Microstructure and erosive resistance of wear-resistant coating on the throttling ring of gun recoil brake

-

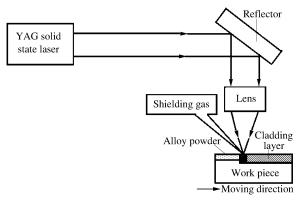

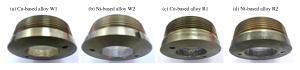

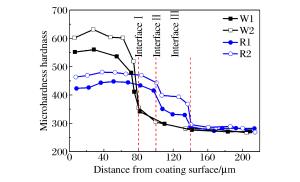

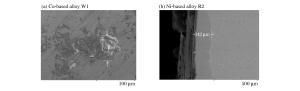

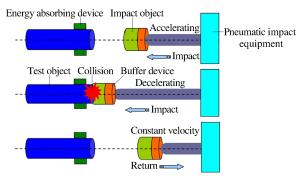

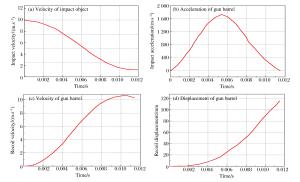

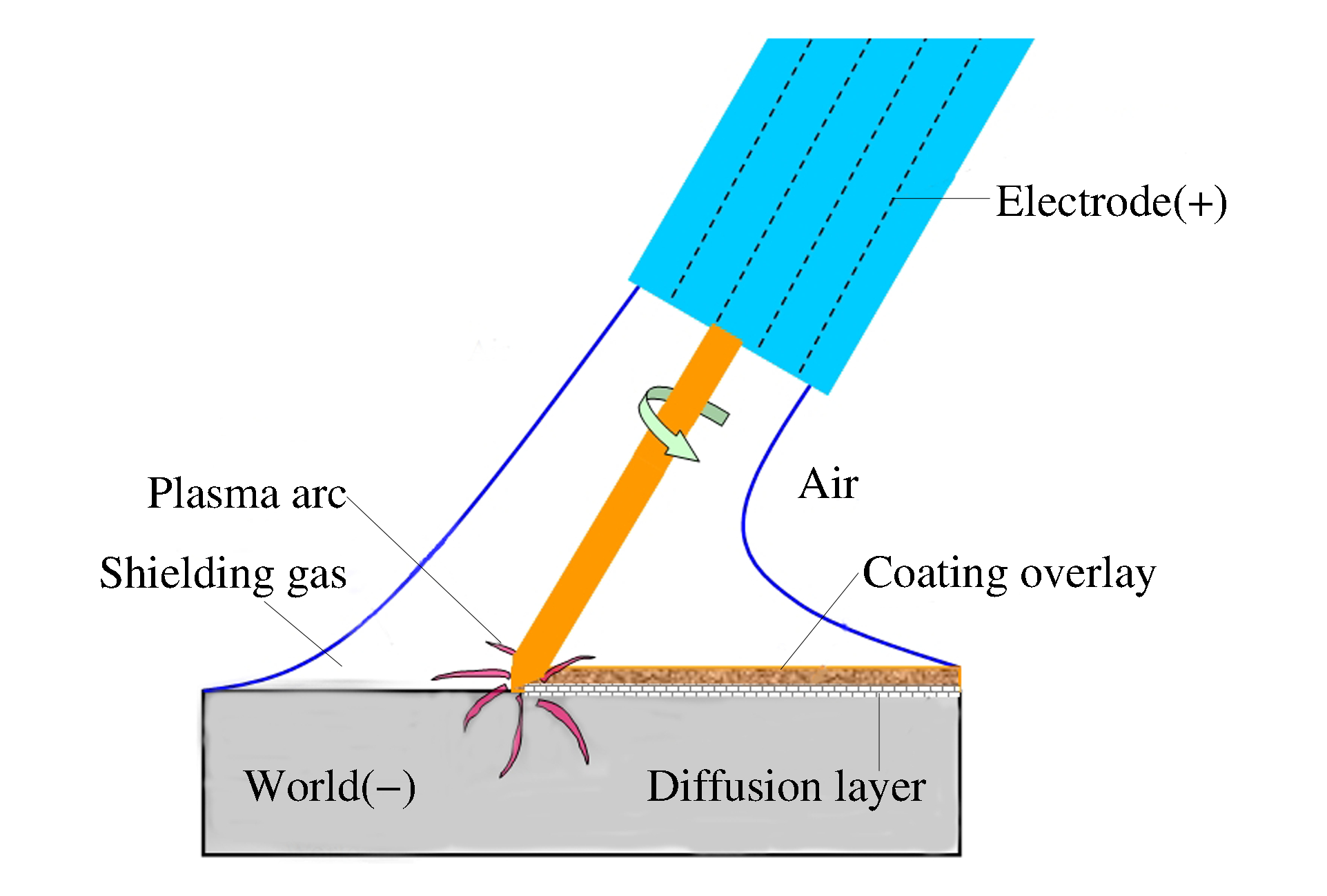

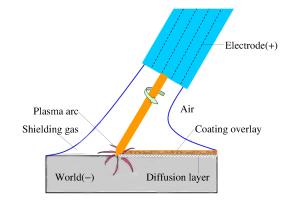

摘要: 火炮驻退机的节制环经常由于冲蚀磨损导致失效。为有效减少节制环磨损程度,提高节制环的可靠性,利用材料表面强化技术,通过微弧沉积与激光熔覆2种技术工艺,制备了铜基合金和镍基合金耐磨涂层,并测试和分析了不同种类涂层的组织形貌、涂层质量及显微硬度。在制备的4种耐磨涂层中,微弧沉积铜基合金涂层和激光熔覆镍基合金涂层的性能较好。为检验合金涂层的实际耐磨性能,在驻退机内安装节制环改进件,在反后坐装置试验台上实施后坐冲击试验。从节制环改进件的磨损形貌和冲蚀磨损量等实验数据得出,激光熔覆镍基合金涂层有较好的耐磨能力,可以作为增强火炮驻退机节制环耐磨能力的有效方法。Abstract: The throttling ring is the key component of a gun recoil brake, erosion wear is the main reason for the failure of the throttling ring. In order to improve the erosive resistance ability and the inherent reliability of throttling ring, with the help of material surface strengthening technology, the wear-resistant alloy coatings on the inner diameter surface of throttling ring were prepared by micro arc deposition and laser cladding coating technology, Cu-based alloy and Ni-based alloy were selected to prepare wear-resistant coatings. Through the microstructure observation, micro hardness test and coating quality comparison of four kinds of wear-resistant coatings, two kinds of coatings were eliminated. In order to test the erosive resistance, the improvd throttling rings were installed on the recoil brake. Erosion wear tests were carried out by recoil mechanism test bench. Wear morphology and wear weight loss of improvement parts are compared under the same conditions. Finally, according to the comprehensive analysis of microstructure, microhardness, energy spectrum and erosion wear test results of wear resistant coatings, it is concluded that the Ni-based alloy coating by laser cladding technology shows the best performance in the above four types of coatings, indicating it is an effective means to improve erosive resistance of the throttling ring.

-

Key words:

- throttling ring /

- erosion wear /

- alloy coating /

- micro arc deposition /

- laser cladding /

- reliability

-

表 1 合金涂层材料成分含量表

Table 1. Element content of alloy coating

(%) 铜基合金 Ni Fe Al Cr Mo C Cu 质量分数 17.5 8.6 6.5 6.0 1.5 0.8 余量 镍基合金 Cr W Fe Cu Si C Ni 质量分数 12.0 8.5 6.0 4.2 1.6 1.0 余量 表 2 微弧沉积涂层工艺参数

Table 2. Process parameters of MAD coating

输出电压/

V放电频率/

Hz电极尺寸/

(mm×mm)输出功率/

kW电极角度/

(°)扫描速度/

(mm·s-1)气体流速/

(L·min-1)80 140 3.2×80 2.0 35 2.6 12 表 3 激光熔覆涂层工艺参数

Table 3. Process parameters of laser cladding coating

粉末厚度/mm 粉末宽度/mm 透镜焦距/mm 激光功率/kW 光斑直径/mm 扫描速度/(mm·s-1) 脉宽/ms 0.4 15 165 2.5 1.75 12 10 表 4 不同合金涂层分析结果对比

Table 4. Quality comparison of four kinds of alloy coatings

样品 涂层显微组织形貌 涂层平均厚度/μm 涂层厚度均匀性 涂层显微硬度 涂层W1(铜基) 无裂纹 80 厚薄不均 560 涂层W2(镍基) 有裂纹 80 厚薄不均 630 涂层R1(铜基) 有裂纹和孔隙 140 均匀致密 440 涂层R2(镍基) 无裂纹 140 均匀致密 460 表 5 节制环改进件的性能参数

Table 5. Performance parameters of improved throttling ring

节制环改进件 涂层显微组织形貌 涂层厚度/

μm图层厚度均匀性 显微硬度 冲蚀磨损量/

g改进件W1

(铜基合金)无裂纹、无孔隙 80 厚薄不均 560 0.47 改进件R2

(镍基合金)无裂纹、无孔隙 140 均匀致密 460 0.26 -

[1] 崔凯波, 秦俊奇, 狄长春, 等.火炮制退机节制环失效微观机理的实验研究[J].爆炸与冲击, 2014, 34(6):736-741. http://www.bzycj.cn/CN/abstract/abstract9410.shtmlCUI Kaibo, QIN Junqi, DI Changchun, et al. Experimental research on microscopic failure mechanism of the throttling ring in a gun recoil brake[J]. Explosion and Shock Waves, 2014, 34(6):736-741. http://www.bzycj.cn/CN/abstract/abstract9410.shtml [2] 王斐, 陈永才, 狄长春, 等.PCrNi3MoVA钢表面微弧沉积Stellite6合金涂层研究[J].热加工工艺, 2015, 44(20):142-145. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=SJGY201520040&dbname=CJFD&dbcode=CJFQWANG Fei, CHEN Yongcai, DI Changchun, et al. Study on micro arc deposit sellite6 alloy coating on PCrNi3MoVA steel surface[J]. Hot Working Technology, 2015, 44(20):142-145. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=SJGY201520040&dbname=CJFD&dbcode=CJFQ [3] 任延杰, 陈荐, 何建军.汽轮机叶片钢表面高能微弧沉积316L不锈钢涂层优化工艺[J].长沙理工大学学报(自然科学版), 2009, 6(1):55-58. doi: 10.3969/j.issn.1672-9331.2009.01.011REN Yanjie, CHEN Jian, HE Jianjun. Optimization of preparation parameters for 316L stainless steel deposition on steam turbine blades by high-energy micro-arc process[J]. Journal of Changsha University of Science & Technology (Natural Science), 2009, 6(1):55-58. doi: 10.3969/j.issn.1672-9331.2009.01.011 [4] HAN B, ZHANG M K, QI C H, et al. Characterization and friction-reduction performances of composite coating produced by laser cladding and ion sulfurizing[J]. Materials Letters, 2015, 150:35-38. doi: 10.1016/j.matlet.2015.02.098 [5] SAQIB S, URBANIC R J, AGGARWAL K. Analysis of laser cladding bead morphology for developing additive manufacturing travel paths[J]. Procedia Cirp, 2014, 17:824-829. doi: 10.1016/j.procir.2014.01.098 [6] SUN R L, LEI Y W, NIU W. Laser clad TiC reinforced NiCrBSi composite coatings on Ti-6Al-4V alloy using a CW CO2 laser[J]. Surface & Coatings Technology, 2009, 203:1395-1399. [7] HE X M, LIU X B, WANG M D, et al. Elevated temperature dry sliding wear behavior of nickel-based composite coating on austenitic stainless steel deposited by a novel central hollow laser cladding[J]. Applied Surface Science, 2011, 258(1):535-541. doi: 10.1016/j.apsusc.2011.08.072 [8] 王少青.阴极微弧沉积制备铝合金热障涂层及数值模拟[D].西安: 西安工业大学, 2013. http://cdmd.cnki.com.cn/Article/CDMD-10702-1013174580.htm [9] 杨艳峰, 郑坚, 狄长春, 等.火炮用PCrMo钢激光熔覆MoS2润滑涂层摩擦学性能研究[J].摩擦学学报, 2016, 36(2):240-246. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=MCXX201602017&dbname=CJFD&dbcode=CJFQYANG Yanfeng, ZHENG Jian, DI Changchun, et al. Tribological properties of MoS2 lubricating coating on gun used PCrMo steel by laser cladding[J]. Tribology, 2016, 36(2):240-246. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=MCXX201602017&dbname=CJFD&dbcode=CJFQ [10] 朱红梅, 龚文娟, 易志威, 等.AZ91镁合金表面激光熔覆Al-Cu合金涂层的组织与性能[J].中国有色金属学报, 2016, 26(7):1498-1504. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201607018ZHU Hongmei, GONG Wenjuan, YI Zhiwei, et al. Microstructure and property of laser cladding Al-Cu alloy coating on surface of AZ91 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(7):1498-1504. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201607018 [11] 宣天鹏.材料表面功能镀覆层及其应用[M].北京:机械工业出版社, 2008. [12] 陈长军, 王茂才, 王东生, 等.高能微弧火花作用下Al-Nd合金在AZ31镁合金表面沉积行为[J].金属热处理, 2009, 34(5):41-45. http://d.old.wanfangdata.com.cn/Periodical/jsrcl200905012CHEN Changjun, WANG Maocai, WANG Dongsheng, et al. Deposition of Al-Nd alloy on surface of AZ31 magnesium alloy by high-energy micro-arc alloying[J]. Heat Treatment of Metals, 2009, 34(5):41-45. http://d.old.wanfangdata.com.cn/Periodical/jsrcl200905012 [13] 陈长军, 王茂才, 刘一鸣, 等.AZ31上高能微弧火花合金化ZM5的研究[J].有色金属, 2008, 60(2):9-13. http://d.old.wanfangdata.com.cn/Periodical/ysjs200802003CHEN Changjun, WANG Maocai, LIU Yiming, et al. Study of high-energy micro-arc alloying ZM5 Mg alloy on AZ31 Mg alloy[J]. Nonferrous Metals, 2008, 60(2):9-13. http://d.old.wanfangdata.com.cn/Periodical/ysjs200802003 [14] 刘延辉.Ti6A14V钛合金表面激光熔覆镍基复合涂层及增强机理研究[D].上海: 华东理工大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10251-1015322686.htm [15] 藏辰峰.辊道辊用20钢表面激光熔覆耐磨损涂层研究[D].沈阳: 东北大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10145-1015562205.htm [16] GUO C, CHEN J M, ZHOU J S. Effects of WC-Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating[J]. Surface & Coatings Technology, 2012, 206:2064-2071. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ0225392939 [17] FERNÁNDEZ M R, GARCÍA A, CUETOS J A. Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC[J]. Wear, 2015, 324-325:80-89. doi: 10.1016/j.wear.2014.12.021 -

下载:

下载: