Dynamic response of existing large oil storage tank under blasting excavation vibration

-

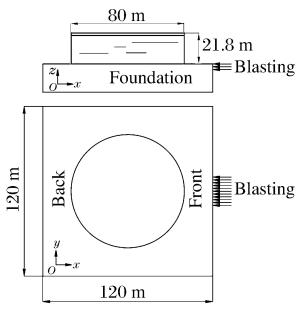

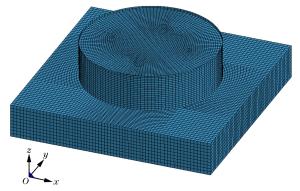

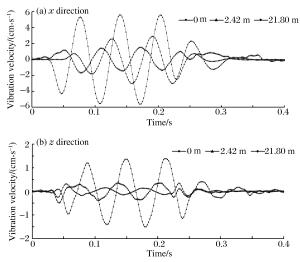

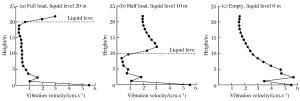

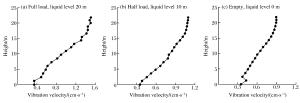

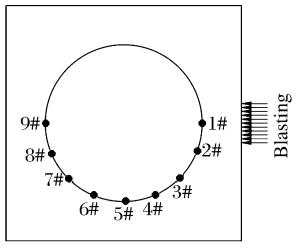

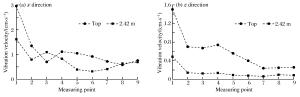

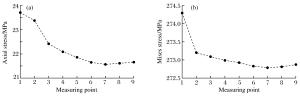

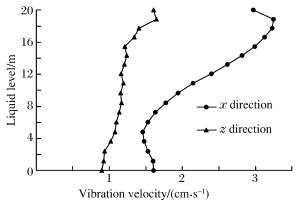

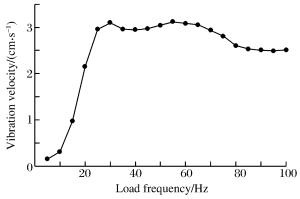

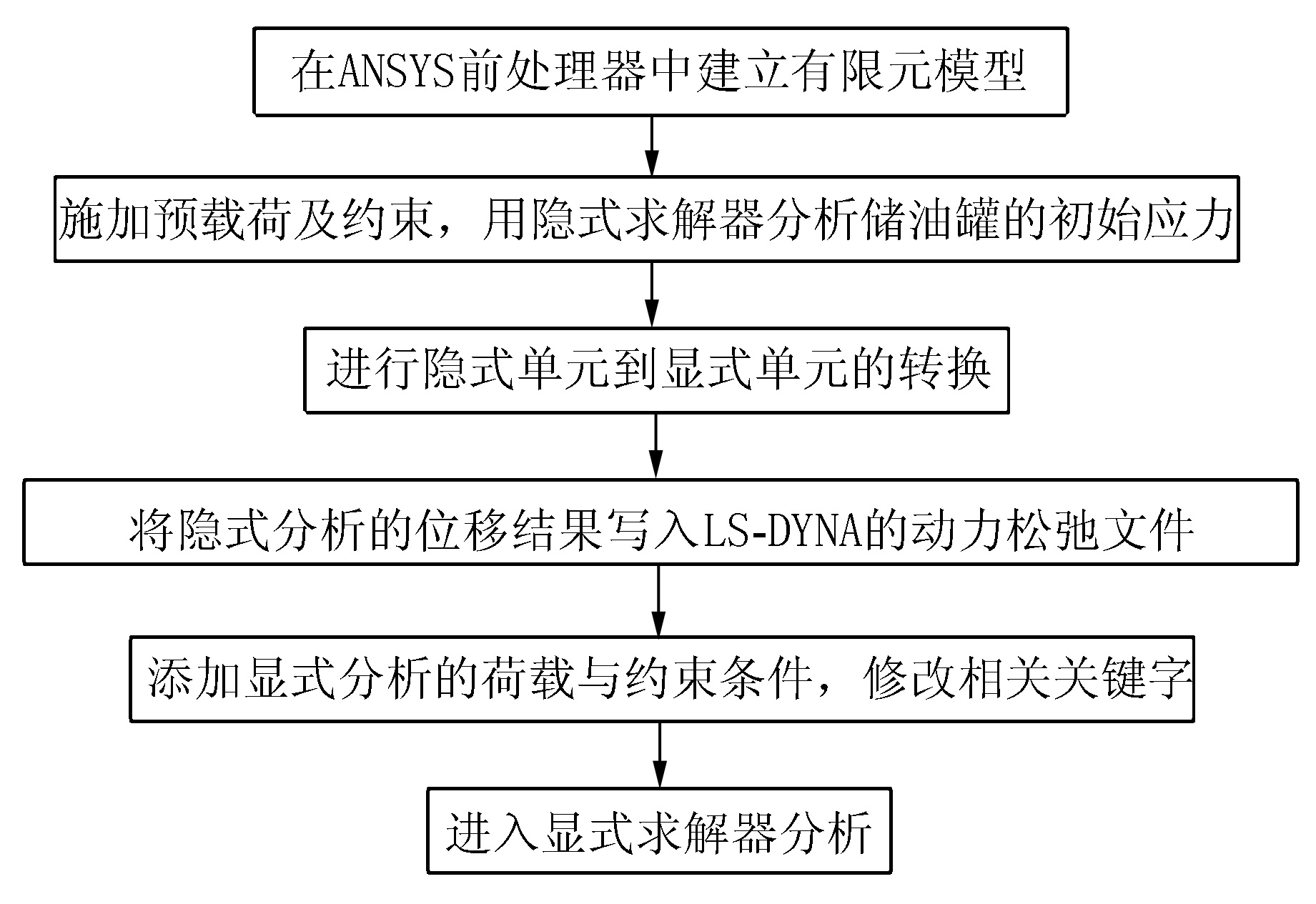

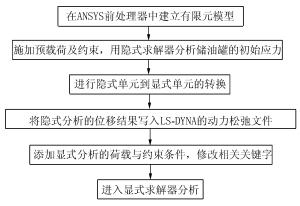

摘要: 针对既有大型储油罐近区基础爆破开挖中的安全问题,采用ANSYS/LS-DYNA的隐式-显式顺序求解方法,结合流固耦合算法,研究了爆破振动下大型储油罐的动力响应规律。分析了罐壁不同位置的质点振速,由于质点振速分布情况较为复杂,不宜用局部质点振速判断罐壁危险点;总结了罐壁上应力的分布规律,结果显示爆破振动对储油罐的影响主要集中在迎爆侧下部,且在罐壁迎爆侧高度为3 m左右的位置最易发生象足屈曲;分析了不同频率爆破振动作用下满载储罐罐壁的质点振速,结果表明在爆破振动主频范围内,载荷频率远大于储罐固有频率条件下,罐壁上质点振速随着爆破振动频率的降低呈减小趋势;建立了储油罐罐壁质点振速与罐内液面高度的关系,结果表明降低液面高度可以有效提高储油罐的爆破振动安全阈值,爆破施工中邻近储罐储液高度不宜高于10 m。Abstract: Aiming at the safety problem of existing large oil tank under near base blasting excavation, the dynamic response of large oil tank is analyzed by numerical simulation method, based on the implicit-to-explicit sequential solution procedure and the fluid solid coupling algorithm of ANSYS/LS-DYNA. different positions are obtained, by which it is not appropriate to determine the dangerous point of the tank wall because the distributions of the particle vibration velocities are very complex. The dynamic stress distribution on the tank wall is summarized, and the results show that the influence of blasting vibration on the oil tank is mainly concentrated on the lower part of the explosion side, and that the elephant foot buckling deformation is most likely produced at the height of 3 meters on the detonation side of tank wall; The particle vibration velocity of the tank wall under different frequency of blasting vibration is analyzed. The results show that in the main frequency range of blasting vibration, the particle vibration velocity on the tank wall decreases with the decrease of blasting vibration frequency if the load frequency is much larger than the natural frequency of the tank; The relationship between the particle vibration velocity and the liquid level in the tank is established, and the results show that lowering the height of liquid level can effectively improve the safety threshold of blasting vibration of the oil tank, and the storage liquid height of adjacent storage tanks should not be higher than 10 m for blasting operations.

-

Key words:

- implicit-to-explicit /

- fluid solid coupling /

- blasting /

- large oil storage tank /

- dynamic response

-

表 1 罐壁详细参数

Table 1. Detailed parameters of tank wall

层数 壁厚/mm 层高/mm 材料 1 32.0 2 420 SPV490Q 2 27.0 2 420 SPV490Q 3 21.5 2 420 SPV490Q 4 18.5 2 420 SPV490Q 5 15.0 2 420 SPV490Q 6 12.0 2 420 SPV490Q 7 12.0 2 420 SPV490Q 8 12.0 2 380 Q-235A.F 9 12.0 2 380 Q-235A.F 表 2 材料基本参数

Table 2. Basic parameters of the materials

材料 E/GPa μ ρ/(kg·m-3) ν/(MPa·s) G/GPa Et/GPa σs/MPa 罐体 210.00 0.30 7 850 - - 22.06 490 基础 - 0.25 2 700 - 15.40 - - 液体 2.18 - 1 000 1.13 - - - 空气 0 - 1.20 - - - - 表 3 储油罐前20阶模态

Table 3. The first 20 modes of storage tank

阶 频率/Hz 流固耦合模态

(本文)空罐模态 本文 文献[9] 1 0.357 27 1.151 6 1.153 7 2 0.357 32 1.151 6 1.153 7 3 0.358 18 1.159 3 1.161 9 4 0.358 18 1.159 3 1.161 9 5 0.363 38 1.164 1 1.165 4 6 0.363 38 1.164 1 1.165 4 7 0.365 83 1.190 1 1.192 8 8 0.365 89 1.190 1 1.192 8 9 0.376 52 1.194 2 1.194 2 10 0.376 57 1.194 2 1.194 2 11 0.380 07 1.239 3 1.237 3 12 0.380 07 1.239 3 1.237 3 13 0.396 89 1.246 5 1.249 4 14 0.396 89 1.246 5 1.249 4 15 0.400 39 1.297 3 1.292 3 16 0.400 46 1.297 3 1.292 3 17 0.424 61 1.331 4 1.334 5 18 0.424 65 1.331 4 1.334 5 19 0.426 53 1.366 2 1.356 6 20 0.426 53 1.366 2 1.356 6 -

[1] 陈志平, 沈建民, 葛颂, 等.基于组合圆柱壳理论的大型油罐应力分析[J].浙江大学学报(工学版), 2006, 40(9):1633-1637. doi: 10.3785/j.issn.1008-973X.2006.09.035CHEN Zhiping, SHEN Jianmin, GE Song, et al. Stress analysis of large oil storage tanks based on combined cylindrical shell[J]. Journal of Zhejiang University (Engineering Science), 2006, 40(9):1633-1637. doi: 10.3785/j.issn.1008-973X.2006.09.035 [2] 张云峰, 袁朝庆, 孙建刚.储罐三维地震响应分析[J].东北石油大学学报, 2003, 27(2):71-74. doi: 10.3969/j.issn.2095-4107.2003.02.023ZHANG Yunfeng, YUAN Zhaoqing, SUN Jiangang. Seismic response analysis of three-dimension tank[J]. Journal of Northeast Petroleum University, 2003, 27(2):71-74. doi: 10.3969/j.issn.2095-4107.2003.02.023 [3] 孙建刚, 王振, 杨宇, 等.模型储罐三维地震反应振动台试验研究[J].地震工程与工程振动, 2008, 28(5):122-132. http://d.old.wanfangdata.com.cn/Periodical/dzgcygczd200805017SUN Jiangang, WANG Zhen, YANG Yu, et al. Finite element analysis of 3D seismic response of unanchored liquid storage tanks[J]. Earthquake Engineering and Engineering Vibration, 2008, 28(5):122-132. http://d.old.wanfangdata.com.cn/Periodical/dzgcygczd200805017 [4] 孙建刚, 张丽, 袁朝庆.立式储罐基础隔震动力反应特性分析[J].地震工程与工程振动, 2001, 21(3):140-144. doi: 10.3969/j.issn.1000-1301.2001.03.025SUN Jiangang, ZHANG Li, YUAN Zhaoqing. Dynamic characteristic analysis of base isolation for vertical storage tank[J]. Earthquake Engineering and Engineering Vibration, 2001, 21(3):140-144. doi: 10.3969/j.issn.1000-1301.2001.03.025 [5] 孙建刚, 郝进锋, 刘扬, 等.考虑摆动效应的立式储罐隔震分析筒化力学模型[J].振动与冲击, 2016, 35(11):20-27. http://d.wanfangdata.com.cn/Periodical/zdycj201611004SUN Jiangang, HAO Jinfeng, LIU Yang, et al. Simplified mechanical model for vibration isolation analysis of a vertical storage tank considering swinging effect[J]. Journal of Vibration and Shock, 2016, 35(11):20-27. http://d.wanfangdata.com.cn/Periodical/zdycj201611004 [6] 王开志, 杨旭升, 梁秋祥.某部储油罐基础开挖爆破设计[J].工程爆破, 2016, 22(4):77-81. doi: 10.3969/j.issn.1006-7051.2016.04.016WANG Kaizhi, YANG Xusheng, LIANG Qiuxiang. Blast design of oil storage tank foundation excavation[J]. Engineering Blasting, 2016, 22(4):77-81. doi: 10.3969/j.issn.1006-7051.2016.04.016 [7] 许红涛.岩石高边坡爆破动力稳定性研究[D].武汉: 武汉大学, 2006. http://cdmd.cnki.com.cn/Article/CDMD-10486-2008010820.htm [8] 张艳.高层结构地震放大作用及反应分析[D].哈尔滨: 中国地震局工程力学研究所, 2011. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D152445 [9] 毕先志, 张巨伟, 崔晓韵, 等.10×104 m3浮顶储油罐的模态分析[J].当代化工, 2011, 40(9):972-974. doi: 10.3969/j.issn.1671-0460.2011.09.027BI Xianzhi, ZHANG Juwei, CUI Xiaoyun, et al. Modal analysis of 10×104 m3 floating roof storage tank[J]. Contemporary Chemical Industry, 2011, 40(9):972-974. doi: 10.3969/j.issn.1671-0460.2011.09.027 [10] 钱七虎, 陈士海.爆破地震效应[J].爆破, 2004, 21(2):1-5. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb200805009QIAN Qihu, CHEN Shihai. Blasting seismic effect[J]. Blasting, 2004, 21(2):1-5. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb200805009 [11] 于蕾.爆破振动对多层建筑物的安全影响[J].铁道工程学报, 2015, 32(3):86-89. doi: 10.3969/j.issn.1006-2106.2015.03.018YU Lei. Safety influence of blasting vibration on multistory building[J]. Journal of Railway Engineering Society, 2015, 32(3):86-89. doi: 10.3969/j.issn.1006-2106.2015.03.018 [12] 戴鸿哲, 王伟, 吴灵宇.立式储液罐提离机理及"象足"变形产生原因[J].哈尔滨工业大学学报, 2008, 40(8):1189-1193. doi: 10.3321/j.issn:0367-6234.2008.08.003DAI Hongzhe, WANG Wei, WU Lingyu. Uplift mechanism and elephant foot bulging of elevated liquid-storage tank[J]. Journal of Harbin Institute of Technology, 2008, 40(8):1189-1193. doi: 10.3321/j.issn:0367-6234.2008.08.003 [13] AGHAJARI S, ABEDI K, SHOWKATI H. Buckling and post-buckling behavior of thin-walled cylindrical steel shells with varying thickness subjected to uniform external pressure[J]. Thin-Walled Structures, 2006, 44(8):904-909. doi: 10.1016/j.tws.2006.08.015 [14] HÜBNER A, TENG J G, SAAL H. Buckling behaviour of large steel cylinders with patterned welds[J]. International Journal of Pressure Vessels & Piping, 2006, 83(1):13-26. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ026060501 [15] 高富强, 张光雄, 杨军.爆破地震荷载作用下建筑结构的动力响应分析[J].爆破, 2015(1):5-10. http://d.old.wanfangdata.com.cn/Periodical/bp201501002GAO Fuqiang, ZHANG Guangxiong, YANG Jun. Dynamic response analysis of building structure under blasting seismic loads[J]. Blasting, 2015(1):5-10. http://d.old.wanfangdata.com.cn/Periodical/bp201501002 [16] 李瑞涛.爆破地震波叠加规律实验研究[D].沈阳: 东北大学, 2008. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1844171 -

下载:

下载: