Blasting vibration safety criterion for semi-ellipse-shaped shaft wall

-

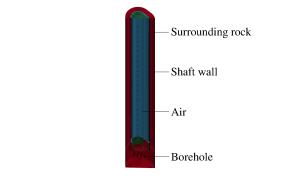

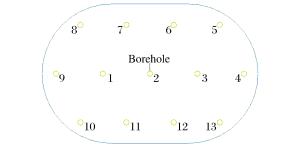

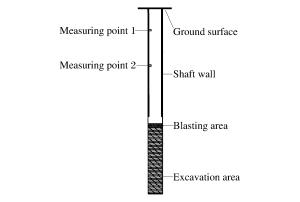

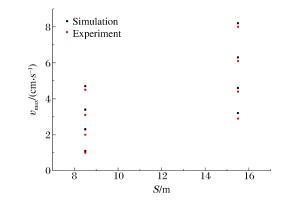

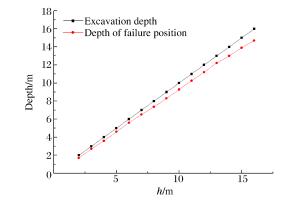

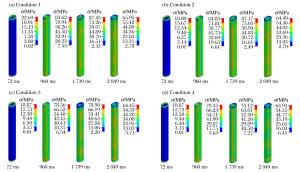

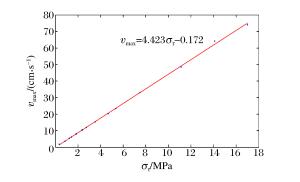

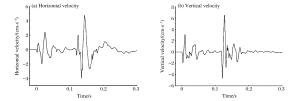

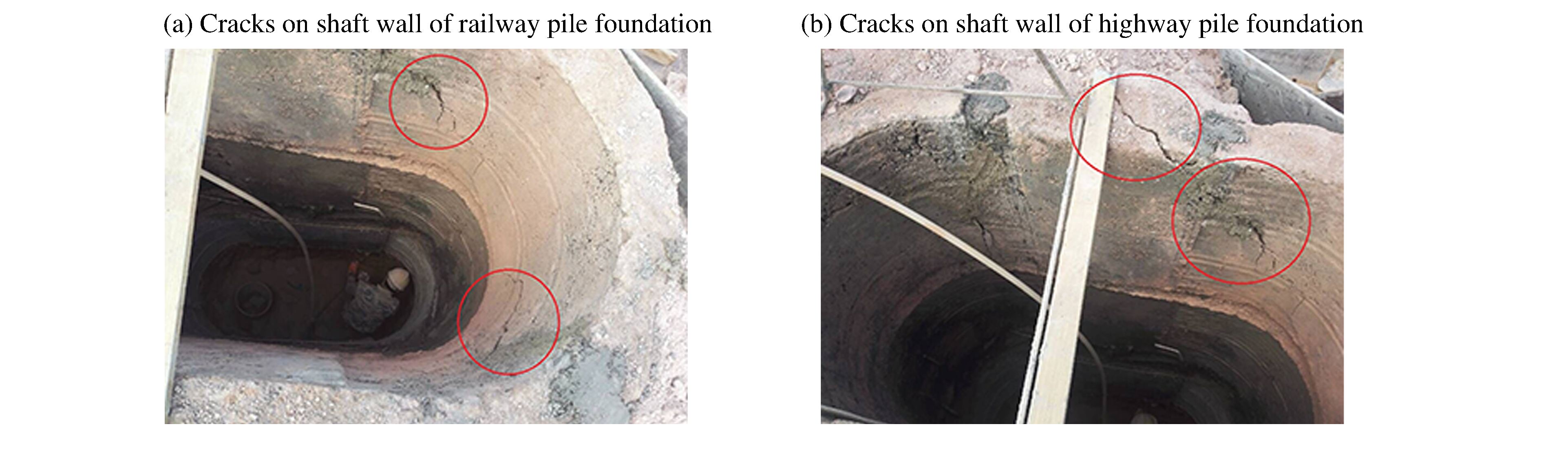

摘要: 钻爆法作为桩基开挖的主要破岩手段,所产生的爆破振动引起桩井护壁结构发生动态响应,进而影响桩井结构的稳定性。利用有限元分析软件ANSYS/LS-DYNA3D,以峰值质点振动速度和有效拉应力作为指标,模拟了椭圆形桩井护壁结构对爆破振动的动态响应。计算结果表明:不同掘井深度的椭圆形桩井护壁对不同段药量爆破振动的动态响应呈相似规律,最大质点峰值振速及峰值拉应力分布一致,均位于护壁井口端的弧形壁部分,响应强度随段药量的减小而减小;护壁结构的峰值拉应力与峰值振速呈线性关系,基于抗拉强度准则,确定了该工程条件下护壁的安全振动速度阈值为8 cm/s,现场测试验证了预设判据的合理性。Abstract: As a major technique for rock breakage, the drill and blast method brings about serious blasting vibration that poses hazards for the structural stability of the shaft wall. In this paper, we simulated the interactive process of the blasting seismic wave and the semi-ellipse-shaped shaft wall using the finite-element numerical software ANSYS/LS-DYNA3D and taking the peak particle velocity (PPV) and the effective tensile stress as the evaluation indexes of the dynamic response. The calculated results indicate that for the shaft walls with different excavation depths there exist similar patterns governing the dynamic response to different maximum charges, and both the peak effective tensile stress and PPV are located at the top arch, whose intensities decrease along with the decrease of the maximum charge. Based on the tensile strength principle and the linear relationship between the peak effective tensile stress and PPV, we established the critical blasting vibration safety criterion as 8 cm/s under the present engineering conditions for this project, and conducted on-site tests which verified the validity of the pre-set criterion.

-

Key words:

- safety vibration velocity /

- shaft wall /

- peak particle velocity

-

表 1 爆破参数

Table 1. Blasting parameters

孔距/mm 排距/mm 炮孔深度/m 药卷直径/mm 单耗/(kg·m-3) 单孔药量/kg 50~80 50~80 1.0(掏槽),0.8(周边) 32 2.6 1.2(掏槽),0.8(周边) 表 2 炸药的材料及状态方程参数

Table 2. Material and EOS parameters of explosive

ρ/(g·cm-3) D/(km·s-1) pCJ/GPa A/GPa B/GPa R1 R2 ω E0/GPa 1.2 4.8 9.7 214.4 18.2 4.2 0.9 0.15 4.192 表 3 岩石材料参数

Table 3. Material parameters of rock

ρ/(g·cm-3) E1/GPa ν σY/GPa E2/GPa β εf 2.7 40 0.22 46 0.04 0.5 0.05 表 4 混凝土材料参数

Table 4. Material parameters of concrete

ρ/(g·cm-3) G/GPa AHJC BHJC CHJC N fc/MPa Tmax/MPa εfmin Smax 2.44 14.86 0.79 1.6 0.007 0.61 48 40 0.01 7 pcr/MPa plock/MPa μcr μlock D1 D2 K1/GPa K2/GPa K3/GPa 160 800 0.001 0.1 0.04 1 85 -171 208 表 5 空气材料参数

Table 5. Material parameters of air

ρ/(kg·m-3) C0 C1 C2 C3 C4 C5 C6 e0/MPa V0 1.25 0 0 0 0 0.4 0.4 0 0.256 1 表 6 测点处峰值振速的模拟与实测结果

Table 6. Simulation and experimental results of peak particle velocity at measuring points

工况 S=15.5 m的圆弧壁中间单元节点的峰值振速/(cm·s-1) S=8.5 m的圆弧与直段连接处单元节点的峰值振速/(cm·s-1) 模拟 实测 模拟 实测 1 4.7 8.0 4.7 4.5 2 6.3 6.1 3.4 3.1 3 4.6 4.4 2.3 2.0 4 3.2 2.9 1.1 1.0 表 7 数值计算结果

Table 7. Numerical calculation results

工况 h/m wmax/kg στ/MPa vmax/(cm·s-1) 1 4 8.0 17.02 74.0 2 4 4.8 14.10 64.1 3 4 4.0 11.14 48.4 4 4 3.6 7.48 33.1 1 8 8.0 5.34 23.4 2 8 4.8 4.67 20.2 3 8 4.0 3.52 15.3 4 8 3.6 2.41 10.4 1 12 8.0 2.73 11.9 2 12 4.8 2.35 10.3 3 12 4.0 1.83 7.8 4 12 3.6 1.22 5.3 1 16 8.0 1.75 7.4 2 16 4.8 1.44 6.4 3 16 4.0 1.12 4.8 4 16 3.6 0.76 3.3 表 8 实测峰值振速

Table 8. Measured peak particle velocities

工况 水平向峰值振速/(cm·s-1) 垂直向峰值振速/(cm·s-1) 测点1 测点2 测点3 测点4 测点1 测点2 测点3 测点4 1 5.9 5.8 6.0 5.9 7.1 7.1 7.1 7.0 2 4.8 4.9 4.8 4.9 6.1 6.2 6.2 6.1 3 3.7 3.5 3.6 3.7 4.5 4.5 4.6 4.5 4 2.6 2.7 2.7 2.7 3.1 3.0 3.1 3.1 -

[1] 蒋楠, 周传波, 罗钢, 等.铁路隧道混凝土衬砌爆破振动安全判据[J].中南大学学报(自然科学版), 2012, 43(7):2746-2750. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zngydxxb201207042JIANG Nan, ZHOU Chuanbo, LUO Gang, et al. Blasting vibration safety criterion of railway tunnel concrete lining[J]. Journal of Central South University (Science and Technology), 2012, 43(7):2746-2750. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_zngydxxb201207042 [2] 李洪涛, 卢文波, 舒大强, 等.P波作用下衬砌混凝土的爆破安全振动速度研究[J].爆炸与冲击, 2007, 27(1):34-39. doi: 10.11883/1001-1455(2007)01-0034-06LI Hongtao, LU Wenbo, SHU Daqiang, et al. Study on the safety velocity for concrete lining under P wave loading[J]. Explosion and Shock Waves, 2007, 27(1):34-39. doi: 10.11883/1001-1455(2007)01-0034-06 [3] 陈明, 卢文波.新浇大坝基础混凝土爆破安全震动速度研究[J].武汉大学学报(工学版), 2004, 37(1):6-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=whsldldxxb200401002CHEN Ming, LU Wenbo. Research on safety vibration velocity for freshly mixed concrete of dam foundation under loading of blasting vibration[J]. Journal of Wuhan University of Hydraulic and Electric Engineering, 2004, 37(1):6-10. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=whsldldxxb200401002 [4] JIANG N, ZHOU C. Blasting vibration safety criterion for a tunnel liner structure[J]. Tunnelling and Underground Space Technology, 2012, 32:52-57. doi: 10.1016/j.tust.2012.04.016 [5] 郝海明, 赵光明, 孟祥瑞.爆破对不同龄期混凝土喷层破坏的数值分析[J].地下空间与工程学报, 2013, 9(1):173-178. http://www.cnki.com.cn/Article/CJFDTotal-BASE201301029.htmHAO Haiming, ZHAO Guangming, MENG Xiangrui. Numerical analysis of blasting on the rupture of concrete spray layer at different ages[J]. Chinese Journal of Underground Space and Engineering, 2013, 9(1):173-178. http://www.cnki.com.cn/Article/CJFDTotal-BASE201301029.htm [6] 易长平. 爆破振动对地下洞室的影响研究[D]. 武汉: 武汉大学, 2005. http://cdmd.cnki.com.cn/Article/CDMD-10486-2006031356.htm [7] OZER U. Environmental impacts of ground vibration induced by blasting at different rock units on the Kadikoy-Kartal metro tunnel[J]. Engineering Geology, 2008, 100(1/2):82-90. https://www.sciencedirect.com/science/article/pii/S001379520800080X [8] NATEGHI R. Prediction of ground vibration level induced by blasting at different rock units[J]. International Journal of Rock Mechanics and Mining Sciences, 2011, 48(6):899-908. doi: 10.1016/j.ijrmms.2011.04.014 [9] JAYASINGHE L B, THAMBIRATNAM D P, PERERA N, et al. Computer simulation of underground blast response of pile in saturated soil[J]. Computers & Structures, 2013, 120:86-95. https://www.sciencedirect.com/science/article/pii/S0045794913000643 [10] BAYRAKTAR A, ALTUNISIK A C, ÖZCAN M. Safety assessment of structures for near-field blast-induced ground excitations using operational modal analysis[J]. Soil Dynamics and Earthquake Engineering, 2012, 39:23-36. doi: 10.1016/j.soildyn.2012.02.005 [11] LU Y, WANG Z, CHONG K. A comparative study of buried structure in soil subjected to blast load using 2D and 3D numerical simulations[J]. Soil Dynamics and Earthquake Engineering, 2005, 25(4):275-288. doi: 10.1016/j.soildyn.2005.02.007 [12] MOBARAKI B, VAGHEFI M. Numerical study of the depth and cross-sectional shape of tunnel under surface explosion[J]. Tunnelling and Underground Space Technology, 2015, 47:114-122. doi: 10.1016/j.tust.2015.01.003 [13] AHMED L, ANSELL A. Structural dynamic and stress wave models for the analysis of shotcrete on rock exposed to blasting[J]. Engineering Structures, 2012, 35:11-17. doi: 10.1016/j.engstruct.2011.10.008 [14] 于亚伦.工程爆破理论与技术[M].北京:冶金工业出版社, 2010. [15] 时党勇.基于ANSYS/LS-DYNA 8.1进行显式动力分析[M].北京:清华大学出版社, 2005:199-216. [16] Century Dynamics Inc. AUTODYN users's manual: Version 12[M]. Oakland: Century Dynamics Inc., 2009. [17] Livermore Software Technology Corporation. LS-DYNA keyword user's manual[M]. Livermore, California: Livermore Software Technology Corporation, 2009. [18] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范[S]. 北京: 中国建筑工业出版社, 2011. [19] NATEGHI R, KIANY M, GHOLIPOURI O. Control negative effects of blasting waves on concrete of the structures by analyzing of parameters of ground vibration[J]. Tunnelling and Underground Space Technology, 2009, 24(6):608-616. doi: 10.1016/j.tust.2009.04.004 [20] 郭仁俊.结构力学[M].北京:中国建筑工业出版社, 2012. [21] 戴俊.岩石动力学特性与爆破理论[M].2版.北京:冶金工业出版社, 2014:91-100. [22] 中华人民共和国国家质量监督检验检疫总局. 爆破安全规程: GB 6722-2014[S]. 北京: 冶金工业出版社, 2014. -

下载:

下载: