Dynamic responses of PE pipes directly buried in high saturated clay to blast wave

-

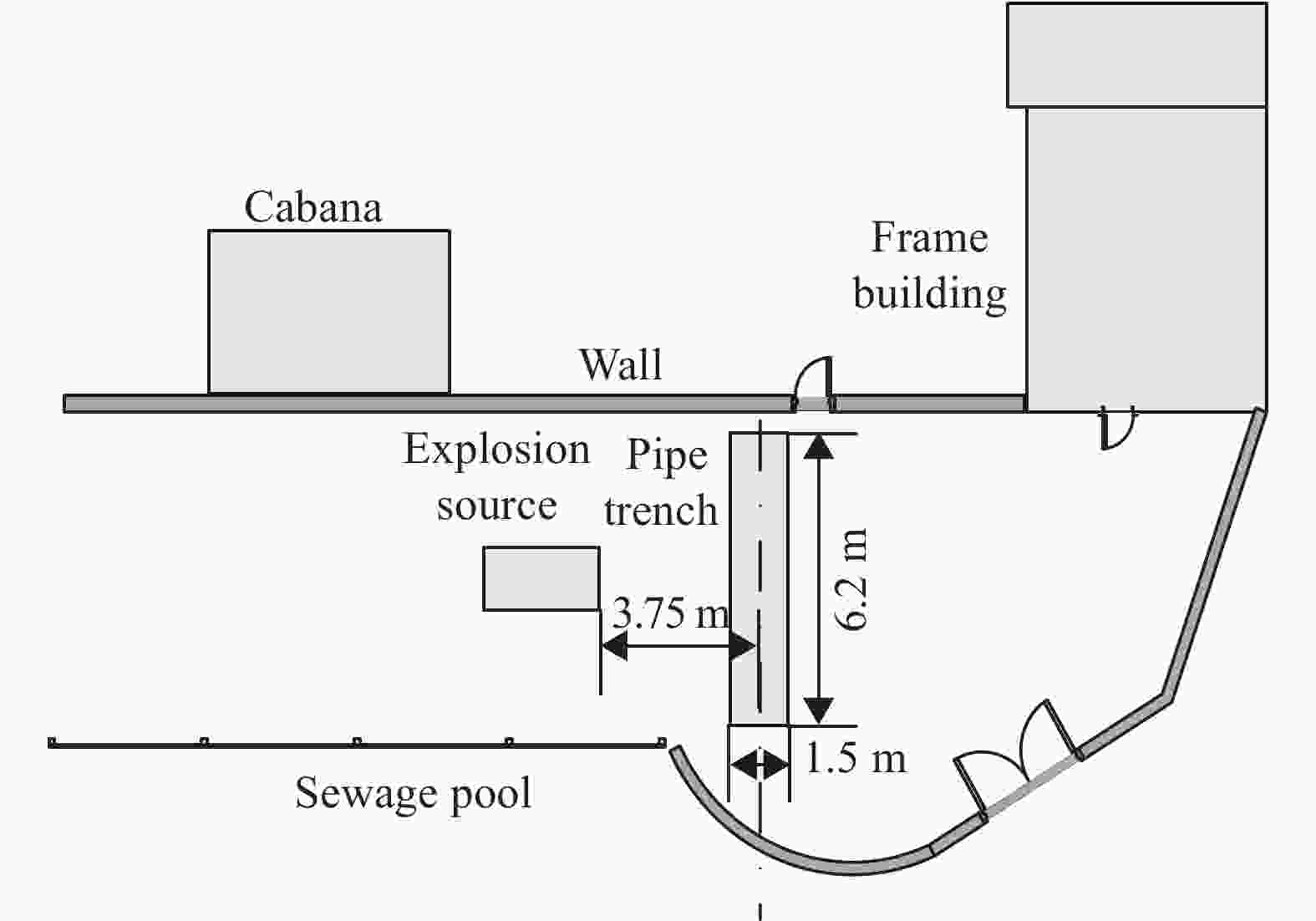

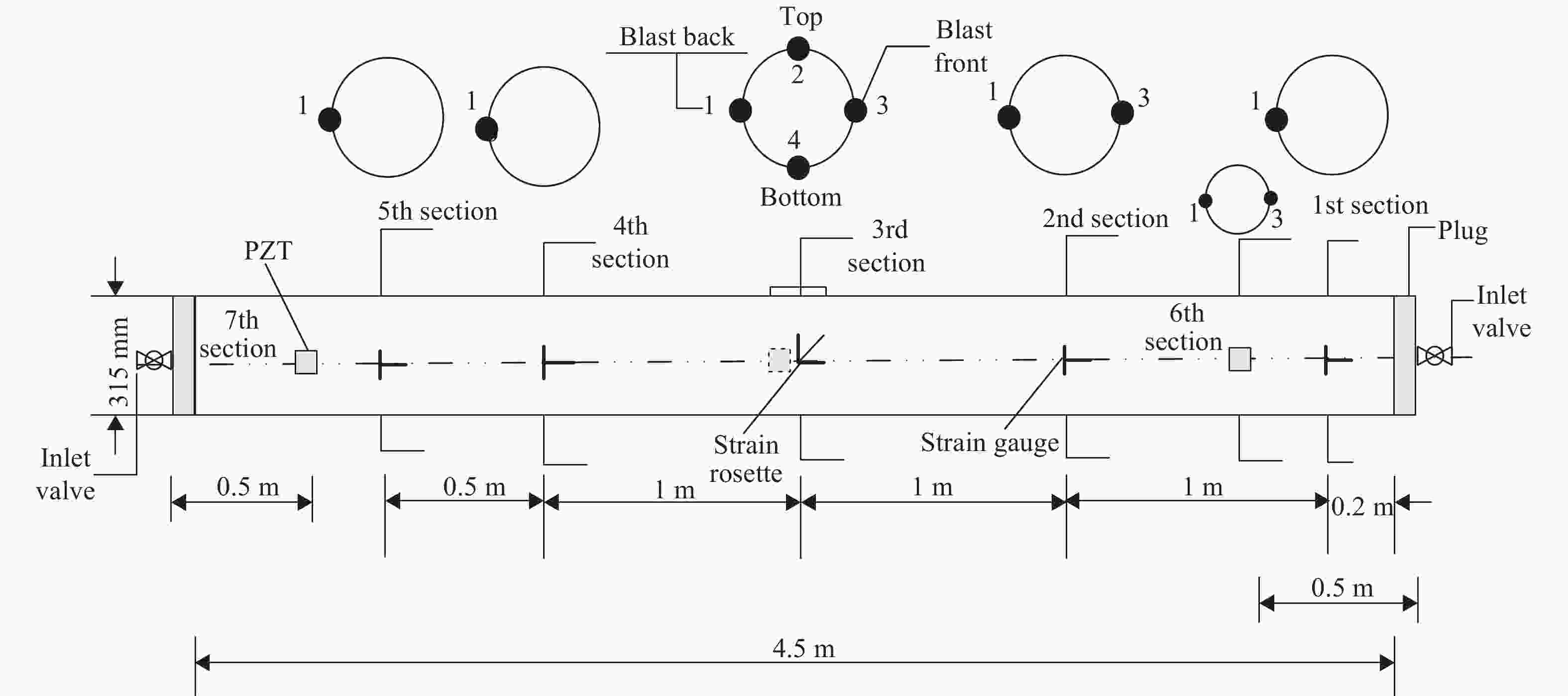

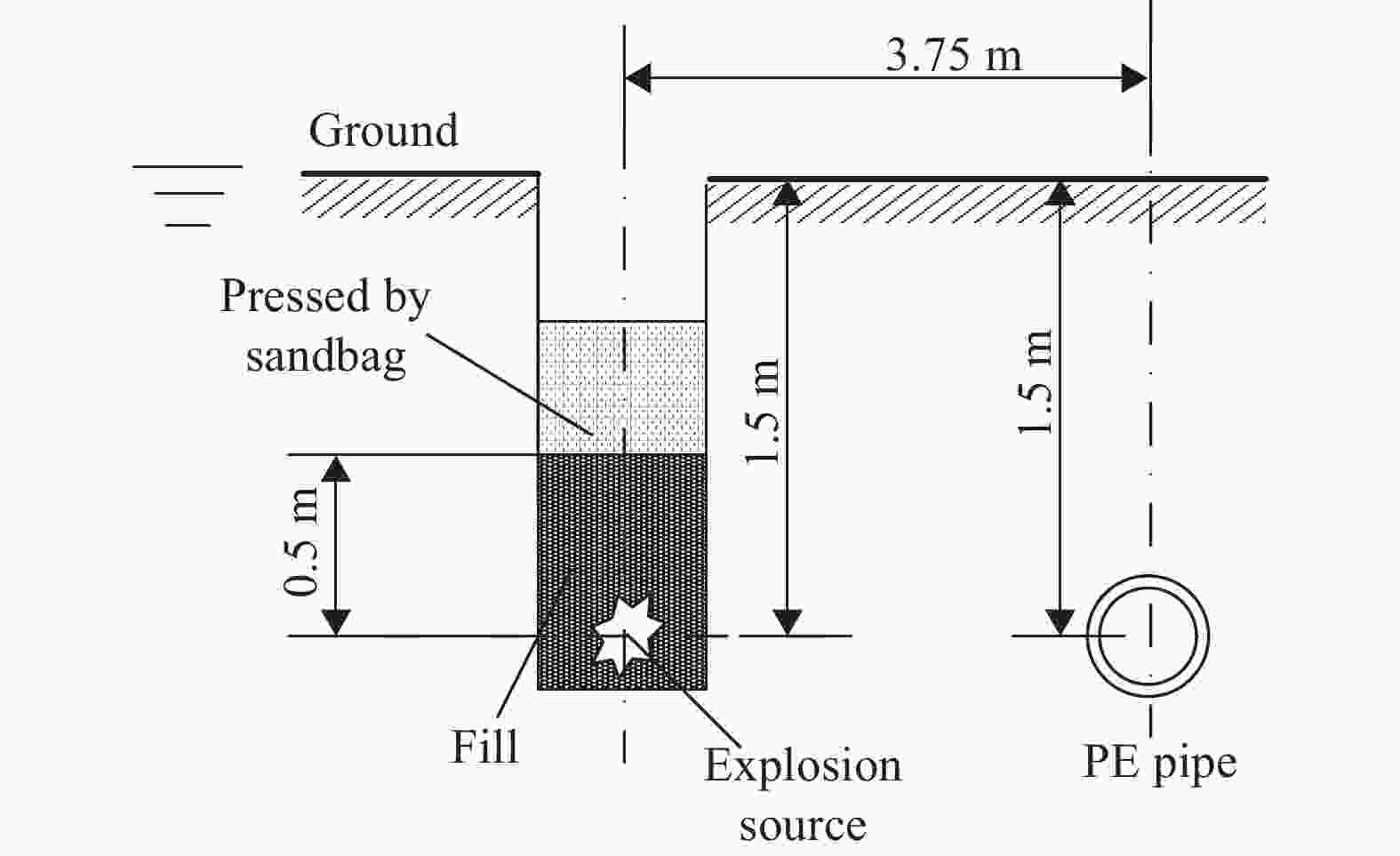

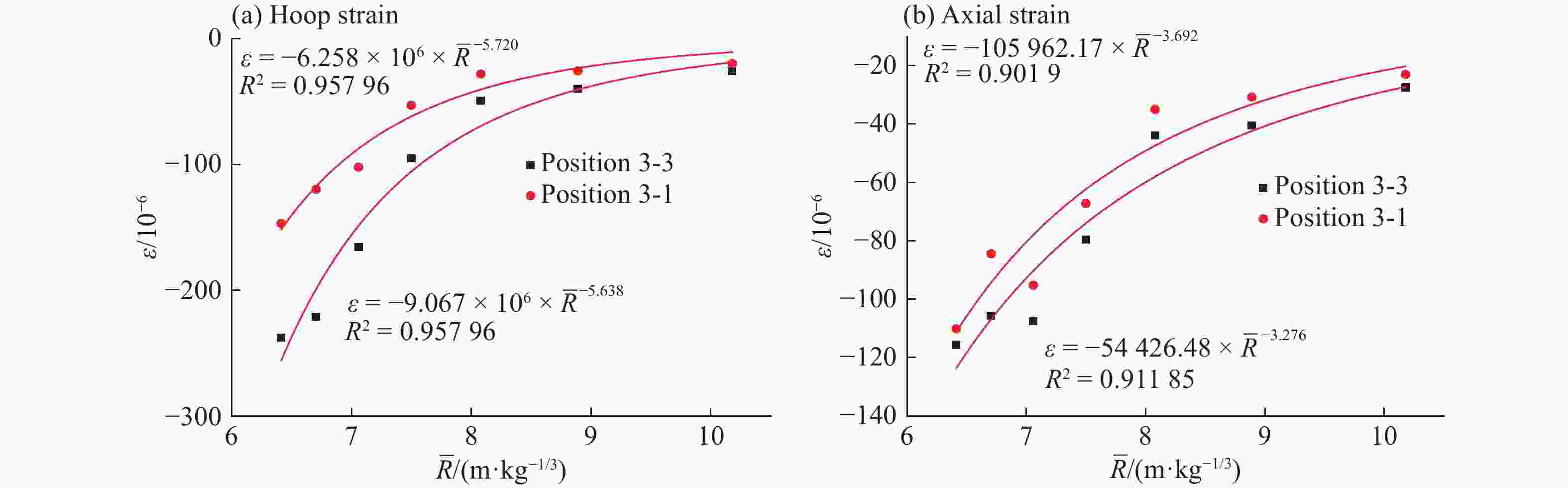

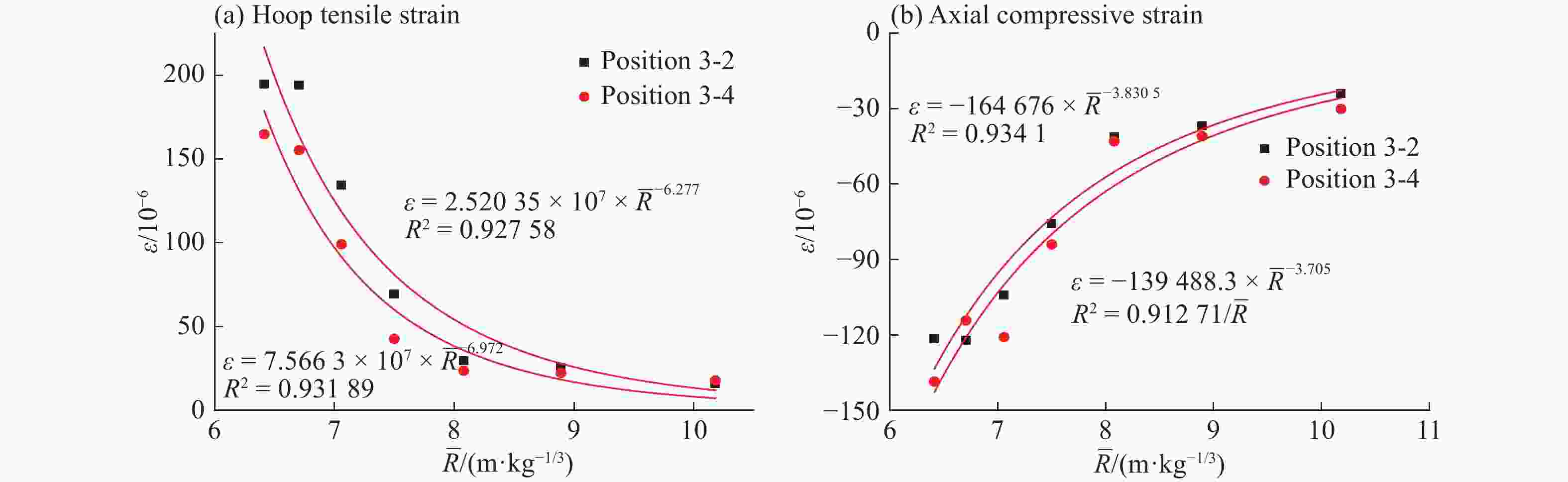

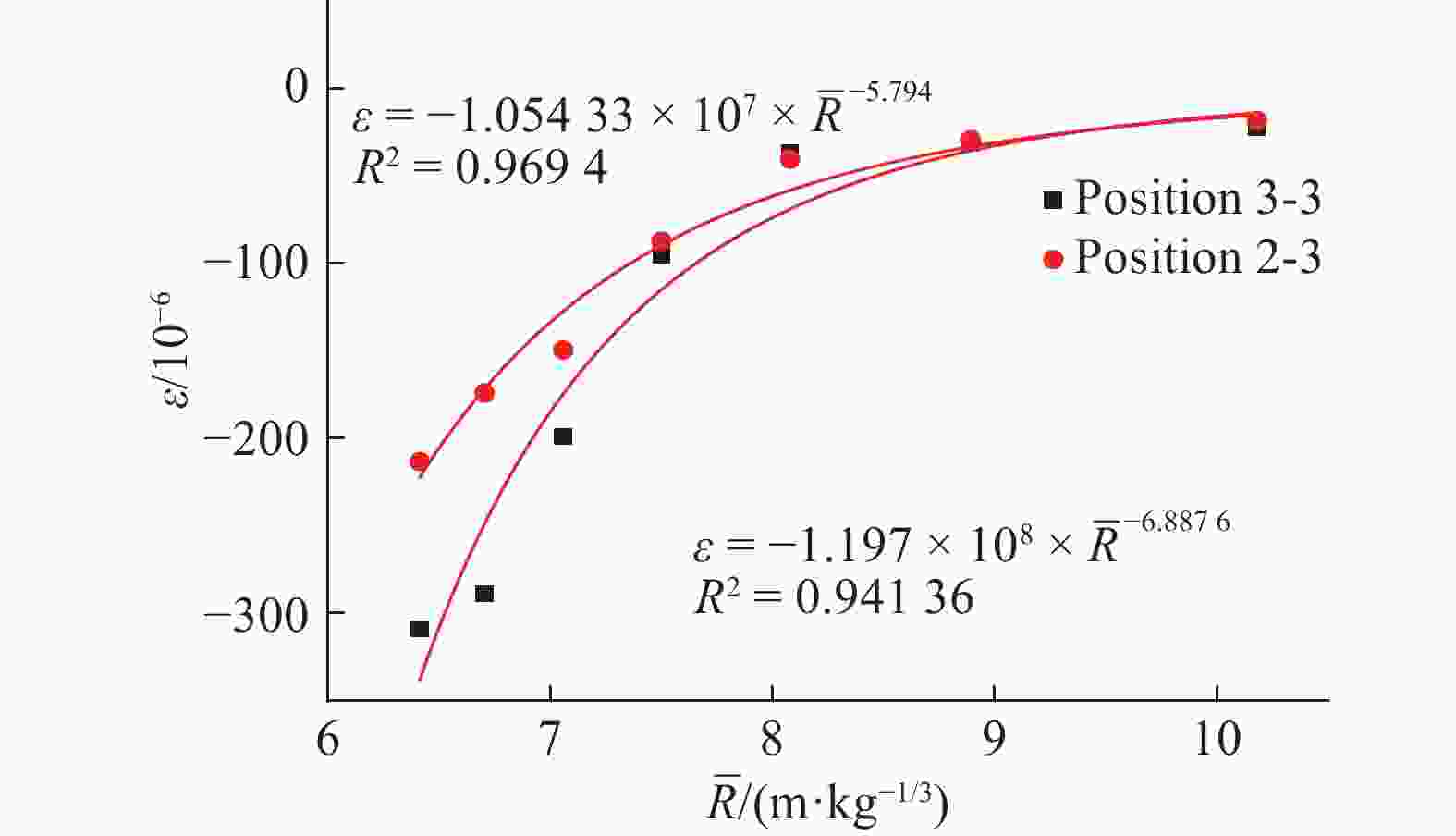

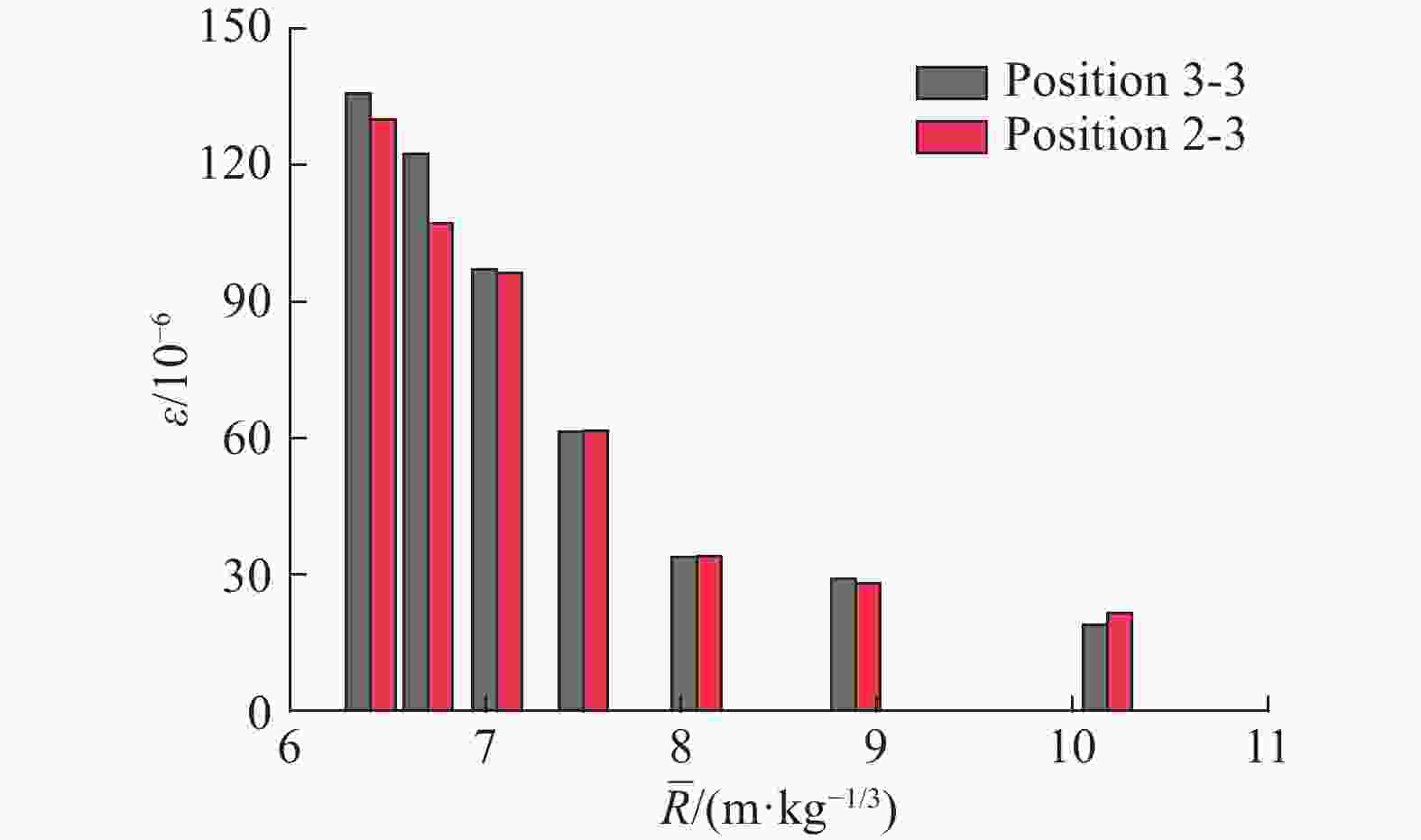

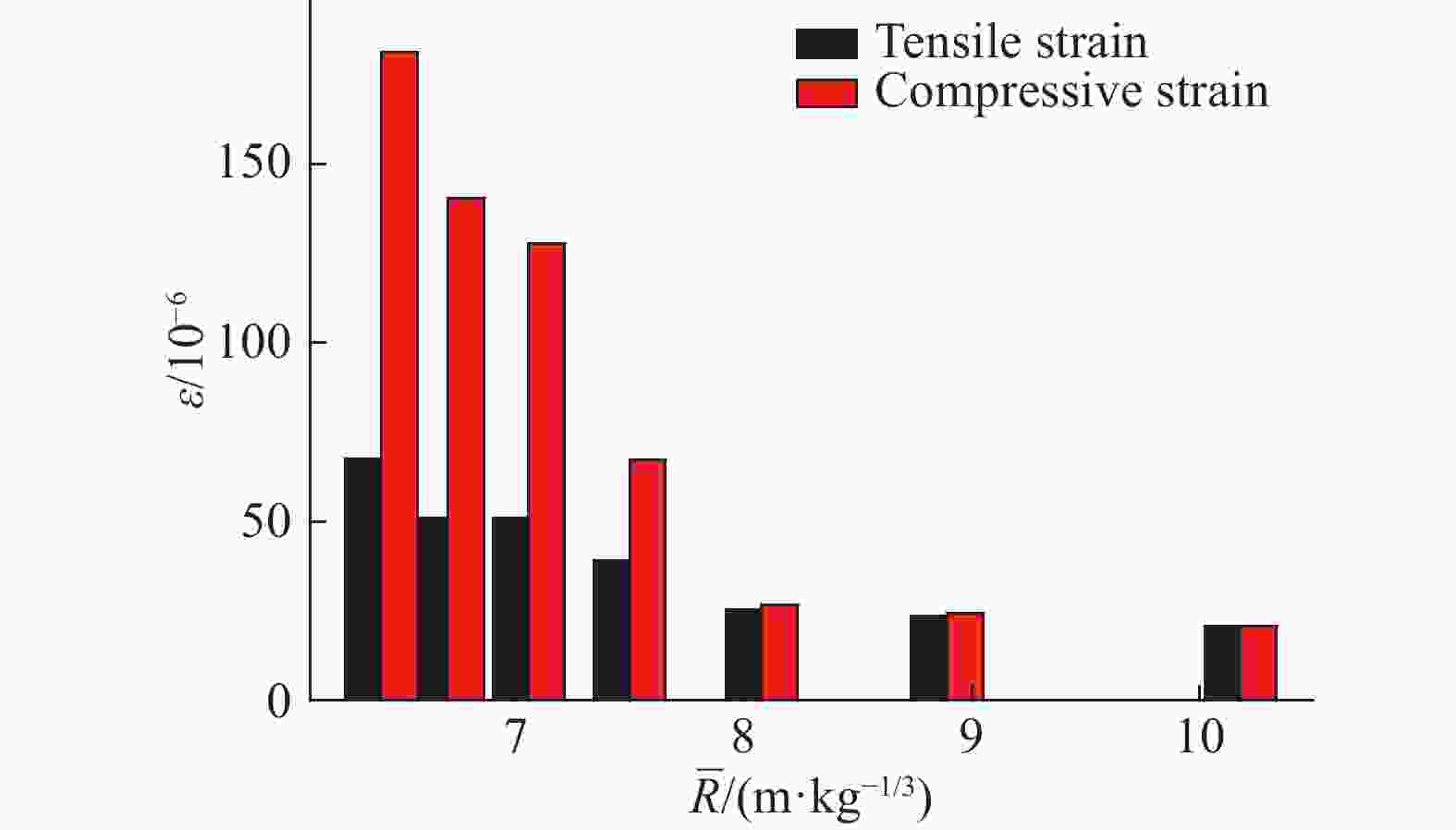

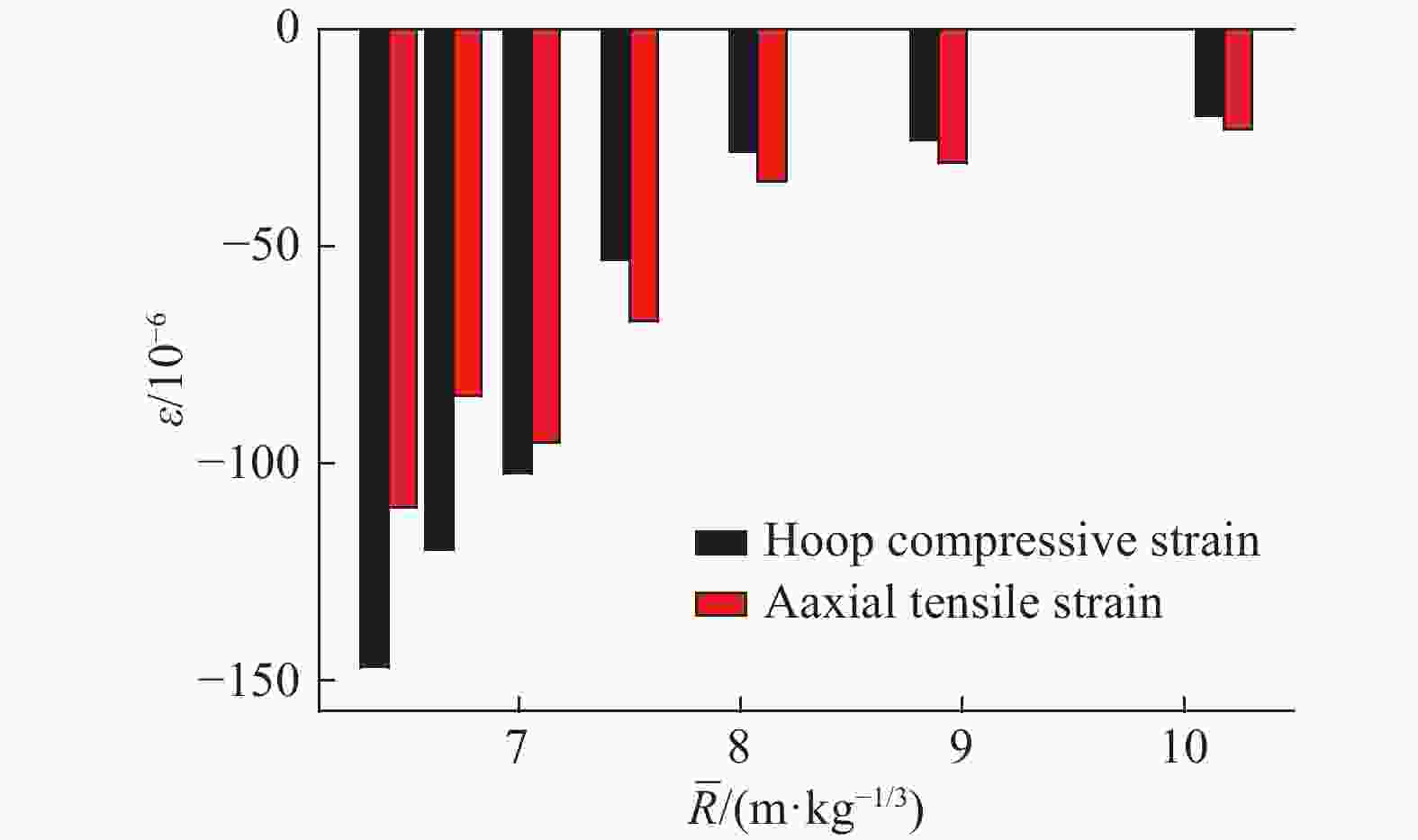

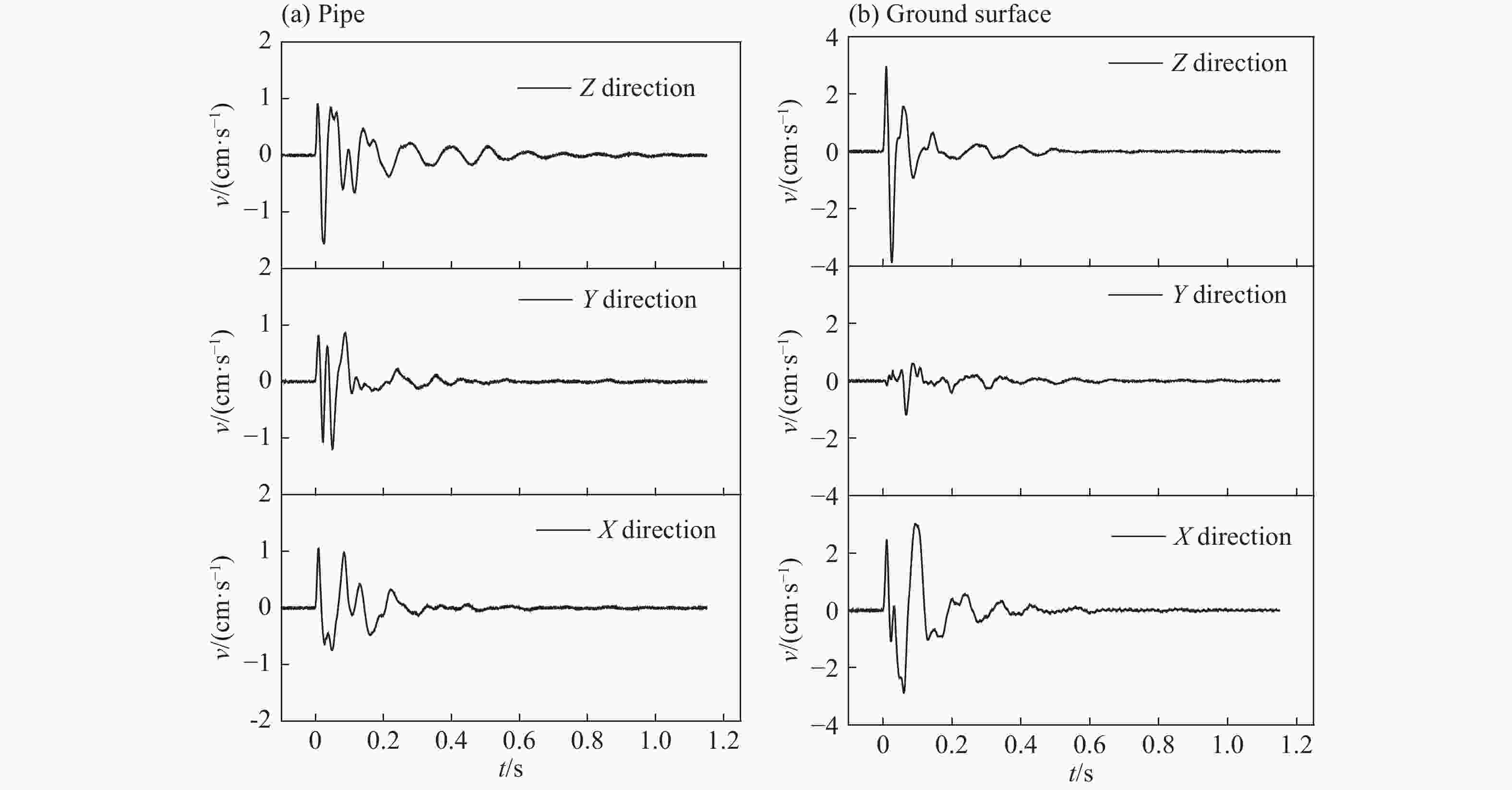

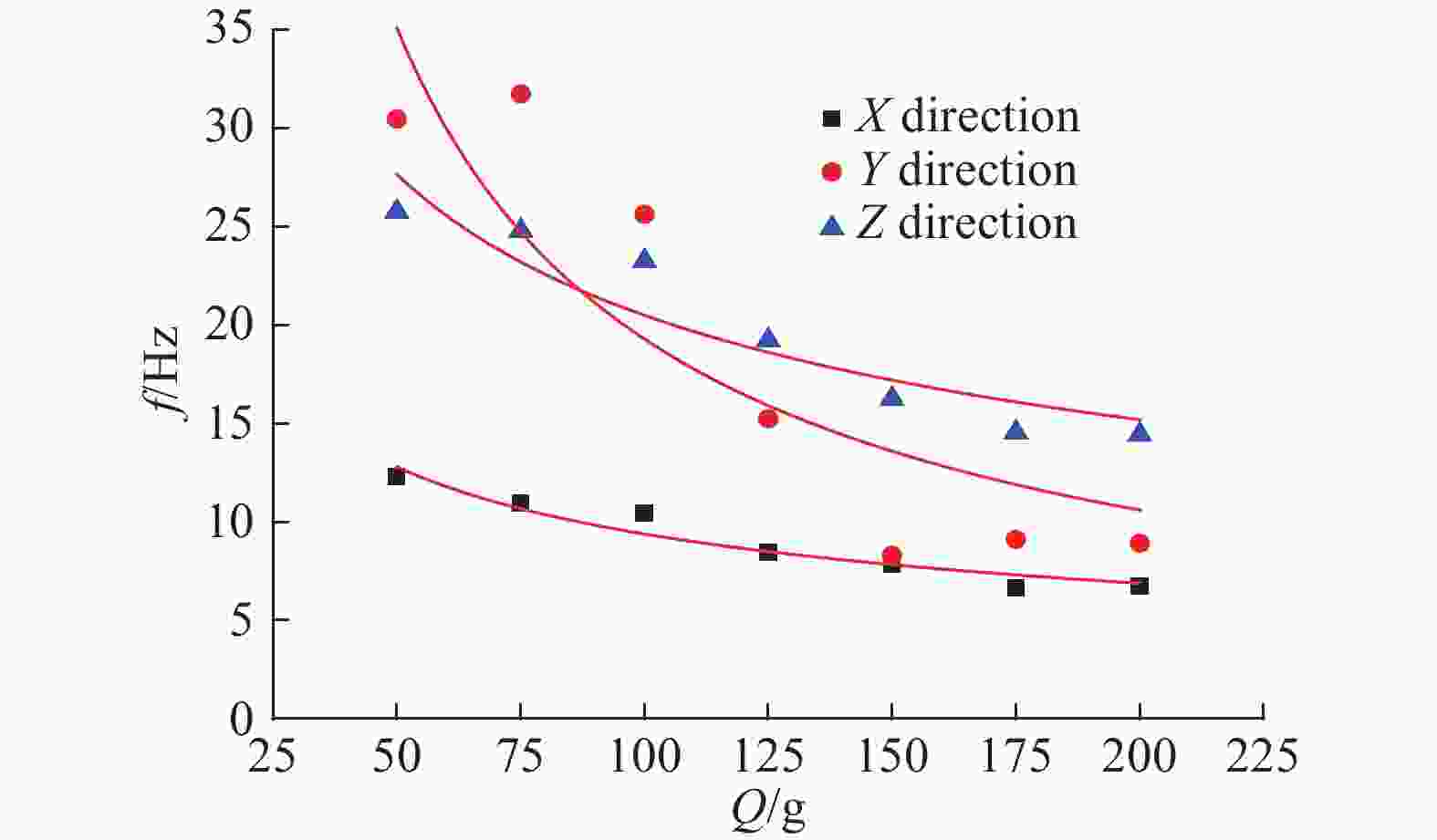

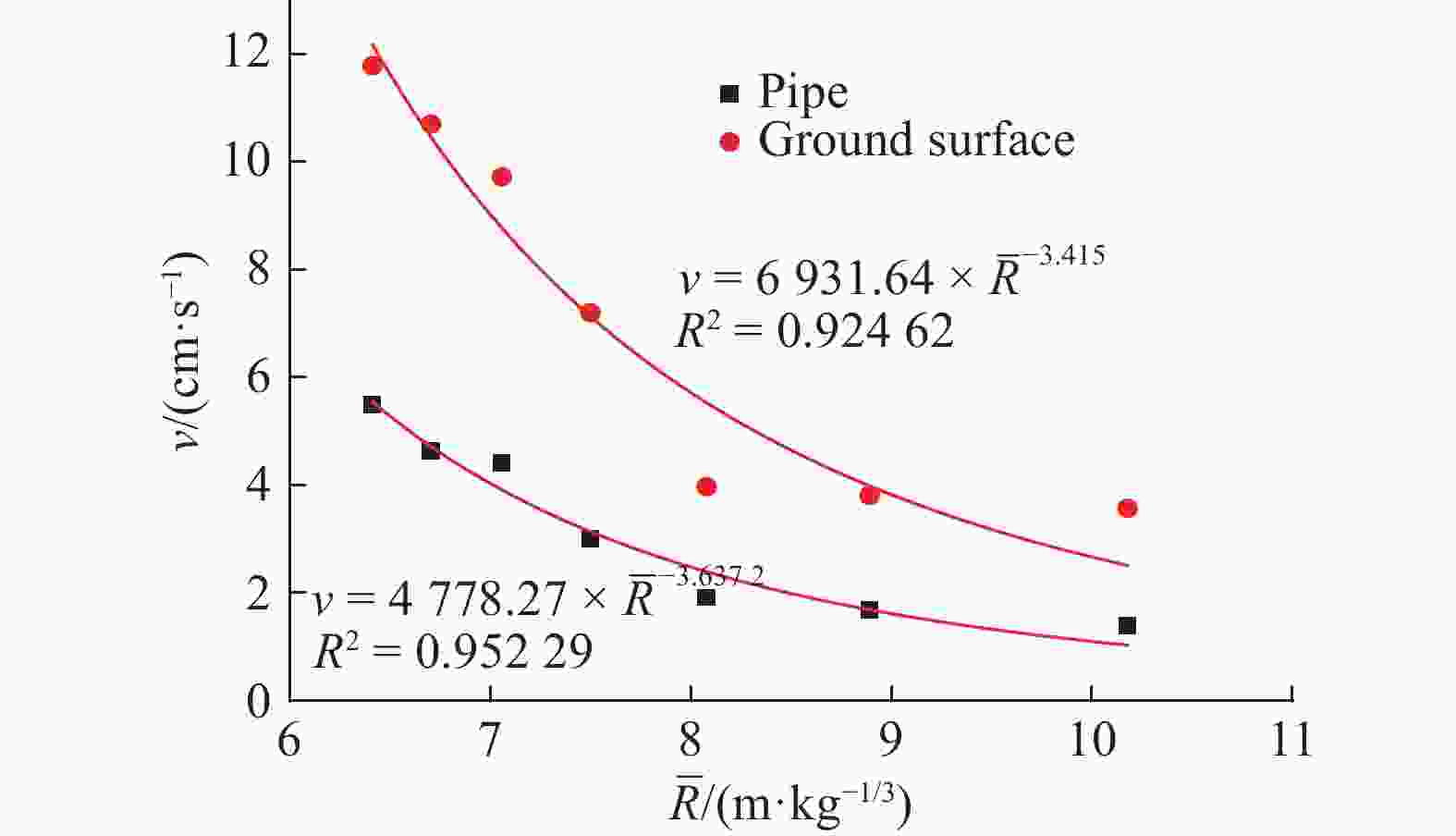

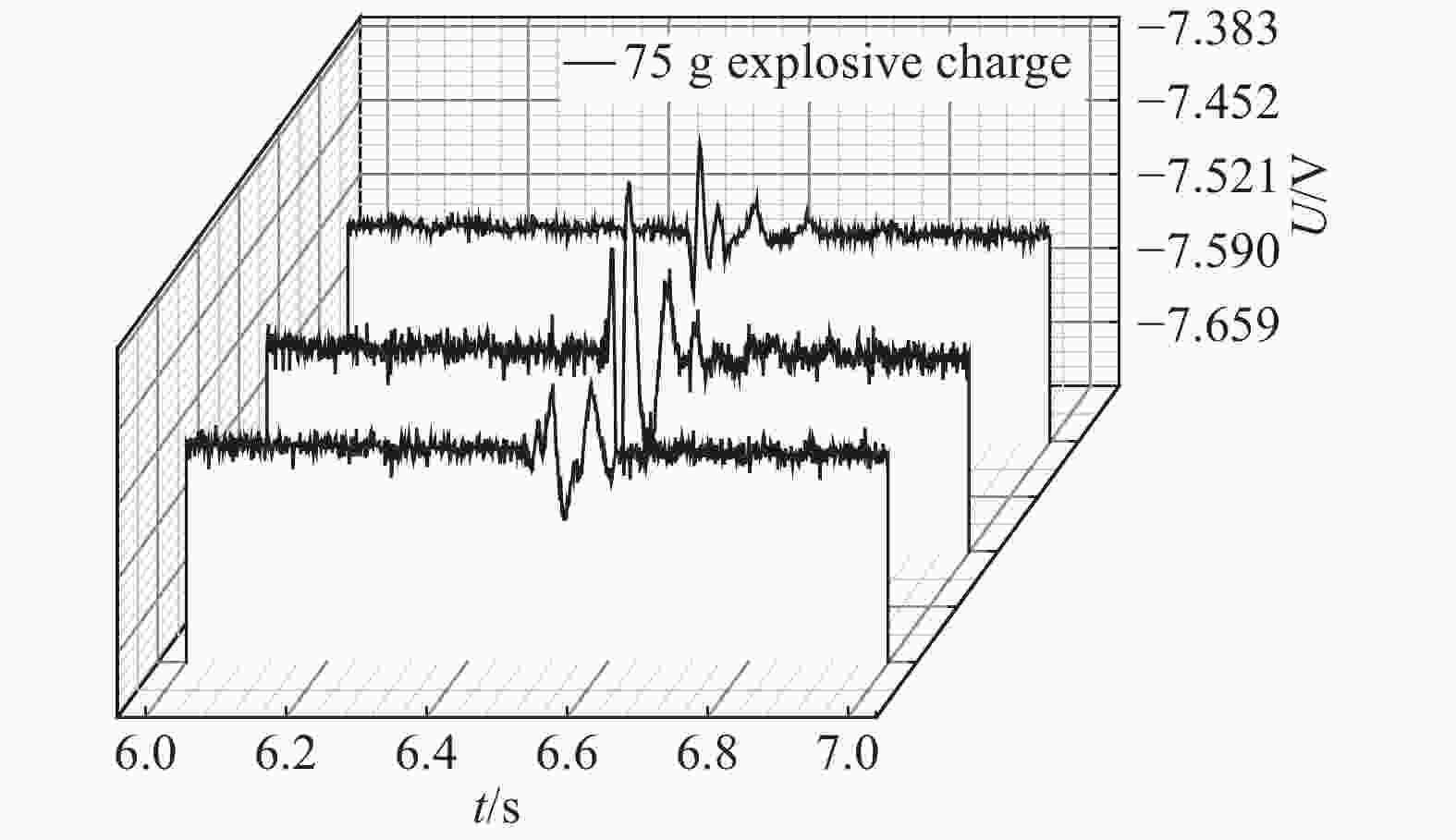

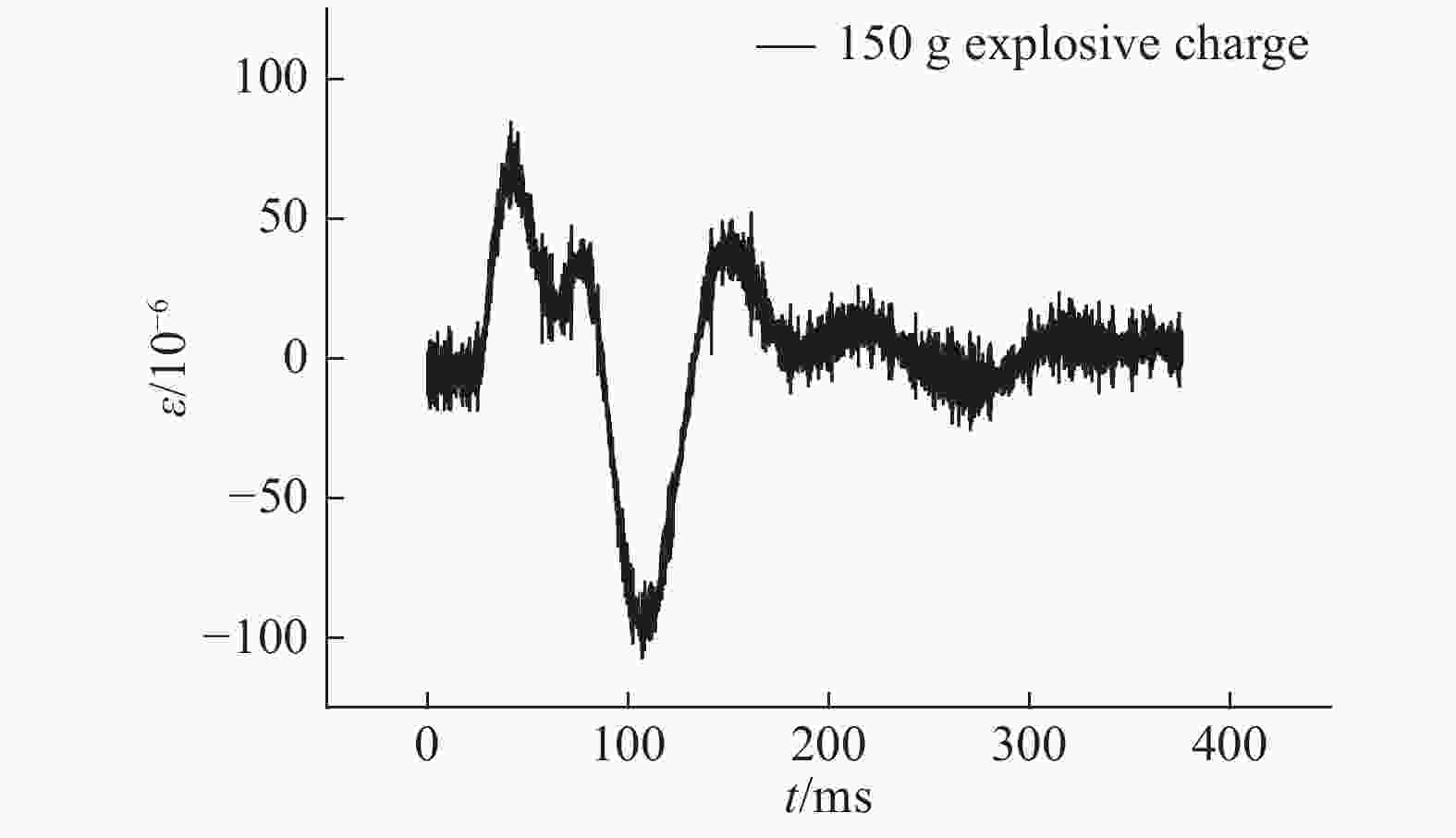

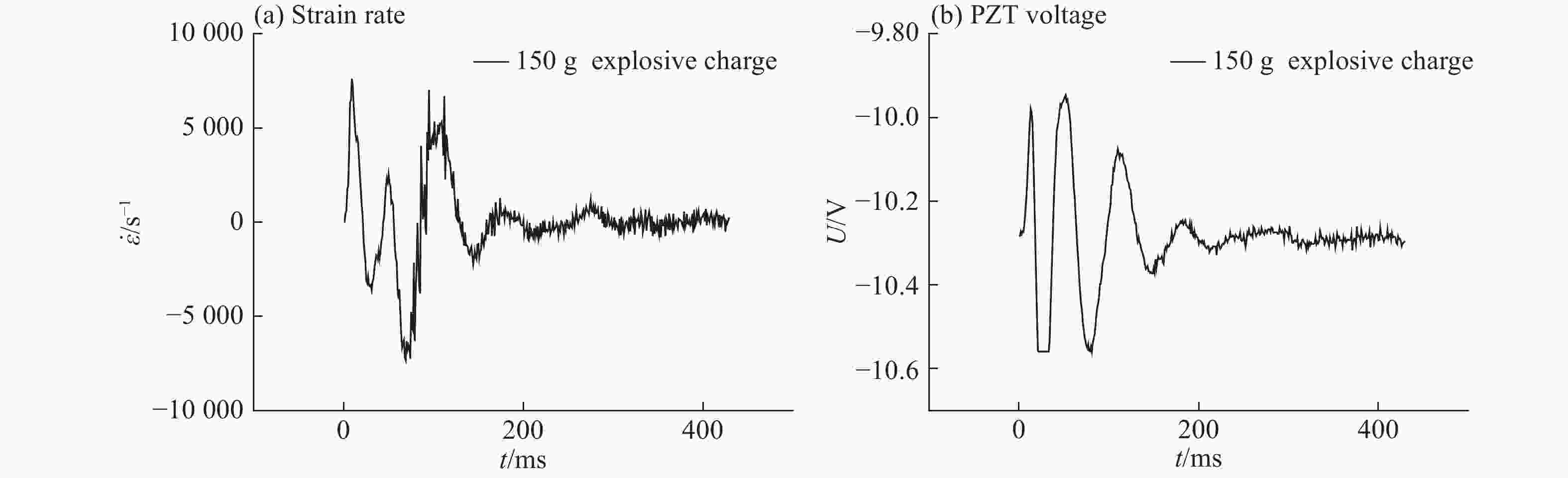

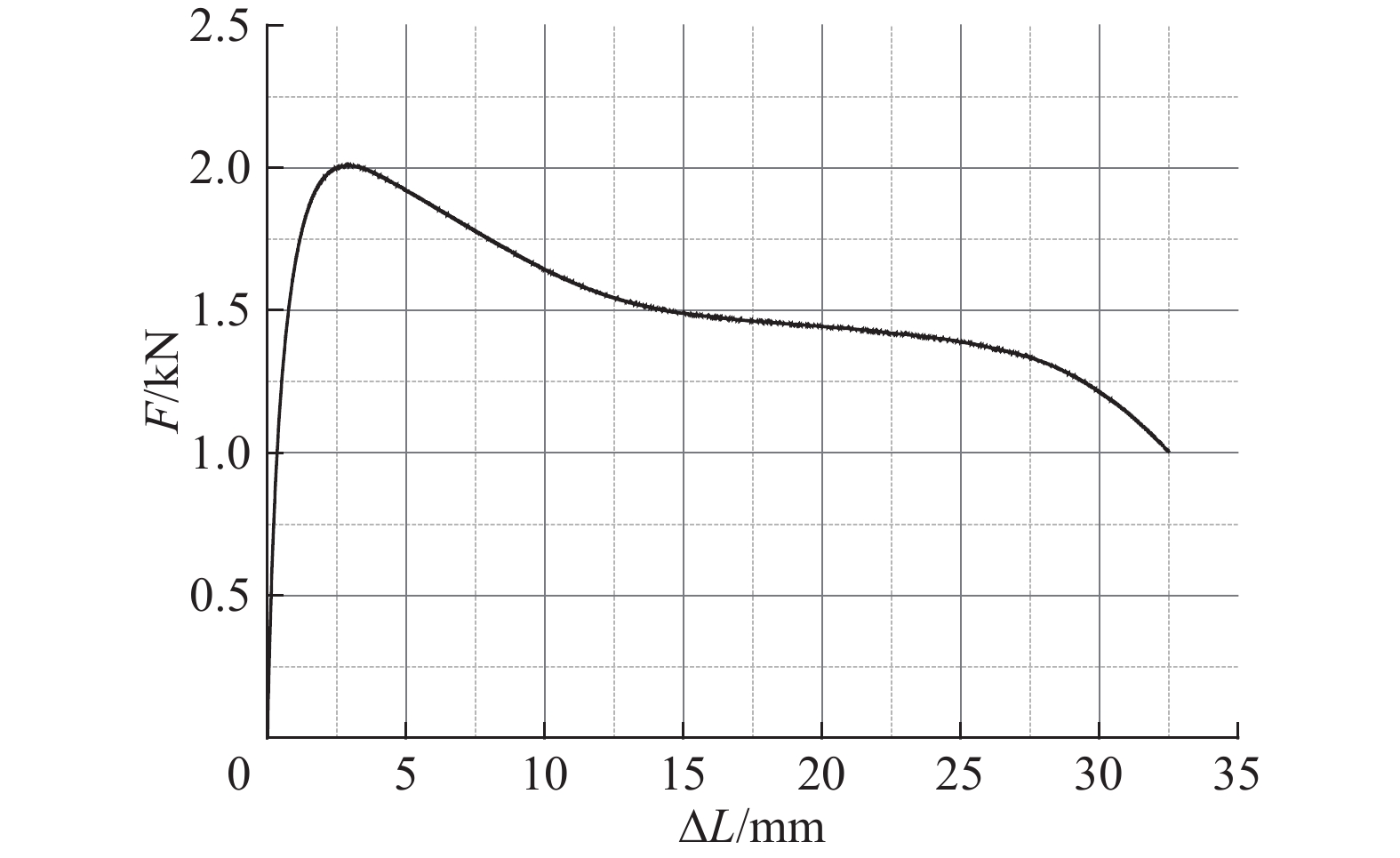

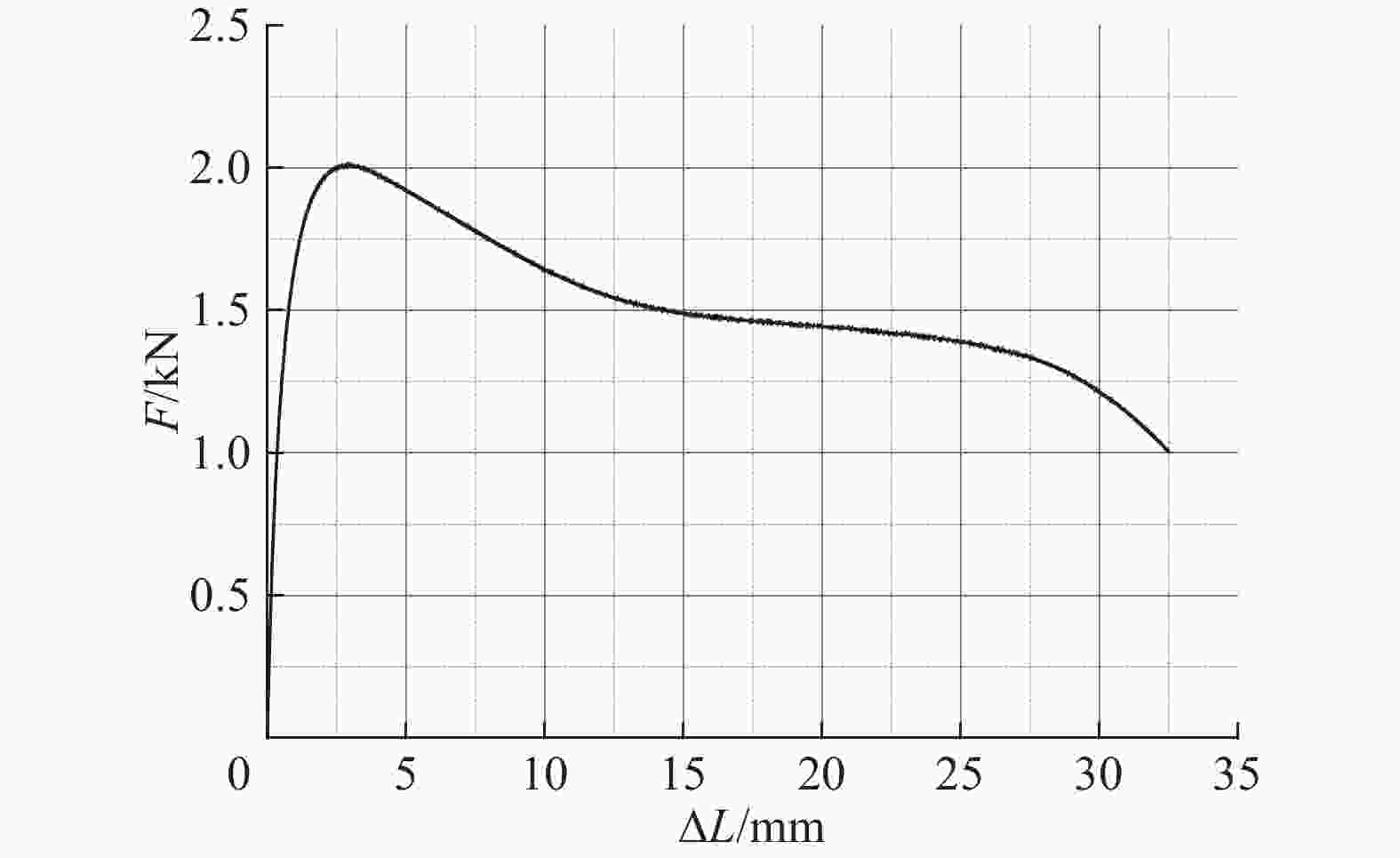

摘要: 为了解决爆破作业对近距离埋地管道的安全评估问题,对高饱和粘土中爆炸波作用下聚乙烯(polyethylene, PE)管道进行了一系列管道动态响应的原型实验,得到了不同药量下管道动应变、动压力的实验数据和管体及地面的振速数据。实验结果表明:PE管动应变峰值同比例距离具有良好的幂函数衰减关系,在6~11 m/kg1/3比例距离范围内,PE管的环向峰值应变衰减指数(绝对值)比轴向峰值应变衰减指数大;管道动态响应的主振频率略高于土体的主振频率,两者在同一量级,管道合成速度衰减指数大体和管道轴向应变衰减指数相当;压电陶瓷片所测得的电压信号和同测点的应变变化率信号具有较强的相关性。高饱和黏性土由于含水量较高,近距离柔性PE管因受到局部冲击会产生较大的环向应变,管道安全计算时应充分考虑这一因素;随着比例距离的增大,环向应变水平降低,轴向应变水平相对增强;压电陶瓷片因为具有良好可靠的动态性能,作为埋地管道现场监测的技术手段值得采用和推广。Abstract: In order to solve the safety assessment of a buried pipeline nearby blasting operation location, a series of dynamic responses of the polyethylene (PE) pipe in high saturated clay under the action of the explosive wave were carried out. The experimental data of the dynamic strain and dynamic pressure were gotten, and the velocity data of the pipe and the ground were measured at the same time. The experimental results show that the peak strain of the PE pipe has a good power function attenuation relationship with scaled distance. In the scaled distance range of 6−11 m/kg1/3, the attenuation index of hoop strain (absolute value) is larger than the attenuation index of axial strain. The main vibration frequency of the dynamic response of the pipeline is slightly higher than the main vibration frequency of the soil, both in the same order. The pipeline synthesis velocity attenuation index is roughly the same as the axial strain attenuation index of the pipe. There is a strong correlation between the dynamic pressure signal measured by PZT and the strain rate signal of the same point. Due to the high water content in the high saturated soil, the PE pipe will be locally impacted and the greater circumferential strain will be produced, so this factor should be taken full account of the pipeline safety assessment. The hoop strain level is reduced, and the axial strain level relatively enhances when the scaled distance increases. Because of good and reliable dynamic performance of the PZT, the PZT is worthy of use and promotion as a mean for field detection of pipelines.

-

Key words:

- blast wave /

- PE pipe /

- saturated soil /

- dynamic strain /

- buried pipeline

-

表 1 不同深度土体纵波波速

Table 1. Longitudinal wave velocities of soil at different depths

实验编号 探头类型 埋深/cm 探头距离/m 纵波声速/(m·s−1) 1 声发射探头 20 0.5 853 2 水介质耦合探头 60 0.5 891 3 水介质耦合探头 100 0.5 954 表 2 不同药量下各测点最大拉应变

Table 2. The maximum tensile strain at each measuring point under different explosive charges

位置 /10−6 Q=50 g Q=75 g Q=100 g Q=125 g Q=150 g Q=175 g Q=200 g 2-1环向 20.7 23.4 25.4 39.1 50.9 50.9 67.6 2-1轴向 19.9 28.3 31.6 47.6 56.9 50.0 59.6 2-3环向 19.6 23.0 22.8 35.0 47.3 42.2 51.3 2-3轴向 21.5 28.0 33.9 61.5 96.3 107.2 130.0 3-1环向 20.3 23.7 25.9 41.2 51.7 49.2 65.6 3-1轴向 13.1 21.4 26.9 46.6 67.6 62.5 82.2 3-1(45°) 5.4 6.3 5.8 14.7 26.7 30.2 37.6 3-2环向 15.9 25.5 29.5 69.4 134.2 194.1 194.7 3-2轴向 18.2 24.3 24.4 41.6 65.5 76.0 87.9 3-3环向 28.8 33.7 28.2 43.6 70.7 98.7 115.3 3-3轴向 19.0 29.1 33.8 61.4 97.0 122.4 135.8 3-4环向 17.7 22.2 23.6 42.6 99.0 155.2 164.8 3-4轴向 18.9 25.6 29.7 51.3 82.1 88.1 102.7 表 3 不同药量下各测点最大压应变

Table 3. The maximum compressive strain at each measuring point under different explosive charges

位置 /10−6 Q=50 g Q=75 g Q=100 g Q=125 g Q=150 g Q=175 g Q=200 g 2-1环向 −20.6 −24.4 −26.7 −67.3 −127.8 −140.6 −181.3 2-1轴向 −19.0 −24.2 −26.8 −49.7 −61.1 −47.0 −57.9 2-3环向 −18.4 −29.5 −40.5 −87.5 −149.7 −174.3 −213.5 2-3轴向 −29.1 −38.4 −42.6 −68.4 −92.3 −78.0 −103.5 3-1环向 −19.9 −25.6 −28.2 −53.1 −102.3 −119.9 −147.0 3-1轴向 −23.0 −30.8 −35.0 −67.3 −95.2 −84.5 −110.1 3-1(45°) −7.3 −6.0 −6.6 −13.8 −25.0 −34.7 −37.0 3-2环向 −10.5 −16.3 −19.2 −41.3 −88.3 −110.4 −134.6 3-2轴向 −23.9 −36.9 −41.1 −75.6 −104.2 −122.3 −121.7 3-3环向 −22.6 −31.5 −37.3 −95.6 −199.1 −289.0 −309.1 3-3轴向 −27.5 −40.6 −44.0 −79.6 −107.6 −105.8 −115.7 3-4环向 −18.4 −27.5 −31.6 −50.6 −69.5 −54.8 −65.2 3-4轴向 −30.1 −41.0 −43.0 −84.0 −121.0 −114.3 −138.6 表 4 不同药量下PE管的PPV和主频

Table 4. The PPVs and main frequencies of the PE pipe under different explosive charges

Q/g X方向 Y方向 Z方向 合成PPV/(cm·s−1) PPV/(cm·s−1) 主频/Hz PPV/(cm·s−1) 主频/Hz PPV/(cm·s−1) 主频/Hz 50 1.14 26.31 0.43 25.84 1.32 27.46 1.39 75 1.20 22.86 0.55 24.69 1.29 25.48 1.68 100 1.05 25.16 1.19 21.62 1.56 24.1 1.91 125 1.68 11.9 1.68 17.24 2.56 20.9 3.00 150 2.92 9.22 2.17 24.60 3.91 18.2 4.41 175 3.53 9.24 2.18 21.98 4.04 17.02 4.63 200 4.43 9.59 2.80 21.98 4.92 16.80 5.49 表 5 不同药量下地表的PPV和主频

Table 5. The PPVs and main frequencies of the ground under different explosive charges

Q/g X方向 Y方向 Z方向 合成PPV/(cm·s−1) PPV/(cm·s−1) 主频/Hz PPV/(cm·s−1) 主频/Hz PPV/(cm·s−1) 主频/Hz 50 2.17 12.3 0.89 30.47 3.30 25.76 3.57 75 2.38 10.93 1.03 31.75 3.62 24.80 3.81 100 3.02 10.44 1.18 25.64 3.87 23.26 3.97 125 5.62 8.45 1.34 15.23 6.98 19.24 7.20 150 9.29 7.83 1.30 8.30 9.44 16.26 9.72 175 9.30 6.63 2.19 9.11 9.35 14.55 10.70 200 9.98 6.73 2.62 8.91 11.73 14.44 11.78 表 6 已有公式计算值和实测数据

Table 6. Deteced data and calculated values by existing formulas

药量/

g比例距离/

(m·kg−1/3)实测值 式(2) 式(3) 式(1) εcir/10−6 εlong/10−6 εcir/10−6 εlong/10−6 εlong/10−6 50 10.18 28.8 27.5 29.2 24.5 32.5 100 8.08 37.3 44.0 56.9 45.2 36.1 150 7.06 199.1 107.6 83.8 64.0 88.3 200 6.41 309.1 115.7 110.2 81.3 107.1 -

[1] DOWDING C H. Blast vibration monitoring and control[M]. New Jersey: Prentice-Hall, 1985: 167−171. [2] ESPARZA E D, WESTINE P S, WENZEL A B. Pipeline response to buried explosive detonations: Vol. 2: technical report[R]. Arlington, USA: American Gas Association, 1981. [3] SISKIND D E, STAGG M S, WIEGAND J E, et al. Surface mine blasting near pressurized transmission pipelines: RI 9523 [R]. Minneapolis, MN: US Department of the Interior Bureau of Mines, 1994. [4] KOURETZIS G P, BOUCKOVALAS G D, GANTES C J. Analytical calculation of blast-induced strains to buried pipelines [J]. International Journal of Impact Engineering, 2007, 34(10): 1683–1704. doi: 10.1016/j.ijimpeng.2006.08.008 [5] 热塑性塑料管材拉伸性能测定: GB/T 8804-2003 [S]. [6] 王峥辉. 下蜀黄土超声波波速与物理力学性质试验研究[D]. 南京: 河海大学, 2007: 57-58. doi: 10.7666/d.y1128172. [7] 温婷, 徐丽丽, 王青, 等. 混凝土表面应变片防水性能的试验研究 [J]. 中国科技信息, 2014(8): 107–110 doi: 10.3969/j.issn.1001-8972.2014.08.035WEN Ting, XU Lili, WANG Qing, et al. Experimental study on waterproof performance of concrete surface stain-gages [J]. China Science and Technology Information, 2014(8): 107–110 doi: 10.3969/j.issn.1001-8972.2014.08.035 [8] 李晓娟, 李全禄, 谢妙霞, 等. 国内外压电陶瓷的新进展及新应用 [J]. 硅酸盐通报, 2006, 25(4): 101–107 doi: 10.3969/j.issn.1001-1625.2006.04.024LI Xiaojuan, LI Quanlu, XIE Miaoxia, et al. New headways and new applications of piezoelectric at home and abroad [J]. Bulletin of the Chinese Ceramic Society, 2006, 25(4): 101–107 doi: 10.3969/j.issn.1001-1625.2006.04.024 [9] 穆朝民, 任辉启, 李永池, 等. 变埋深条件下饱和土爆炸能量耦合系数的试验研究 [J]. 岩土力学, 2010, 31(5): 1574–1578 doi: 10.3969/j.issn.1000-7598.2010.05.039MU Chaomin, REN Qihui, LI Yongchi, et al. Experiment study of explosion energy coupling coefficient with different burial depths in saturated soils [J]. Rock and Soil Mechanics, 2010, 31(5): 1574–1578 doi: 10.3969/j.issn.1000-7598.2010.05.039 [10] 库特乌佐夫. 爆破工程师手册[M]. 刘清泉, 译. 北京: 煤炭工业出版社, 1992: 137−138. [11] DATTA T K. Seismic response of buried pipelines: a state-of-the-art review [J]. Nuclear Engineering and Design, 1999, 192(2/3): 271–284. doi: 10.1016/S0029-5493(99)00113-2 -

下载:

下载: