| [1] |

钟纬烈.铁电体物理学[M].北京:科学出版社, 1996.

|

| [2] |

杜金梅, 张毅, 张福平, 等.冲击加载下PZT95/5铁电陶瓷的脉冲大电流输出特性[J].物理学报, 2006, 55(5):2584-2589. doi: 10.7498/aps.55.2584DU Jinmei, ZHANG Yi, ZHANG Fuping, et al. Large current out-put of PZT 95/5 ferroelectric ceramics under shock loading[J]. Acta Physica Sinica, 2006, 55(5):2584-2589. doi: 10.7498/aps.55.2584

|

| [3] |

LYSNE P C, PERCIVAL C M. Electric energy generation by shock compression of ferroelectric ceramics: Normal-mode response of PZT 95/5[J]. Journal of Applied Physics, 1975, 46(4):1519-1525. doi: 10.1063/1.321803

|

| [4] |

SETCHELL R E. Shock wave compression of the ferroelectric ceramic Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3: Depoling currents[J]. Journal of Applied Physics, 2005, 97(1):013507. doi: 10.1063/1.1828215

|

| [5] |

SETCHELL R E. Shock wave compression of the ferroelectric ceramic Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3: Hugoniot states and constitutive mechanical properties[J]. Journal of Applied Physics, 2003, 94(1):573-588. doi: 10.1063/1.1578526

|

| [6] |

ZHANG F P, HE H L, LIU G M, et al. Failure behavior of Pb(Zr0.95Ti0.05)O3 ferroelectric ceramics under shock compression[J]. Journal of Applied Physics, 2013, 113(18):183501. doi: 10.1063/1.4803052

|

| [7] |

ZEUCH D H, MONTGOMERY S T, HOLCOMB D J. Uniaxial compression experiments on lead zirconate titanate 95/5-2Nb ceramic: Evidence for an orientation-dependent, "maximum compressive stress" criterion for onset of the ferroelectric to antiferroelectric polymorphic transformation[J]. Journal of Materials Research, 2000, 15(3):689-703. doi: 10.1557/JMR.2000.0102

|

| [8] |

ZEUCH D H, MONTGOMERY S T, HOLCOMB D J. The effects of nonhydrostatic compression and applied electric field on the electromechanical behavior of poled lead zirconate titanate 95/5-2Nb ceramic during the ferroelectric to antiferroelectric polymorphic transformation[J]. Journal of Materials Research, 1999, 14(5):1814-1827. doi: 10.1557/JMR.1999.0245

|

| [9] |

AVDEEV M, JORGENSEN J D, SHORT S, et al. Pressure-induced ferroelectric to antiferroelectric phase transition in Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3[J]. Physical Review B, 2006, 73(6):064105. doi: 10.1103/PhysRevB.73.064105

|

| [10] |

FENG N, NIE H, CHEN X, et al. Depoling of porous Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3 ferroelectric ceramics under shock wave load[J]. Current Applied Physics, 2010, 10(6):1387-1390. doi: 10.1016/j.cap.2010.04.012

|

| [11] |

SETCHELL R E. Shock wave compression of the ferroelectric ceramic Pb0.99(Zr0.95Ti0.05)0.98Nb0.02O3: Microstructural effects[J]. Journal of Applied Physics, 2007, 101(5):053525. doi: 10.1063/1.2697428

|

| [12] |

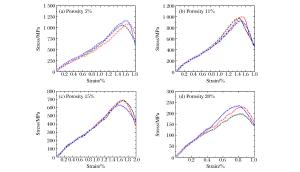

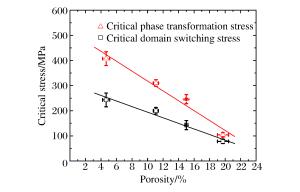

蒋招绣, 辛铭之, 申海艇, 等.多孔未极化Pb(Zr0.95Ti0.05)O3铁电陶瓷单轴压缩力学响应与相变[J].物理学报, 2015, 64(13):134601. doi: 10.7498/aps.64.134601JIANG Zhaoxiu, XIN Mingzhi, SHEN Haiting, et al. Mechanical properties and phase transformation of porous unpoled Pb(Zr0.95Ti0.05)O3 ferroelectric ceramics under uniaxial compression[J]. Acta Physica Sinica, 2015, 64(13):134601. doi: 10.7498/aps.64.134601

|

| [13] |

蒋招绣, 申海艇, 辛铭之, 等.多孔极化PZT95/5铁电陶瓷单轴压缩力学响应与放电特性[J].固体力学学报, 2016, 37(1):50-57. http://www.cqvip.com/QK/95077X/201601/668194836.htmlJIANG Zhaoxiu, SHEN Haiting, XIN Mingzhi, et al. Mechanical properties and depoling of porous poled PZT95/5 ferroelectric ceramics under uniaxial compression[J]. Chinese Journal of Solid Mechanics, 2016, 37(1):50-57. http://www.cqvip.com/QK/95077X/201601/668194836.html

|

| [14] |

王礼立.应力波基础[M].2版.北京:国防工业出版社, 2010.

|

| [15] |

YANG L M, SHIM V P W. An analysis of stress uniformity in split Hopkinson bar test specimens[J]. International Journal of Impact Engineering, 2005, 31(2):129-150. doi: 10.1016/j.ijimpeng.2003.09.002

|

| [16] |

朱珏, 胡时胜, 王礼立.SHPB试验中粘弹性材料的应力均匀性分析[J].爆炸与冲击, 2006, 26(4):315-322. doi: 10.11883/1001-1455(2006)04-0315-08ZHU Jue, HU Shisheng, WANG Lili. Analysis on stress uniformity of viscoelastic materials in split Hopkinson bar tests[J]. Explosion and Shock Waves, 2006, 26(4):315-322. doi: 10.11883/1001-1455(2006)04-0315-08

|

| [17] |

毛勇建, 李玉龙.SHPB试验中试件的轴向应力均匀性[J].爆炸与冲击, 2008, 28(5):448-454. doi: 10.11883/1001-1455(2008)05-0448-07MAO Yongjian, LI Yulong. Axial stress uniformity in specimens of SHPB tests[J]. Explosion and Shock Wave, 2008, 28(5):448-454. doi: 10.11883/1001-1455(2008)05-0448-07

|

| [18] |

SCHREIER H, ORTEU J J, SUTTON M A. Image correlation for shape, motion and deformation measurements[M]. New York: Springer, 2009.

|

| [19] |

FREW D J, FORRESTAL M J, CHEN W. Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar[J]. Experimental Mechanics, 2002, 42(1):93-106. doi: 10.1007/BF02411056

|

| [20] |

LI Q M, MENG H. About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test[J]. International Journal of Solids and Structures, 2003, 40(2):343-360. doi: 10.1016/S0020-7683(02)00526-7

|

| [21] |

FORRESTAL M J, WRIGHT T W, CHEN W. The effect of radial inertia on brittle samples during the split Hopkinson pressure bar test[J]. International Journal of Impact Engineering, 2007, 34(3):405-411. doi: 10.1016/j.ijimpeng.2005.12.001

|

| [22] |

杨卫.力电失效学[M].北京:清华大学出版社, 2000.

|

下载:

下载: