Dynamic constitutive relation based on J-C model of Q235 steel

-

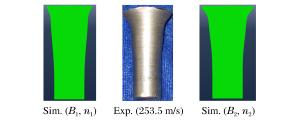

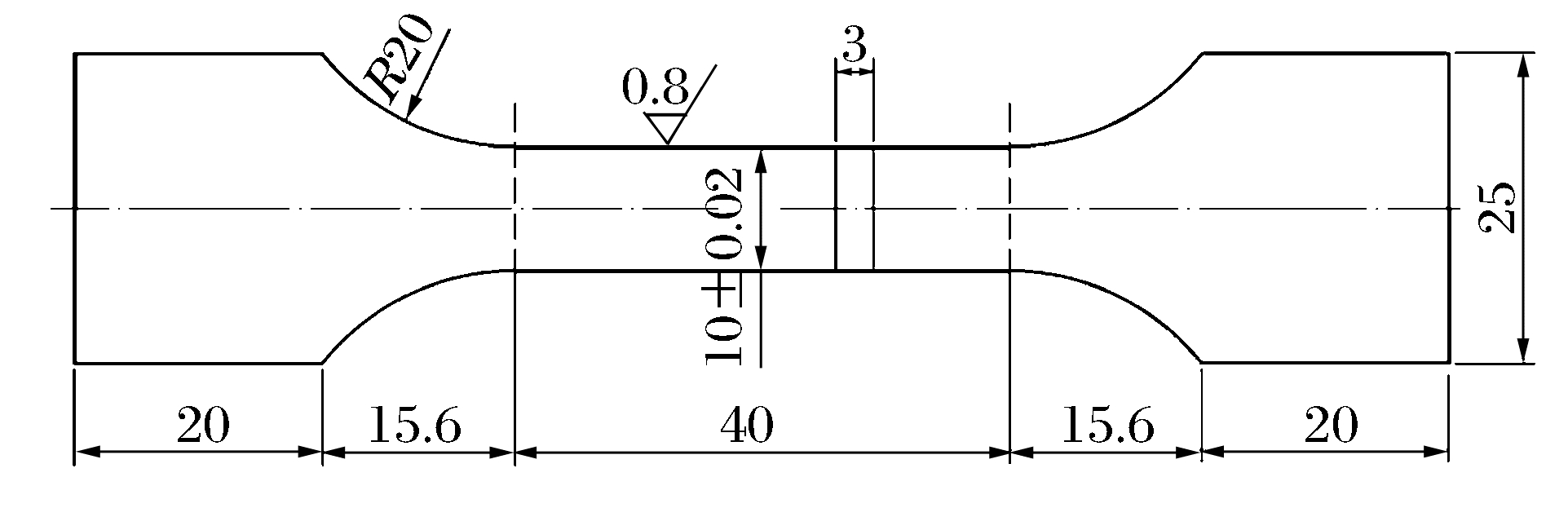

摘要: 采用万能材料试验机、分离式霍普金森压杆和拉杆系统,研究了Q235钢在常温至900 ℃的准静态和动态压缩及拉伸力学性能。基于实验结果,修正了Johnson-Cook(J-C)本构模型中的温度软化项,提出了Q235钢的修正J-C本构模型,并利用Taylor撞击实验和数值仿真验证了其动态本构关系。

-

关键词:

- 动态力学性能 /

- 本构关系 /

- Taylor撞击 /

- Q235钢 /

- Johnson-Cook本构模型

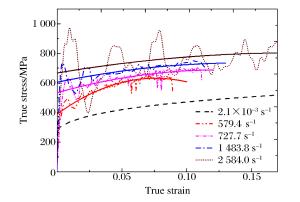

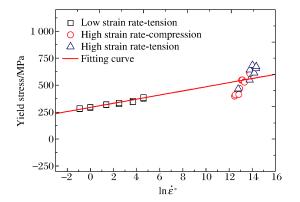

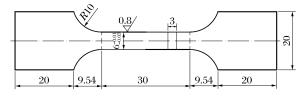

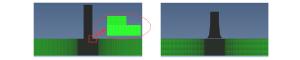

Abstract: In this paper, we studied the quasi-static performance and the dynamic compression and tensile properties of the Q235 steel at temperatures ranging from the room temperature to 900 ℃ using a universal testing machine and the split Hopkinson bar system. Based on the experimental results, we modified the thermal softening item in the Johnson-Cook (J-C) constitutive model and proposed a revised J-C constitutive model for Q235 steel, which we then validated using Taylor impact experiments and corresponding numerical simulations. -

表 1 Q235钢的本构模型参数

Table 1. Parameters of constitutive model for Q235 steel

ρ/(g·cm-3) E/GPa ν Tr/K Tm/K ${{\dot{\varepsilon }}_{0}}$/s-1 χ cp/(J·kg-1·K-1) 7.8 200 0.33 293 1 795 2.1×10-3 0.9 469 A/MPa B/MPa n C m1 m2 m 293.8 230.2 0.578 0.065 2 1.762 1.278 0.706 -

[1] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[C]//Proceedings of the 7th International Symposium on Ballistics. The Hague, Netherlands, 1983: 541-547. https://www.researchgate.net/publication/313069830_A_constitutive_model_and_data_for_metals_subjected_to_large_strains_high_strain_rates_and_high_temperatures [2] ZERILLI F J, ARMSTRONG R W. Dislocation-mechanics-based constitutive relations for material dynamics calculations[J]. Journal of Applied Physics, 1987, 61(5):1816-1825. doi: 10.1063/1.338024 [3] STEINBERG D J, COCHRAN S G, GUINAN M W. A constitutive model for metals applicable at high-strain rate[J]. Journal of Applied Physics, 1980, 51(3):1498-1504. doi: 10.1063/1.327799 [4] 陈小伟, 张方举, 梁斌, 等.A3钢钝头弹撞击45钢板破坏模式的试验研究[J].爆炸与冲击, 2006, 26(3):199-207. doi: 10.11883/1001-1455(2006)03-0199-09CHEN Xiaowei, ZHANG Fangju, LIANG Bin, et al. Three modes of penetration mechanics of A3 steel cylindrical projectiles impact onto 45 steel plates[J]. Explosion and Shock Waves, 2006, 26(3):199-207. doi: 10.11883/1001-1455(2006)03-0199-09 [5] 陈刚, 陈小伟, 陈忠富, 等.A3钢钝头弹撞击45钢板破坏模式的数值分析[J].爆炸与冲击, 2007, 27(5):390-397. doi: 10.11883/1001-1455(2007)05-0390-08CHEN Gang, CHEN Xiaowei, CHEN Zhongfu, et al. Simulations of A3 steel blunt projectiles impacting 45 steel plates[J]. Explosion and Shock Waves, 2007, 27(5):390-397. doi: 10.11883/1001-1455(2007)05-0390-08 [6] CHEN X W, WEI L M, LI J C. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target[J]. International Journal of Impact Engineering, 2015, 79:102-116. doi: 10.1016/j.ijimpeng.2014.11.007 [7] DENG Y F, ZHANG W, CAO Z S. Experimental investigation on the ballistic resistance of monolithic and multi-layered plates against ogival-nosed rigid projectiles impact[J]. Materials and Design, 2013, 44:228-239. doi: 10.1016/j.matdes.2012.06.048 [8] DENG Y F, ZHANG W, YANG Y G, et al. Experimental investigation on the ballistic performance of double-layered plates subjected to impact by projectile of high strength[J]. International Journal of Impact Engineering, 2014, 70:38-49. doi: 10.1016/j.ijimpeng.2014.03.003 [9] 张伟, 肖新科, 郭子涛, 等.双层A3钢靶对平头杆弹的抗侵彻性能研究[J].高压物理学报, 2012, 26(2):163-170. doi: 10.11858/gywlxb.2012.02.007ZHANG Wei, XIAO Xinke, GUO Zitao, et al. Investigation on the ballistic resistance of double-layered A3 steel targets against blunt projectile impact[J]. Chinese Journal of High Pressure Physics, 2012, 26(2):163-170. doi: 10.11858/gywlxb.2012.02.007 [10] 郭子涛, 郭钊, 张伟.单层A3钢薄靶在不同头型弹体斜撞击下的失效模式和防护性能研究[J].振动与冲击, 2018, 37(1):27-31. http://www.doc88.com/p-3049100067915.htmlGUO Zitao, GUO Zhao, ZHANG Wei. Study on failure patterns and ballistic resistance of thin single A3 steel targets obliquely impacted by different nose shape projectiles[J]. Journal of Vibration and Shock, 2018, 37(1):27-31. http://www.doc88.com/p-3049100067915.html [11] 陈俊岭, 舒文雅, 李金威.Q235钢材在不同应变率下力学性能的试验研究[J].同济大学学报(自然科学版), 2016, 44(7):1071-1075. doi: 10.11908/j.issn.0253-374x.2016.07.014CHEN Junling, SHU Wenya, LI Jinwei. Experimental study on dynamic mechanical property of Q235 steel at different strain rates[J]. Journal of Tongji University (Natural Science), 2016, 44(7):1071-1075. doi: 10.11908/j.issn.0253-374x.2016.07.014 [12] JOUN M S, EOM J G, LEE M C. A new method for acquiring true stress-strain curves over a large range of strains using a tensile test and finite element method[J]. Mechanics of Materials, 2008, 40(7):586-593. doi: 10.1016/j.mechmat.2007.11.006 [13] EHLERS S, VARSTA P. Strain and stress relation for non-linear finite element simulations[J]. Thin-Walled Structures, 2009, 47(11):1203-1217. doi: 10.1016/j.tws.2009.04.005 [14] CHOUNG J M, CHO S R. Study on true stress correction from tensile tests[J]. Journal of Mechanical Science and Technology, 2008, 22(6):1039-1051. doi: 10.1007/s12206-008-0302-3 [15] 陈刚, 陈忠富, 陶俊林, 等.45钢动态塑性本构参量与验证[J].爆炸与冲击, 2005, 25(5):451-456. doi: 10.11883/1001-1455(2005)05-0451-06CHEN Gang, CHEN Zhongfu, TAO Junlin, et al. Investigation and validation on plastic constitutive parameters of 45 steel[J]. Explosion and Shock Waves, 2005, 25(5):451-456. doi: 10.11883/1001-1455(2005)05-0451-06 [16] 肖新科. 双层金属靶的抗侵彻性能和Taylor杆的变形与断裂[D]. 哈尔滨: 哈尔滨工业大学, 2010. http://cdmd.cnki.com.cn/Article/CDMD-10213-1011278906.htm [17] BØRVIK T, HOPPERSTAD O S, BERSTAD T, et al. A computational model of viscoplasticity and ductile damage for impact and penetration[J]. European Journal of Mechanics: A/Solids, 2001, 20(5):685-712. doi: 10.1016/S0997-7538(01)01157-3 -

下载:

下载: