J-C model based failure criterion and verification of Q235 steel

-

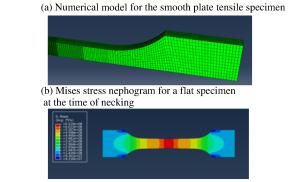

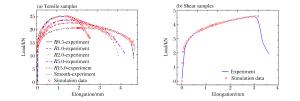

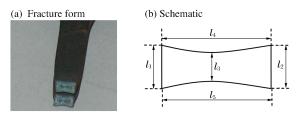

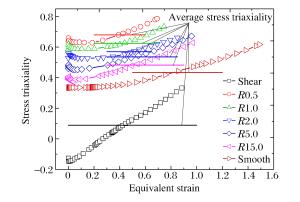

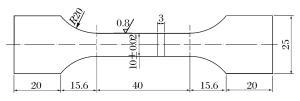

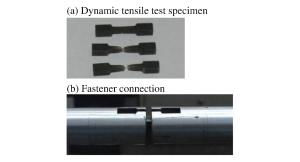

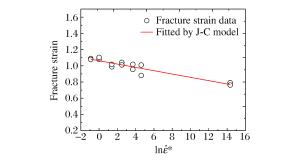

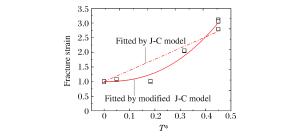

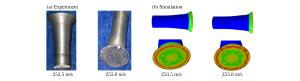

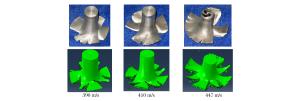

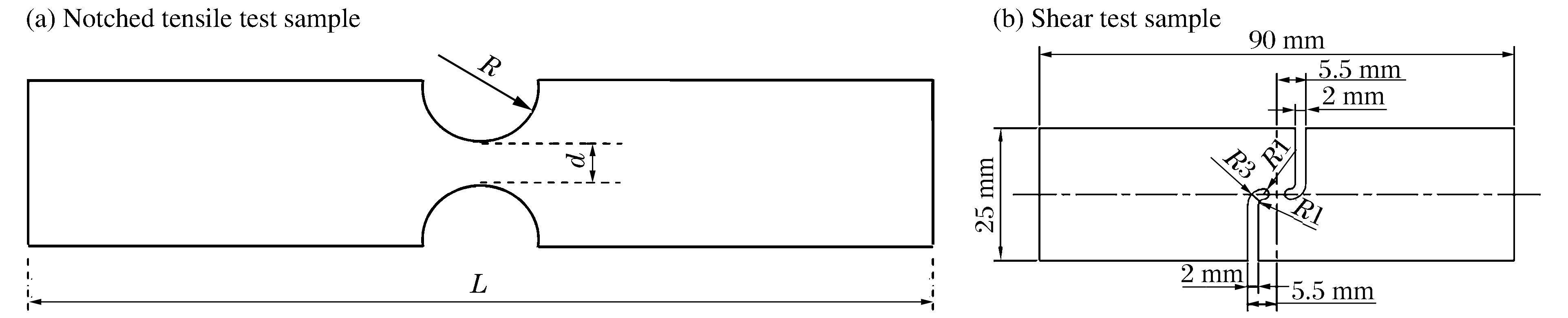

摘要: 使用Instron材料试验机、霍普金森拉杆(SHTB)对Q235钢试件进行了不同温度下的准静态和动态拉伸实验,研究了温度、应变率及应力三轴度对Q235钢失效应变的影响,结果表明:Q235钢失效应变随温度的升高而增加,随应变率的增加而减小,随应力三轴度的增加先减小后增加再减小。基于实验结果对Q235钢J-C失效模型中的温度项进行了修正,并结合数值模拟提出了基于J-C失效模型的应力三轴度三分段式失效准则,通过Taylor撞击实验和数值模拟对给出的模型相关参量进行了验证,实验与模拟结果吻合较好。Abstract: In this paper, we conducted quasi-static and dynamic tensile tests on Q235 steel at different temperatures using the Instron tensile strength tester and the split Hopkinson bar and studied the effects of temperature, strain rates and stress triaxiality on the steel's failure strains of Q235. The results show that Q235 steel's failure strains increase with a rise in temperature but decrease with a rise the strain rates while, with a rise in the stress triaxiality, they decrease at first but then increase. Based on these results and combining them with numerical simulation, we modified the item of temperature effects and proposed a revised three-section failure criterion of stress triaxiality for J-C failure model, with relevant parameters determined and verified using Taylor impacting experiments and corresponding numerical simulations. The experimental results accord well with those from simulation.

-

Key words:

- Q235 steel /

- failure criterion /

- stress triaxiality /

- Taylor impact

-

表 1 Q235钢的失效模型相关参数

Table 1. Material parameters for Q235 steel

E/GPa ν ρ/(kg·m-3) Tr/K Tm/K cp/(J·kg-1·K-1) χ $ {\dot \varepsilon _0} $/s-1 200 0.33 7 800 293 1 795 469 0.9 2.1×10-3 D01 D02 D03 D1 D2 D3 D4 D5 D6 0.511 -6.80 4.047 0.472 18.728 -7.805 -0.019 3 13.017 2.338 -

[1] JOHNSON G R, COOK W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures[J]. Engineering Fracture Mechanics, 1985, 21:31-48. doi: 10.1016/0013-7944(85)90052-9 [2] BAO Y B, WIERZBICKI T. On fracture locus in the equivalent strain and stress triaxiality space[J]. International Journal of Mechanical Sciences, 2004, 46:81-98. doi: 10.1016/j.ijmecsci.2004.02.006 [3] 陈刚.半穿甲战斗部弹体穿甲效应数值模拟与实验研究[D].四川绵阳: 中国工程物理研究院, 2006. http://cdmd.cnki.com.cn/Article/CDMD-82818-2007021523.htm [4] 陈小伟, 张方举, 梁斌, 等.A3钢钝头弹撞击45钢板破坏模式的试验研究[J].爆炸与冲击, 2006, 26(3):199-207. doi: 10.3321/j.issn:1001-1455.2006.03.002CHEN Xiaowe, ZHANG Fangju, LIANG bin, et al. Three modes of penetration mechanics of A3 steel cylindrical projectiles impact onto 45 steel plates[J]. Explosion and Shock Waves, 2006, 26(3):199-207. doi: 10.3321/j.issn:1001-1455.2006.03.002 [5] 陈刚, 陈小伟, 陈忠富, 等.A3钢钝头弹撞击45钢板破坏模式的数值分析[J].爆炸与冲击, 2007, 27(5):390-397. doi: 10.3321/j.issn:1001-1455.2007.05.002CHEN Gang, CHEN Xiaowei, CHEN Zhongfu, et al. Simulations of A3 steel blunt projectiles impacting 45 steel plates[J]. Explosion and Shock Waves, 2007, 27(5):390-397. doi: 10.3321/j.issn:1001-1455.2007.05.002 [6] CHEN X W, WEI L M, LI J C. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target[J]. International Journal of Impact Engineering, 2015, 79(2):102-116. https://www.sciencedirect.com/science/article/pii/S0734743X14002590 [7] DENG Yunfei, ZHANG Wei, CAO Zongsheng. Experimental investigation on the ballistic resistance of monolithic and multi-layered plates against ogival-nosed rigid projectiles impact[J]. Materials and Design, 2013, 44:228-239. doi: 10.1016/j.matdes.2012.06.048 [8] DENG Yunfei, ZHANG Wei, YANG Y, et al. Experimental investigation on the ballistic performance of double layered plates subjected to impact by projectile of high strength[J]. International Journal of Impact Engineering, 2014, 70(8):38-49. https://www.sciencedirect.com/science/article/pii/S0734743X14000712 [9] 张伟, 肖新科, 郭子涛, 等.双层A3钢靶对平头杆弹的抗侵彻性能研究[J].高压物理学报, 2012, 26(2):163-170. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201201512175ZHANG Wei, XIAO Xinke, GUO Zitao, et al. Investigation on the ballistic resistance of double-layered A3 steel targets against blunt projectile impact[J]. Chinese Journal of High Pressure Physics, 2012, 26(2):163-170. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201201512175 [10] 郭子涛, 郭钊, 张伟.单层A3钢薄靶在不同头型弹体斜撞击下的失效模式和防护性能研究[J], 振动与冲击, 2018, 37(1):27-31. http://d.old.wanfangdata.com.cn/Periodical/zdycj201801005GUO Zitao, GUO Zhao, ZHANG Wei. Study on failure patterns and ballistic resistance of thin single A3 steel targets obliquely impacted by different nose shape projectiles[J]. Journal of Vibration and Shock, 2018, 37(1):27-31. http://d.old.wanfangdata.com.cn/Periodical/zdycj201801005 [11] 林莉, 支旭东, 范锋, 等.Q235B钢Johnson-Cook模型参数的确定[J].振动与冲击, 2014, 33(9):153-158. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201409030.htmLIN Li, ZHI Xudong, FAN Feng, et al. Determination of parameters of Johnson-Cook models of Q235B steel[J]. Journal of Vibration and Shock, 2014, 33(9):153-158. http://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201409030.htm [12] HANCOCK J W, MACKENZIE A C. On the mechanisms of ductile failure in high strength steels subjected to multi-axial stress-states[J]. Journal of the Mechanics and Physics of Solids, 1976, 24(2):147-169. https://www.sciencedirect.com/science/article/pii/0022509676900247 [13] MACKENZIE A C, HANCOCK J W, BROWN D K. On the influence of state of stress on ductile failure initiation in high strength steels[J]. Engineering Fracture Mechanics, 1977, 9(1):167-188. doi: 10.1016/0013-7944(77)90062-5 [14] CHOUNG J M, CHO S R. Study on true stress correction from tensile tests[J]. Journal of Mechanical Science and Technology, 2008, 22(6):1039-1051. doi: 10.1007/s12206-008-0302-3 [15] JOUN M, EOM J G, LEE M C. A new method for acquiring true stress-strain curves over a large range of strains using a tensile test and finite element method[J]. Mechanics of Materials, 2008, 40(7):586-593. doi: 10.1016/j.mechmat.2007.11.006 [16] LEE Y W, WIERZBICKI T. Fracture prediction of thin plates under localized impulsive loading[J]. International Journal of Impact Engineering, 2005, 31(10):1277-1308. doi: 10.1016/j.ijimpeng.2004.07.011 [17] 郭子涛, 高斌, 郭钊, 等.基于J-C模型的Q235钢的动态本构关系[J].爆炸与冲击, 2018, 38(4):804-810. http://www.bzycj.cn/CN/abstract/abstract9848.shtmlGUO Zitao, GAO Bin, GUO Zhao, et al. Study on the J-C model based dynamic constitutive relation of Q235 steel[J]. Explosion and Shock Waves, 2018, 38(4):804-810. http://www.bzycj.cn/CN/abstract/abstract9848.shtml -

下载:

下载: