Dynamic response of sandwich beam with foldable core under blast loading

-

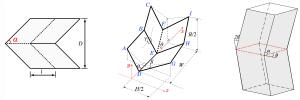

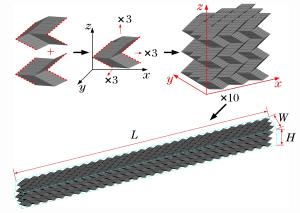

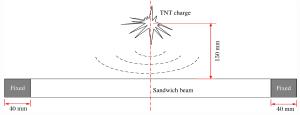

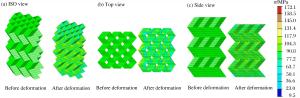

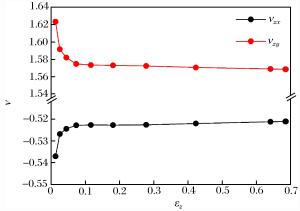

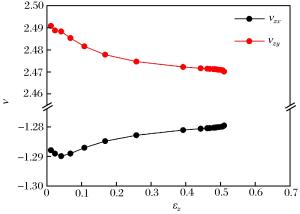

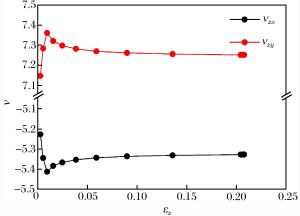

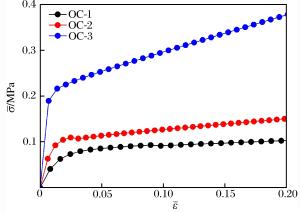

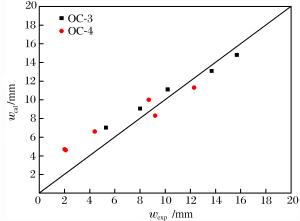

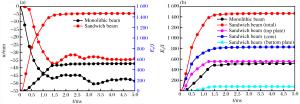

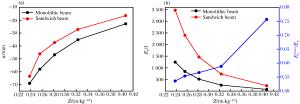

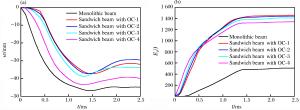

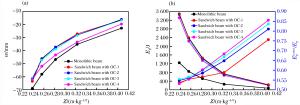

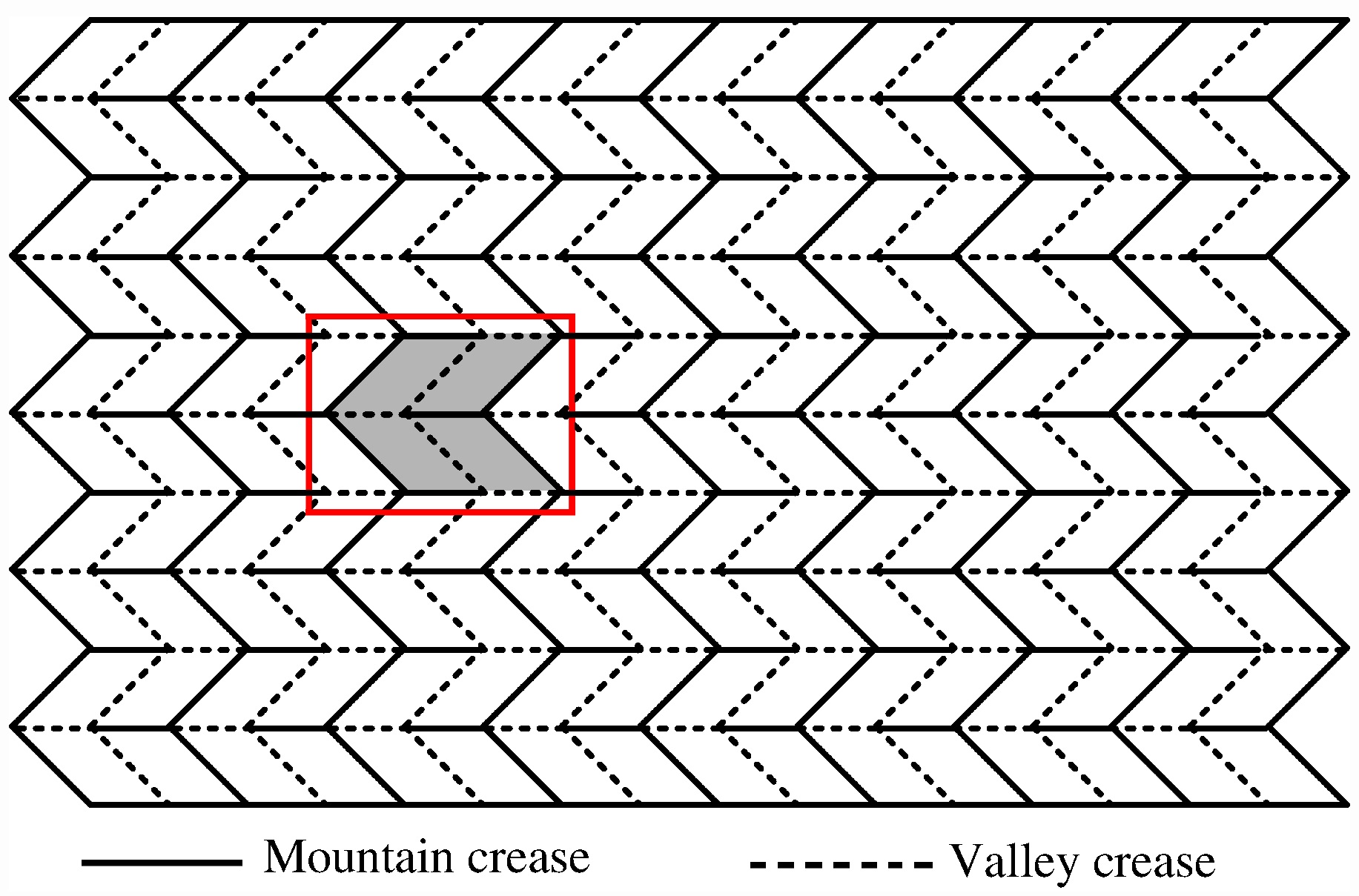

摘要: 基于目前研究最广泛的刚性折纸(Tachi-origami)样式,通过改变其初始折叠角度构建出4种不同的蜂窝胞元,并且通过排列分布将其组成夹芯梁。采用商用有限元软件Abaqus/explicit对准静态和爆炸载荷作用下可折叠芯层夹芯梁的力学响应进行研究,分析可折叠芯层的泊松比变化规律、夹芯梁背板挠度以及能量吸收机理;并将夹芯梁与等质量的实体梁进行对比。采用后面板最大挠度作为抗爆性能的评价,结果发现:可折叠芯层在准静态载荷下具有一定的负泊松比效应;夹芯梁的抗爆性能优于实体梁,曲边蜂窝的初始折角对其作为芯层夹芯梁的抗爆性能有较大影响,随着初始折角的逐渐增大,其抗爆性能逐渐下降;当初始折角为直角时对应于方孔直边蜂窝,其抗爆性能最差。Abstract: In this study four different honeycomb cells were fabricated by changing the original folding angle based on the Tachi-origami pattern that is at present being studied widely, and sandwich beams were made from them by arranging them specifically. The quasi-static mechanical response of the foldable core and dynamic response of the sandwich beam with different foldable core shapes was investigated using the commercial package ABAQUS/explicit. The out-plane Poisson ratio's variation of the foldable core, the back-sheet deflection and the plastic dissipation energy of the sandwich beam were analyzed and compared with the monolithic beam. The anti-explosive performance of the sandwich beams was evaluated by the maximum deflection of the back-sheet. The results show that there is a negative Poisson ratio's performance of the foldable core under quasi-static loading. The blast resistance of the sandwich beam is better than that of the monolithic one. The effect of the original folding angle on the dynamic response is very obvious for the curved web honeycomb. The blast-resistant performance decreases gradually as the original folding angle increases. The blast resistance of the sandwich beam with a straight web honeycomb core is comparatively the worst among the four honeycomb cores.

-

Key words:

- foldable curved web honeycomb /

- sandwich beam /

- dynamic response /

- energy absorption

1) “第十一届全国爆炸力学学术会议”推荐论文 -

表 1 不同蜂窝胞元夹芯梁的几何参数

Table 1. Geometry parameters of different honeycomb core cells

折叠芯层 l/mm D/mm α/(°) β/(°) γ/(°) θ/(°) W/mm H/mm L/mm OC-1 13.66 27.32 45.00 35.27 90.00 60.00 40.98 66.92 725.56 OC-2 11.13 19.28 60.00 26.57 90.00 75.53 40.98 67.69 725.56 OC-3 10.00 19.36 75.00 14.51 90.00 86.16 40.98 67.77 725.56 OC-4 9.66 22.59 90.00 0 90.00 90.00 40.98 67.77 725.56 -

[1] 王志华, 朱峰, 赵隆茂.多孔金属夹芯结构动力学行为及其应用[M].北京:兵器工业出版社, 2010. [2] RUSSELL B P, LIU T, FLECK N A, et al. The soft impact of composite sandwich beams with a square-honeycomb core[J]. International Journal of Impact Engineering, 2012, 48(1):65-81. https://www.sciencedirect.com/science/article/pii/S0734743X11000868 [3] LIU Y, ZHANG X C. The influence of cell micro-topology on the in-plane dynamic crushing of honeycombs[J]. International Journal of Impact Engineering, 2009, 36(1):98-109. doi: 10.1016/j.ijimpeng.2008.03.001 [4] MCSHANE G J, RADFORD D D, DESHPANDE V S, et al. The response of clamped sandwich plates with lattice cores subjected to shock loading[J]. European Journal of Mechanics A/Solids, 2006, 25(2):215-229. doi: 10.1016/j.euromechsol.2005.08.001 [5] LV C, KRISHNARAJU D, KONJEVOD G, et al. Origami based mechanical metamaterials[J]. Scientific Reports, 2014(4):5979.DOI: 10.1038/srep05979. [6] MORI O, SAWADA H, FUNASE R et al. First solar power sail demonstration by IKAROS[J]. Transactions of the Japan Society for Aeronautical and Space Sciences Aerospace Technology Japan, 2010, 8(27):25-31. https://www.researchgate.net/profile/Yasuyuki_Miyazaki/publication/253733249_First_Solar_Power_Sail_Demonstration_by_IKAROS/links/53fa697a0cf20a4549700683.pdf?origin=publication_list [7] TSUDA Y, MORI O, FUNASE R, et al. Flight status of IKAROS deep space solar sail demonstrator[J]. Acta Astronautica, 2011, 69(9):833-840. https://www.researchgate.net/publication/241078802_Flight_status_of_IKAROS_deep_space_solar_sail_demonstrator [8] ZIRBEL S A, LANG R J, THOMSON M W, et al. Accommodating thickness in origami-based deployable arrays[J]. Journal of Mechanical Design, 2013, 135(11):111005-11. doi: 10.1115/1.4025372 [9] LIU Zhengyou, ZHANG Xixiang, MAO Yiwei, et al. Locally resonant sonic materials[J]. Science, 2000, 289(5485):1734-1736.DOI: 10.1126/science.289.5485.1734. [10] MALDOVAN M. Sound and heat revolutions in phononics[J]. Nature, 2013, 503(7475):209-217.DOI: 10.1038/nature12608. [11] GRZESCHIK M, FISCHER S, DRECHSLER K. Potential of high performance foldcores made out of PEEK polymer[C]//SAMPE Europe Technical Conference and "Table-Top" Exhibition 2009. Bristol, United Kingdom, 2009: 94-101. [12] HEIMBS S, MIDDENDORF P, KILCHERT S, et al. Numerical simulation of advanced folded core materials for structural sandwich applications[C]//The 1st European Air and Space Conference. Deutscher Luft-und Raumfahrt Kongress. Berlin, Germany, 2007: 2889-2896. [13] HEIMBS S, MIDDENDORF P, KILCHERT S, et al. Experimental and numerical analysis of composite folded sandwich core structures in compression[J]. Applied Composite Materials, 2007, 14(5/6):363-377. doi: 10.1007/s10443-008-9051-9 [14] HEIMBS S. Virtual testing of sandwich core structures using dynamic finite element simulations[J]. Computational Materials Science, 2009, 45(2):205-216. doi: 10.1016/j.commatsci.2008.09.017 [15] WACHINGER G, ANGERER E, MIDDENDORF P, et al. Impact protection structures for composite fuselage application[C]//SAMPE Europe International Conference. Paris, France, 2008: 271-277. [16] IMBALZANO G, TRAN P, NGO T D, et al. A numerical study of auxetic composite panels under blast loadings[J]. Composite Structures, 2016, 135(1):339-352. https://www.researchgate.net/profile/Tuan_Ngo2/publication/282594124_A_Numerical_Study_of_Auxetic_Composite_Panels_under_Blast_Loadings/links/5614772408ae4ce3cc63c7ae.pdf?inViewer=true&pdfJsDownload=true&disableCoverPage=true&origin=publication_detail [17] GERETTO C, CHUNG KIM YUEN S, NURICK G N. An experimental study of the effects of degrees of confinement on the response of square mild steel plates subjected to blast loading [J]. International Journal of Impact Engineering, 2015(79):32-44.DOI: 10.1016/j.ijimpeng.2014.08.002. [18] YAHAYA M A, RUAN D, LU G, et al. Response of aluminium honeycomb sandwich panels subjected to foam projectile impact: An experimental study[J]. International Journal of Impact Engineering, 2015, 75(1):100-109. https://www.sciencedirect.com/science/article/pii/S0734743X1400181X -

下载:

下载: