Effect of axial pulse magnetic field on shaped charge jet action

-

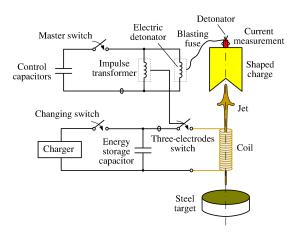

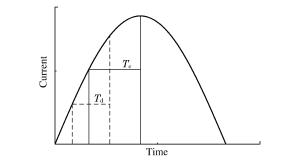

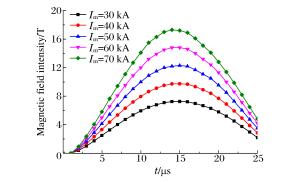

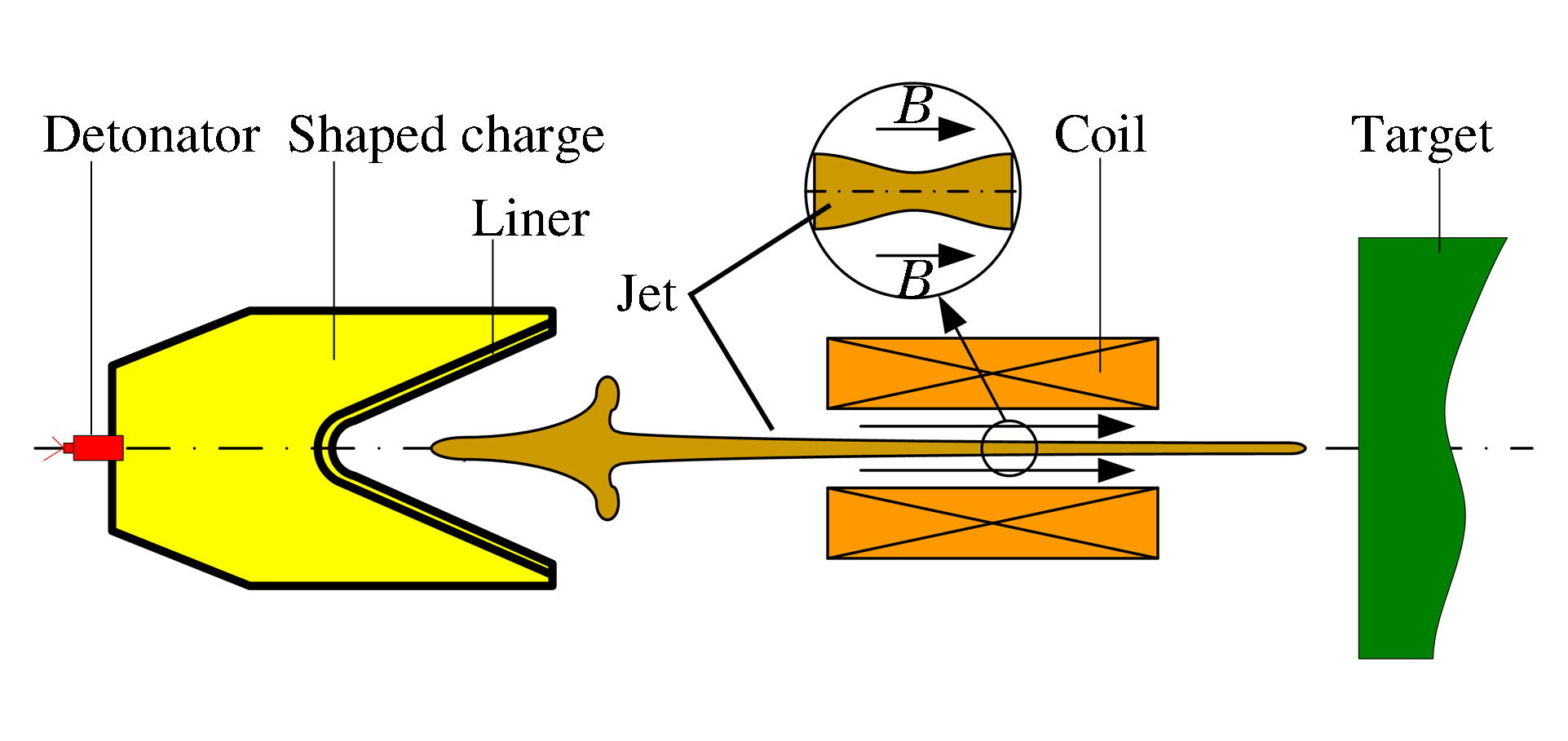

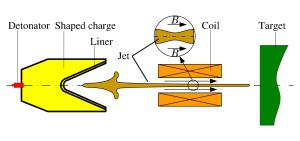

摘要: 为掌握轴向脉冲磁场对金属射流的作用规律,基于破甲弹金属射流对目标的作用原理及磁场与金属射流之间的相互作用关系,设计了励磁线圈对破甲弹金属射流作用的试验系统,并开展了相关实弹试验,突破了金属射流形成和励磁线圈脉冲电流产生之间时序匹配的关键技术,得出了使金属射流发生有效变形的合理储能电容器组电参数和励磁线圈结构参数。试验结果表明,当电容器电压为5 kV、电容为1 200 μF、励磁线圈长度为50 mm时,破甲弹金属射流对目标靶板的侵彻穿深增量最大,破甲效果最佳;各因素对破甲弹金属射流侵彻穿深能力影响程度由大到小分别是电容器组充电电压、电容器组电容、线圈长度。研究成果为破甲弹威力电磁增强技术可行性论证、原理试验及励磁线圈结构设计提供了重要的理论和技术支撑。Abstract: In order to understand the effect of axial pulse magnetic field on the shaped charge jet (SCJ), we designed an experiment system and carried out related experiments based on the mechanism of a high-explosive anti-tank (HEAT) penetrating a target and the interaction between the magnetic field and SCJ, and came up with the key technology to match the time sequence between the formation of SCJ and the pulsed current generation of the coils, which was a major breakthrough. The experiment results show that the increment of the penetration depth for SCJ penetrating the target is largest when the voltage is 5 kV, the capacitor is 1 200 μF and the length of coil is 50 mm. The influence factors of the penetration depth are respectively the charging voltage of the capacitor, the capacitance and the coil length, each in a descending order. These results provide an important theoretical foundation and technical support for the feasibility demonstration, principle test and related physical design of the coil of the enhanced HEAT by the electromagnetic method.

-

Key words:

- axial pulse magnetic field /

- high-explosive anti-tank (HEAT) /

- shaped charge jet /

- pulse current /

- coil

-

表 1 不同充电电压下破甲弹起爆的延时时序

Table 1. Delay time sequence of HEAT firing under different charge voltage

充电电压/kV tc/μs 3 926~1 041 5 418~533 6 368~483 表 2 试验原始数据

Table 2. Experiment data

No. U/kV L/mm C/μF B/T d/mm 1 0 0 0 0 52.10 2 0 50 0 0 56.08 3 0 100 0 0 53.96 4 0 150 0 0 52.90 5 3 100 800 9.68 54.10 6 3 50 1 200 9.74 56.20 7 5 100 1 200 14.84 77.90 8 5 50 800 14.63 77.04 9 5 50 1 200 17.25 97.80 10 6 150 1 200 10.51 58.94 表 3 正交试验因素水平表

Table 3. Orthogonal factor level table

因素水平 U/kV L/mm C/μF 1 3 50 800 2 5 100 1 200 表 4 极差分析

Table 4. Range analysis

分析结果 侵彻深度指标 U L C K1, ave 55.15 66.62 66.57 K2, ave 77.74 66.00 67.05 R 22.59 0.62 1.48 -

[1] 陈少辉, 李治源, 雷彬, 等.大气/钢靶板交界处对平行入射聚能射流干扰的数值模拟[J].爆炸与冲击, 2011, 31(6):630-634. http://www.bzycj.cn/CN/abstract/abstract8748.shtmlCHEN Shaohui, LI Zhiyuan, LEI Bin, et al. Numerical simulation of air/steel target interface effects on parallel injecting shaped charge jet[J]. Explosion and Shock Waves, 2011, 31(6):630-634. http://www.bzycj.cn/CN/abstract/abstract8748.shtml [2] 孙承纬.爆炸物理学[M].北京:科学出版社, 2011:1048-1061. [3] 武双章, 顾文彬, 李旭锋.楔形罩线型聚能装药侵彻钢锭[J].爆炸与冲击, 2016, 36(3):353-358. doi: 10.11883/1001-1455(2016)03-0353-06WU Shuangzhang, GU Wenbin, LI Xufeng. Penetration of steel ingot by linear shaped charge with cuniform cove[J]. Explosion and Shock Waves, 2016, 36(3):353-358. doi: 10.11883/1001-1455(2016)03-0353-06 [4] 祖旭东, 黄正祥, 贾鑫.橡胶复合靶板抗射流侵彻的理论和实验研究[J].爆炸与冲击, 2012, 32(4):376-383. doi: 10.11883/1001-1455(2012)04-0376-08ZU Xudong, HUANG Zhengxiang, JIA Xin. Theoretical and experimental study on rubber composite armor anti-shaped charge jet penetration[J]. Explosion and Shock Waves, 2012, 32(4):376-383. doi: 10.11883/1001-1455(2012)04-0376-08 [5] KARLSSON H. Computer simulation of shaped charge jet fragmentation[C]//The 19th International Symposium on Ballistics. Interlaken, Switzerland, 2001: 819-826. [6] HORSFALL I, PETROU E, CHAMPION S M. Shaped charge attack of spaced and composite armour[C]//The 23th International Symposium on Ballistics. Tarragona, Spain, 2007: 1281-1288. [7] SHVETSOV G A, MATROSOV A D, FEDOROV S V, et al. Electromagnetic control of the shaped-charge effect[C]//The 19th International Symposium of Ballistics. Interlaken, Switzerland, 2001: 851-857. https://www.researchgate.net/publication/267818866_ELECTROMAGNETIC_CONTROL_OF_THE_SHAPED-CHARGE_EFFECT [8] SHVETSOV G A, MATROSOV A D. Qualitative physical model for the disruption of shaped-charge jets by a current pulse[C]//The 20th International Symposium on Ballistics. Orlando, Florida, 2002: 613-619. [9] SHVETSOV G A, MATROSOV A D, FEDOROV S V, et al. Effect of external magnetic fields on shaped-charge operation[J]. International Journal of Impact Engineering, 2011:521-526. http://www.sciencedirect.com/science/article/pii/S0734743X10001703 [10] FEDOROV S V, BABKIN A V, LADOV S V, et al. Magnetic armor as a method of anti-terror protection of objects against shaped-charge action[C]//The 23th International Symposium on Ballistics. Tarragona, Spain, 2007: 1091-1098. http://www.researchgate.net/publication/266346129_MAGNETIC_ARMOR_AS_A_METHOD_OF_ANTITERROR_PROTECTION_OF_OBJECTS_AGAINST_SHAPED-CHARGE_ACTION [11] FEDOROV S V. Magnetic stabilization of elongation of metal shaped charge jets[C]//The 25th International Symposium on Ballistics. Beijing, China, 2010: 967-975. http://www.wanfangdata.com.cn/details/detail.do?_type=conference&id=WFHYXW378921 [12] FEDOROV S V, LADOV S V. Powerful electric discharge as method of anti-shaped-charge protection[C]//The 27th International Symposium on Ballistics. Freiburg, Germany, 2013: 1723-1734. http://www.researchgate.net/publication/290294942_Powerful_electric_discharge_as_method_of_anti_shaped-charge_protection [13] FRED G, JAMES D, CHRIS R, et al. Shaped charge jets driven by electromagnetic energy[C]//The 28th International Symposium on Ballistics. Atlanta, Georgia, 2014: 15-26. -

下载:

下载: