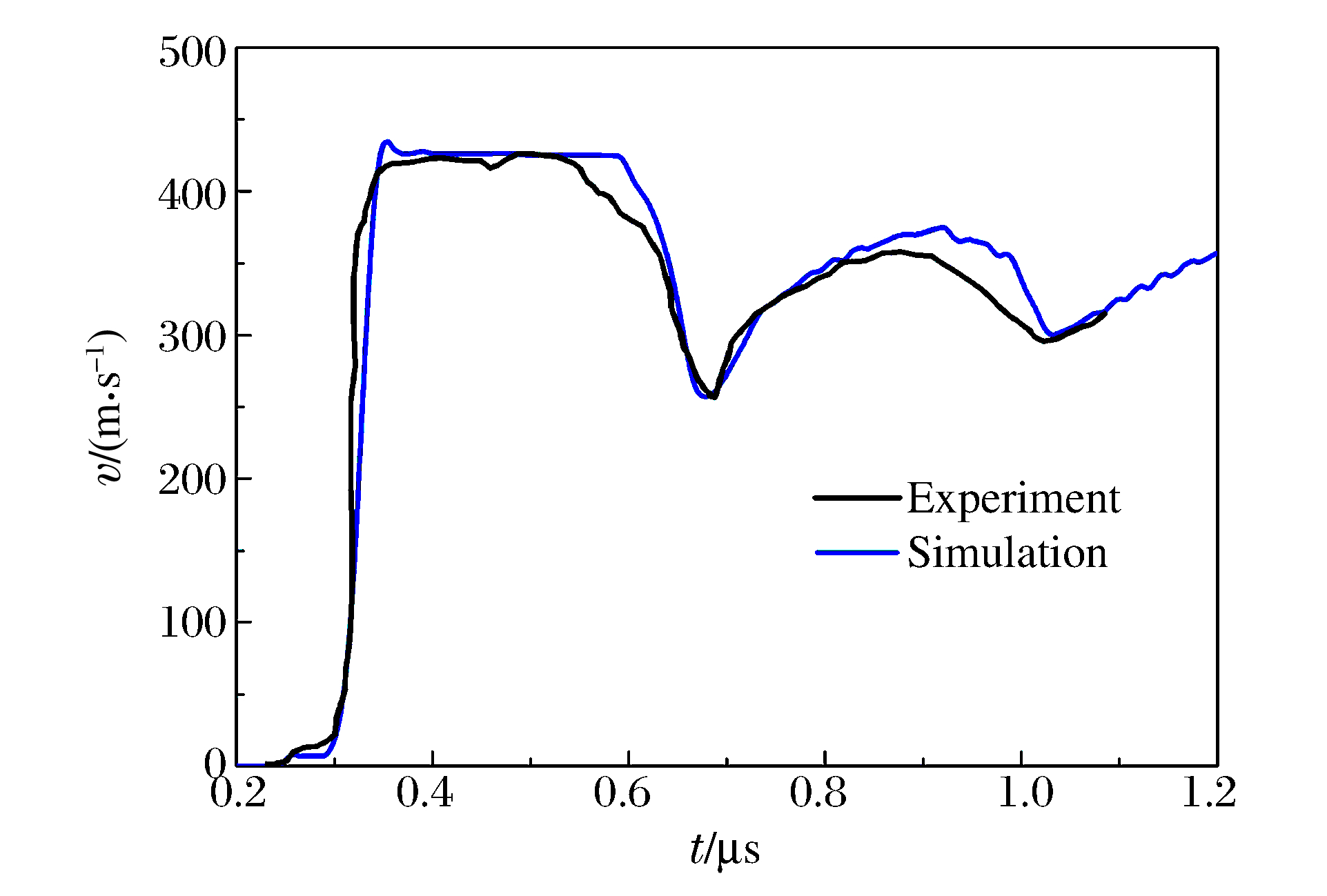

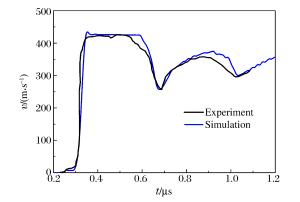

Glam B, Strauss M, Eliezer S, et al. Shock compression and spall formation in aluminum containing helium bubbles at room temperature and near the melting temperature: Experiments and simulations[J]. International Journal of Impact Engineering, 2014, 65(4):1-12. http://www.sciencedirect.com/science/article/pii/S0734743X13002030

|

| [12] |

Tonks D L, Zurek A K, Thissell W R. Coalescence rate model for ductile damage in metals[J]. Journal de Physique Ⅳ, 2003, 110(9):893-898.

|

| [13] |

彭辉, 李平, 裴晓阳, 等.动态损伤演化的空间不连续性实验研究[J].物理学报, 2013, 62(22):226201. doi: 10.7498/aps.62.226201Peng Hui, Li Ping, Pei Xiaoyang, et al. Experimental study of the spatial discontinuity of dynamic damage evolution[J]. Acta Physica Sinica, 2013, 62(22):226201. doi: 10.7498/aps.62.226201

|

| [14] |

Zhang F G, Zhou H Q, Hu J, et al. Modelling of spall damage in ductile materials and its application to the simulation of the plate impact on copper[J]. Chinese Physics B, 2012, 21(9):094601. doi: 10.1088/1674-1056/21/9/094601

|

| [15] |

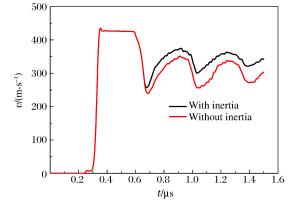

张凤国, 周洪强, 张广财, 等.惯性及弹塑性效应对延性金属材料层裂损伤的影响[J].物理学报, 2011, 60(7):074601. http://d.old.wanfangdata.com.cn/Periodical/wlxb201107066Zhang Fengguo, Zhou Hongqiang, Zhang Guangcai, et al. Inertial and elastic-plastic effect on spallation damage of ductile metals[J]. Acta Physica Sinica, 2011, 60(7):074601. http://d.old.wanfangdata.com.cn/Periodical/wlxb201107066

|

| [16] |

张凤国, 王裴, 胡晓棉, 等.爆轰加载下锡金属连续层裂损伤机理的数值分析[J].高压物理学报, 2017, 31(3):280-285. http://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201703009.htmZhang Fengguo, Wang Pei, Hu Xiaomian, et al. Numerical analysis of high explosive-induced multiple layers in Sn metal[J]. Chinese Journal of High Pressure Physics, 2017, 31(3):280-285. http://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201703009.htm

|

| [17] |

Johnson J N. Dynamic fracture and spallation in ductile solids[J]. Journal of Applied Physics, 1981, 52(4):2812-2825. doi: 10.1063/1.329011

|

| [18] |

Shao J L, Wang P, He A M. Compression-induced stacking fault tetrahedra around He bubbles in Al[J]. Journal of Applied Physics, 2014, 116(16):163516. doi: 10.1063/1.4900784

|

下载:

下载: