Fracture characteristics of brittle particles at different loading velocities

-

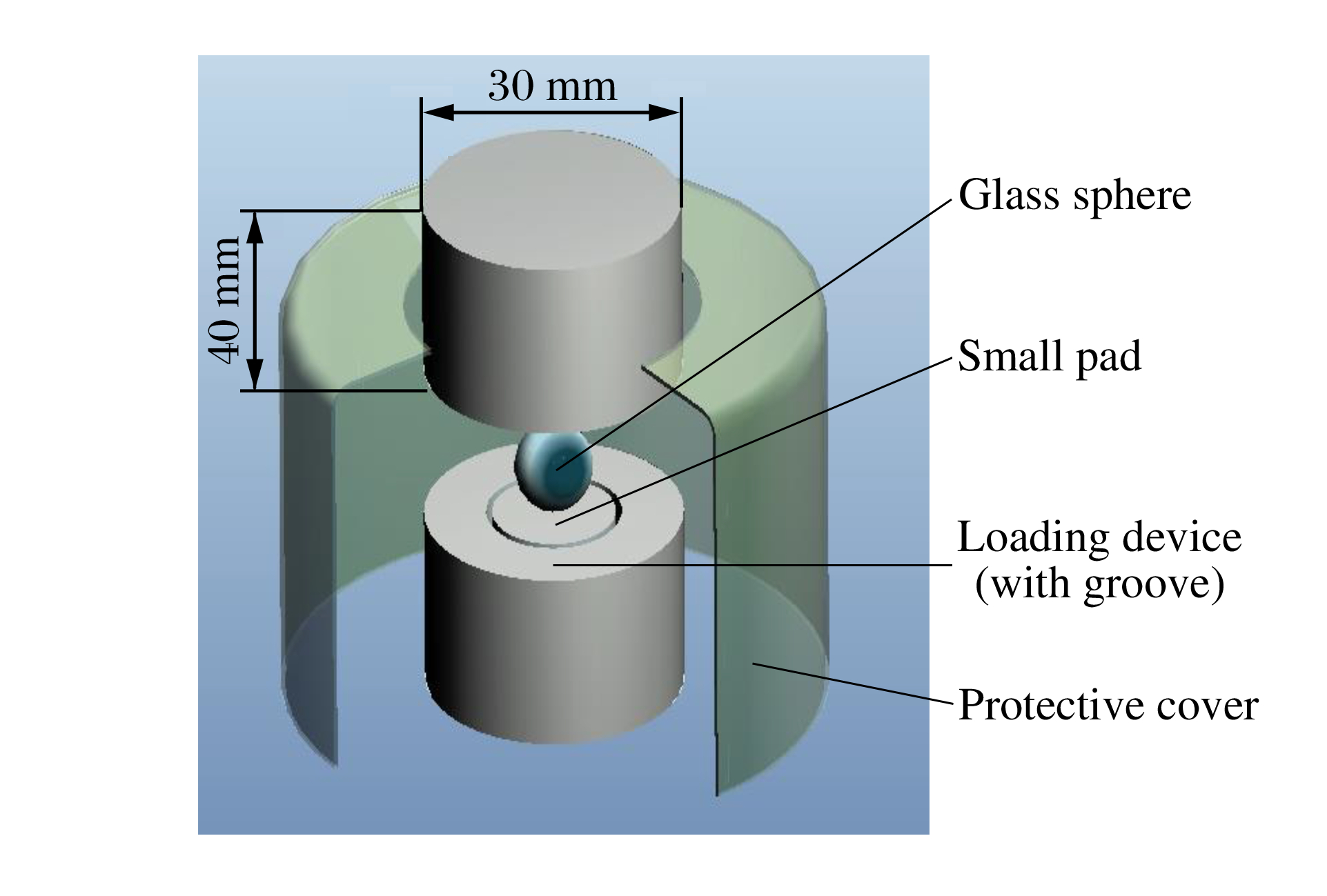

摘要: 对直径为8mm的K9玻璃球进行了加载速度为2×10-7和2×10-6m/s的准静态单轴压缩实验以及加载速度为3.4、7.1和10.6m/s的动态单轴压缩实验,研究了K9玻璃单颗粒破碎强度的Weibull分布特性,结合破碎产物的形貌特征,分析了不同加载速度下脆性材料拉伸破坏机制和剪切破坏机制的转变过程,提出了一种拉剪耦合的时序破坏模型,由此揭示了加载速度与3个破坏区的关系。考虑拉伸和剪切失效准则,应用ABAQUS软件进行数值模拟,并初步验证了该破坏模型的冲击过程。研究结果对于认识脆性颗粒材料的动态破坏具有很好的参考意义。Abstract: Uniaxial compression experiments of K9 glass spheres with a diameter of 8mm were conducted to obtain the fracture responses of brittle particles at five loading velocities, i.e.2×10-7 and 2×10-6m/s for quasi-static loading and 3.4, 7.1 and 10.6m/s for impact loading using a split Hopkinson pressure bar. Based on the Weibull distribution and recovery specimen products, a novel model combing the tensile failure and the shear failure was proposed to explain the process of the breaking evolution, revealing the relationship of the loading velocity and the three breaking zones. The model was validated using numerical simulation. Our study can serve as valuable reference for the study of the dynamic failure of brittle granular materials.

-

Key words:

- dynamics /

- brittle material /

- Weibull distribution /

- tension-shear coupling

-

表 1 Weibull分布的拟合参数

Table 1. Fitting parameters of Weibull distribution

实验组 n v/(m·s-1) m σ0/MPa r S-1 24 2×10-7 7.52 44.18 0.946 S-2 28 2×10-6 2.82 54.13~69.02 0.862 D-1 24 3.4 9.01 79.50 0.926 D-2 24 7.1 7.05 114.85 0.945 D-3 24 10.6 6.17 123.91 0.980 -

[1] 陈生水, 霍家平, 章为民."5·12"汶川地震对紫坪铺混凝土面板坝的影响及原因分析[J].岩土工程学报, 2008, 30(6):795-801. doi: 10.3321/j.issn:1000-4548.2008.06.003Chen Shengshui, Huo Jiaping, Zhang Weimin. Analysis of effects of "5·12" Wenchuan earthquake on Zipingpu concrete face rock-fill dam[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(6):795-801. doi: 10.3321/j.issn:1000-4548.2008.06.003 [2] 孙成林.2003年中国粉体工业现状[J].硫磷设计与粉体工程, 2004(4):7-10. doi: 10.3969/j.issn.1009-1904.2004.04.002Sun Chenglin. Present situation of China's bulk material handling industry in 2003[J]. Sulphur Phosphorus & Bulk Materials Handling Related Engineering, 2004(4):7-10. doi: 10.3969/j.issn.1009-1904.2004.04.002 [3] Hostler S R. Wave propagation in granular materials[D]. Los Angeles: California Institute of Technology, 2004. [4] 郑文, 徐松林, 胡时胜.侧限压缩下干燥砂的动态力学性能[J].爆炸与冲击, 2011, 31(6):619-623. doi: 10.11883/1001-1455(2011)06-0619-05Zheng Wen, Xu Songlin, Hu Shisheng. Dynamic mechanical properties of dry sand under confined compression[J]. Explosion and Shock Waves, 2011, 31(6):619-623. doi: 10.11883/1001-1455(2011)06-0619-05 [5] 黄俊宇, 徐松林, 王道荣, 等.脆性颗粒材料的动态多尺度模型研究[J].岩土力学, 2013, 34(4):15-25. http://d.old.wanfangdata.com.cn/Periodical/ytlx201304004Huang Junyu, Xu Songlin, Wang Daorong, et al. Investigation on dynamic multiscale model for brittle granular materials[J]. Rock and Soil Mechanics, 2013, 34(4):15-25. http://d.old.wanfangdata.com.cn/Periodical/ytlx201304004 [6] Huang J, Xu S, Hu S. Influence of particle breakage on the dynamic compression responses of brittle granular materials[J]. Mechanics of Materials, 2014, 68(1):15-28. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=8ea5fda98364f87c012e63a533916200 [7] Huang J, Xu S, Hu S. Effects of grain size and gradation on the dynamic responses of quartz sands[J]. International Journal of Impact Engineering, 2013, 59(9):1-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=59a54936136a4136e9aabd7251787ea7 [8] Huang J Y, Lu L, Fan D, et al. Heterogeneity in deformation of granular ceramics under dynamic loading[J]. Scripta Materialia, 2016, 111:114-118. doi: 10.1016/j.scriptamat.2015.08.028 [9] Salman A D, Biggs C A, Fu J, et al. An experimental investigation of particle fragmentation using single particle impact studies[J]. Powder Technology, 2002, 128(1):36-46. doi: 10.1016/S0032-5910(02)00151-1 [10] 陈星.基于ABAQUS的冰雹撞击有限元分析[D].呼和浩特: 内蒙古工业大学, 2013. http://cdmd.cnki.com.cn/Article/CDMD-10128-1014012690.htm [11] Huang J, Xu S, Hu S. The role of contact friction in the dynamic breakage behavior of granular materials[J]. Granular Matter, 2015, 17(1):111-120. doi: 10.1007/s10035-014-0543-z [12] Huang J, Xu S, Yi H, et al. Size effect on the compression breakage strengths of glass particles[J]. Powder Technology, 2014, 268(1):86-94. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=4d228583d84abb7a94a657b3a95a1c17 [13] 徐松林, 唐志平, 谢卿, 等.压剪联合冲击下K9玻璃中的失效波[J].爆炸与冲击, 2005, 25(5):385-392. doi: 10.3321/j.issn:1001-1455.2005.05.001Xu Songlin, Tang Zhiping, Xie Qing, et al. Experimental investigation on failure wave in K9 glass under combined pressure and shear impact loading[J]. Explosion and Shock Waves, 2005, 25(5):385-392. doi: 10.3321/j.issn:1001-1455.2005.05.001 [14] 胡时胜, 王礼立, 宋力, 等.Hopkinson压杆技术在中国的发展回顾[J].爆炸与冲击, 2014, 34(6):641-657. doi: 10.11883/1001-1455(2014)06-0641-17Hu Shisheng, Wang Lili, Song Li, et al. Review of the development of Hopkinson pressure bar technique in China[J]. Explosion and Shock Waves, 2014, 34(6):641-657. doi: 10.11883/1001-1455(2014)06-0641-17 [15] McDowell G R, Amon A. The application of Weibull statistics to the fracture of soil particles[J]. Journal of the Japanese Geotechnical Society Soils & Foundation, 2000, 40(5):133-141. [16] Hertz H. On the contact of elastic solids[J]. Journal für die Reine und Angewandte Mathematik, 1882, 92:156-171. http://d.old.wanfangdata.com.cn/OAPaper/oai_arXiv.org_0805.0712 [17] Cheong Y S, Reynolds G K, Salman A D, et al. Modelling fragment size distribution using two-parameter Weibull equation[J]. International Journal of Mineral Processing, 2004, 74(50):S227-S237. http://d.old.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0210611406/ [18] Salman A D, Gorham D A. The fracture of glass spheres[J]. Powder Technology, 2000, 107(1):179-185. -

下载:

下载: