Failure mode and energy absorption mechanism of steel/aluminum composite plates impacted by spherical fragment

-

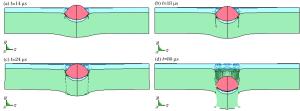

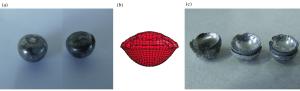

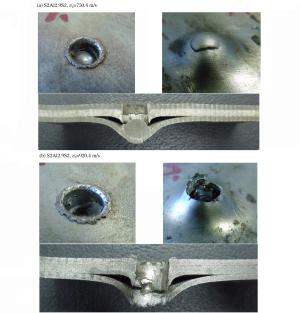

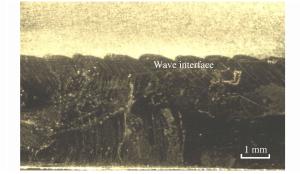

摘要: 为研究复合靶板自身结构对其防护性能的影响,针对面密度相同的两层钢/铝、三层钢/铝/钢爆炸复合板以及均质钢板,采用系列弹道实验和LS-DYNA3D非线性有限元程序分析了复合靶板在球形破片侵彻作用下的失效模式和吸能机理,讨论了靶板层数、厚度和界面结合情况对失效模式的影响。研究结果表明:较其他因素而言,界面结合状态对靶板失效模式的影响最明显,当界面结合良好时,各层靶板均发生剪切冲塞破坏,而当结合界面发生拉伸失效时,较薄的背板以延性扩孔破坏为主;随着靶板总厚度的增大,靶板更易发生剪切冲塞破坏;当靶板的面密度和总厚度分别相等时,三层复合靶板的防护性能优于双层靶板。Abstract: In order to investigate the influence of target structure on the protective performance, series of ballistic experiments and LS-DYNA 3D finite element code were adopted to research the failure mode and energy absorption mechanism of two-layer (steel/aluminum) and three-layer (steel/aluminum/steel) explosive welded targets, as well as a monolithic steel target, which were perforated by spherical fragments. The effects of the layer number, thickness and the combination of the interface on the failure mode were analyzed based on the experimental and numerical results obtained. The results show that the influence of the combination of the target interfaces on the failure mode is the most obvious as compared with the other influencing factors. The fracture mechanism of different plates were shearing and plugging when the interface was well bonded but, when the bonding interface failed due to tension, the thinner rear plate failed mainly due to ductile prolonging deformation. With the increase of the total thickness, the targets were more apt to suffer damage resulting from shearing and plugging. The protective performance of the three-layer composite target is superior to that of the two-layer one with the same areal density and total thickness.

-

Key words:

- failure mode /

- energy absorption mechanism /

- explosive welded plate /

- bonding interface

-

表 1 靶板的组合方式

Table 1. Plate thickness and combination

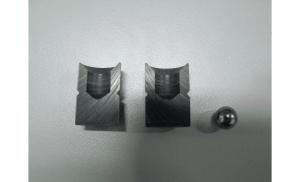

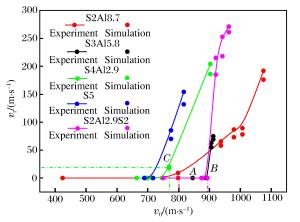

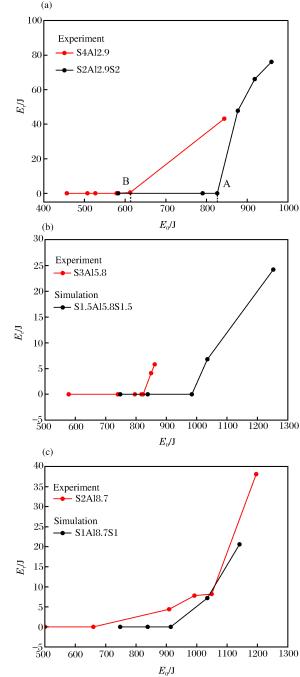

n 靶板组合 h/mm H/mm Q235 LY12 Q235 1 S5 5.0 - - 5.0 2 S4Al2.9 4.0 2.9 - 6.9 2 S3Al5.8 3.0 5.8 - 8.8 2 S2Al8.7 2.0 8.7 - 10.7 3 S2Al2.9S2 2.0 2.9 2.0 6.9 表 2 不同组合靶板弹道侵彻实验结果

Table 2. Experimental results for different targets in ballistic experiments

单位:m/s 靶板组合 第1发 第2发 第3发 第4发 第5发 v0 vr v0 vr v0 vr v0 vr v0 vr S5 717.2 85.2 775.2 154.2 816.8 - - - - - S4Al2.9 699.9 0 713.3 0 747.7 0 769.2 20.3 902.8 204.2 S3Al5.8 845.5 0 876.9 0 888.9 0 891.8 C 905.9 62.8 S2Al8.7 695.2 0 798.2 C 937.2 65.4 979.3 86.8 1 007 89.2 S2Al2.9S2 873.9 0 876.9 0 893.5 C 920.4 215 942.0 252.7 注:"C"表示靶板处在临界穿透状态, 破片的剩余速度为零。 -

[1] ALMOHANDES A A, ABDEL-KADER M S, ELEICHE A M. Experimental investigation of the ballistic resistance of steel-fiberglass reinforced polyester laminated plates[J]. Composite Part B, 1996, 27(5):447-458. doi: 10.1016/1359-8368(96)00011-X [2] ZUKAS J A, SCHEFFLER D R. Impact effects in multilayered plates[J]. International Journal of Solids and Structures, 2001, 38(19):3321-3328. doi: 10.1016/S0020-7683(00)00260-2 [3] CORRAN R S J, SHADBOLT P J, RUIZ C. Impact loading of plates: An experimental investigation[J]. International Journal of Impact Engineering, 1983, 1(1):3-22. doi: 10.1016/0734-743X(83)90010-6 [4] DEY S, BØRVIK T, HOPPERSTAD O S, et al. On the influence of constitutive relation in projectile impact of steel plates[J]. International Journal of Impact Engineering, 2007, 34(3):464-486. doi: 10.1016/j.ijimpeng.2005.10.003 [5] BEN-DOR G, DUBINSKY A, ELPERIN T. Effect of air gaps on the ballistic resistance of ductile shields perforated by non-conical impactors[J]. Journal of Mechanics of Materials and Structures, 2006, 1(2):279-299. DOI: 10.2140/jomms.2006.1.279. [6] DEY S, BØRVIK T, HOPPERSTAD O S, et al. On the influence of fracture criterion in projectile impact of steel plates[J]. Computational Materials Science, 2006, 38(1):176-191. doi: 10.1016/j.commatsci.2006.02.003 [7] MANES A, LUMASSI D, GIUDICI L, et al. An experimental-numerical investigation on aluminum tubes subjected to ballistic impact with soft core 7.62 ball projectiles[J]. Thin Wall Structures, 2013, 73(4):68-80. DOI: 10.1016/j.tws.2013.07.015. [8] 邓云飞, 张伟, 曹宗胜.间隙对A3钢薄板抗卵形头弹侵彻性能影响的实验研究[J].振动与冲击, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018DENG Yunfei, ZHANG Wei, CAO Zongsheng. Effect of gap on the ballistic performance of doublevlayered A3 steel shields against ogival rigid projectiles[J]. Journal of Vibration and Shock, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018 [9] 杜忠华, 赵国志, 欧阳春.多层陶瓷复合轻装甲结构的抗弹性分析[J].南京理工大学学报(自然科学版), 2002, 26(2):147-151. http://d.wanfangdata.com.cn/Periodical_njlgdxxb200202010.aspxDU Zhonghua, ZHAO Guozhi, OUYANG Chun. The analysis of defensible performance against complex light multi-player armour of ceramic[J]. Journal of Nanjing University of Science and Technology (Natural Science Edition), 2002, 26(2):147-151. http://d.wanfangdata.com.cn/Periodical_njlgdxxb200202010.aspx [10] ZHOU N, WANG J X, YANG R, et al. Damage mechanism and anti-penetration performance of multi-layered explosively welded plates impacted by spherical projectile[J]. Theoretical and applied fracture mechanics, 2012, 60(1):23-30. doi: 10.1016/j.tafmec.2012.06.004 [11] 陈昕, 朱锡, 梅志远, 等.UHMWPE球面层合板弹道侵彻性能研究[J].振动与冲击, 2011, 30(4):119-123. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-AGLU201207005092.htmCHEN Xin, ZHU Xi, MEI Zhiyuan, et al. Research on ballistic penetration properties of UHMWPE spherical laminates[J]. Journal of Vibration and Shock, 2011, 30(4):119-123. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-AGLU201207005092.htm [12] 陈小伟, 张方举, 梁斌, 等.A3钢钝头弹撞击45钢板破坏模式的实验研究[J].爆炸与冲击, 2006, 26(3):199-207. doi: 10.11883/1001-1455(2006)03-0199-09CHEN Xiaowei, ZHANG Fangju, LIANG Bin, et al. Three modes of penetration mechanics of A3 steel cylindrical peojectiles impact onto 45 steel plates[J]. Explosion and Shock Waves, 2006, 26(3):199-207. doi: 10.11883/1001-1455(2006)03-0199-09 [13] 宋博, 胡时胜, 王礼立.分层材料的不同排列次序对透射冲击波强度的影响[J].兵工学报, 2000, 21(3):272-274. http://www.cqvip.com/QK/94928X/200003/1001110292.htmlSONG Bo, HU Shisheng, WANG Lili. Influence on the transmitted intensity of shock wave through different tatic orders of layered materials[J]. Acta armamentar, 2000, 21(3):272-274. http://www.cqvip.com/QK/94928X/200003/1001110292.html [14] CHEN X W, LI Q M. Shear plugging and perforation of ductile circular plates struck by a blunt projectile[J]. International Journal of Impact Engineering, 2003, 28(5):513-536. doi: 10.1016/S0734-743X(02)00077-5 [15] 张国伟.终点效应及靶场试验[M].北京:北京理工大学出版社, 2009:72-73. [16] 钱伟长.穿甲力学[M].北京:国防工业出版社, 1984:238-287. [17] 周楠, 王金相, 谢君, 等.球形弹丸作用下钢/铝爆炸复合靶的抗侵彻性能计算与分析[J].高压物理学报, 2013, 27(6):839-846. doi: 10.11858/gywlxb.2013.06.008ZHOU Nan, WANG Jinxiang, XIE Jun, et al. Calculation and analysis for the anti-penetration performance of explosively welded steel/aluminum plates target by the penetration of spherical projectile[J]. Chinese Journal of High Pressure Physics, 2013, 27(6):839-846. doi: 10.11858/gywlxb.2013.06.008 -

下载:

下载: