Explosion suppression effect of CH4/air by combined porous materials in a container piping system

-

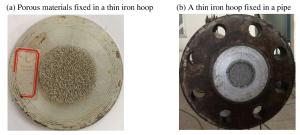

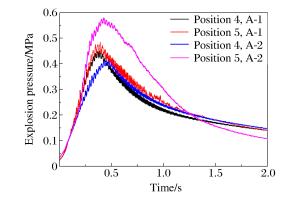

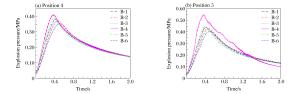

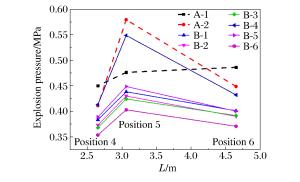

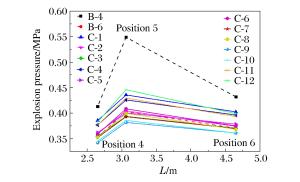

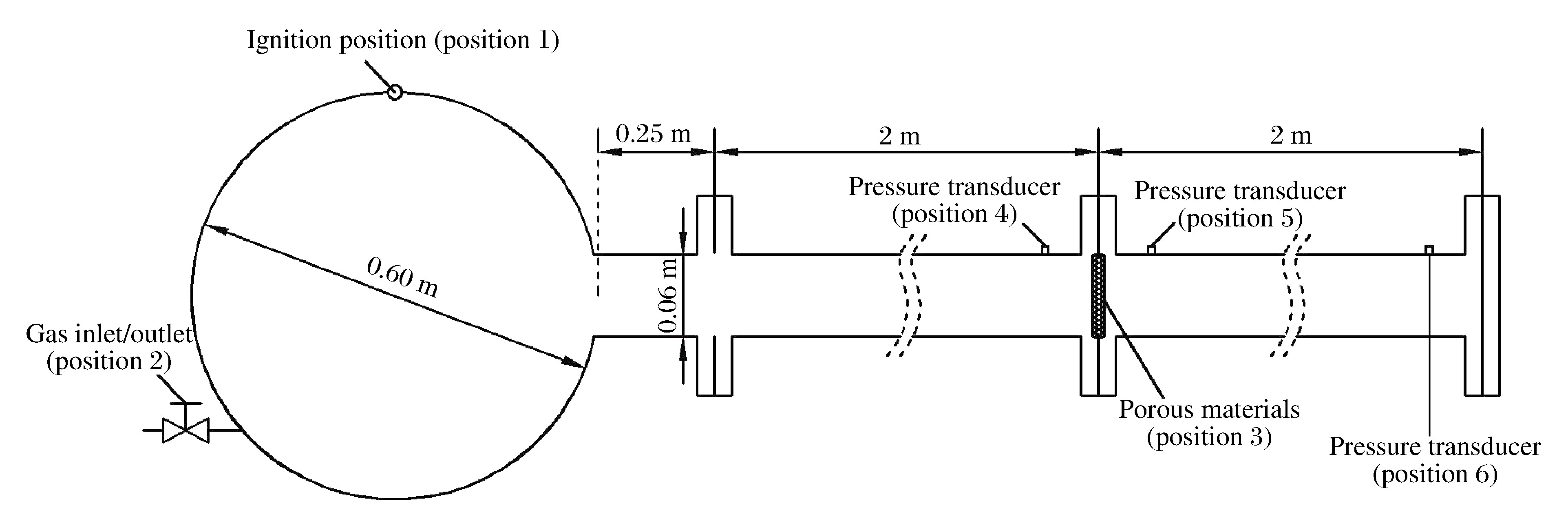

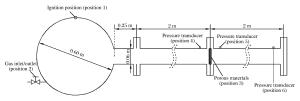

摘要: 为研究多孔材料对可燃气体的抑爆效果,选取了3类6种多孔材料分别组合后进行实验研究。以甲烷/空气预混气体作为研究对象,利用自制薄型铁环将多孔材料固定在密闭容器管道系统内,对比分析了薄型铁环、单层型多孔材料、双层组合型多孔材料和三层组合型多孔材料的抑爆效果。结果表明:薄型铁环增强了气体爆炸强度,铁环后爆炸压力最大;多孔材料抑爆效果明显,双层组合型多孔材料抑爆效果相比单层型多孔材料和三层组合型多孔材料稳定;抑爆效果最佳的组合型多孔材料为Al2O3 10 mm/30 PPI+SiC 20 mm/20 PPI,爆炸压力抑制效果最佳的组合型多孔材料为Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/10 PPI。Abstract: The combinations which were structured from three categories of porous materials including six sub-categories, were tested for studying the suppression effects of the porous materials on the explosion of the combustible gas. The combustible gas was the methane-air mixture. The porous materials were fixed in a closed container piping system by using a self-made thin iron hoop, then the explosion suppression effects of a thin iron hoop, single-layer porous materials, double-layer combination porous materials and three-layer combination porous materials were compared. The results show that the thin iron hoop could enhance the gas explosive intensity and the maximum explosion pressure was achieved behind the iron hoop. The explosion suppression effects of the porous materials were obvious, and the explosion suppression effects of the double-layer combination porous materials were more stable compared to those of the single-type porous materials and the three-layer combination porous materials. The optimized combination of the porous materials for explosion suppression turned out to be Al2O3 10 mm/30 PPI+SiC 20 mm/20 PPI, and the optimized combination of the porous materials for explosion pressure suppression turned out to be Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/10 PPI.

-

表 1 多孔材料几何参数

Table 1. Geometrical parameters of porous materials

多孔材料 厚度/mm 孔径/PPI 体积密度/(g·cm-3) 通孔率/% Fe-Ni 10 90 0.417 2 ≥98 10 40 0.269 4 ≥98 SiC 20 20 0.603 0 80~90 20 10 0.579 5 80~90 Al2O3 10 50 0.580 3 80~90 10 30 0.724 9 80~90 表 2 多孔材料抑爆实验方案

Table 2. Experimental scheme of porous materials for suppressing explosion

分组 实验方案 A (1) None (2) Iron hoop B (1) Fe-Ni 10 mm/90 PPI (2) Fe-Ni 10 mm/40 PPI (3) SiC 20 mm/20 PPI (4) SiC 20 mm/10 PPI (5) Al2O3 10 mm/50 PPI (6) Al2O3 10 mm/30 PPI C (1) Fe-Ni 10 mm/90 PPI+SiC 20 mm/20 PPI (2) Fe-Ni 10 mm/90 PPI+SiC 20 mm/10 PPI (3) Fe-Ni 10 mm/40 PPI+SiC 20 mm/20 PPI (4) Fe-Ni 10 mm/40 PPI+SiC 20 mm/10 PPI (5) Fe-Ni 10 mm/90 PPI+Al2O3 10 mm/50 PPI (6) Fe-Ni 10 mm/90 PPI+Al2O3 10 mm/30 PPI (7) Fe-Ni 10 mm/40 PPI+Al2O3 10 mm/50 PPI (8) Fe-Ni 10 mm/40 PPI+Al2O3 10 mm/30 PPI (9) Al2O3 10 mm/50 PPI+SiC 20 mm/20 PPI (10) Al2O3 10 mm/30 PPI+SiC 20 mm/20 PPI (11) Al2O3 10 mm/50 PPI+SiC 20 mm/10 PPI (12) Al2O3 10 mm/30 PPI+SiC 20 mm/10 PPI D (1) Al2O3 10 mm/50 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/20 PPI (2) Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/20 PPI (3) Al2O3 10 mm/50 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/10 PPI (4) Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/90 PPI+SiC 20 mm/10 PPI (5) Al2O3 10 mm/50 PPI+Fe-Ni 10 mm/40 PPI+SiC 20 mm/20 PPI (6) Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/40 PPI+SiC 20 mm/20 PPI (7) Al2O3 10 mm/50 PPI+Fe-Ni 10 mm/40 PPI+SiC 20 mm/10 PPI (8) Al2O3 10 mm/30 PPI+Fe-Ni 10 mm/40 PPI+SiC 20 mm/10 PPI 表 3 在无多孔材料的情况下密闭容器管道系统内气体爆炸特征参数

Table 3. Characteristic parameters of gas explosion in closed vessel piping system without porous materials

实验编号 pmax/MPa (dp/dt)max/(MPa·s-1) K/(MPa2·s-1) 位置4 位置5 位置4 位置5 位置4 位置5 A-1 0.450 0.476 22.611 19.770 10.175 9.412 A-2 0.411 0.580 6.318 7.179 2.597 4.164 表 4 加入单层型多孔材料后密闭容器管道系统内气体爆炸特征参数

Table 4. Characteristic parameters of gas explosion in closed vessel piping system with single-layer porous materials

实验编号 pmax/MPa (dp/dt)max/(MPa·s-1) K/(MPa2·s-1) 位置4 位置5 位置4 位置5 位置4 位置5 B-1 0.383 0.438 2.445 2.855 0.936 1.250 B-2 0.373 0.430 1.990 2.820 0.742 1.213 B-3 0.368 0.424 1.945 1.810 0.716 0.767 B-4 0.413 0.549 5.330 7.260 2.201 3.986 B-5 0.389 0.449 2.435 2.890 0.947 1.298 B-6 0.354 0.403 1.835 1.840 0.650 0.742 表 5 加入双层组合型多孔材料后密闭容器管道系统内气体爆炸特征参数

Table 5. Characteristic parameters of gas explosion in closed vessel piping system with double-layer combination porous materials

实验编号 pmax/MPa (dp/dt)max/(MPa·s-1) K/(MPa2·s-1) 位置4 位置5 位置4 位置5 位置4 位置5 C-1 0.386 0.436 2.685 2.995 1.036 1.306 C-2 0.360 0.405 3.075 3.160 1.107 1.280 C-3 0.355 0.394 2.495 2.210 0.886 0.871 C-4 0.377 0.426 1.925 2.185 0.726 0.931 C-5 0.362 0.401 2.030 1.825 0.735 0.732 C-6 0.359 0.409 1.785 1.990 0.641 0.814 C-7 0.352 0.393 1.500 1.590 0.528 0.625 C-8 0.353 0.400 2.225 2.630 0.785 1.052 C-9 0.342 0.382 1.545 1.610 0.631 0.615 C-10 0.345 0.386 1.460 1.510 0.504 0.583 C-11 0.377 0.430 2.820 2.870 1.063 1.234 C-12 0.383 0.446 2.890 3.335 1.107 1.487 表 6 加入三层组合型多孔材料后密闭容器管道系统内气体爆炸特征参数

Table 6. Characteristic parameters of gas explosion in closed vessel piping system with three-layer combination porous materials

实验编号 pmax/MPa (dp/dt)max/(MPa·s-1) K/(MPa2·s-1) 位置4 位置5 位置4 位置5 位置4 位置5 D-1 0.354 0.397 4.038 2.290 1.429 0.909 D-2 0.401 0.458 4.340 2.500 1.740 1.145 D-3 0.348 0.392 3.270 1.950 1.138 0.764 D-4 0.334 0.376 3.090 1.975 1.032 0.743 D-5 0.353 0.386 3.720 1.830 1.313 0.706 D-6 0.400 0.460 3.410 3.285 1.364 1.511 D-7 0.362 0.411 3.940 2.130 1.426 0.875 D-8 0.369 0.419 2.295 2.385 0.847 0.999 -

[1] 崔克清, 张礼敬, 陶刚.化工安全设计[M].北京:化学工业出版社, 2004:1-2. [2] ROBERT Z. Deflagration suppression using expanded metal mesh and polymer foams[J]. Journal of Loss Prevention in the Process Industries, 2007, 20(4):659-663. https://www.deepdyve.com/lp/elsevier/deflagration-suppression-using-expanded-metal-mesh-and-polymer-foams-PeaLrTuryo [3] 孙建华, 李艳霞, 魏春荣, 等.泡沫铁镍金属抑制瓦斯爆炸冲击波的实验研究[J].功能材料, 2013, 44(10):1390-1394. doi: 10.3969/j.issn.1001-9731.2013.10.005SUN Jianhua, LI Yanxia, WEI Chunrong, et al. Experimental study on the porous foam iron-nickel metal inhibition of gas explosion wave[J]. Journal of Functional Materials, 2013, 44(10):1390-1394. doi: 10.3969/j.issn.1001-9731.2013.10.005 [4] VASIL'EV A A. Near-limiting detonation in channels with porous walls[J]. Combustion, Explosion, and Shock Waves, 1994, 30(1):101-106. doi: 10.1007/BF00787892 [5] DIAMANTIS D J, MASTORAKOS E, GOUSSIS D A. Simulations of premixed combustion in porous media[J]. Combustion Theory and Modelling, 2002, 6(3):383-411. doi: 10.1088/1364-7830/6/3/301 [6] JOO H I, DUNCAN K, CICCARELLI G. Flame quenching performance of ceramic foam[J]. Combustion Science and Technology, 2006, 178(10/11):1755-1769. doi: 10.1080/00102200600788692?needAccess=true [7] 喻健良, 蔡涛, 李岳, 等.丝网结构对爆炸气体淬熄的试验研究[J].燃烧科学与技术, 2008, 14(2):97-100. http://cdmd.cnki.com.cn/Article/CDMD-10141-2005070890.htmYU Jianliang, CAI Tao, LI Yue, et al. Experiment to quench explosive gas with structure of wire mesh[J]. Journal of Combustion Science and Technology, 2008, 14(2):97-100. http://cdmd.cnki.com.cn/Article/CDMD-10141-2005070890.htm [8] NIE B, HE X, ZHANG R, et al. The roles of foam ceramics in suppression of gas explosion overpressure and quenching of flame propagation[J]. Journal of Hazardous Materials, 2011, 192(2):741-747. doi: 10.1016/j.jhazmat.2011.05.083 [9] 魏春荣, 徐敏强, 王树桐, 等.多孔材料抑制瓦斯爆炸火焰波的实验研究[J].中国矿业大学学报, 2013, 42(2):206-213. http://www.cnki.com.cn/Article/CJFDTotal-ZGKD201302007.htmWEI Chunrong, XU Minqiang, WANG Shutong, et al. Experiment of porous materials for suppressing the gas explosion flame wave[J]. Journal of China University of Mining and Technology, 2013, 42(2):206-213. http://www.cnki.com.cn/Article/CJFDTotal-ZGKD201302007.htm [10] 石油化工静电接地设计规范: SH/T 3097-2017[S]. 北京: 国家石油和化学工业局, 2000: 6. [11] 尤明伟, 喻源, 蒋军成, 等.不同管长条件下连通容器预混气体的爆炸[J].燃烧科学与技术, 2012, 18(3):256-259. http://www.oalib.com/paper/5140604YOU Mingwei, YU Yuan, JIANG Juncheng, et al. Premixed flammable gas explosion in containers connected by pipes with different lengths[J]. Journal of Combustion Science and Technology, 2012, 18(3):256-259. http://www.oalib.com/paper/5140604 [12] CUI Y Y, WANG Z R, ZHOU K B, et al. Effect of wire mesh on double-suppression of CH4/air mixture explosions in a spherical vessel connected to pipelines[J]. Journal of Loss Prevention in the Process Industries, 2017, 45:66-77. https://www.researchgate.net/publication/272390393_A_high-precision_method_for_calculating_the_pressure_drop_across_wire_mesh_filters [13] ZHANG J, SUN Z, ZHENG Y, et al. Coupling effects of foam ceramics on the flame and shock wave of gas explosion[J]. Safety Science, 2012, 50(4):797-800. doi: 10.1016/j.ssci.2011.08.031 [14] OH K H, KIM H, KIM J B, et al. A study on the obstacle-induced variation of the gas explosion characteristics[J]. Journal of Loss Prevention in the Process Industries, 2001, 14(6):597-602. doi: 10.1016/S0950-4230(01)00054-7 [15] 韩丰磊. 多孔材料抑制火焰传播的实验研究及数值模拟[D]. 大连: 大连理工大学, 2008: 27-34. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1247906 [16] SUN J, YI Z, WEI C, et al. The comparative experimental study of the porous materials suppressing the gas explosion[J]. Procedia Engineering, 2011, 26:954-960. doi: 10.1016/j.proeng.2011.11.2262 -

下载:

下载: