Fracture behavior of magnesium alloy MB2 under quasi-static and dynamic tension loading based on Johnson-Cook model

-

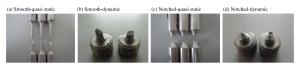

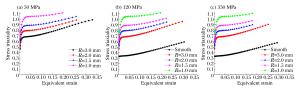

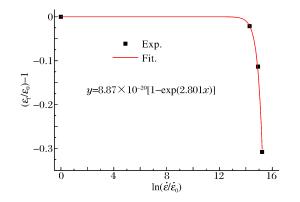

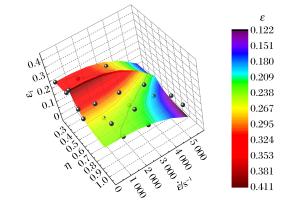

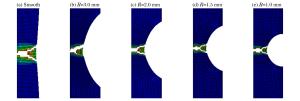

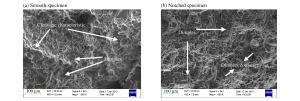

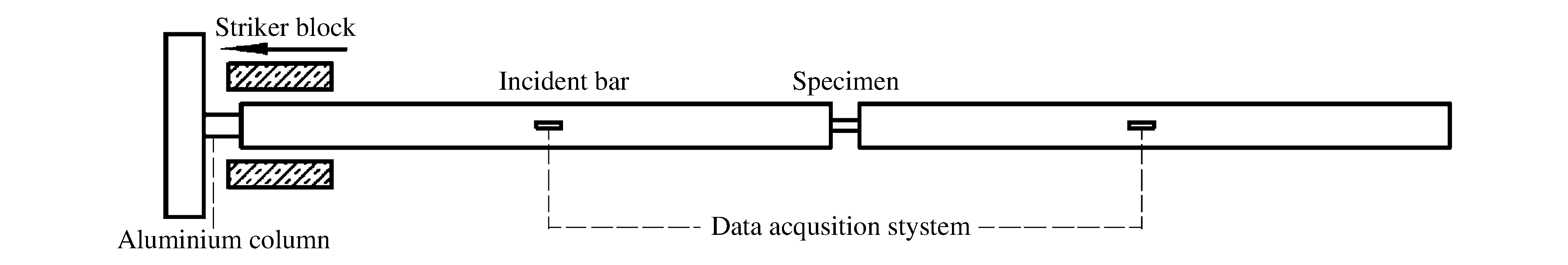

摘要: 为了研究不同应力状态和应变率条件下镁合金MB2的拉伸破坏行为,利用材料试验机和分离式Hopkinson拉杆(SHTB),对镁合金MB2的光滑及缺口圆柱试件进行了动静态拉伸加载;拟合得到了镁合金MB2的动静态拉伸本构关系,建立了其修正的Johnson-Cook失效破坏准则,并对不同试件的拉伸破坏行为进行了数值模拟;利用SEM对宏观破坏模式对应的微观损伤机理进行了分析。结果表明,随着应力三轴度的增加,镁合金MB2的等效破坏应变先增大后减小,宏观破坏模式由剪切转为正拉断,微观损伤机制由混合断裂转变为韧窝断裂;而随着应变率的增加,等效破坏应变不断减小,破坏模式不发生改变。Johnson-Cook本构关系和修正后的Johnson-Cook失效破坏准则能较好地拟合动态静态拉伸实验结果并预测不同试件的杯锥形破坏特征。Abstract: In the present study, we loaded smooth and notched cylindrical specimens of magnesium alloy MB2 under quasi-static and dynamic tension states using the material testing machine and split Hopkinson tension bar (SHTB), to characterize the alloy's tensile fracture behaviors under different stress states and strain rates. The constitution of the alloy for quasi-static and dynamic tension states was fitted and the modified fracture criterion based on the Johnson-Cook model was established and then used to simulate the fracture behavior of different tensile specimens. The microscopic damage mechanisms corresponding to the macroscopic fracture pattern was analyzed by SEM. The results show that with the increase of the stress triaxiality, the equivalent strain to fracture of the alloy increases at first and then decreases, and the fracture pattern changes from shear fracture to vertical tension fracture with micro damage mechanisms changing from the mixed failure to the dimple failure; with the increase of the strain rate, the equivalent strain to fracture decreases, and the fracture pattern remains the same. The Johnson-Cook constitution and the modified Johnson-Cook fracture criterion can be used to fit the experimental results under quasi-static and dynamic tension states and predict the cup-cone fracture characteristics of different specimens.

-

Key words:

- fracture behavior /

- SHTB experiment /

- magnesium alloy MB2 /

- stress triaxiality /

- strain rate

-

表 1 不同类型试件的等效破坏应变

Table 1. Equivalent fracture strain of different specimens

入射波幅值/MPa 等效破坏应变 光滑 R=3.0 mm R=2.0 mm R=1.5 mm R=1.0 mm 50 未断裂 0.333 8 0.250 2 0.254 1 0.205 3 120 0.311 7 0.307 1 0.225 7 0.239 7 0.197 7 350 0.289 3 0.249 2 0.180 0 0.175 8 0.177 6 表 2 缺口试件的平均应变率

Table 2. Average strain rates of different specimens

入射波幅值/MPa 平均应变率/s-1 R=3 mm R=2 mm R=1.5 mm R=1 mm 50 828 968 1 047 1 239 120 2 315 2 573 2 569 2 694 350 3 905 4 129 4 914 4 981 -

[1] 胡昌明, 李英雷, 胡时胜, 等.高温-高应变率下MB2合金的动态力学性能及变形机理[J].兵器材料科学与工程, 2009, 32(5):8-11. doi: 10.3969/j.issn.1004-244X.2009.05.003Hu Changming, Li Yinglei, Hu Shisheng, et al. Dynamic mechanical properties and deformation mechanism of MB2 ally under high temperature and high strain rates[J]. Ordnance Material Science and Engineering, 2009, 32(5):8-11. doi: 10.3969/j.issn.1004-244X.2009.05.003 [2] Zhao Feng, Li Yulong, Suo Tao, et al. Compressive deformation behavior of AZ31 magnesium alloy under quasi-static and dynamic loading[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7):1316-1320. doi: 10.1016/S1003-6326(09)60297-1 [3] 刘正, 董阳, 毛萍莉, 等.轧制AZ31镁合金板材(4 mm)动态压缩性能与失效行为[J].材料工程, 2015, 43(2):61-66. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clgc201502010Liu Zheng, Dong Yang, Mao Pingli, et al. Dynamic compressive properties and failure behaviour of rolled AZ31 magnesium alloy sheet (4 mm)[J]. Journal of Materials Engineering, 2015, 43(2):61-66. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clgc201502010 [4] Hancock J W, Mackenzie A C. On the mechanisms of ductile failure in high strength steels subjected to multi axial stress states[J]. Journal of the Mechanics and Physics of Solids, 1976, 24(2):147-160. http://www.sciencedirect.com/science/article/pii/0022509676900247 [5] Hopperstad O S, Børvika T, Langseth M, et al. On the influence of stress triaxiality and strain rate on the behaviour of a structural steel. Part Ⅰ. Experiments[J]. European Journal of Mechanics, 2003, 22(1):1-13. http://www.sciencedirect.com/science/article/pii/S0997753802000050 [6] Børvik T, Hopperstad O S, Berstada T. On the influence of stress triaxiality and strain rate on the behaviour of a structural steel. Part Ⅱ. Numerical study[J]. European Journal of Mechanics, 2003, 22(1):15-32. http://www.sciencedirect.com/science/article/pii/S0997753802000050 [7] Bao Y B. Dependence of ductile crack formation in tensile tests on stress triaxiality, stress and strain ratios[J]. Engineering Fracture Mechanics, 2005, 72(4):505-522. doi: 10.1016/j.engfracmech.2004.04.012 [8] Anderson D, Winkler S, Bardelcik A, et al. Influence of stress triaxiality and strain rate on the failure behavior of a dual-phase DP780 steel[J]. Materials and Design, 2014, 60(8):198-207. http://www.sciencedirect.com/science/article/pii/S0261306914002660 [9] 汤安民, 师俊平.几种金属材料宏观断裂形式的试验研究[J].应用力学学报, 2004, 21(3):142-144. doi: 10.3969/j.issn.1000-4939.2004.03.032Tang Anmin, Shi Junping. Experiment analysis of macroscopic fracture forms for several metal materials[J]. Journal of Applied Mechanics, 2004, 21(3):142-144. doi: 10.3969/j.issn.1000-4939.2004.03.032 [10] 李智慧, 师俊平, 汤安民.金属材料脆性断裂机理的实验研究[J].应用力学学报, 2012, 29(1):48-53. http://d.old.wanfangdata.com.cn/Periodical/yylxxb201201009Li Zhihui, Shi Junping, Tang Anmin. Experimental research on the brittle fracture mechnism in metal material[J]. Journal of Applied Mechanics, 2012, 29(1):48-53. http://d.old.wanfangdata.com.cn/Periodical/yylxxb201201009 [11] 陈刚, 陈忠富, 徐伟芳, 等.45钢的J-C损伤失效参量研究[J].爆炸与冲击, 2007, 27(2):131-135. doi: 10.3321/j.issn:1001-1455.2007.02.007Chen Gang, Chen Zhongfu, Xu Weifang, et al. Investigation on the J-C ductile fracture parameters of 45 steel[J]. Explosion and Shock Waves, 2007, 27(2):131-135. doi: 10.3321/j.issn:1001-1455.2007.02.007 [12] 朱浩, 朱亮, 陈剑虹.应力三轴度和应变率对6063铝合金力学性能的影响及材料表征[J].材料科学与工程学报, 2007, 25(30):358-362. http://d.old.wanfangdata.com.cn/Periodical/clkxygc200703009Zhu Hao, Zhu Liang, Chen Jianhong. Influence of stress triaxiality and strain rate on the mechanics behavior of 6063 aluminum ally and material characterization[J]. Journal of Materials Science and Engineering, 2007, 25(30):358-362. http://d.old.wanfangdata.com.cn/Periodical/clkxygc200703009 [13] 张伟, 肖新科, 魏刚.7A04铝合金的本构关系和失效模型[J].爆炸与冲击, 2011, 31(1):81-87. http://www.bzycj.cn/CN/abstract/abstract8637.shtmlZhang Wei, Xiao Xinke, Wei Gang. Constitutive relation and fracture model of 7A04 aluminum alloy[J]. Explosion and Shock Waves, 2011, 31(1):81-87. http://www.bzycj.cn/CN/abstract/abstract8637.shtml [14] Bridgman P W. Studies in large plastic flow and fracture with special emphasis on the effects of hydrostatic pressure[M]. New York: McGraw Hill, 1952. [15] Feng Fei, Huang Shangyu, Meng Zhenghua, et al. A constitutive and fracture model for AZ31B magnesium alloy in the tensile state[J]. Materials Science and Engineering A, 2014, 594(4):334-343. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d335194d2ce47f81a6af424288a3bfd4 [16] Alves M, Jones N. Influence of hydrostatic stress on failure of axisymmetric notched specimens[J]. Journal of the Mechanics and Physics of Solids, 1999, 47(3):643-667. doi: 10.1016/S0022-5096(98)00060-X [17] Goto D M, Koss D A, Jablokov V. The influence of tensile stress states on the failure of HY-100 steel[J]. Metallurgical and Materials Transactions A, 1999, 30(11):2835-2842. doi: 10.1007/s11661-999-0121-x [18] Bao Y B, Wierzbicki T. On fracture locus in the equivalent strain and stress triaxiality space[J]. International Journal of Mechanical Sciences, 2004, 46(1):81-98. doi: 10.1016/j.ijmecsci.2004.02.006 [19] 贾东, 莫军, 黄西成, 等.镁合金MB2在高应力三轴度下的拉伸破坏行为研究[J].实验力学, 2016, 31(1):87-95. http://d.old.wanfangdata.com.cn/Periodical/sylx201601011Jia Dong, Mo Jun, Huang Xicheng, et al. On the fracture behavior of magnesium alloy MB2 subjected to high stress triaxiality stretching[J]. Journal of Experimental Mechanics, 2016, 31(1):87-95. http://d.old.wanfangdata.com.cn/Periodical/sylx201601011 -

下载:

下载: