Impact-induced initiation criteria of PTFE/Al by split Hopkinson pressure bar

-

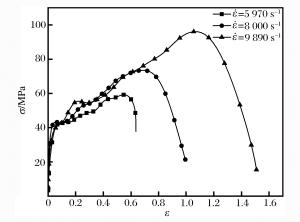

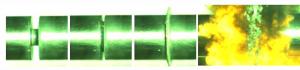

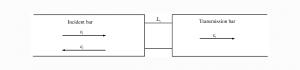

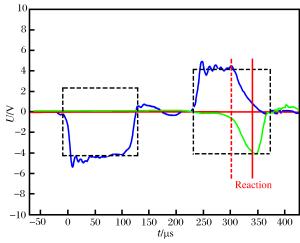

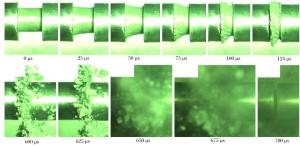

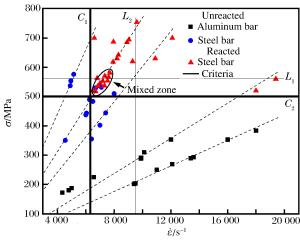

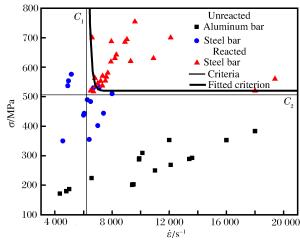

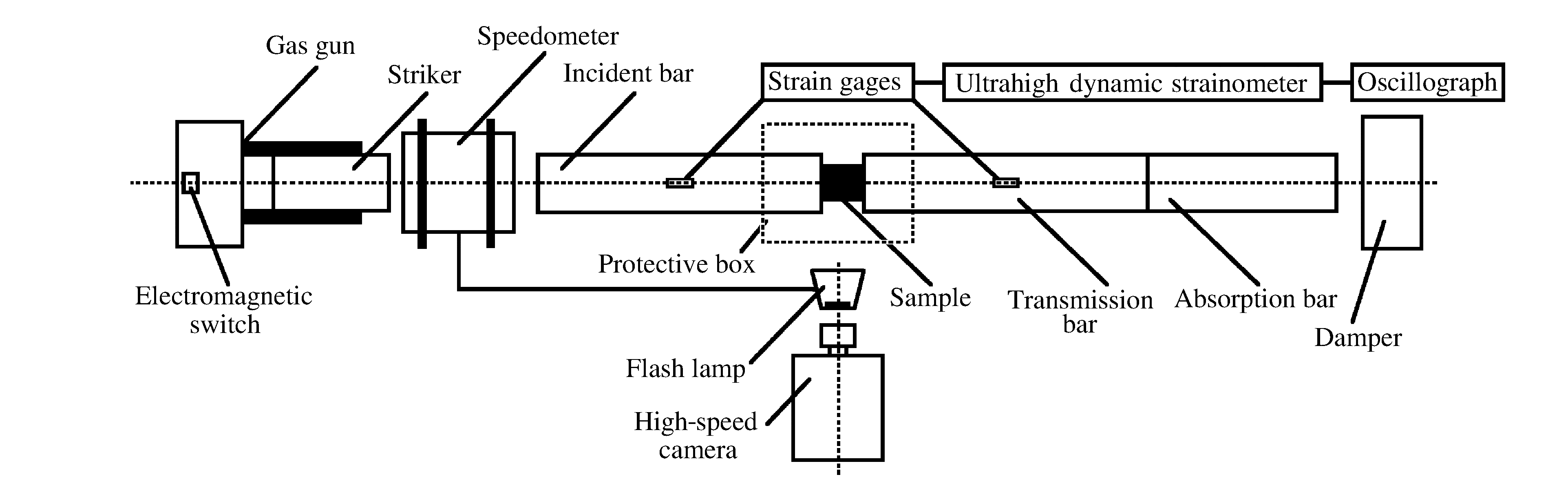

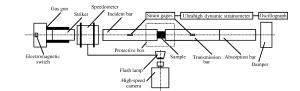

摘要: 采用分离式霍普金森压杆(SHPB)加载方法和高速摄影技术,对混合压制烧结法制备的铝颗粒增强聚四氟乙烯复合材料(polytetrafluoroethylene/Al,PTFE/Al)的冲击反应临界条件进行研究。实验中采用钢杆、铝杆和不同尺寸的试样,进行不同加载条件下的测试,实验结果表明:PTFE/Al复合材料的冲击反应过程主要可分为变形、碎裂、反应阶段,其冲击反应临界同时关联于应力和应变率。并基于实验获得了PTFE/Al复合材料的冲击反应临界渐进线应力和应变率,通过对实验数据的归纳和分析,初步提出实验条件下关联应力和应变率的PTFE/Al临界反应关系式,获得冲击反应阈值预测曲线。Abstract: Impact-induced initiation criteria of Al particles reinforced PTFE (PTFE/Al) prepared by compression/sintering were studied by split Hopkinson pressure bar (SHPB) and high speed photography in this work. SHPB systems comprising of either steel or aluminum bars were applied to test PTFE/Al samples of different dimensions, in order to study the effect of the impact stress and the loading strain rate on the impact-induced initiation behaviors of PTFE/Al. It shows that the impact-induced initiation process of PTFE/Al mainly includes the deformation, fragmentation and reaction, which is simultaneously related to the impact stress and the loading strain rate. Based on the experimental results, the criteria of impact stress and loading strain rate for the impact-induced initiation of PTFE/Al have been obtained. Moreover, an analytical expression of impact-induced initiation criteria including impact stress and loading strain rate was established and a theoretical curve was predicted for the impact-induced initiation events of PTFE/Al under SHPB tests.

-

Key words:

- PTFE/Al /

- split Hopkinson pressure bar /

- impact-induced reaction /

- reaction criteria

-

表 1 SHPB冲击加载实验结果

Table 1. Experimental results of SHPB impact loading

编号 压杆材质 应变率/s-1 应力/MPa 反应 1 铝 9400 202 否 2 钢 9300 620 是 3 钢 7200 553 是 4 钢 7400 444 否 5 钢 4950 554 否 6 铝 5000 187 否 表 2 SHPB冲击加载实验参数

Table 2. Parameters for SHPB impact loading experiment

图号 压杆材质 试样尺寸 冲击速度/(m·s-1) 应变率/s-1 应力/MPa 脉冲宽度/μs 反应 6 钢 $\emptyset $6 mm×4 mm 28 6840 535 120 是 7 铝 $\emptyset $6 mm×3 mm 31 9400 202 120 否 8 钢 $\emptyset $8 mm×8 mm 43 5150 576 120 否 -

[1] JOSHI V S. Process for making polytetrafluoroethylene-aluminium composite andproduct made: US6547993B1[P]. 2003. [2] 乔良, 涂建, 赵利军, 等.A1/W/PTFE粒径级配关系对材料强度影响的实验研究[J].兵器材料科学与工程, 2014, 37(6):17-21. doi: 10.3969/j.issn.1004-244X.2014.06.005QIAO Liang, TU Jian, ZHAO Lijun, et al. Influence of particle sizegrading on strength of A1/W/PTFE composite[J]. Ordnance Material Science and Engineering, 2014, 37(6):17-21. doi: 10.3969/j.issn.1004-244X.2014.06.005 [3] 阳世清, 徐松林, 张彤.PTFE/Al反应材料制备工艺及性能[J].国防科技大学学报, 2008, 30(6):40-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gfkjdxxb200806009YANG Shiqing, XU Songlin, ZHANG Tong. Preparation and performance of PTEF/Al reactive materials[J]. Journal of National University of Defense Technology, 2008, 30(6):40-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gfkjdxxb200806009 [4] 赵鹏铎, 卢芳云, 李俊玲, 等.活性材料PTFE/Al动态压缩性能[J].含能材料, 2009, 17(4):459-462. doi: 10.3969/j.issn.1006-9941.2009.04.020ZHAO Pengduo, LU Fangyun, LI Junling, et al. The dynamic compressive properties of Al/PTFE reactive materials[J]. Chinese Journal of Energetic Materials, 2009, 17(4):459-462. doi: 10.3969/j.issn.1006-9941.2009.04.020 [5] 徐松林.Al/PTFE含能反应材料力学性能研究[D].长沙: 国防科技大学, 2010.XU Songlin. Study on the mechanical performance of Polytetrafluorethylene/Al energetic reactive materials[D]. Changsha: National University of Defense Technology, 2010. [6] 王海福, 刘宗伟, 俞为民, 等.活性破片能量输出特性试验研究[J].北京理工大学学报, 2009, 29(8):663-666. http://lib.cqvip.com/qk/81668X/200001/31768611.htmlWANG Haifu, LIU Zongwei, YU Weimin, et al. Experimental investigation of energy release characteristics of reactive fragments[J]. Transactions of Beijing Institute of Technology, 2009, 29(8):663-666. http://lib.cqvip.com/qk/81668X/200001/31768611.html [7] ZHANG X F, SHI A S, QIAO L, et al. Experimental study on impact-initiated characters of multifunctional energetic structural materials[J]. Journal of Applied Physics, 2013, 113(8):083508. doi: 10.1063/1.4793281 [8] 帅俊峰, 蒋建伟, 王树有, 等.复合反应破片对钢靶侵彻的实验研究[J].含能材料, 2009, 17(6):722-725. doi: 10.3969/j.issn.1006-9941.2009.06.019SHUAI Junfeng, JIANG Jianwei, WANG Shuyou, et al. Compound reactive fragment penetrating steel target[J]. Chinese Journal of Energetic Materials, 2009, 17(6):722-725. doi: 10.3969/j.issn.1006-9941.2009.06.019 [9] 谢长友, 蒋建伟, 帅俊峰, 等.复合反应破片对柴油油箱的毁伤效应实验研究[J].高压物理学报, 2009, 23(6):447-452. doi: 10.3969/j.issn.1000-5773.2009.06.008XIE Changyou, JIANG Jianwei, SHUAI Junfeng, et al. Experimental study on the damage effect of compound reactive fragment penetrating diesel oil tank[J]. Chinese Journal of High Pressure Physics, 2009, 23(6):447-452. doi: 10.3969/j.issn.1000-5773.2009.06.008 [10] 辛春亮, 史文卿, 张雷雷, 等.活性药型罩聚能装药子弹对钢锭的毁伤效应研究[C]//第6届含能材料与钝感弹药技术学术研讨会论文集.成都, 2014. [11] GE C, DONG Y X, MAIMAITITUERSUN W. Microscale simulation on mechanical properties of Al/PTFE composite based on real microstructures[J]. Materials, 2016, 9(7):590.DOI: 10.3390/ma9070590. [12] 乌布力艾散·麦麦提图尔荪, 葛超, 董永香, 等.基于Al/PTFE真实细观特性统计模型的宏观力学性能模拟[J].复合材料学报, 2016, 33(11):9-17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201611016MAIMAITITUERSUN Wubuliaisan, GE Chao, DONG Yongxiang, et al. Simulation on mechanical properties of Al/PTFE based on mesoscopic statistical model[J]. Acta Materiae Compositae Sinica, 2016, 33(11):9-17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201611016 [13] AMES R G. Vented chamber calorimetry for impact-initiated energetic materials[C]//43rd AIAA Aerospace Sciences Meeting and Exhibit. Reno, Nevada, 2005. [14] LEE R J, JR W M, CARNEY J R, et al. Reactive materials studies[C]//Proceedings of the Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter. AIP Publishing, 2006: 169-174. [15] FENG B, FANG X, LI Y C, et al. An initiation phenomenon ofAl/PTFE under quasi-static compression[J]. Chemical Physics Letters, 2015, 637:38-41. doi: 10.1016/j.cplett.2015.07.056 [16] HUNT E M, MALCOLM S, PANTOYA M L, et al. Impact ignition of nano and micron composite energetic materials[J]. International Journal of Impact Engineering, 2009, 36(6):842-846. doi: 10.1016/j.ijimpeng.2008.11.011 [17] MOCK W, DROTAR J T. Effect of aluminum particle size on the impact initiation of pressed ptfe/Al composite rods[C]//Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter. American Institute of Physics, 2007: 971-974. [18] 任会兰, 李尉, 刘晓俊, 等.钨颗粒增强铝/聚四氟乙烯材料的冲击反应特性[J].兵工学报, 2016, 37(5):872-878. doi: 10.3969/j.issn.1000-1093.2016.05.014REN Huilan, LI Wei, LIU Xiaojun, et al. Reaction behaviors of AI/PTFE materials enhanced by W particles[J]. Acta Armamentarii, 2016, 37(5):872-878. doi: 10.3969/j.issn.1000-1093.2016.05.014 [19] WANG L, LIU J X, LI S K, et al. Investigation on reaction energy, mechanical behavior and impact insensitivity of W-PTFE-Al composites with different W percentage[J]. Material and Design, 2016, 92:397-404. doi: 10.1016/j.matdes.2015.12.045 [20] 徐松林, 阳世清, 赵鹏铎, 等.PTFE/Al含能复合材料的压缩力学行为研究[J].力学学报, 2009, 41(5):708-712. doi: 10.3321/j.issn:0459-1879.2009.05.013XU Songlin, YANG Shiqing, ZHAO Pengduo, et al. The study on the compressive behavior of Al/PTFE energetic composite[J]. Chinese Journal of Theoretical and Applied Mechanics, 2009, 41(5):708-712. doi: 10.3321/j.issn:0459-1879.2009.05.013 [21] GE C, DONG Y X, MAIMAITITUERSUN W, et al. Experimental study on impact-induced initiation thresholds of polytetrafluoroethylene/aluminum composite[J]. Propellants Explosives Pyrotechnics, 2017, 42:514-522. DOI: 10.1002/prep.201600216. [22] CHEN W, SONG B. Split Hopkinson (Kolsky) bar:Design testing and application[M]. New York:Spring, 2011. [23] YAVUZ H, TUFEKCI K, KAYACAN R, et al. Predicting the dynamic compressive strength of carbonate rocks from quasi-static properties[J]. Experimental Mechanics, 2013, 53(3):367-376. doi: 10.1007/s11340-012-9648-7 [24] Herbold E B, Nesterenko V F, Benson D J, et al. Particle size effect on strength, failure, and shock behavior in polytetrafluoroethylene-Al-W granular composite materials[J]. Journal of Applied Physics, 2008, 104(10):103903. DOI: 10.1063/1.3000631. -

下载:

下载: