| [1] |

KHAN A S, PANDEY A, GNAUPEL-HEROLD T, et al. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures[J]. International Journal of Plasticity, 2011, 27(5):688-706. doi: 10.1016/j.ijplas.2010.08.009

|

| [2] |

AL-SAMMAN T, LI X, CHOWDHURY S G. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy[J]. Materials Science and Engineering:A, 2010, 527(15):3450-3463. doi: 10.1016/j.msea.2010.02.008

|

| [3] |

ESKANDARI M, ZAREI-HANZAKI A, PILEHVA F, et al. Ductility improvement in AZ31 magnesium alloy using constrained compression testing technique[J]. Materials Science and Engineering:A, 2013, 576(6):74-81. https://www.sciencedirect.com/science/article/pii/S0921509313003201

|

| [4] |

LIU Xiao, JONAS J J, LI Luoxing, et al. Flow softening, twinning and dynamic recrystallization in AZ31 magnesium[J]. Materials Science and Engineering:A, 2013, 583(42):242-253. https://www.sciencedirect.com/science/article/pii/S092150931300734X

|

| [5] |

LIU Xiao, JONAS J J, ZHU Biwu, et al. Variant selection of primary extension twins in AZ31 magnesium deformed at 400℃[J]. Materials Science and Engineering:A, 2016, 649:461-467. doi: 10.1016/j.msea.2015.10.020

|

| [6] |

YE Tuo, LI Luoxing, GUO Pengcheng, et al. Effect of aging treatment on the microstructure and flow behavior of 6063 aluminum alloy compressed over a wide range of strain rate[J]. International Journal of Impact Engineering, 2016, 90:72-80. doi: 10.1016/j.ijimpeng.2015.12.005

|

| [7] |

Yokoyama T. Impact tensile stress-strain characteristics of wrought magnesium alloys[J]. Strain, 2003, 39(4):167-175. doi: 10.1046/j.1475-1305.2003.00086.x

|

| [8] |

WU B L, ZHANG Y D, WAN G, et al. Primary twinning selection with respect to orientation of deformed grains in ultra-rapidly compressed AZ31 alloy[J]. Materials Science and Engineering:A, 2012, 541:120-127. doi: 10.1016/j.msea.2012.02.012

|

| [9] |

WAN G, WU B L, ZHANG Y D, et al. Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy[J]. Materials Science and Engineering:A, 2010, 527(12):2915-2924. doi: 10.1016/j.msea.2010.01.023

|

| [10] |

MUKAI T, YAMANOI M, WATANABE H, et al. Effect of grain refinement on tensile ductility in ZK60 magnesium alloy under dynamic loading[J]. Materials Transactions, 2005, 42(7):1177-1181. http://cat.inist.fr/?aModele=afficheN&cpsidt=1102494

|

| [11] |

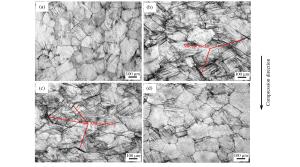

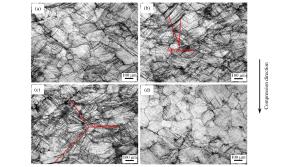

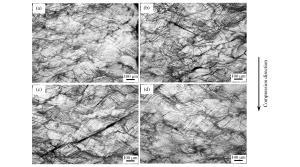

毛萍莉, 刘正, 王长义, 等.高应变速率下AZ31B镁合金的压缩变形组织[J].中国有色金属学报, 2009, 19(5):816-820. http://www.ysxbcn.com/down/down_36237.htmlMAO Pingli, LIU Zheng, WANG Changyi, et al. Deformation microstructure of AZ31B magnesium alloy under high strain rate compression[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5):816-820. http://www.ysxbcn.com/down/down_36237.html

|

| [12] |

郭鹏程, 曹淑芬, 叶拓, 等.高速冲击载荷下AM80镁合金的力学本构及仿真模拟[J].中国有色金属学报, 2017, 27(6):1075-1082. http://www.ysxbcn.com/paper/paper_316358.htmlGUO Pengcheng, CAO Shufen, YE Tuo, et al. Mechanical constitutive equation and simulation of AM80 magnesium alloy uder high speed impact load[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6):1075-1082. http://www.ysxbcn.com/paper/paper_316358.html

|

| [13] |

MUKAI T, YAMANOI M, HIGASHI K. Processing of ductile magnesium alloy under dynamic tensile loading[J]. Materials Transactions, 2001, 42(12):2652-2654. doi: 10.2320/matertrans.42.2652

|

| [14] |

FENG Fei, HUANG Shangyu, MENG Zhenghua, et al. Experimental study on tensile property of AZ31B magnesium alloy at different high strain rates and temperatures[J]. Materials and Design, 2014, 57(5):10-20. https://www.sciencedirect.com/science/article/pii/S0261306913011643?_escaped_fragment_=

|

| [15] |

ULACIA I, DUDAMELL N V, GALVEZ F, et al. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates[J]. Acta Materialia, 2010, 58(8):2988-2998. doi: 10.1016/j.actamat.2010.01.029

|

| [16] |

DUDAMELL N V, ULACIA I, GALVEZ F, et al. Influence of texture on the recrystallization mechanisms in an AZ31 Mg sheet alloy at dynamic rates[J]. Materials Science and Engineering:A, 2012, 532(1):528-535. http://www.sciencedirect.com/science/article/pii/S0921509311012391

|

| [17] |

MAO Pingli, LIU Zheng, WANG Changyi. Texture effect on high strain rates tension and compression deformation behavior of extruded AM30 alloy[J]. Materials Science and Engineering:A, 2012, 539(2):13-21. https://www.sciencedirect.com/science/article/pii/S0921509311014493

|

| [18] |

ZHAO Shiteng, MENG Chenlu, MAO Fengxin, et al. Influence of severe plastic deformation on dynamic strain aging of ultrafine grained Al-Mg alloys[J]. Acta Materialia, 2014, 76(2):54-67. https://www.sciencedirect.com/science/article/pii/S1359645414003425

|

| [19] |

毛勇建, 李玉龙, 史飞飞.用经典Hopkinson杆测试弹性模量的初步探讨[J].固体力学学报, 2009, 30(2):170-176. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gtlxxb200902010MAO Yongjian, LI Yulong, SHI Feifei. A discussion on determining Youg's moduli by conventional split Hopkinson bar[J]. Chinese Journal of Solid Mechanics, 2009, 30(2):170-176. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gtlxxb200902010

|

| [20] |

郭鹏程, 钱立和, 孟江英, 等.高锰奥氏体TWIP钢的单向拉伸与拉压循环变形行为[J].金属学报, 2014, 50(4):415-422. http://www.oalib.com/paper/4690981GUO Pengcheng, QIAN Lihe, MENG Jiangying, et al. Monotonic tension and tension-compression cyclic deformation behaviours of high manganese austenitic TWIP steel[J]. Acta Metallurgica Sinica, 2014, 50(4):415-422. http://www.oalib.com/paper/4690981

|

| [21] |

LEE W S, TANG Z C. Relationship between mechanical properties and microstructural response of 6061-T6 aluminum alloy impacted at elevated temperatures[J]. Materials and Design, 2014, 58(6):116-124. https://www.sciencedirect.com/science/article/pii/S026130691400082X

|

| [22] |

胡昌明, 贺红亮, 胡时胜.45号钢的动态力学性能研究[J].爆炸与冲击, 2003, 23(2):188-192. http://www.bzycj.cn/CN/abstract/abstract10045.shtmlHU Changming, HE Hongliang, HU Shisheng. A study on dynamic mechancial behaviors of 45 steel[J]. Explosion and Shock Waves, 2003, 23(2):188-192. http://www.bzycj.cn/CN/abstract/abstract10045.shtml

|

| [23] |

XIE Chao, FANG Qihong, LIU Xiao, et al. Theoretical study on the {1012} deformation twinning and cracking in coarse-grained AM80 magnesium alloys[J]. International Journal of Plasticity, 2016, 82:44-61. doi: 10.1016/j.ijplas.2016.02.001

|

| [24] |

AHMAD I R, SHU D W. Compressive and constitutive analysis of AZ31B magnesium alloy over a wide range of strain rates[J]. Metals and Materials International, 2015, 21(5):823-831. doi: 10.1007/s12540-015-5120-4

|

| [25] |

刘庆.镁合金塑性变形机理研究进展[J].金属学报, 2010, 46(11):1458-1472. https://www.wenkuxiazai.com/doc/52292f28e009581b6ad9eb34.htmlLIU Qing. Research progress on plastic deformation mechanism of Mg alloys[J]. Acta Metallurgica Sinica, 2010, 46(11):1458-1472. https://www.wenkuxiazai.com/doc/52292f28e009581b6ad9eb34.html

|

| [26] |

YANG Yongbiao, WANG Fuchi, TAN Chengwen, et al. Plastic deformation mechanisms of AZ31 magnesium alloy under high strain rate compression[J]. Transactions of Nonferrous Metals Socity of China, 2008, 18(5):1043-1046. doi: 10.1016/S1003-6326(08)60178-8

|

下载:

下载: