Simulation experiment on small-size tank impacted by conical projectiles

-

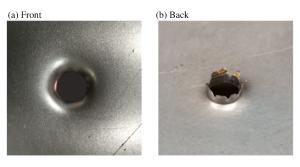

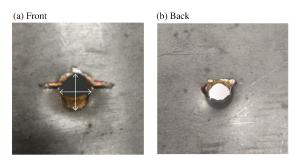

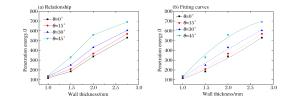

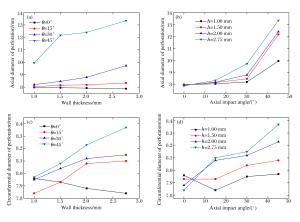

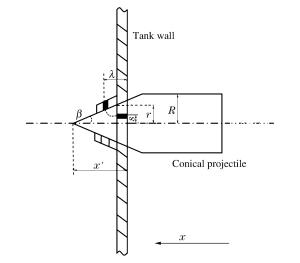

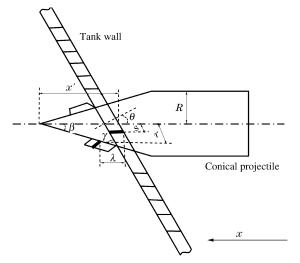

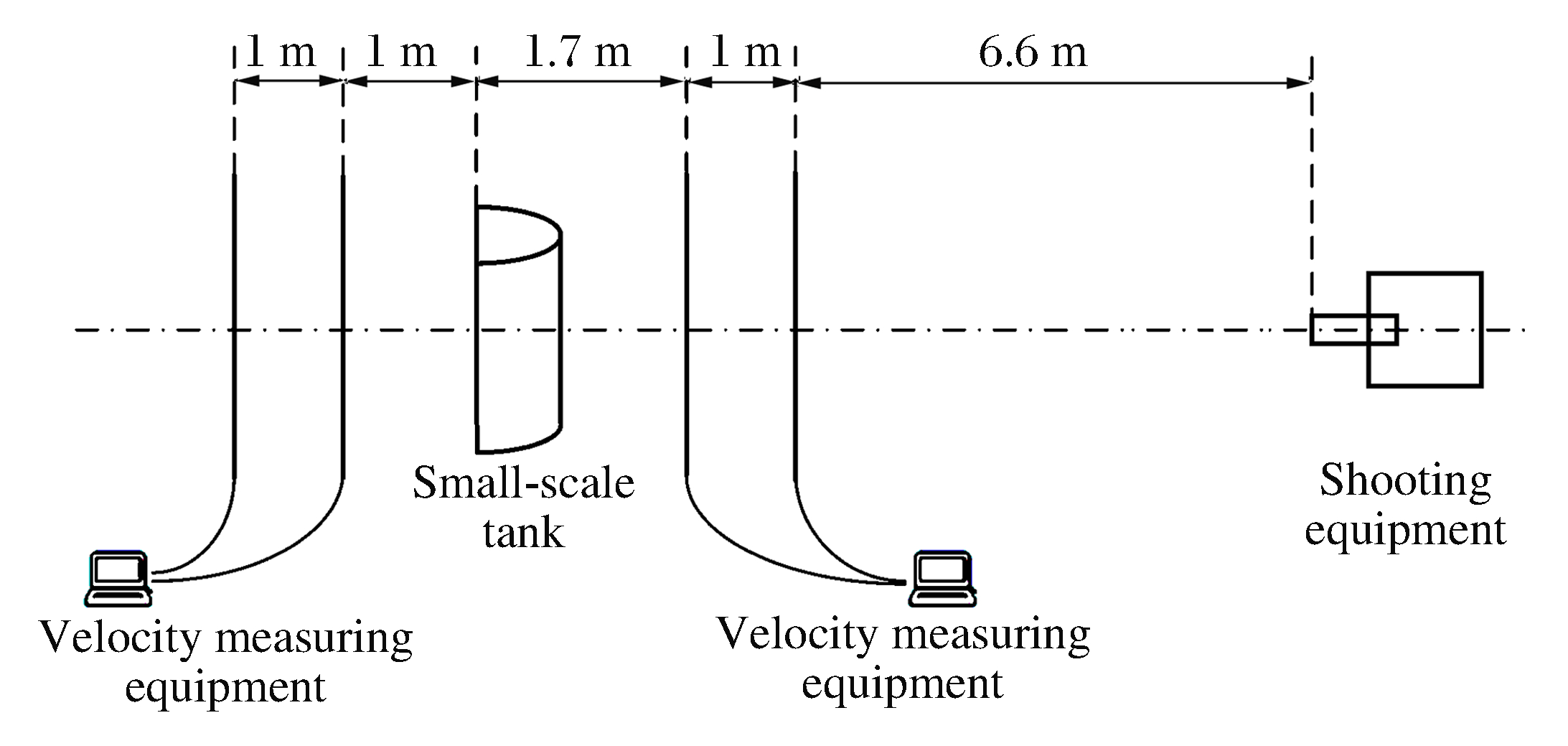

摘要: 化工园区内,容器爆炸事故易引发多米诺效应,产生的碎片击中临近目标设备或装置可能造成事故后果升级。通过开展尖头碎片撞击小尺寸储罐模拟实验,得到了不同轴向撞击角的尖头碎片撞击不同壁厚小尺寸储罐的穿透形貌、穿透能量以及穿孔直径。结果表明:(1)尖头碎片以0°轴向撞击角穿透罐壁形成的穿孔正面近似圆形,以15°、30°及45°轴向撞击角撞击形成的穿孔正面近似椭圆形且有2个条形翻边,穿孔背面均呈现花瓣型开裂;(2)轴向撞击角越大,壁厚越大,所需的穿透能量越大;(3)轴向撞击角与壁厚对穿孔轴向直径影响显著,但穿孔环向直径变化幅度不大。最后,根据穿甲力学理论和动量守恒定理,推导出适用于0°~45°轴向撞击角的尖头碎片剩余速度理论计算公式。Abstract: In this work, to forestall the domino effects resulting from the container explosion that may lead to serious damages to equipments and devices in a chemical industry park impacted by explosion fragments, we obtained the penetrating morphology, penetration energy and perforation diameter, of small-size tanks with different wall thicknesses that were impacted by conical projectiles at different axial impact angles, with the following results achieved:that the front penetrating morphology is nearly circular when the axial impact angle is 0°, and is nearly oval with two flangings when the axial impact angle is 15°, 30°, and 45°; that their backs are both dehiscent like petals; the larger the axial impact angle and tank wall thickness, the more penetration energy is needed; and that the axial impact angle and tank wall thickness have significant influence on the axial diameter of the perforation, but barely affect the circumferential diameter of the perforation. Also, based on the mechanics of perforation and the laws of conservation of momentum, we derived the residual velocity formula of conical projectiles suitable for axial impact angles ranging from 0 to 45 degrees.

-

Key words:

- conical projectiles /

- small-size tank /

- axial impact angle /

- residual velocity

-

表 1 尖头碎片剩余速度的实验值与理论计算值对比

Table 1. Experimentally obtained value and theoretically calculated value of residual velocity of conical projectiles

实验编号 h/mm θ/(°) vi的实验值/(m·s-1) vr/(m·s-1) 相对误差/% 实验 理论计算 1 1.00 0 842 826 825 0.06 2 1.50 0 853 828 828 0 3 2.00 0 859 813 826 1.58 4 2.75 0 840 765 796 4.05 5 1.00 15 859 842 843 0.17 6 1.50 15 864 836 841 0.57 7 2.00 15 859 809 828 2.40 8 2.75 15 858 779 817 4.82 9 1.00 30 861 843 843 0 10 1.50 30 853 819 827 0.97 11 2.00 30 860 801 825 3.03 12 2.75 30 859 775 812 4.79 13 1.00 45 855 836 829 0.79 14 1.50 45 857 812 819 0.87 15 2.00 45 863 786 813 3.40 16 2.75 45 858 761 790 3.91 注:相对误差为尖头碎片剩余速度的实验值与理论计算值之间的相对误差。 -

[1] 穆建春, 乔志宏, 张依芬, 等.自由梁中部在平头子弹横向正冲击下的穿透及变形[J].爆炸与冲击, 2000, 20(3):200-207. DOI: 10.3321/j.issn:1001-1455.2000.03.002.MU Jianchun, QIAO Zhihong, ZHANG Yifen, et al. Perforation and deformation of free-free beam by transverse impact of flat-nosed missile at the middle of its span[J]. Explosion and Shock Waves, 2000, 20(3):200-207. DOI: 10.3321/j.issn:1001-1455.2000.03.002. [2] PALMER A, NEILSON A, SIVADASAN S. Pipe perforation by medium-velocity impact[J]. International Journal of Impact Engineering, 2006, 32(7):1145-1157. DOI: 10.1016/j.ijimpeng.2004.09.010. [3] WANG Y, LEE S C. Experimental study of water tank under impulsive loading[J]. Archives of Civil & Mechanical Engineering, 2015, 15(4):986-996. DOI: 10.1016/j.acme.2014.09.006. [4] SUN D, JIANG J, ZHANG M, et al. Ballistic experiments on the mechanism of protective layer against domino effect caused by projectiles[J]. Journal of Loss Prevention in the Process Industries, 2016, 40(3):17-28. DOI: 10.1016/j.jlp.2015.11.020. [5] YU H, JEONG D Y. Impact dynamics and puncture failure of pressurized tank cars with fluid-structure interaction:a multiphase modeling approach[J]. International Journal of Impact Engineering, 2016, 90(4):12-25.DOI: 10.1016/j.ijimpeng.2015.11.014. [6] 唐恩凌, 施晓涵, 王猛, 等.高速碰撞下圆柱壳自由梁的穿孔特性[J].爆炸与冲击, 2016, 36(8):121-128. DOI: 10.11883/1001-1455(2016)01-0121-08.TANG Enling, SHI Xiaohan, WANG Meng, et al. Perforation characteristics of cylindrical shell free beam under high-speed impact[J]. Explosion and Shock Waves, 2016, 36(8):121-128. DOI: 10.11883/1001-1455(2016)01-0121-08. [7] 王晓强, 朱锡, 梅志远, 等.低合金船用结构钢抗高速破片能力研究[J].材料工程, 2009, 33(8):1-5.DOI: 10.3969/j.issn.1001-4381.2009.08.001.WAMG Xiaoqiang, ZHU Xi, MEI Zhiyuan, et al. Experimental investigation into anti-penetrating capacity of low allow ship hull steel strctures to high velocity steel fragment[J]. Journal of Materials Engineering. 2009, 33(8):1-5. DOI: 10.3969/j.issn.1001-4381.2009.08.001. [8] 朱东.大型钢储罐在撞击和爆炸荷载作用下的动力响应分析[D].杭州: 浙江大学, 2016: 22-33. http://cdmd.cnki.com.cn/Article/CDMD-10335-1016264290.htm [9] 任会兰, 宁建国.冲击固体力学[M].北京:国防工业出版社, 2013:201-240. [10] 邓云飞, 孟凡柱, 李剑锋, 等.Q235钢板对半球形头弹抗侵彻特性[J].爆炸与冲击, 2015, 35(3), 386-392. DOI: 10.11883/1001-1455(2015)03-0386-07.DENG Yunfei, MENG Fanzhu, LI Jianfeng, et al. The ballistic performance of Q235 metal plates subjected to impact by hemispherically-nosed projectiles[J]. Explosion and Shock Waves, 2015, 35(3):386-392. DOI: 10.11883/1001-1455(2015)03-0386-07. -

下载:

下载: