Dynamic response of cold-formed thin-wall steel lipped channel under axial impact

-

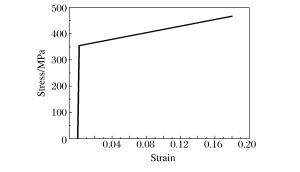

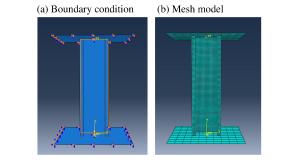

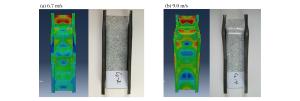

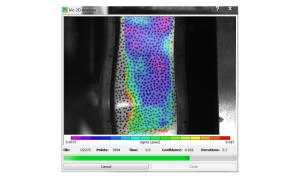

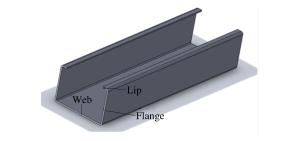

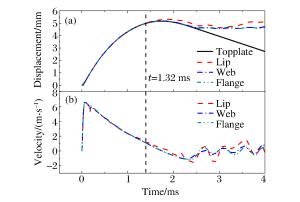

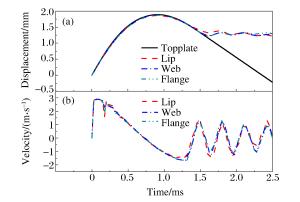

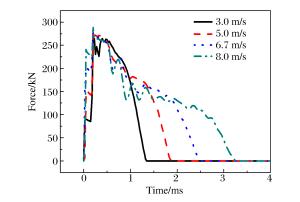

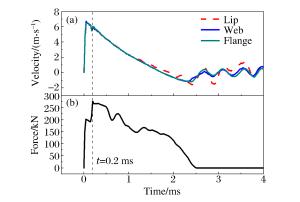

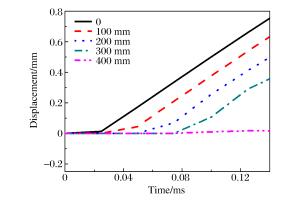

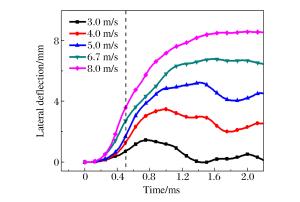

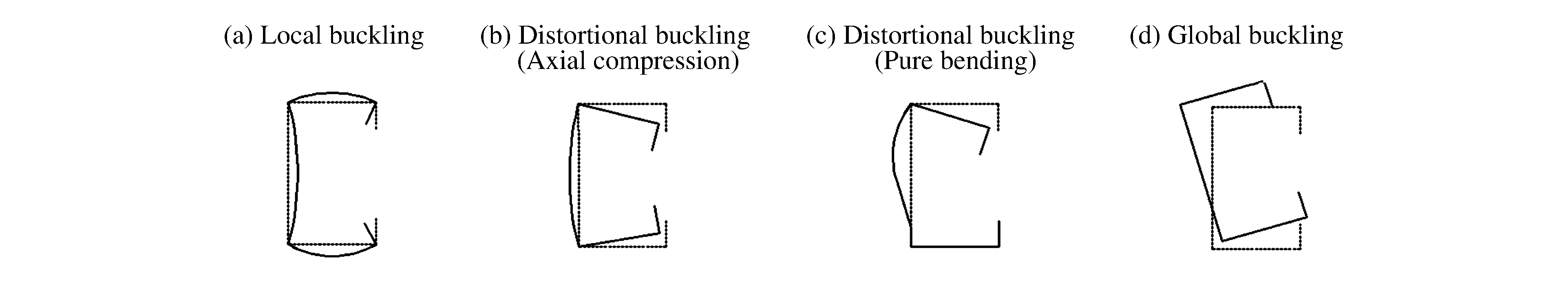

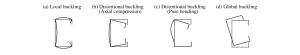

摘要: 针对轴向冲击载荷下C型冷弯薄壁钢构件的动力响应,采用商业有限元软件Abaqus建立了能够反映冲击过程的有限元模型。通过对比有限元模拟和落锤实验中利用数字散斑技术采集的数据以及试样残余变形,验证了数值模型的可靠性。采用该模型分析了在不同冲击速度下翼缘、腹板和卷边质点的轴向位移-时间曲线以及腹板横向挠度的变化,结果表明:在较低冲击能量的作用下,翼缘对卷边的约束作用明显;而在较高冲击能量的加载过程中,冲击端卷边的轴向位移和速度明显大于翼缘和腹板,卷边破坏严重;随着冲击速度的提升,C型冷弯薄壁钢构件的动态屈曲临界载荷相应提升。Abstract: In our study, we established a finite element model using Abaqus, a commercially available software, to simulate the dynamic response of a cold-formed thin-wall steel lipped channel under axial compact, and verified its reliability by the highly consistent data and residual deformation obtained both from the finite element simulation and a drop hammer test. Based on the finite element model, we analyzed the axial displacement histories of the web, the flange and the lip, and the changing process of the web's lateral deflection under different impact energies. The results indicate that the axial displacement and the speed of the lip are significantly greater than those of the web and the flange during the loading process of higher impact energy, while the flange exerts an obvious constraint on the lip under lower impact energy. The dynamic critical load of the cold-formed steel channel under axial impact increases as the impact velocity goes up.

-

Key words:

- steel structure /

- dynamic response /

- drop hammer test /

- axial impact

-

表 1 非线性分析中引入的屈曲模态及比例系数

Table 1. Buckling modes and their proportional coefficients in nonlinear analysis

有限元模态 临界载荷/kN 模态分数/% 模态比重 缺陷幅值 Ⅰ 415.24 22.76 1.00 0.137 Ⅱ 440.53 21.46 0.94 0.129 Ⅲ 461.18 20.50 0.90 0.127 Ⅳ 504.07 18.76 0.84 0.115 Ⅴ 572.11 16.52 0.80 0.169 -

[1] 冷弯薄壁型钢结构技术规范: GB50018-2002[S]. 北京: 中国计划出版社, 2002. [2] AISI. Specification for the design of cold-formed steel structural members, cold-formed steel design manual-Part Ⅴ[M]. Washington D C: American Iron and Steel Institute, 2005. [3] ZEINODDINI V M, SCHAFER B W. Simulation of geometric imperfections in cold-formed steel members using spectral representation approach[J]. Thin-Walled Structures, 2012, 60:105-117. doi: 10.1016/j.tws.2012.07.001 [4] RUSINEK A, ZAERA R, KLEPACZKO J R. Constitutive relations in 3-D for a wide range of strain rates and temperatures-application to mild steels[J]. International Journal of Solids and Structures, 2007, 44(17):5611-5634. doi: 10.1016/j.ijsolstr.2007.01.015 [5] KENNY S, PEGG N, TAHERI F. Dynamic elastic buckling of a slender beam with geometric imperfections subject to an axial impulse[J]. Finite Elements in Analysis and Design, 2000, 35(3):227-246. doi: 10.1016/S0168-874X(99)00067-0 [6] BONADA J, CASAFONT M, ROURE F, et al. Selection of the initial geometrical imperfection in nonlinear FE analysis of cold-formed steel rack columns[J]. Thin-Walled Structures, 2012, 51:99-111. doi: 10.1016/j.tws.2011.10.003 [7] KARAGIOZOVA D, JONES N. Dynamic elastic-plastic buckling phenomena in a rod due to axial impact[J]. International Journal of Impact Engineering, 1996, 18(7/8):919-947. http://www.sciencedirect.com/science/article/pii/S0734743X96000358 [8] 肖刚. 结构在约束下和动力作用下屈曲的数值模拟[D]. 上海: 上海交通大学, 2008. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D060764 [9] VOLMIR S A. Nonlinear dynamics of plates and shells[M]. Moscow: Science, 1972. -

下载:

下载: