Dynamic mechanical properties of 2A16-T4 aluminum alloy at wide-ranging strain rates

-

摘要: 为了研究2A16-T4铝合金的动态力学性能,利用电子万能试验机、高速液压伺服试验机及霍普金森压杆(SHPB)装置进行常温下准静态、中应变率和高应变率的动态力学性能实验,得到不同应变率下的应力应变曲线,基于修正的Johnson-Cook本构模型对它进行拟合,并分析材料中应变率力学特性对模型应变率敏感参量的影响。结果表明:2A16-T4铝合金在应变率10-4~102 s-1范围内应变率敏感性较弱,而在102~103 s-1范围内应变率敏感性较强,且应变率强化效应随塑性应变的增大而减小;同时,在10-4~103 s-1范围内具有较强的应变硬化效应,且应变硬化效应随应变率的增大而减小;此外,修正Johnson-Cook本构模型的拟合结果与实验结果吻合很好,能够很好表征材料的动态力学行为,且考虑材料中应变率力学特性可提高本构模型参量的准确性。

-

关键词:

- Johnson-Cook模型 /

- 高速液压伺服试验机 /

- 中应变率 /

- 2A16-T4铝合金 /

- 应变率效应

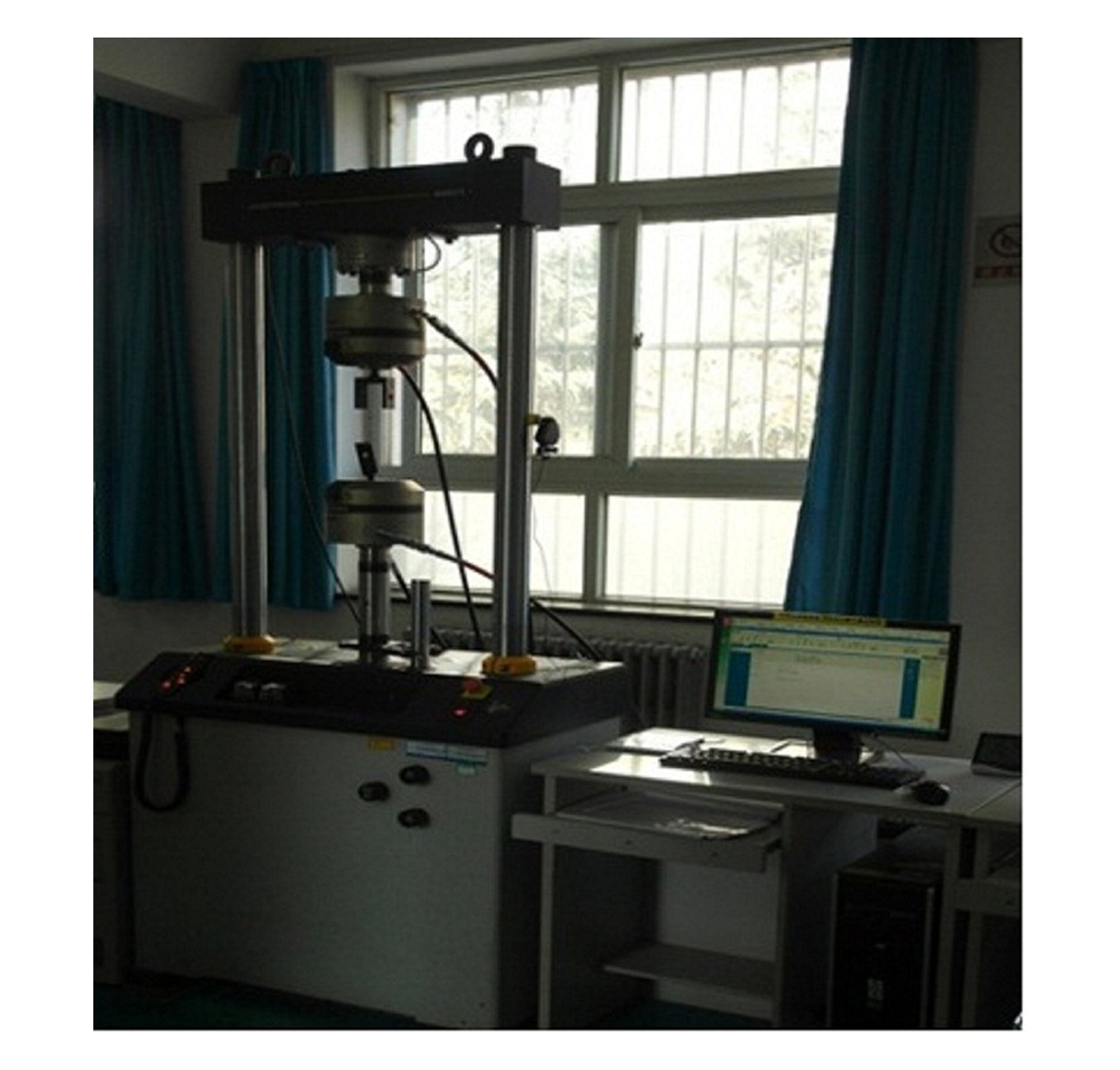

Abstract: In order to study the dynamic mechanical properties of 2A16-T4 aluminum alloy, experiments for the alloy at quasi-static, intermediate, and high strain rates were performed using an electronic multi-purpose testing machine, a high velocity hydraulic servo-testing machine and a split Hopkinson press bar (SHPB) at room temperature, and the stress-strain curves at different strain rates were obtained, with a modified Johnson-Cook constitutive model fitted. The dynamic mechanical properties at intermediate strain rates and its influence on the constitutive model's parameters were analyzed. The results show that the strain rate hardening effect on the 2A16-T4 aluminum alloy is not obvious between 10-4~102 s-1, but it is obvious between 102~103 s-1, decreasing with the increase of the plastic strain. In addition, this effect is obvious between 10-4~103 s-1, decreasing with the increase of the strain rate. Moreover, the fitted results of modified Johnson-Cook constitutive model agree well with the experiment results, representing well the alloy's dynamic mechanical properties, which can improve the precision of the model's rate-sensitive parameters over a wide range of strain rates. -

表 1 2A16-T4铝合金应变率参数拟合结果

Table 1. Fitted results of strain rate sensitive parameters

情况 C P C P C P ${\bar{C}} $ ${\bar{P}} $ ε=0.03 ε=0.08 ε=0.12 1 2.3×10-3 1.29 1.80×10-3 1.04 1.20×10-3 0.95 1.77×10-3 1.093 2 4.9×10-9 6.69 4.75×10-9 6.60 4.72×10-9 6.55 4.79×10-9 6.630 3 1.9×10-11 8.71 1.82×10-11 8.63 1.78×10-11 8.58 1.83×10-11 8.660 -

[1] 赵寿根, 何著, 杨嘉陵, 等.几种航空铝材动态力学性能实验[J].北京航空航天大学学报, 2007, 33(8):982-985. doi: 10.3969/j.issn.1001-5965.2007.08.027Zhao Shougen, He Zhu, Yang Jialing, et al. Experiment investigation of dynamic material property of aluminum alloy[J]. Journal of Beijing University of Aeronautics and Astronautics, 2007, 33(8):982-985. doi: 10.3969/j.issn.1001-5965.2007.08.027 [2] Holt D L, Babcock S G, Green S J, et al. The strain-rate dependence of the flow stress in some aluminum alloys[J]. Transactions of the ASM: Transactions Quarterly, 1967, 60(2):152-159. [3] 王洪欣, 查晓雄.3004铝的动态力学性能及本构关系[J].华中科技大学学报, 2011, 39(5):39-42.Wang Hongxin, Zha Xiaoxiong. Dynamic mechanical behavior and constitutive model of 3004 aluminum alloys[J]. Journal of Huazhong University of Science and Technology, 2011, 39(5):39-42. [4] 张伟, 魏刚, 肖新科, 等.2A12铝合金本构关系和失效模型[J].兵工学报, 2013, 34(3):276-282. http://d.old.wanfangdata.com.cn/Periodical/bgxb201303004Zhang Wei, Wei Gang, Xiao Xinke, et al. Constitutive relation and fracture criterion of 2A12 aluminum alloys[J]. Acta Armamentarii, 2013, 34(3):276-282. http://d.old.wanfangdata.com.cn/Periodical/bgxb201303004 [5] 张伟, 肖新科, 魏刚.7A04铝合金的本构关系和失效模型[J].爆炸与冲击, 2011, 31(1):81-87. doi: 10.11883/1001-1455(2011)01-0081-07Zhang Wei, Xiao Xinke, Wei Gang. Constitutive relation and fracture model of 7A04 aluminum alloys[J]. Explosion and Shock Waves, 2011, 31(1):81-87. doi: 10.11883/1001-1455(2011)01-0081-07 [6] 张正礼.2024铝合金动态力学本构模型构建[J].沈阳航空航天大学学报, 2014, 31(2):47-50. doi: 10.3969/j.issn.2095-1248.2014.02.011Zhang Zhengli. Construction of dynamic mechanical constitutive model of 2024 aluminum[J]. Journal of Shenyang Aerospace University, 2014, 31(2):47-50. doi: 10.3969/j.issn.2095-1248.2014.02.011 [7] 朱耀.AA 7055铝合金在不同温度及应变率下力学性能的实验研究[D].哈尔滨: 哈尔滨工业大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10213-1011278756.htm [8] 谢灿军, 童明波, 刘富, 等.7075-T6铝合金动态力学试验及本构模型研究[J].振动与冲击, 2014, 33(18):100-114. http://d.old.wanfangdata.com.cn/Periodical/zdycj201418018Xie Canjun, Tong Mingbo, Liu Fu, et al. Dynamic tests and constitutive model for 7075-T6 aluminum alloy[J]. Journal of Vibration and Shock, 2014, 33(18):110-114. http://d.old.wanfangdata.com.cn/Periodical/zdycj201418018 [9] 杨超, 朱涛, 肖守讷.列车车体铝合金动态力学性能及其对吸能的影响[J].中南大学学报(自然科学版), 2015, 46(7):2744-2749.Yang Chao, Zhu Tao, Xiao Shoune. Dynamic mechanical properties of aluminum alloy used in carbodies of trains and effect on energy absorption[J]. Journal of Central South University (Science and Technology), 2015, 46(7):2744-2749. [10] Yatnalkar R S. Experimental investigation of plastic deformation of Ti-6Al-4V under various loading conditions[D]. The Ohio State: The Ohio State University, 2010. [11] Wood P K C, Schley C A, Kenny S, et al. Validating performance of automotive materials at high strain rate for improved crash design[C]//9th International LS-DYNA Users Conference. Detroit, 2006. [12] 白春玉, 刘小川, 周苏枫, 等.中应变率下材料动态拉伸关键参数测试方法[J].爆炸与冲击, 2015, 35(4):507-512. doi: 10.11883/1001-1455(2015)04-0507-06Bai Chunyu, Liu Xiaochuan, Zhou Sufeng, et al. Material key parameters measurement method in the dynamic tensile testing at intermediate strain rate[J]. Explosion and Shock Waves, 2015, 35(4):507-512. doi: 10.11883/1001-1455(2015)04-0507-06 [13] 余同希, 邱信明.冲击动力学[M].北京:清华大学出版社, 2011. [14] Johnson G R, Cook W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[C]//Proceedings of the 7th International Symposium on Ballistics. The Hague, Netherlands, 1983: 541-547. [15] Kang W J, Cho S S, Huh H, et al. Modified Johnson-Cook model for vehicle body crashworthiness simulation[J]. International Journal of Vehicle Design, 1999, 21(4):424-435. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=caec5e2883f57b1720cefbd750b33c61 [16] Cowper G R, Symonds P S. Strain hardening and strain rate effects in the impact loading of cantilever beams[R]. Division of Applied Mathematics, Brown University, 1957. [17] Huh H, Kang W J, Han S S. A tension split Hopkinson bar for investigating the dynamic behavior of sheet metals[J]. Experimental Mechanics, 2002, 42(1):8-17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=355b24d3ea891696370e4add7922dbb8 -

下载:

下载: