Dynamic constitutive model of concrete after salt corrosion

-

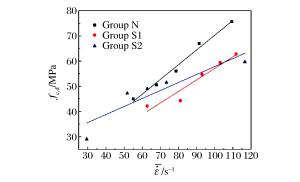

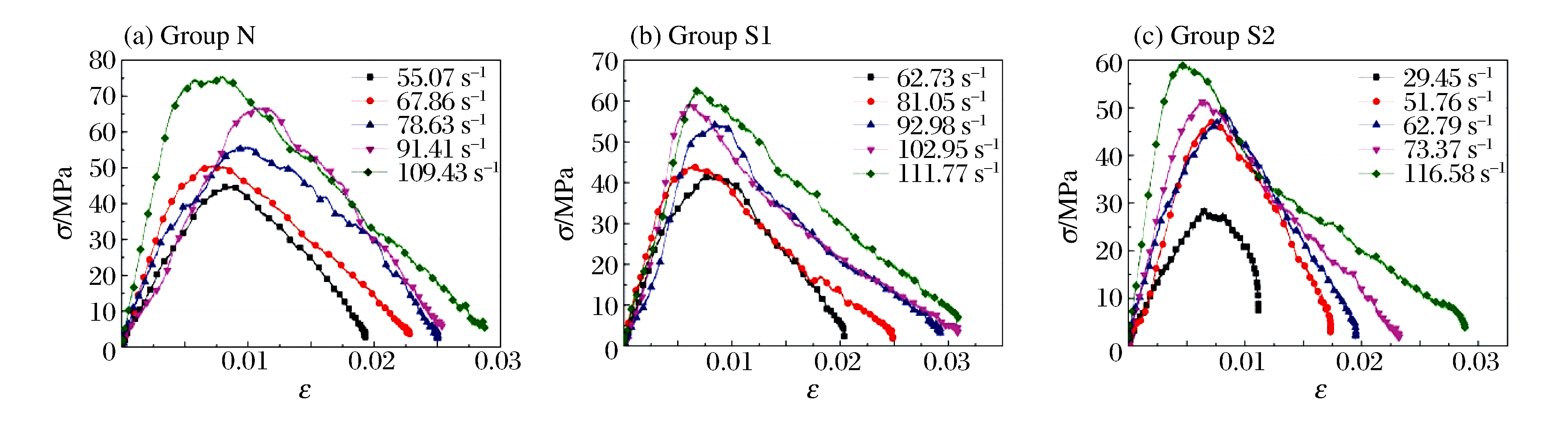

摘要: 为探究混凝土受盐腐蚀后的动态力学响应,配置了粉煤灰质量分数为15%的普通硅酸盐水泥混凝土,将其置于质量分数均为15%的NaCl和Na2SO4溶液中浸泡腐蚀60 d后,利用∅100 mm分离式霍普金森压杆实验装置,测试其受腐蚀后的动态力学性能,并结合宏观唯象损伤统计理论和Weibull分布思想,建立了混凝土受盐腐蚀后的动态统计损伤本构模型。结果表明:受盐腐蚀后,混凝土试件的动态抗压强度均有不同程度的下降,且NaCl溶液腐蚀试件的降幅大于Na2SO4溶液腐蚀试件;模型曲线与实验曲线的拟合度较高,能够较准确地描述混凝土在冲击荷载作用下的动态力学响应规律。Abstract: To explore the dynamic mechanical behaviors of the concrete corroded by salt solution, we fabricated concrete specimens of ordinary Portland cement with fly ash of 15% mass fraction and, having them immersed for 60 d in NaCl and Na2SO4 solutions with a 15% mass fraction, studied their dynamic mechanical properties using a ∅100 mm split Hopkinson pressure bar apparatus. Then, based on the macro phase-only statistical damage theory and the Weibull distribution theory, we built a dynamic statistical damage constitutive model for the specimen's mechanical behaviors. The results indicate that the dynamic compressive strength of the corroded specimens experiences a significant decrease, and the declines of the specimens corroded by NaCl are bigger than those corroded by Na2SO4. Based on the closely fitted curves of the model and the experiment, this established model can accurately estimate the dynamic mechanical behaviors of concrete under impact loading.

-

Key words:

- salt corrosion /

- concrete /

- dynamic compressive strength /

- damage theory /

- Weibull distribution /

- constitutive model

-

表 1 混凝土配合比

Table 1. Mix proportions of concrete

kg/m3 水泥 水 灞河中砂 石灰岩碎石 粉煤灰 338 215 643 1 144 60 表 2 不同应变率下模型参数

Table 2. Model parameters at different strain rates

样品组 ${\bar {\dot \varepsilon }}$/s-1 a/10-5 m 样品组 ${\bar {\dot \varepsilon }}$/s-1 a/10-5 m 样品组 ${\bar {\dot \varepsilon }}$/s-1 a/10-5 m 55.07 3.68 0.162 62.73 13.01 0.190 29.45 0.04 0.102 67.86 20.61 0.211 81.05 57.64 0.285 51.76 0.24 0.110 N 78.63 6.72 0.173 S1 92.98 11.05 0.171 S2 62.79 1.19 0.145 91.41 0.10 0.094 102.95 2.17 0.096 73.37 4.52 0.169 109.43 171.01 0.431 111.77 12.89 0.146 116.58 20.31 0.212 表 3 动态强度增长因子与平均应变率对数的关系

Table 3. Relation of dynamic compressive strength increase factor with the logarithm of average strain rate

样品组 拟合公式 转换后的拟合公式 C N I=-3.316 8+2.480 2 lg ${\bar {\dot \varepsilon }}$ I=1-0.747 8 lg ${\bar {\dot \varepsilon }}$ -0.747 8 S1 I=-3.620 5+2.691 7 lg ${\bar {\dot \varepsilon }}$ I=1-0.743 5 lg ${\bar {\dot \varepsilon }}$ -0.743 5 S2 I=-1.203 1+1.426 1 lg ${\bar {\dot \varepsilon }}$ I=1-1.185 4 lg ${\bar {\dot \varepsilon }}$ -1.185 4 -

[1] Uysal M, Yilmaz K, Ipek M. The effect of mineral admixtures on mechanical properties, chloride ion permeability and impermeability of self-compacting concrete[J]. Construction & Building Materials, 2012, 27(1):263-270. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f70dd84308a1d0eac0b8d89a78611866 [2] 袁承斌, 张德峰, 刘荣桂, 等.不同应力状态下混凝土抗氯离子侵蚀的研究[J].河海大学学报(自然科学版), 2003, 31(1):50-54. doi: 10.3321/j.issn:1000-1980.2003.01.012Yuan Chengbin, Zhang Defeng, Liu Ronggui, et al. Diffusivity of chloride in concrete in different stress states[J]. Journal of Hehai University (Natural Sciences), 2003, 31(1):50-54. doi: 10.3321/j.issn:1000-1980.2003.01.012 [3] Hossain K M A, Lachemi M. Performance of volcanic ash and pumice based blended cement concrete in mixed sulfate environment[J]. Cement & Concrete Research, 2006, 36(6):1123-1133. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ef2703e202ecda3452a4e824b41f226f [4] 范颖芳, 黄振国, 郭乐工, 等.硫酸盐腐蚀后混凝土力学性能研究[J].郑州工业大学学报, 1999, 20(1):91-93. doi: 10.3969/j.issn.1671-6833.1999.01.028Fan Yingfang, Huang Zhenguo, Guo Legong, et al. Research on mechanics property of concrete after corrosion of sulphate[J]. Journal of Zhengzhou University of Technology, 1999, 20(1):91-93. doi: 10.3969/j.issn.1671-6833.1999.01.028 [5] Chindaprasirt P, Chalee W. Effect of sodium hydroxide concentration on chloride penetration and steel corrosion of fly ash-based geopolymer concrete under marine site[J]. Construction & Building Materials, 2014, 63(8):303-310. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e399e90b1fa8ca6d2d460f2b58bc078e [6] Kwon S J, Na U J, Sang S P, et al. Service life prediction of concrete wharves with early-aged crack: Probabilistic approach for chloride diffusion[J]. Structural Safety, 2009, 31(1):75-83. doi: 10.1016/j.strusafe.2008.03.004 [7] 史美伦, 张雄, 吴科如.混凝土中氯离子渗透性测定的电化学方法[J].硅酸盐通报, 1998(6):55-59. http://www.cnki.com.cn/Article/CJFDTOTAL-GSYT806.012.htmShi Meilun, Zhang Xiong, Wu Keru. Electrochemical methods for the measurement of chloride permeability in concrete[J]. Bulletin of the Chinese Ceramic Society, 1998(6):55-59. http://www.cnki.com.cn/Article/CJFDTOTAL-GSYT806.012.htm [8] Deby F, Carcassès M, Sellier A. Probabilistic approach for durability design of reinforced concrete in marine environment[J]. Cement & Concrete Research, 2009, 39(5):466-471. http://www.sciencedirect.com/science/article/pii/S0008884609000507 [9] Sun C, Chen J, Zhu J, et al. A new diffusion model of sulfate ions in concrete[J]. Construction & Building Materials, 2013, 39(1):39-45. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=6df55ec9fa30547979f31d38ae712382 [10] Thomas M, Bamforth P B. Modeling chloride diffusion in concrete: Effect of fly ash and slag[J]. Cement & Concrete Research, 1999, 29(4):487-495. http://www.sciencedirect.com/science/article/pii/S0008884698001926 [11] 金祖权, 孙伟, 张云升, 等.混凝土在硫酸盐、氯盐溶液中的损伤过程[J].硅酸盐学报, 2006, 34(5):630-635. doi: 10.3321/j.issn:0454-5648.2006.05.025Jin Zuquan, Sun Wei, Zhang Yunsheng, et al. Damage of concrete in sulfate and chloride solution[J]. Journal of the Chinese Ceramic Society, 2006, 34(5):630-635. doi: 10.3321/j.issn:0454-5648.2006.05.025 [12] 吴政, 张承娟.单向荷载作用下岩石损伤模型及其力学特性研究[J].岩石力学与工程学报, 1996, 15(1):55-61. doi: 10.3321/j.issn:1000-6915.1996.01.008Wu Zheng, Zhang Chengjuan. Investigation of rock damage model, and its mechanical behaviour[J]. Chinese Journal of Rock Mechanics and Engineering, 1996, 15(1):55-61. doi: 10.3321/j.issn:1000-6915.1996.01.008 [13] 李兆霞.损伤力学及其应用[M].北京:科学出版社, 2002. [14] 徐卫亚, 韦立德.岩石损伤统计本构模型的研究[J].岩石力学与工程学报, 2002, 21(6):787-791. doi: 10.3321/j.issn:1000-6915.2002.06.006Xu Weiya, Wei Lide. Study on statistical damage constitutive model of rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2002, 21(6):787-791. doi: 10.3321/j.issn:1000-6915.2002.06.006 -

下载:

下载: