| [1] |

COOPER M G, FAIRWEATHER M, TITE J P. On the mechanisms of pressure generation in vented explosions [J]. Combustion and Flame, 1986, 65(1): 1–14. DOI: 10.1016/0010-2180(86)90067-2.

|

| [2] |

CHAO J, BAUWENS C R, DOROFEEV S B. An analysis of peak overpressures in vented gaseous explosions [J]. Proceedings of the Combustion Institude, 2011, 33(2): 2367–2374. DOI: 10.1016/j.proci.2010.06.144.

|

| [3] |

师喜林, 王志荣, 蒋军成. 球形容器内气体的泄爆过程 [J]. 爆炸与冲击, 2009, 29(4): 390–394. DOI: 10.11883/1001-1455(2009)04-0390-05.SHI Xilin, WANG Zhirong, JIANG Juncheng. Explosion-vented processes for methane-air premixed gas in spherical vessels with venting pipes [J]. Explosion and Shock Waves, 2009, 29(4): 390–394. DOI: 10.11883/1001-1455(2009)04-0390-05.

|

| [4] |

胡俊, 浦以康, 万士昕, 等. 柱形容器开口泄爆过程中压力发展特性的实验研究 [J]. 爆炸与冲击, 2001, 21(1): 47–52. doi: 10.3321/j.issn:1001-1455.2001.01.010HU Jun, PU Yikang, WAN Shixin, et al. Experimental investigations of pressure development during explosion vent from cylindrical vessels [J]. Explosion and Shock Waves, 2001, 21(1): 47–52. doi: 10.3321/j.issn:1001-1455.2001.01.010

|

| [5] |

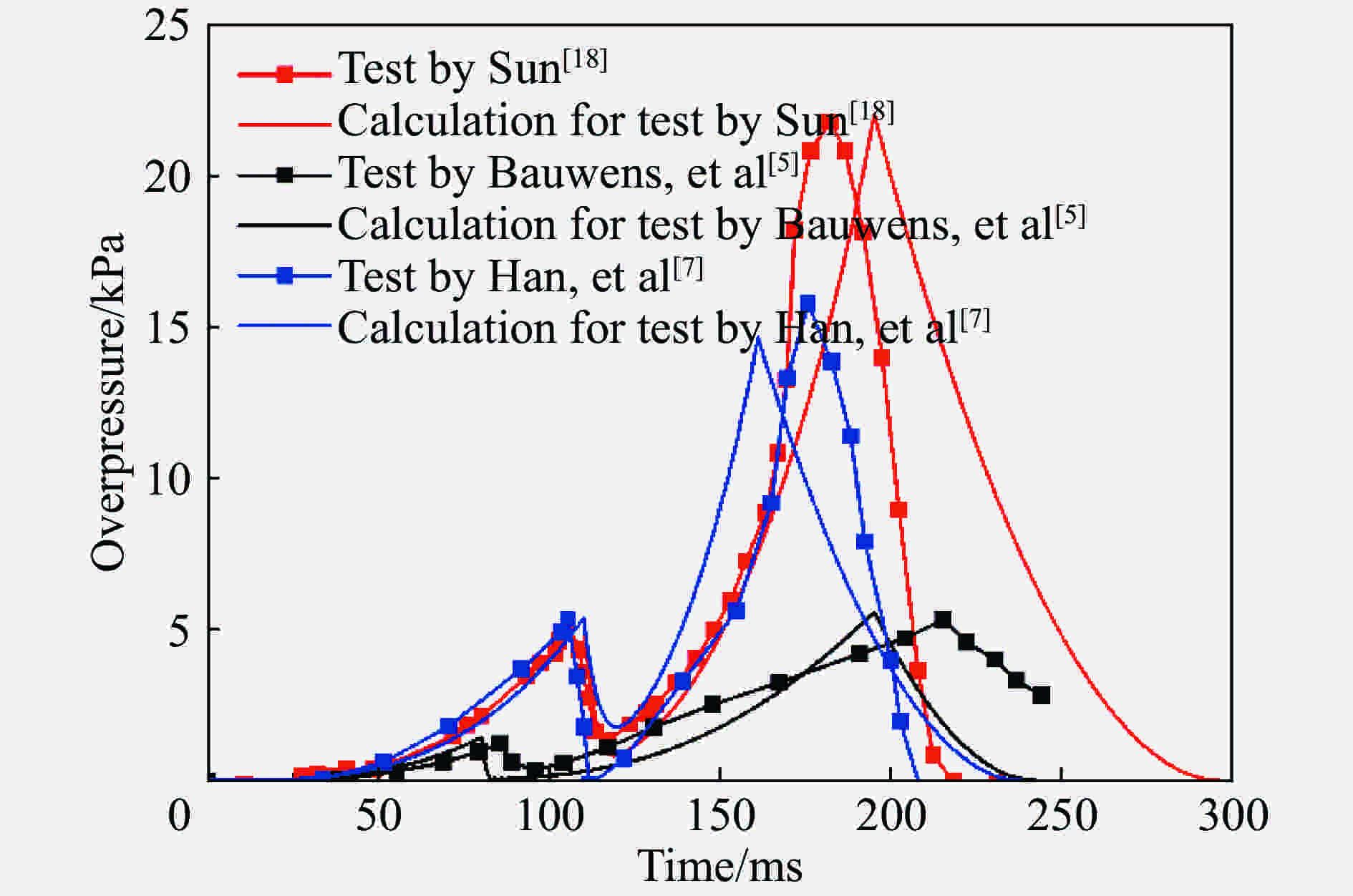

BAUWENS C R, CHAFFEE J, DOROFEEV S. Effect of ignition location, vent size, and obstacles on vented explosion overpressures in propane-air mixtures [J]. Combustion Science and Technology, 2010, 182(11−12): 1915–1932. DOI: 10.1080/00102202.2010.497415.

|

| [6] |

BRADLEY D, MITCHESON A. The venting of gaseous explosions in spherical vessels: Ⅱ: theory and experiment [J]. Combustion and Flame, 1978, 32: 237–255. DOI: 10.1016/0010-2180(78)90099-8.

|

| [7] |

HAN Yongli, CHEN Longzhu. Mechanical model of domestic gas explosion load [J]. Transactions of Tianjin University, 2008, 14(6): 434–440. DOI: 10.1007/s12209-008-0075-x.

|

| [8] |

UGARTE O J, AKKERMAN V, RANGWALA A S. A computational platform for gas explosion venting [J]. Process Safety and Environmental Protection, 2016, 99: 167–174. DOI: 10.1016/j.psep.2015.11.001.

|

| [9] |

National Fire Protection Association. Standard on explosion protection by deflagration venting: NFPA68-2013 [S]. Quincy: National Fire Protection Association, 2013.

|

| [10] |

SUSTEK J, JANOVSKY B. Comparison of empirical and semi-empirical equations for vented gas explosion with experimental data [J]. Journal of Loss Prevention in the Process Industries, 2013, 26(6): 1549–1557. DOI: 10.1016/j.jlp.2013.08.014.

|

| [11] |

KOBIERA A, KINDRACKI J, ZYDAK P, et al. A new phenomenological model of gas explosion based on characteristics of flame surface [J]. Journal of Loss Prevention in the Process Industries, 2007, 20(3): 271–280. DOI: 10.1016/j.jlp.2007.04.023.

|

| [12] |

KIM Joon Hyun, KIM Joo-Hyun. Simplified modeling of deflagration in vessels [J]. Journal of Mechanical Science and Technology, 2004, 18(8): 1338–1348. DOI: 10.1007/bf02984248.

|

| [13] |

GU X Z, HAQ M Z, LAWES M, et al. Laminar burning velocity and Markstein lengths of methane-air mixtures [J]. Combustion and Flame, 2000, 121(1−2): 41–58. DOI: 10.1016/S0010-2180(99)00142-X.

|

| [14] |

赵衡阳. 气体和粉尘爆炸原理[M]. 北京: 北京理工大学出版社, 1996.

|

| [15] |

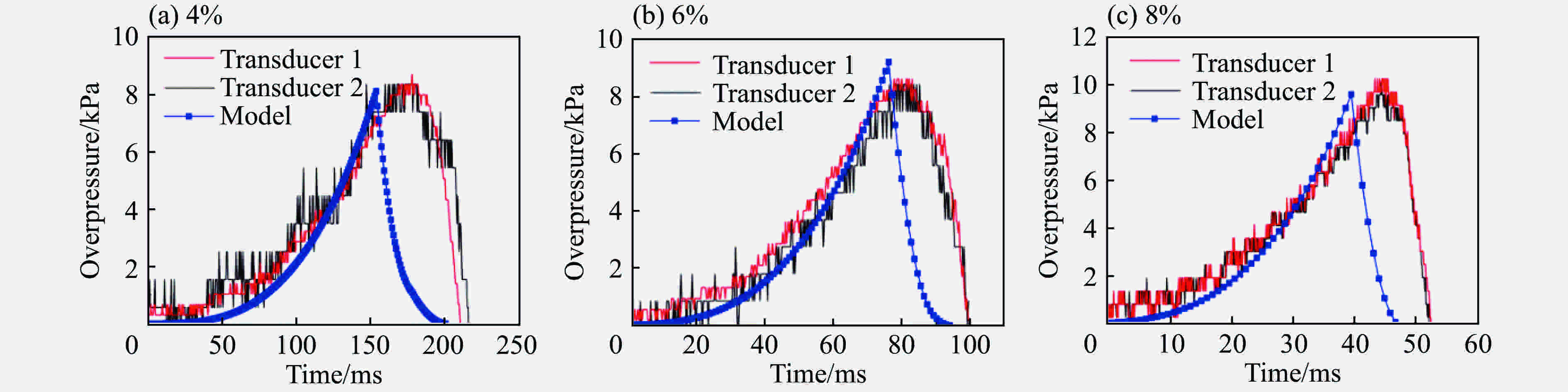

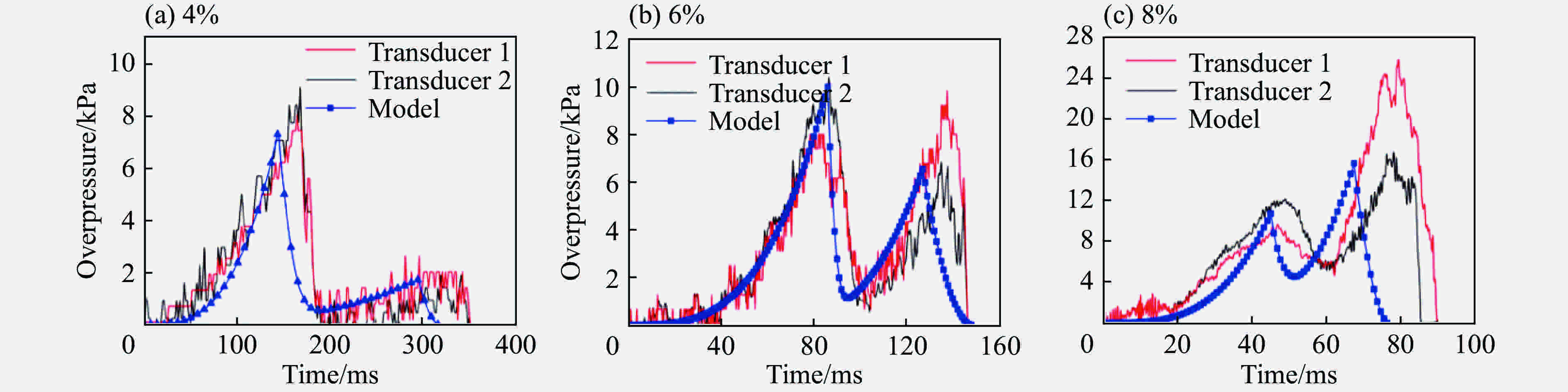

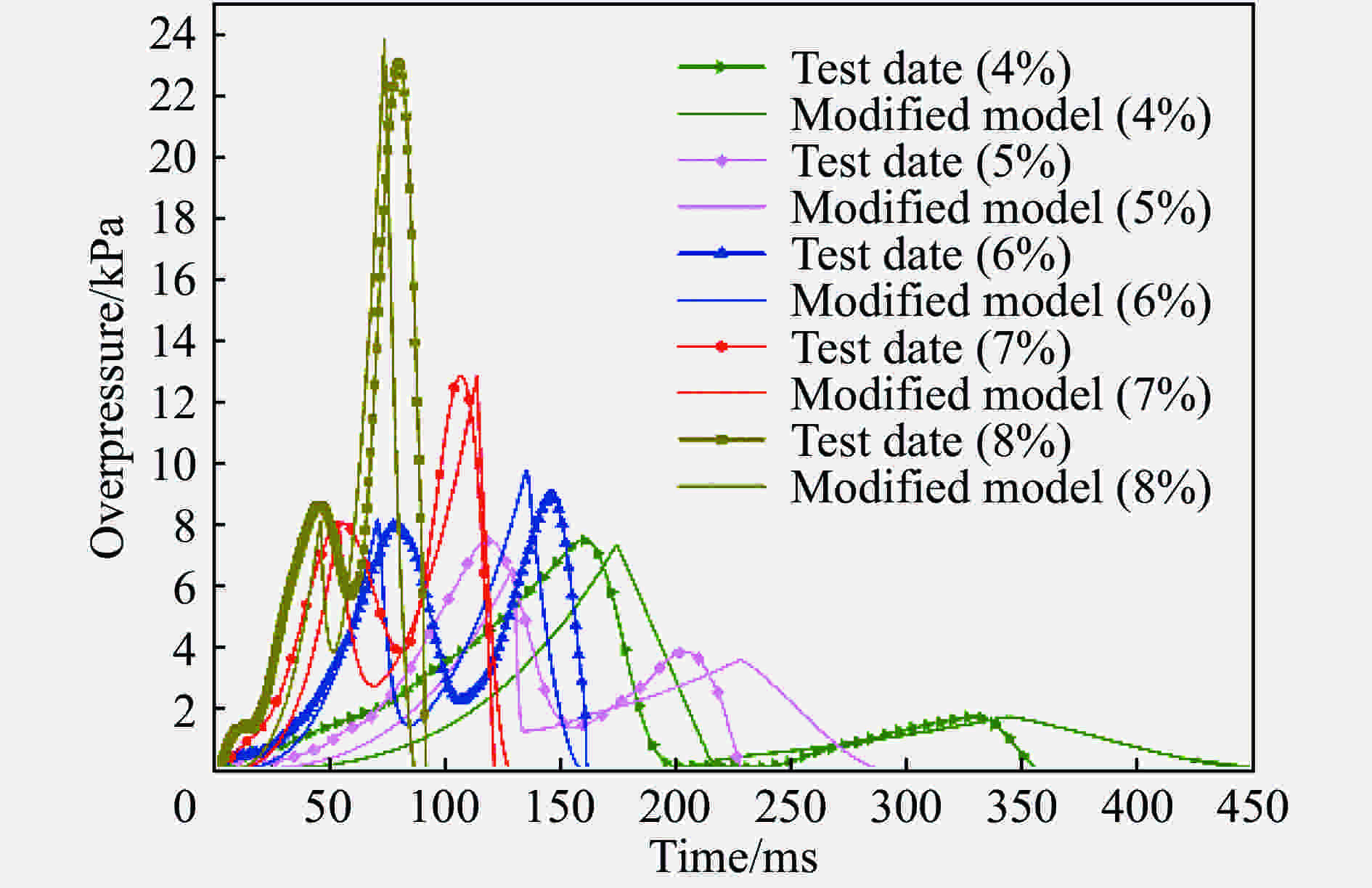

BAO Qi, FANG Qin, ZHANG Yadong, et al. Effects of gas concentration and venting pressure on overpressure transients during vented explosion of methane-air mixtures [J]. Fuel, 2016, 175: 40–48. DOI: 10.1016/j.fuel.2016.01.084.

|

| [16] |

MOEN I O, LEE J H S, HJERTAGER B H, et al. Pressure develpoment due to turbulent flame propagation in large-scale methane-air explosions [J]. Combustion and Flame, 1982, 47: 31–52. doi: 10.1016/0010-2180(82)90087-6

|

| [17] |

WEI Haiqiao, GAO Dongzhi, ZHOU Lei, et al. Different combustion modes caused by flame-shock interactions in a confined chamber with a perforated plate [J]. Combustion and Flame, 2017, 178: 277–285. DOI: 10.1016/j.combustflame.2017.01.011.

|

| [18] |

孙敖. 建筑物内可燃气体爆炸泄放研究[D]. 南京: 解放军理工大学, 2013.

|

| [19] |

MASRI A R, IBRAHIM S S, NEHZAT N, et al. Experimental study of premixed flame propagation over various solid obstructions [J]. Experimental Thermal and Fluid Science, 2000, 21(1-3): 109–116. DOI: 10.1016/S0894-1777(99)00060-6.

|

| [20] |

孙松, 高康华. 管道内气体爆炸时火焰传播湍流因子的研究 [J]. 煤炭学报, 2016, 41(S2): 441–447. DOI: 10.13225/j.cnki.jccs.2016.0102.SUN Song, GAO Kanghua. Study on turbulence factors of flame propagation in tube under gas explosion [J]. Journal of China Coal Society, 2016, 41(S2): 441–447. DOI: 10.13225/j.cnki.jccs.2016.0102.

|

| [21] |

PAOLO C, ROTA R, CARR S, et al. Vented gas deflagration: a detailed mathematical model tuned on a large set of experimental data [J]. Combustion and Flame, 1990, 80(1): 49–64. DOI: 10.1016/0010-2180(90)90051-R.

|

下载:

下载: