Experimental investigation on deflagration to detonation transition of HMX/TNT/AL compositions at fast thermal ignition

-

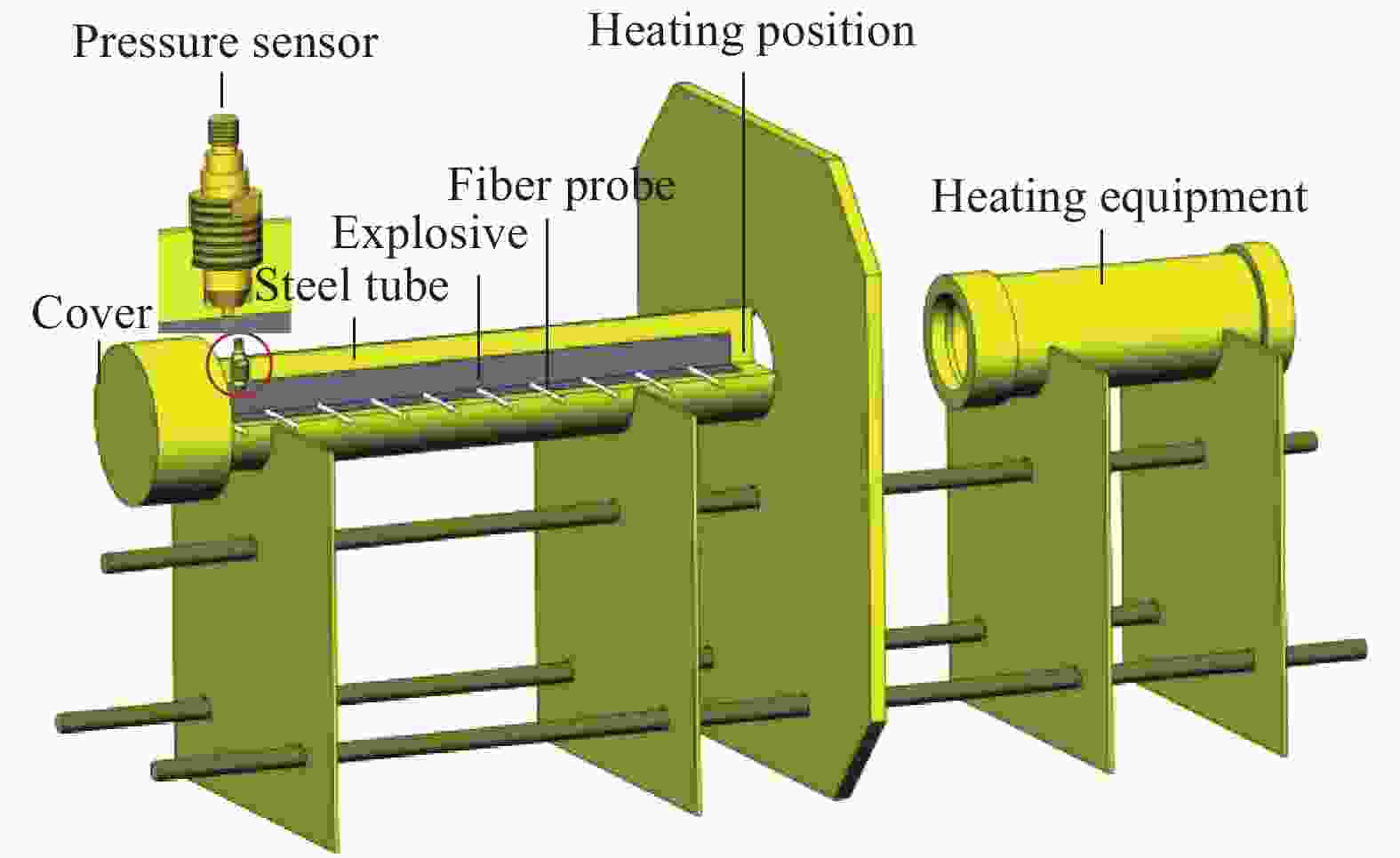

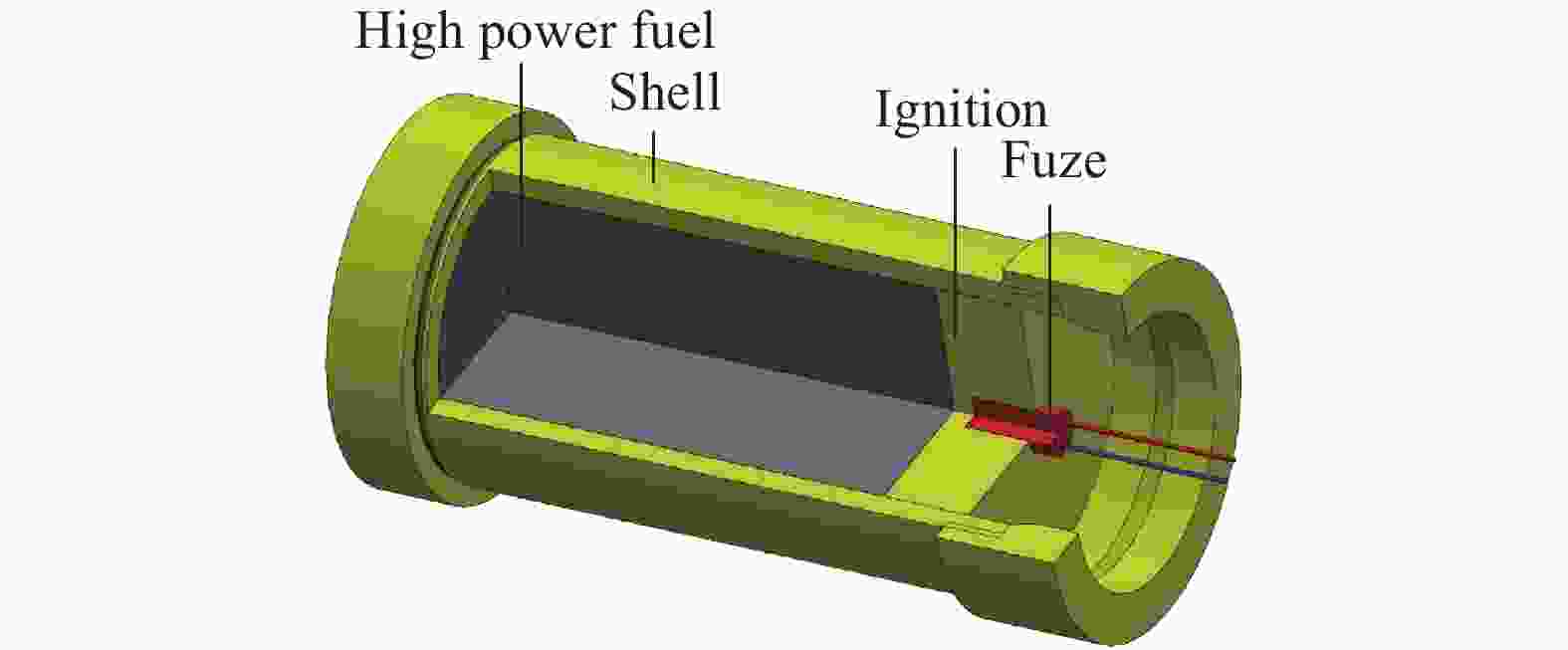

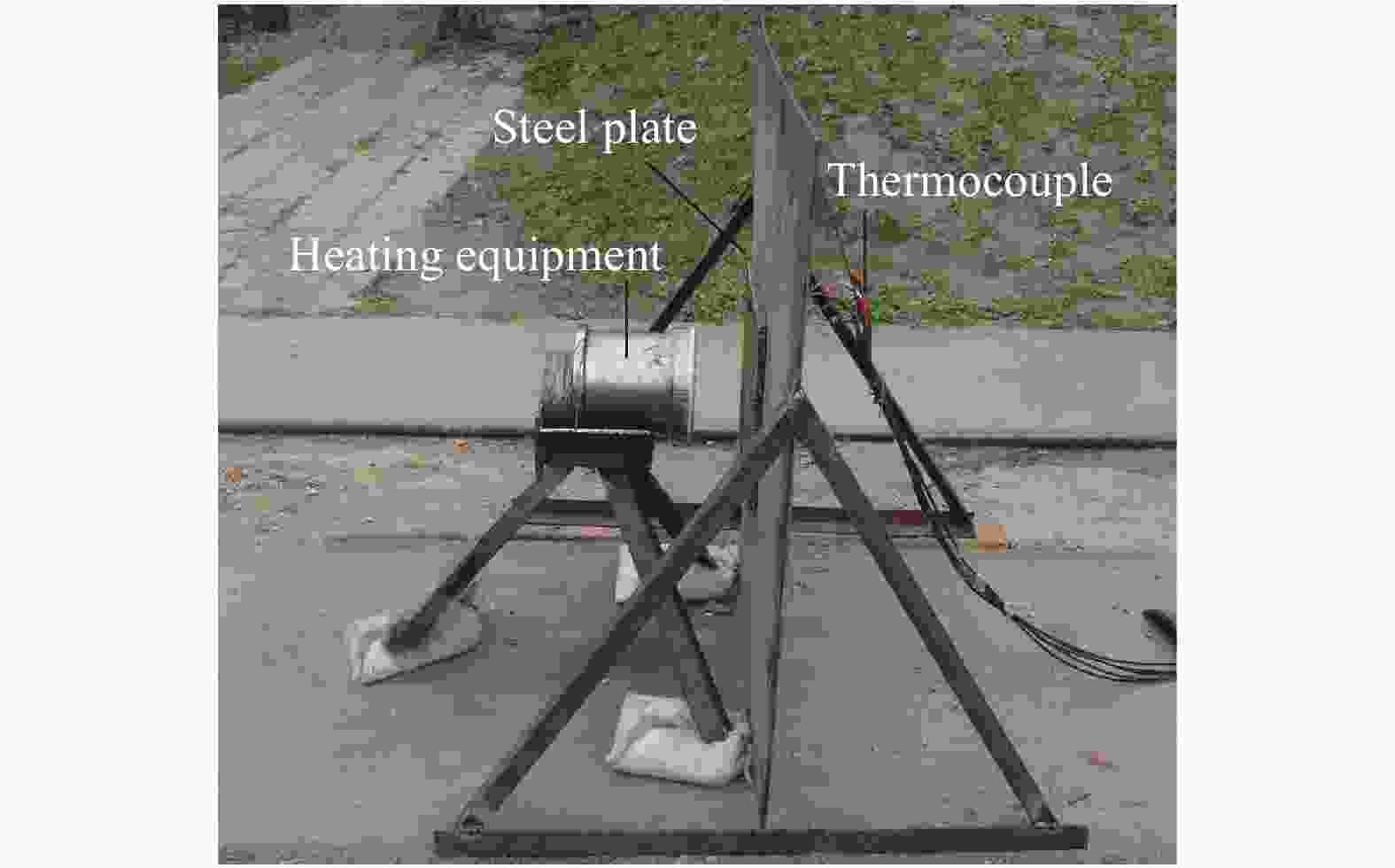

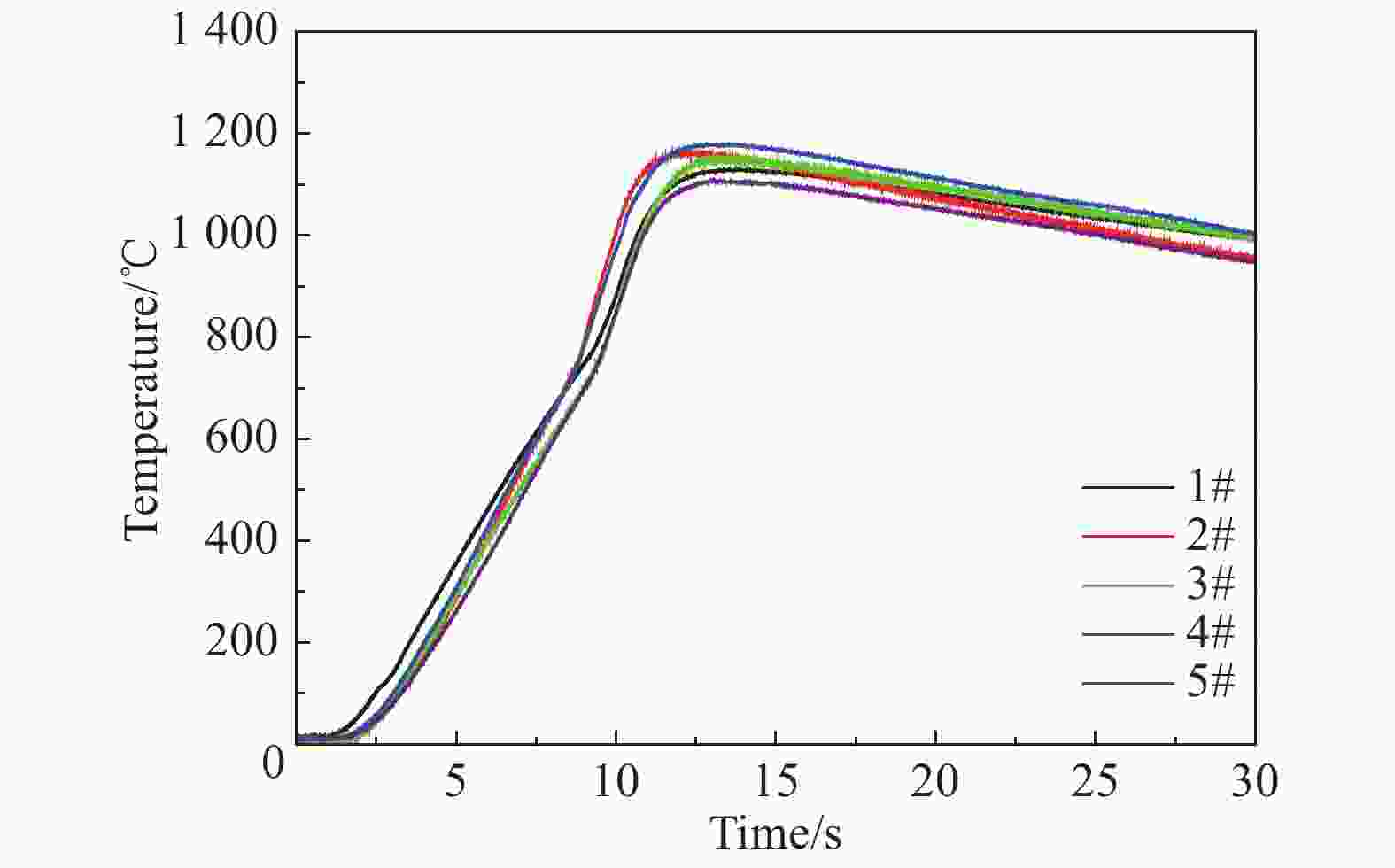

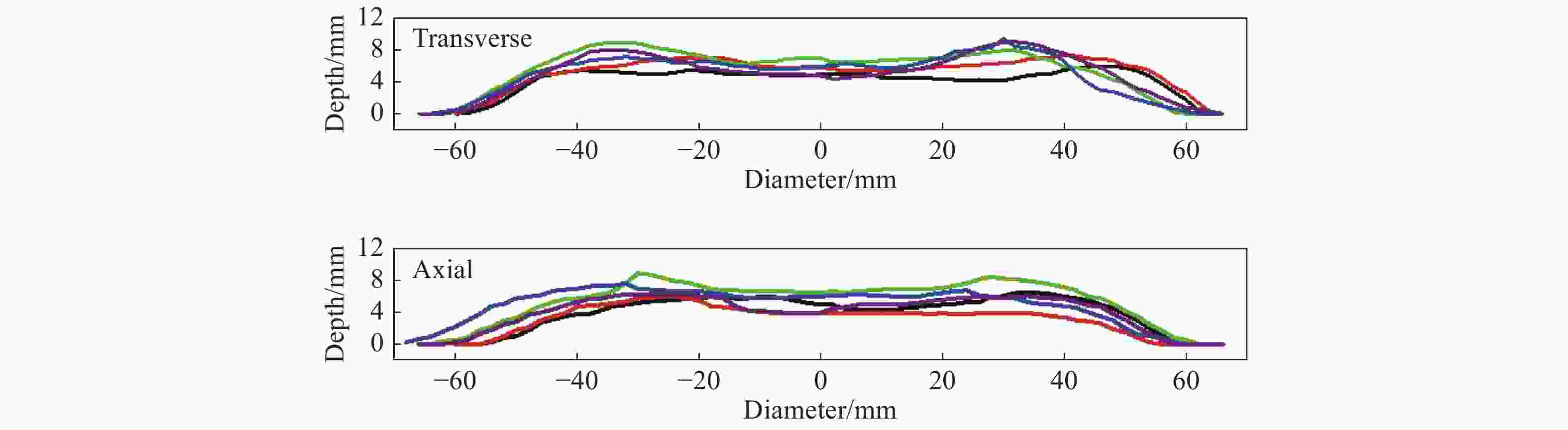

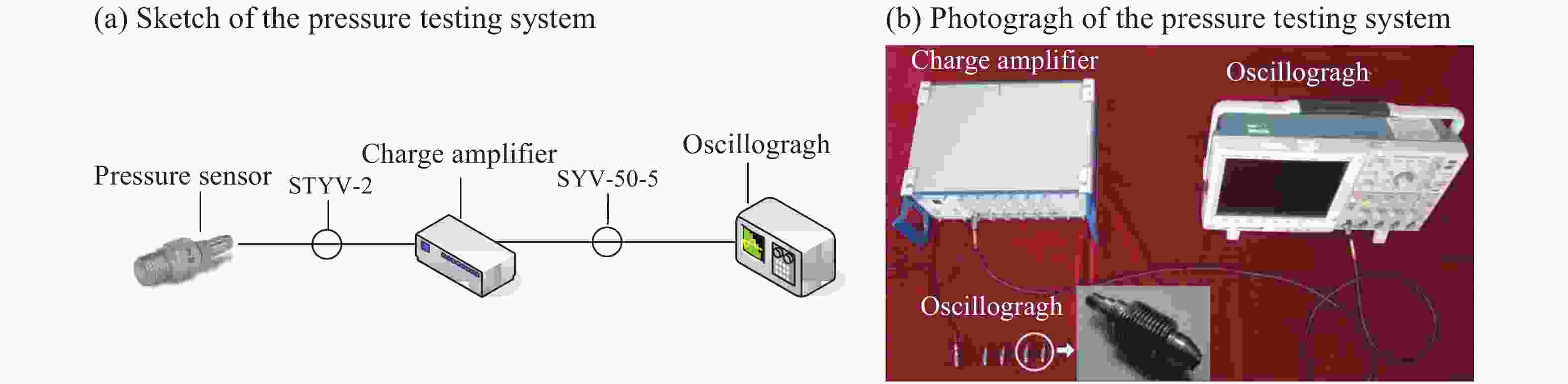

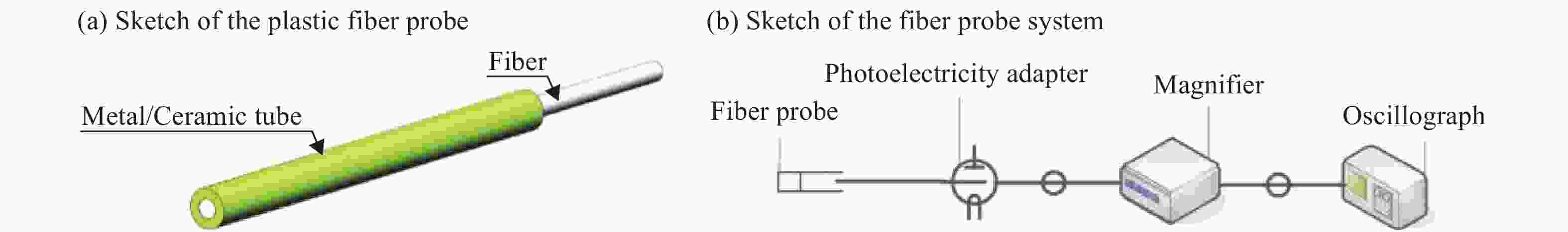

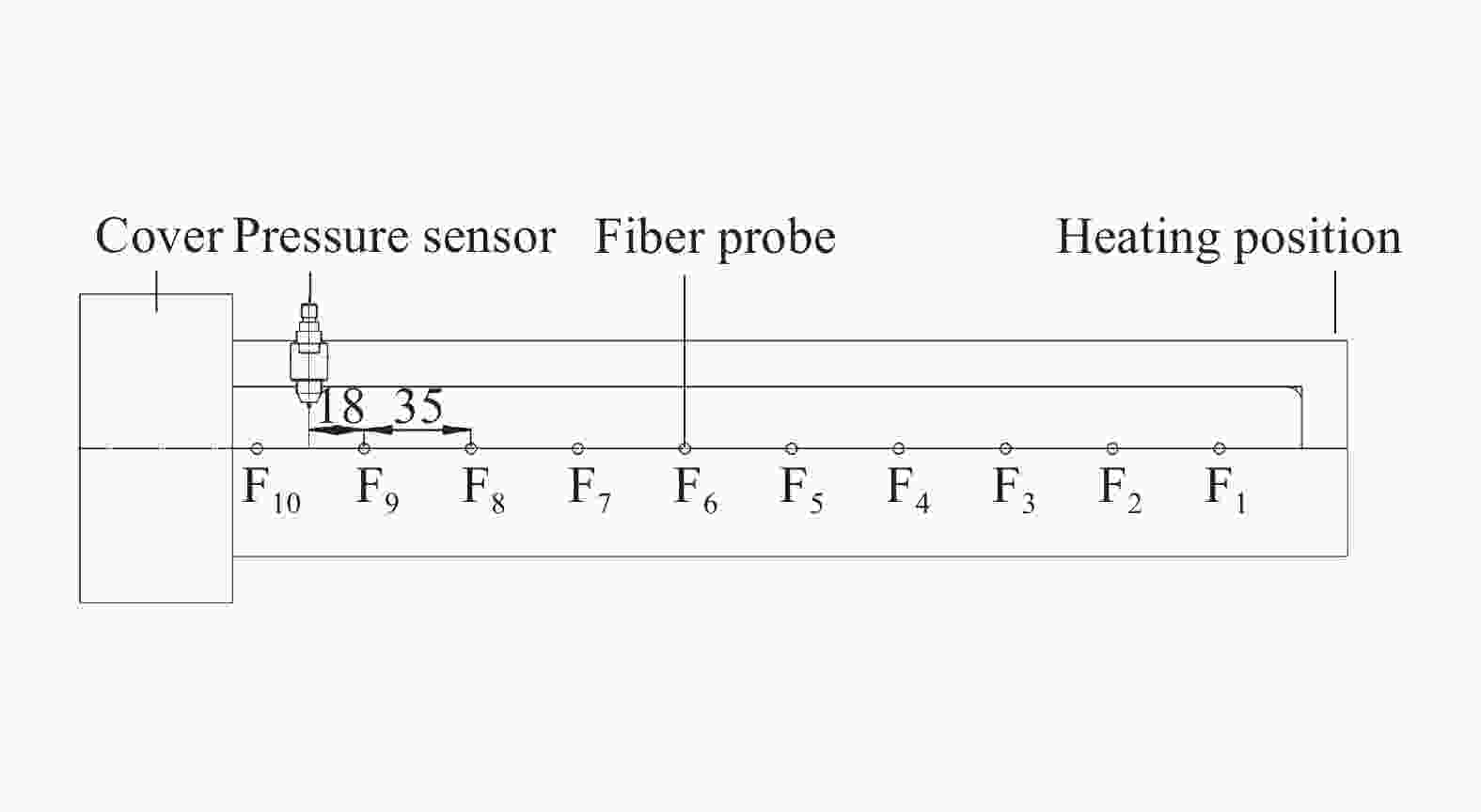

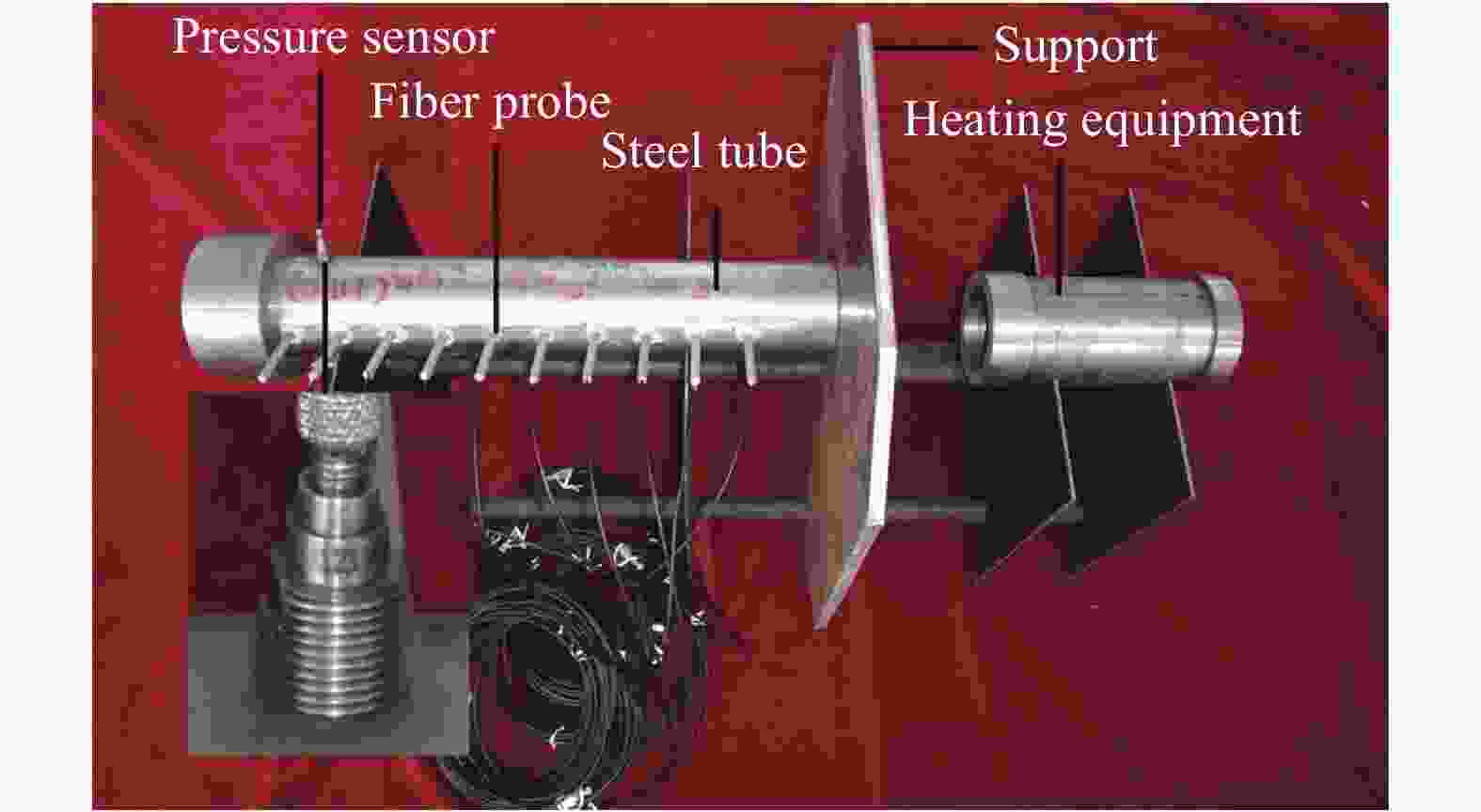

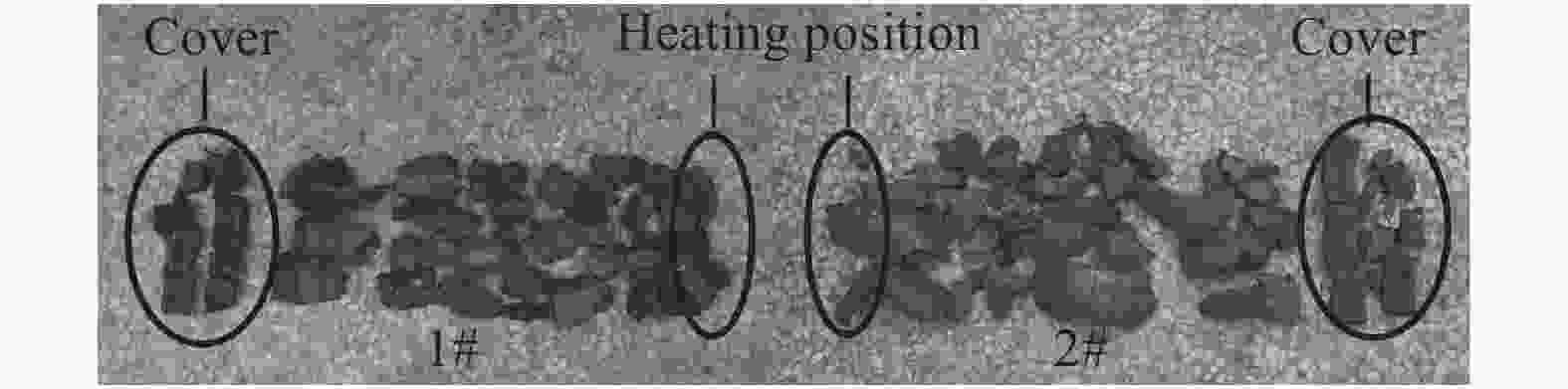

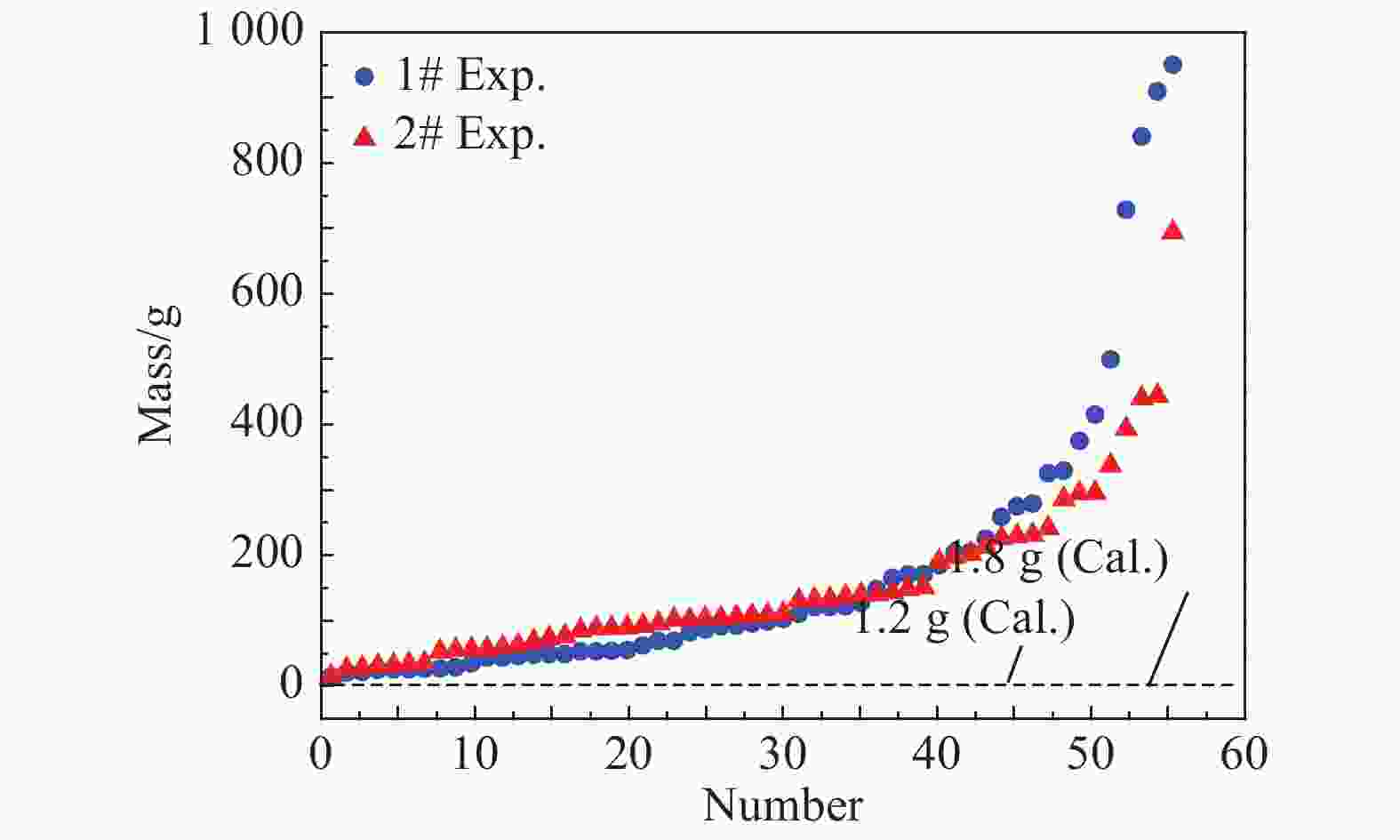

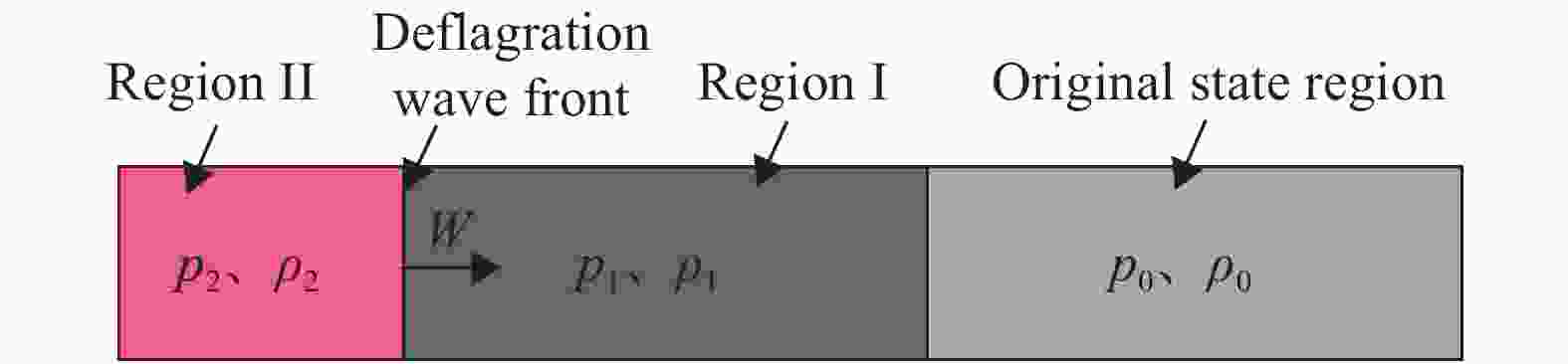

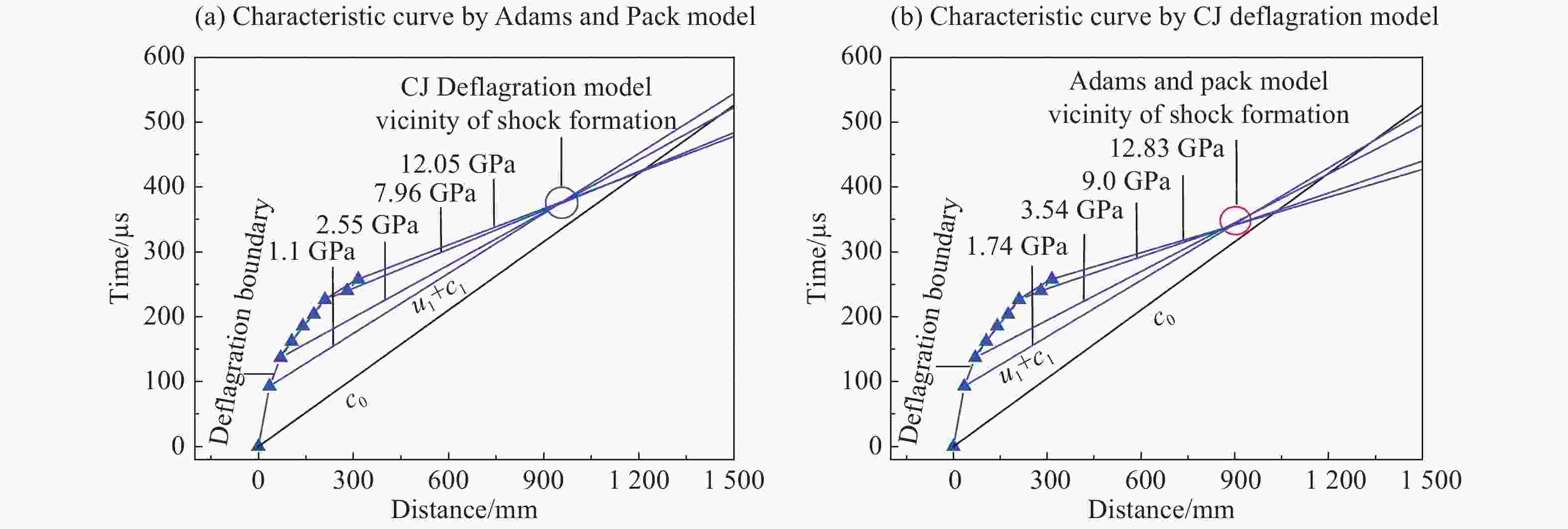

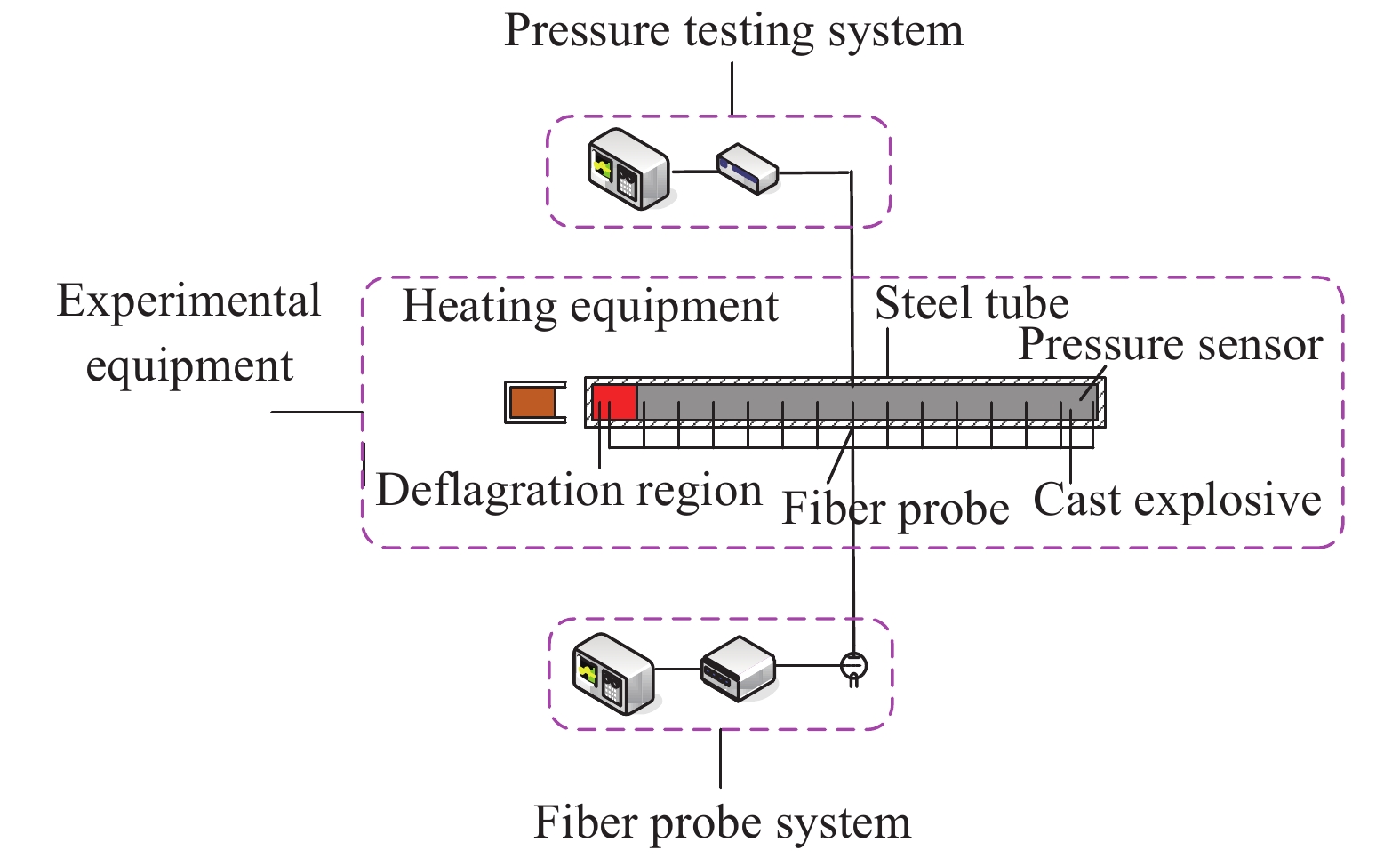

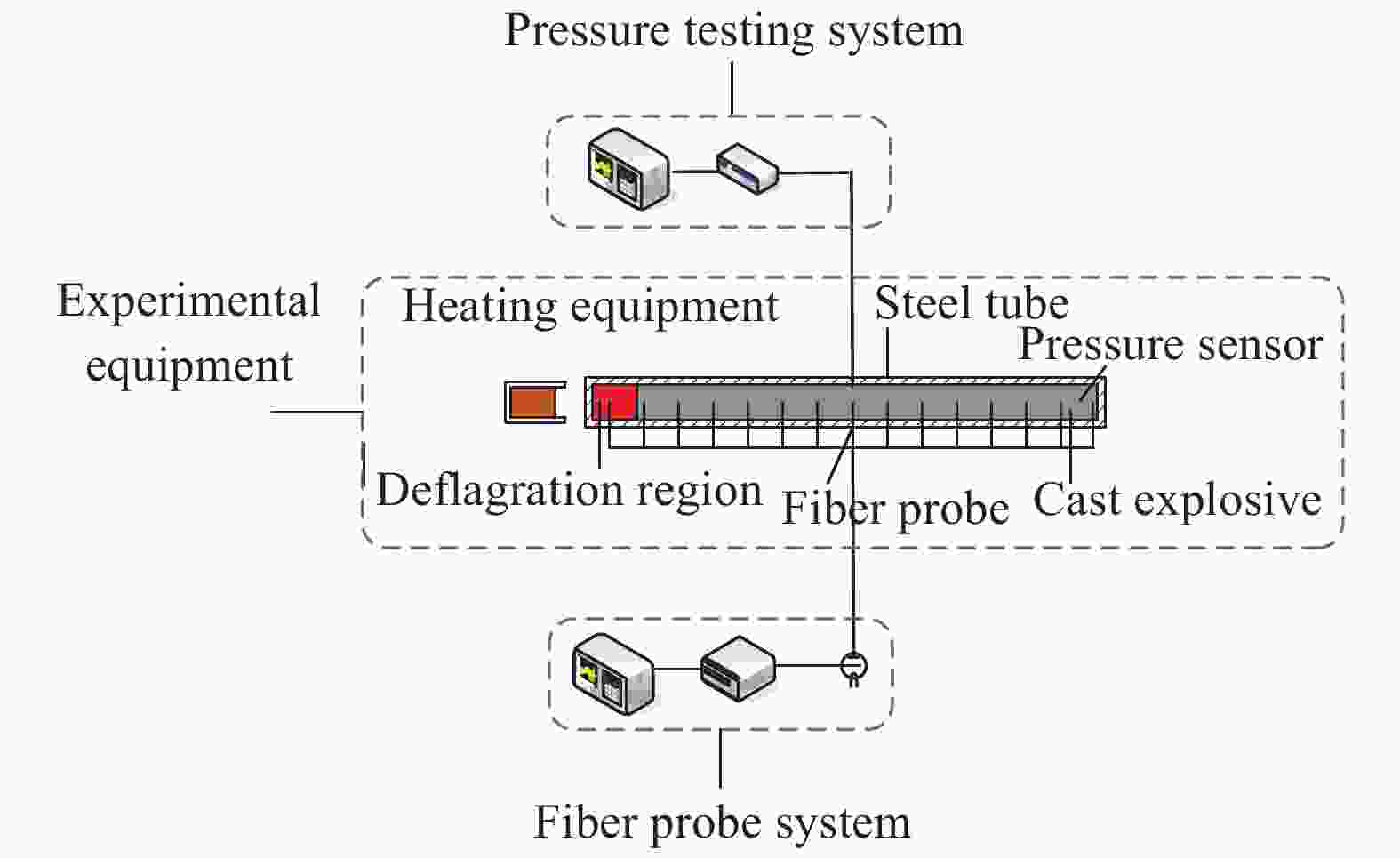

摘要: 以熔铸型含铝混合炸药熔奥梯铝为对象,研究铸装含铝混合炸药快速热点火后的燃烧转爆轰特性。建立了快速热点火燃烧转爆轰实验平台,由实验装置(加热装置、约束钢管、炸药)、压力测试系统、光纤测速系统组成;加热装置加热15 mm厚45钢钢板,峰值温度大于1 100 ℃,温升速率为85~95 ℃/s。开展了快速热点火带壳熔奥梯铝炸药燃烧转爆轰实验,由加热装置加热约束钢管内熔奥梯铝炸药,炸药化学反应阵面压力和传播速度分别由压电性高压压力传感器和光纤探针测定;实测阵面压力约1 GPa,传播速度最大约2 600 m/s。由光纤数据获得炸药化学反应阵面传播轨迹,通过特征线方法获得冲击形成点,半定量给出冲击形成距离大于850 mm;并比较了管体破片质量实测值与炸药完全爆轰时破片平均质量计算值,实测值远小于计算值。综合实测化学反应阵面传播速度和压力、冲击形成距离分析、破片质量比较,可确定熔奥梯铝炸药没有发生完全爆轰,其化学反应状态为爆燃。另外,采用Adams和Pack模型、CJ燃烧模型,都能够半定量的预估冲击形成距离和燃烧波后压力,为实验设计提供依据,但CJ燃烧模型的计算结果更接近于实测值。Abstract: Cast HMX/TNT/AL compositions are an aluminized explosive. In the present investigation of the deflagration to detonation transition of the cast HMX/TNT/AL compositions with a metal shell at fast thermal ignition, we constructed an experimental platform of DDT of the explosives with a metal shell at fast thermal ignition, which was composed of an experimental equipment, a pressure testing system and a fiber probe system used in the velocity measure. The experimental equipment was composed of the fast heating equipment, the steel tube and the explosives. The peak temperatures were more than 1 100 °C, the temperature rise ranged from 85 °C/s to 95 °C/s when the steel plates 16 mm chick were heated up by the fast heating equipment. Experiments on DDT of the explosives were conducted in which the cast HMX/TNT/AL compositions in the steel tube was heated up using the fast heating equipment. The velocity of the chemical reaction front was measured by the fiber probe as less than 2 600 m/s. The pressure of the chemical reaction front was measured by the high pressure sensor as approximately 1 GPa. The track of the chemical reaction front was obtained using the fiber history. The vicinity and distance of the shock formation were obtained through the characteristics diagram, showing the distance as more than 850 mm. Comparison was made between the estimated fragment mass values of the models and the measured values, with the latter larger than the former. It was concluded that the state of the chemical reaction on the cast HMX/TNT/AL compositions was not detonation but deflagration. According to the Adams & Pack model and the CJ deflagration model, the distance of the shock formation and the pressure of combustion wave was semi-quantitatively evaluated. The results of the CJ deflagration model was found to be closer to the measured values than the Adams & Pack model.

-

表 1 压力特征参数

Table 1. Pressure parameters

实验序号 压力峰值/MPa 时间/µs 1# 1 050 73.5 2# 1 136 69.0 表 2 燃烧区和压缩区状态参数

Table 2. State parameters of Region Ⅰ and Region Ⅱ

Adams and Pack 模型 p1/GPa p2/GPa (u1+c1)/(m·s−1) u1/(m·s−1) c1/(m·s−1) ρ1/(kg·m−3) W/(m·s−1) ρ2/(kg·m−3) E1/(kJ·g−1) E2/(kJ·g−1) 1.74 1.70 3 460 305 3 155 1 993 376 378 871.6 2 775.4 3.54 3.26 3 989 570 3 419 2 159 796 617 1 630.4 3 273.5 6.25 5.20 4 654 902 3 752 2 370 1 400 843 2 604.5 3 811.6 6.90 5.58 4 798 974 3 824 2 415 1 535 883 2 816.6 3 913.6 9.0 6.71 5 228 1 189 4 039 2 551 1 945 991 3 458.6 4 192.4 12.83 8.34 5 912 1 531 4 381 2 767 2 592 1 132 4 500.2 4 559.5 CJ 燃烧模型 p1/GPa p2/GPa (u1+c1)/(m·s−1) u1/(m·s−1) c1/(m·s−1) ρ1/(kg·m−3) W/(m·s−1) u2/(m·s−1) ρ2/(kg·m−3) E1/(kJ·g−1) E2/(kJ·g−1) 1.1 0.32 3 246 198 3 048 1 925 376 −2 077 138 565.7 1 423.8 2.55 0.78 3 708 429 3 279 2 071 796 −1 895 283 1 227.2 1 715.5 5.11 1.67 4 390 770 3 620 2 286 1 400 −1 623 476 2 214.3 2 164.6 5.77 1.90 4 546 848 3 698 2 335 1 535 −1 561 518 2 443.3 2 271.0 7.96 2.71 5 022 1 086 3 936 2 486 1 945 −1 369 645 3 148.2 2 603.3 12.05 4.29 5 782 1 466 4 316 2 726 2 592 −1 060 841 4 299.2 3 160.8 -

[1] Evaluation experiment of nonnuclear ammunition about Fatalness: MIL-STD-2015C [S]. 2003: 47−52. [2] MACEK A. Transition from deflagration to detonation in cast explosives [J]. Journal of Chemical Physics, 1959, 31(2): 162–167. doi: 10.1063/1.1730287 [3] GRIFFITH N, GROOCOKE J M. The burning to detonation in solid explosive [J]. Journal of Chemical Physics, 1960: 4154–4165. doi: 10.1039/jr9600004154 [4] MCAFEE J M, ASAY B W, CAMPBELL A W, et al. Deflagration to detonation in granular HMX, ignition, kinetics and shock formation[C]//Proceedings 10th Symp(Int) on Detonation. Maryland: NSWC, 1993: 716−720. DOI: CDSTIC.DOE.10162277. [5] LEURET F, CHAISSE F, PRESLES H N. Experimental study of the low velocity detonation regime during the deflagration to detonation transition in a high density explosive[C]// Proceedings of 11th International Symposium on Detonation//Snowmass, Colorado, 1998: 693−701. [6] GIFFORD M J, TSEMBELIS A K, FIELD J E. Anomalous detonation velocities following type II deflagration to detonation transitions in pentaerythritol tetranitrate [J]. Journal of J Applied Phys, 2002, 91(4): 4995–5002. doi: 10.1063/1.1462415 [7] SANDUSKY H W, GRANHOLM R H, BOHL D G, et al. Deflagration to detonation transition in LX-04 as a function of loading density, temperature, and confinement[C]//13th International Detonation Symposium. Norfolk, VA, United States, 2006: 1−9. [8] TARVER C M, GOODALE T C, SHAW R, et al. Deflagration to detonation transiton studies for two potential isomeric cast primary explosives[C] //6th Symposium (International) on Detonation//Coronado, California, 1976: 231−250. [9] CHUZEVILLE V, BAUDIN G, LEFRANCOIS A, et al. Detonation initiation of heterogeneous melt cast high explosives[C]// 41st International Pyrotechnic Seminar, EUROPYRO, 2015: 1−5. DOI: 10.1063/1.4971467. [10] RAO P T, GONTHIER K A. Mesostructure dependent reactive burn modeling of porous solid explosives[C]//50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, 2014: 1−10. DOI: 10.2514/6.2014-3810. [11] RAO P T, GONTHIER K A. Analysis of compaction shock interactions during DDT of low density HMX [J]. Shock Compression of Condensed Matter, 2015: 1–7. doi: 10.1063/1.4971610 [12] TRINGE J W, VANDERSALL K S, REAUGH J E. Observation and Modeling of Deflagration to Detonation Transition (DDT) in Low Density HMX [J]. Shock Compression of Condensed Matter, 2015, 1793(1): 060024. doi: 10.1063/1.4971580 [13] BODARD S, LAPÉBIE E, SAUREL R. Experiments and modeling of dynamic powder compaction in the scope of deflagration to detonation transition studies [J]. Shock Compression of Condensed Matter, 2015, 1793(1): 040029. doi: 10.1063/1.4971523 [14] Dattelbaum D M, Sheffield S A, Gustavsen R L. A comparison of the shock initiation sensitivities, and resulting reactive flow of several 2,4,6-trinitrotoluene-based explosives [C]// Fifteenth International Detonation Symposium, 2014: 740−749. [15] 孙锦山. 含能材料的燃烧转爆轰研究 [J]. 含能材料, 1994, 2(3): 1–12SUN Jinshan. Study of deflagration to detonation transiton in energetic materials [J]. Chinese Journal of Energetic Materials, 1994, 2(3): 1–12 [16] 张超, 马亮, 赵凤起, 等. 含能材料燃烧转爆轰研究进展 [J]. 含能材料, 2015, 23(10): 1028–1036ZHANG Chao, MA Liang, ZHAO Fengqi, et al. Review on Deflagration to detonation transition of energetic materials [J]. Chinese Journal of Energetic Materials, 2015, 23(10): 1028–1036 [17] 王平. 凝聚相炸药DDT的实验研究与数值模拟[D]. 北京: 北京理工大学, 1992: 30−45.WANG Ping. Experimental study and numerical simulation for deflagration to detonation transition about condensed explosives[D]. Beijing: Beijing Institute of Technology, 1992: 30−45. [18] 文尚刚, 王胜强, 黄文斌, 等. 高密度B炸药的燃烧转爆轰实验研究 [J]. 爆炸与冲击, 2007, 27(11): 567–571WEN Shanggang, WANG Shengqiang, HUANG Wenbin, et al. An experimental study on deflagration to detonation transition in high denstity compositon B [J]. Explosion and Shock Waves, 2007, 27(11): 567–571 [19] 赵同虎, 张新彦, 李斌, 等. 颗粒状HMX、RDX的燃烧转爆轰实验研究 [J]. 含能材料, 2003, 11(12): 187–190 doi: 10.11943/j.issn.1006-9941.2015.10.021ZHAO Tonghu, ZHANG Xinyan, LI Bin, et al. Experimental study on the deflagration to detonation transition for granular HMX, RDX [J]. Energetic Materials, 2003, 11(12): 187–190 doi: 10.11943/j.issn.1006-9941.2015.10.021 [20] 杨涛. 高装填密度火药床燃烧转爆轰的实验研究和数值模拟[D]. 南京: 华东工学院, 1995: 8−22.YANG Tao. Experimental study and numerical simulation for deflagration to detonation transition in high packed propellant bed[D]. Nanjing: East China Institute of Technolagy, 1995: 8−22. [21] 段宝福. 新型钝感工业炸药的燃烧转爆轰研究[M]. 北京: 中国水利水电出版社, 2009: 55−62.DUAN Baofu. Study on deflagration to detonation transition for new style deterred industrial explosive. Beijing: China Waterpower Press, 2009: 55−62. [22] 张超, 赵凤起, 金朋刚等. p(BAMO-AMMO)热塑性高能推进剂燃烧转爆轰试验研究 [J]. 火炸药学报, 2016, 39(04): 92–96ZHANG Chao, ZHAO Fengqi, JIN Penggang, et al. Experimental study on deflagration to detonation transition (DDT) in p(BAMO-AMMO) thermoplastic high energy propellants [J]. Chinese Journal of Explosives & Propellants, 2016, 39(04): 92–96 [23] 陈晓明, 赵瑛, 宋长文, 等. 发射药燃烧转爆轰的试验研究 [J]. 火炸药学报, 2012, 35(4): 69–72 doi: 10.3969/j.issn.1007-7812.2012.04.018CHEN Xiaoming, ZHAO Ying, SONG Changwen, et al. Experimental study on deflagration to fetonation transition of gun propellants [J]. Chinese Journal of Explosives & Propellants, 2012, 35(4): 69–72 doi: 10.3969/j.issn.1007-7812.2012.04.018 [24] 秦能. 一种RDX-CMDB推进剂危险性能研究 [J]. 含能材料, 2011, 19(06): 725–729 doi: 10.3969/j.issn.1006-9941.2011.06.027QIN Neng, PEI Jiangfeng, WANG Mingxing. Hazard property of the RDX-CMDB propellant [J]. Chinese Journal of Energetic Materials, 2011, 19(06): 725–729 doi: 10.3969/j.issn.1006-9941.2011.06.027 [25] 秦能, 裴江峰, 王明星. 几种典型固体推进剂的燃烧转爆轰实验研究 [J]. 火炸药学报, 2010, 33(04): 86–89 doi: 10.3969/j.issn.1007-7812.2010.04.022QIN Neng, PEI Jiangfeng, WANG Mingxing. Experimental study on deflagration to detonation transition of several typical solid propellants [J]. Chinese Journal of Explosives & Propellants, 2010, 33(04): 86–89 doi: 10.3969/j.issn.1007-7812.2010.04.022 [26] 冯晓军, 杨建刚, 徐洪涛, 等. AP和Al含量对DNTF基炸药燃烧转爆轰的影响 [J]. 含能材料, 2016, 24(08): 752–756 doi: 10.11943/j.issn.1006-9941.2016.08.005FENG Xiaojun, YANG Jiangang, Xu Hongtao, et al. Effect of content of AP and Al on the deflagration to detonation transition of DNTF-based explosives [J]. Chinese Journal of Energetic Materials, 2016, 24(08): 752–756 doi: 10.11943/j.issn.1006-9941.2016.08.005 [27] 陈朗, 王飞, 伍俊英, 等. 高密度压装炸药燃烧转爆轰研究 [J]. 含能材料, 2011, 19(06): 697–704 doi: 10.3969/j.issn.1006-9941.2011.06.022CHEN Lang, WANG Fei, WU Junying, et al. Investigation of the deflagration to detonation transition in pressed high density explosives [J]. Chinese Journal of Energetic Materials, 2011, 19(06): 697–704 doi: 10.3969/j.issn.1006-9941.2011.06.022 [28] 代晓淦, 王娟, 文玉史, 等. PBX-2炸药加热条件下燃烧转爆轰特性 [J]. 含能材料, 2013, 21(05): 649–652 doi: 10.3969/j.issn.1006-9941.2013.05.017DAI Xiaogan, WANG Juan, WEN Yushi, et al. Deflagration to detonation transition characteristics for heated PBX-2 [J]. Chinese Journal of Energetic Materials, 2013, 21(05): 649–652 doi: 10.3969/j.issn.1006-9941.2013.05.017 [29] 金韶华, 松全才. 炸药理论[M]. 西安: 西北工业大学出版社, 2010: 288−304. [30] 兵器工业第二零四研究所. 混合炸药及其发展[M]. 西安, 2008: 52−56. [31] 兵器工业第二零四研究所. 火炸药手册[M]. 西安, 1987: 200−201. [32] 九零三所情报室. 高能炸药性能数据手册[M]. 四川绵阳, 1982: 65−66. [33] 成大先. 机械设计手册[M]. 北京: 化学工业出版社, 2004: 3−15. [34] 赵生伟, 周刚, 初哲, 等. 快速热作用下带壳铸装梯黑铝炸药热响应实验研究 [J]. 兵工学报, 2014, 30(S2): 302–308 doi: 10.3321/j.issn:1000-1093.2009.08.003ZHAO Shengwei, ZHOU Gang, CHU Zhe, et al. Experiment investigation on thermal response of cast TNT/RDX/AL [J]. Acta Armamentarii, 2014, 30(S2): 302–308 doi: 10.3321/j.issn:1000-1093.2009.08.003 -

下载:

下载: