Experimental study of dispersal and cloud explosion of a new micro-emulsified diesel fuel and its explosion suppression performance assessment

-

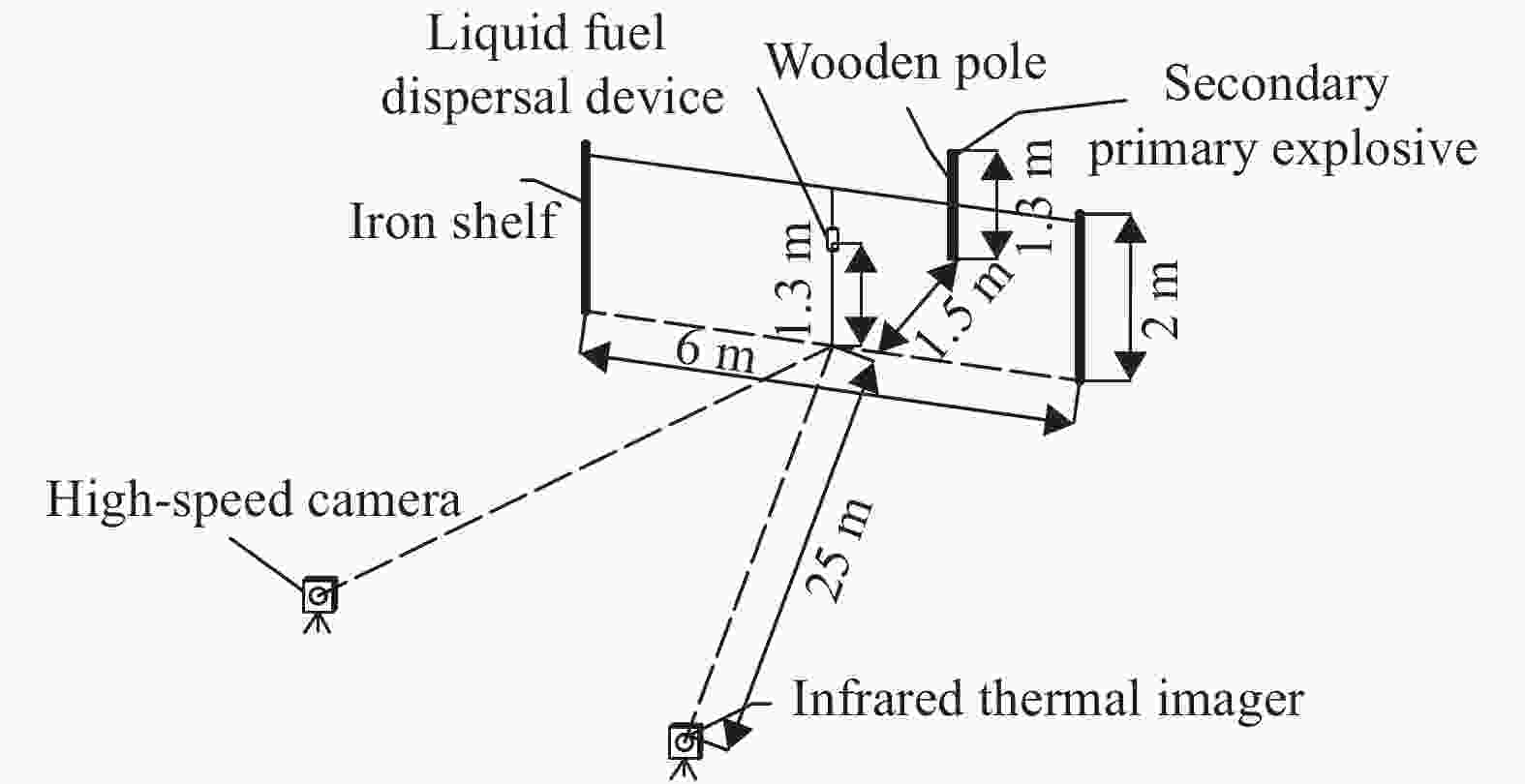

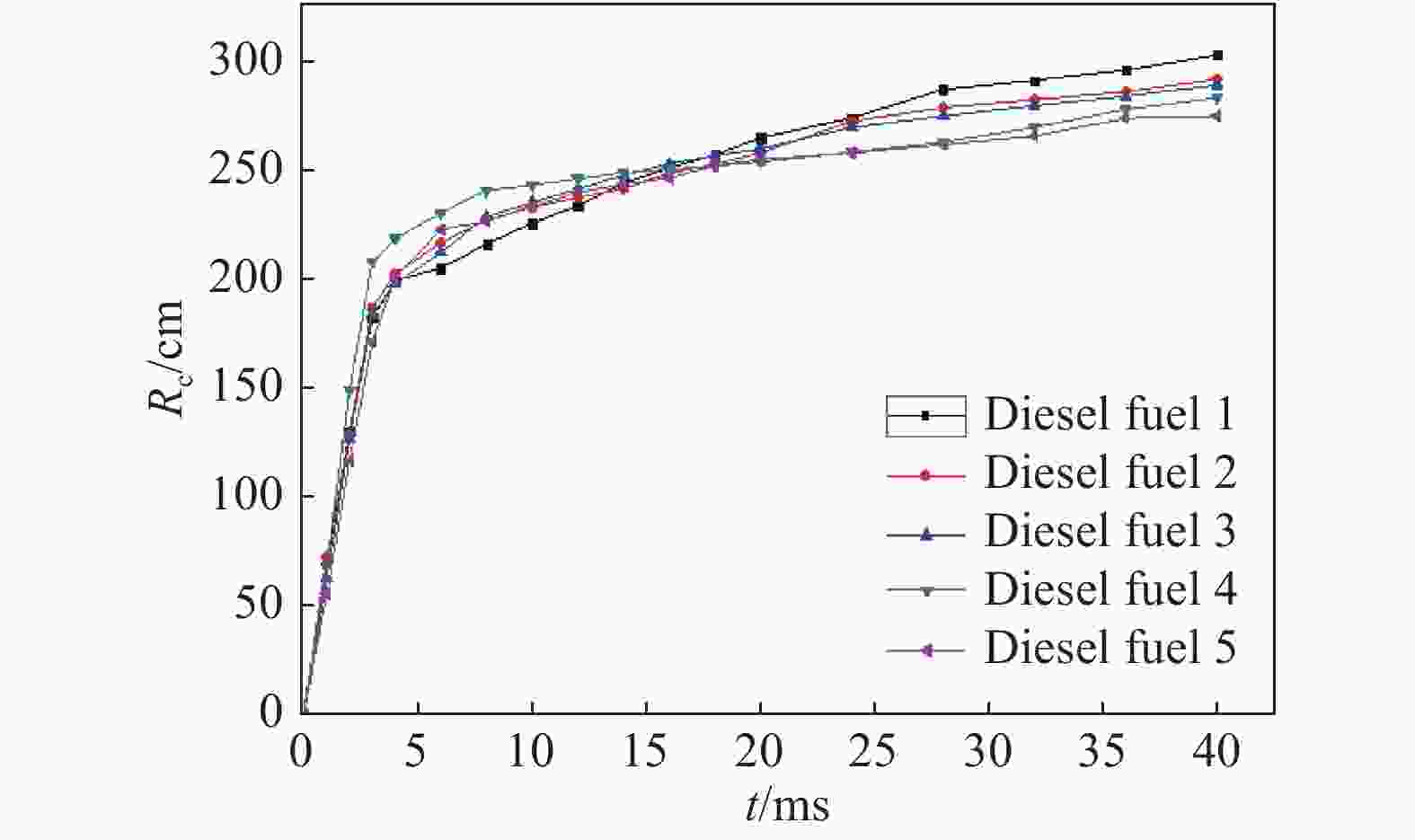

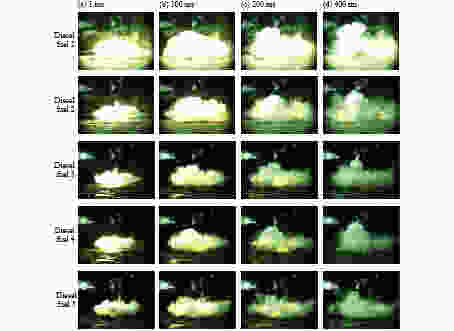

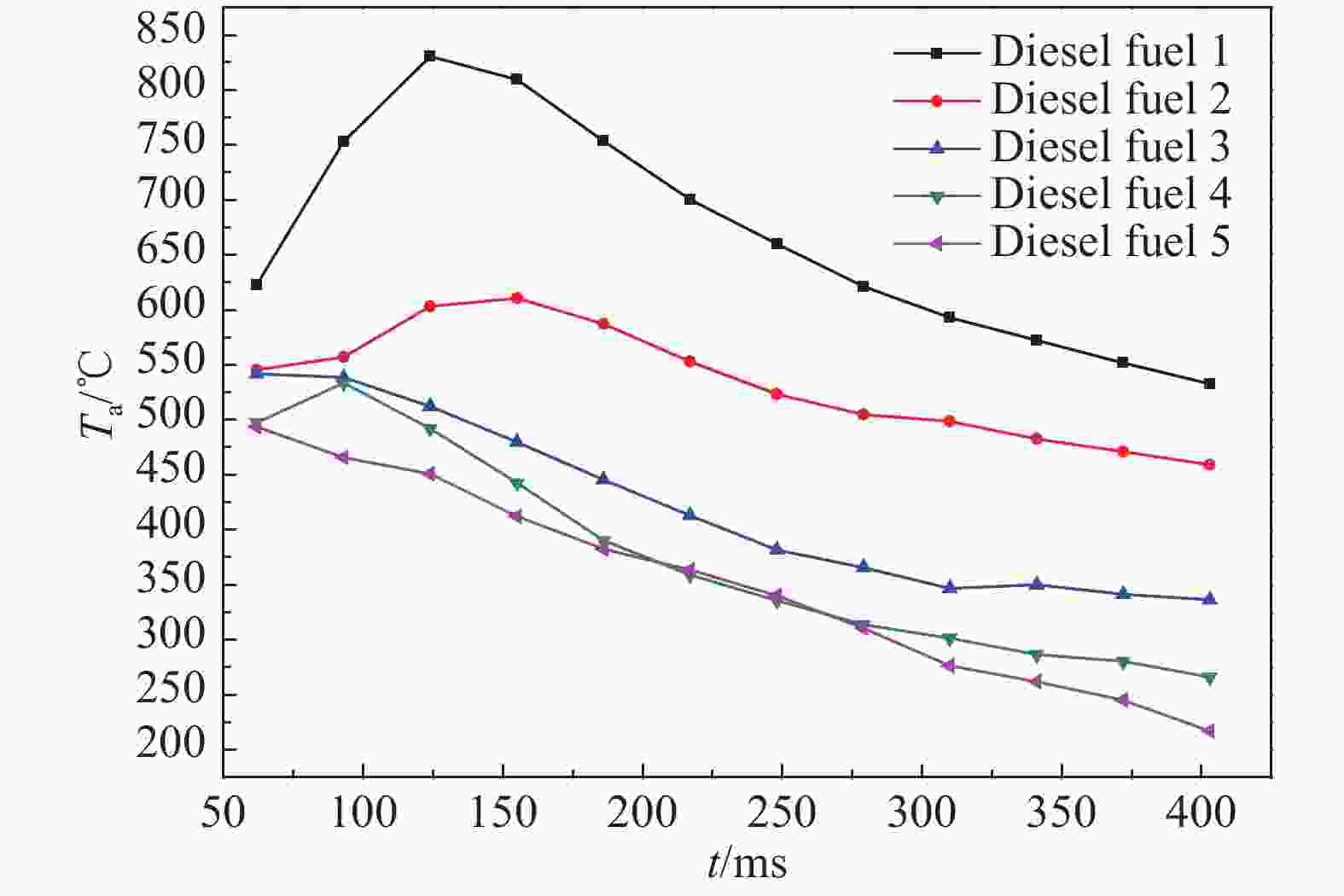

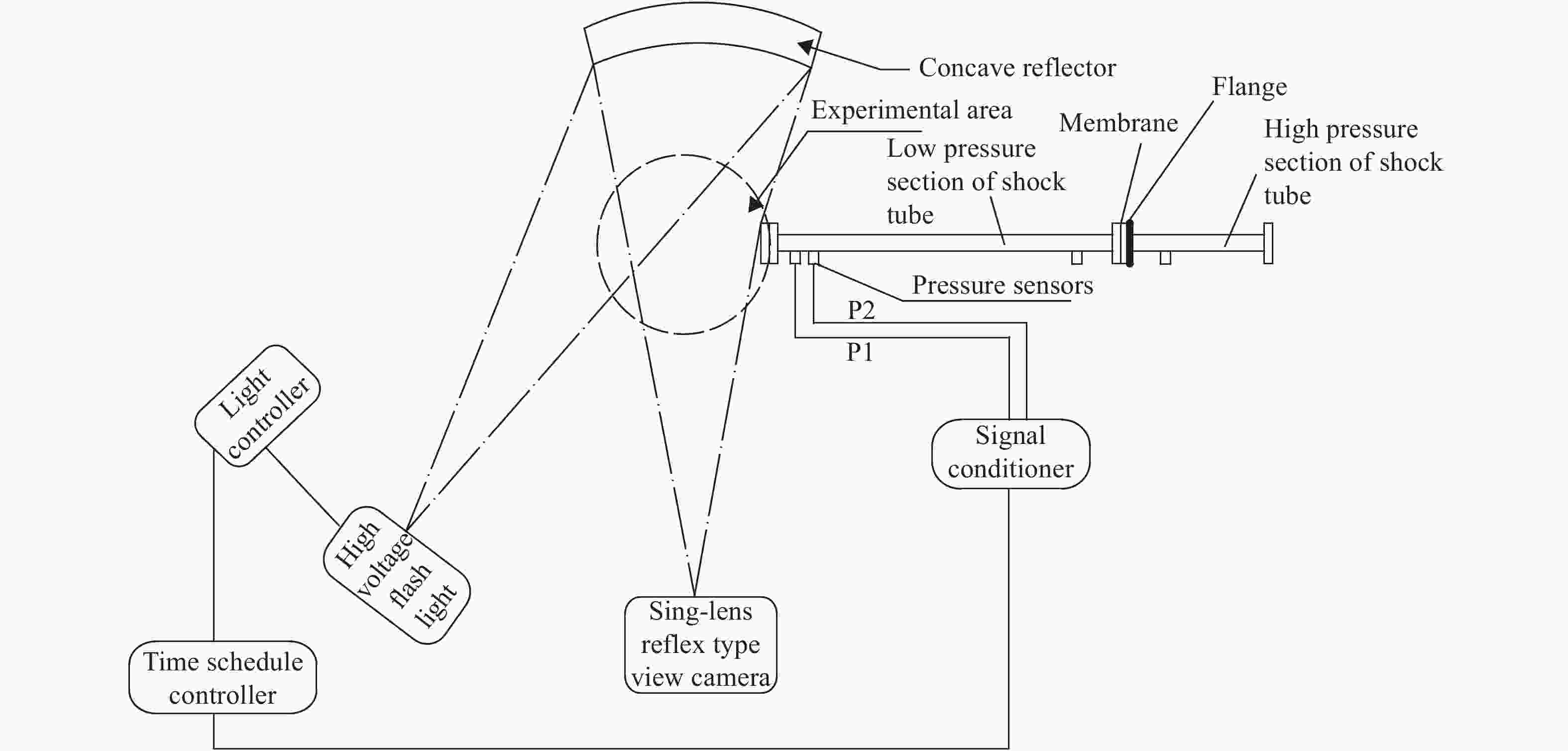

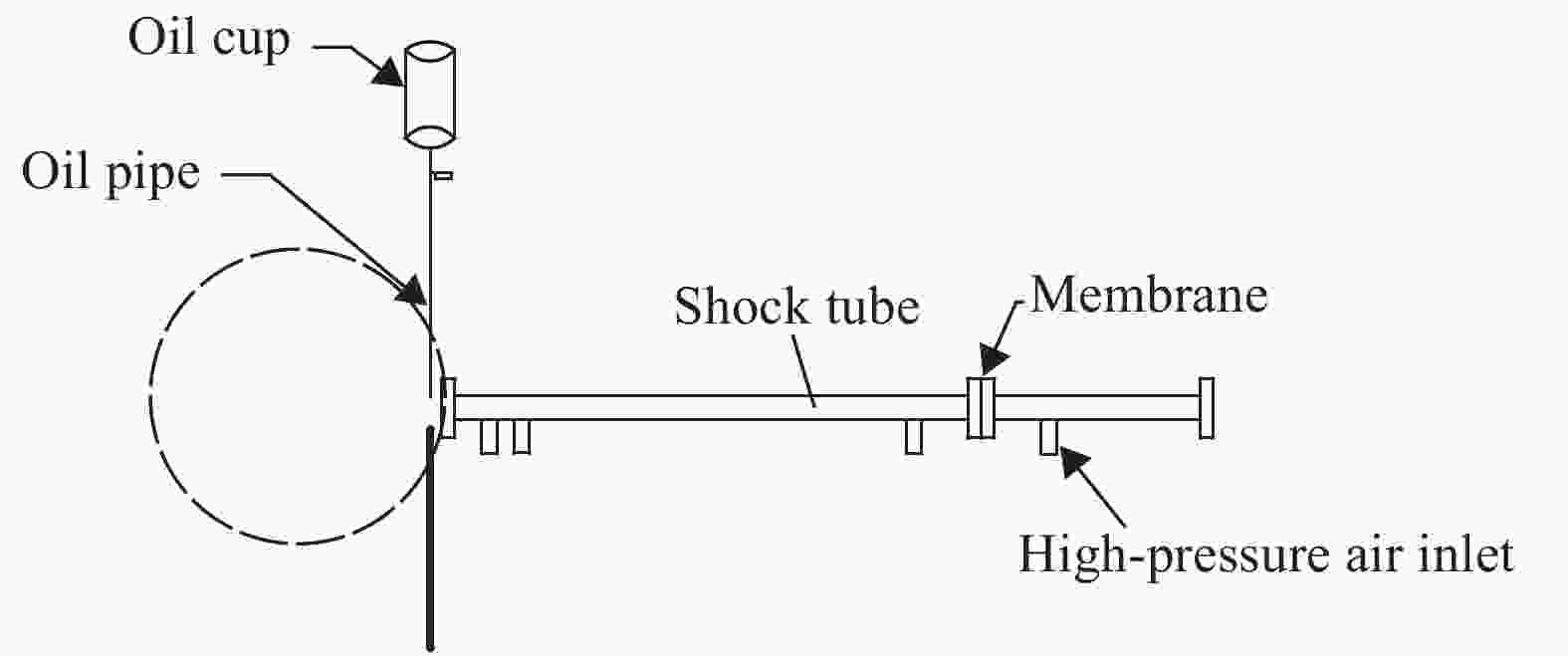

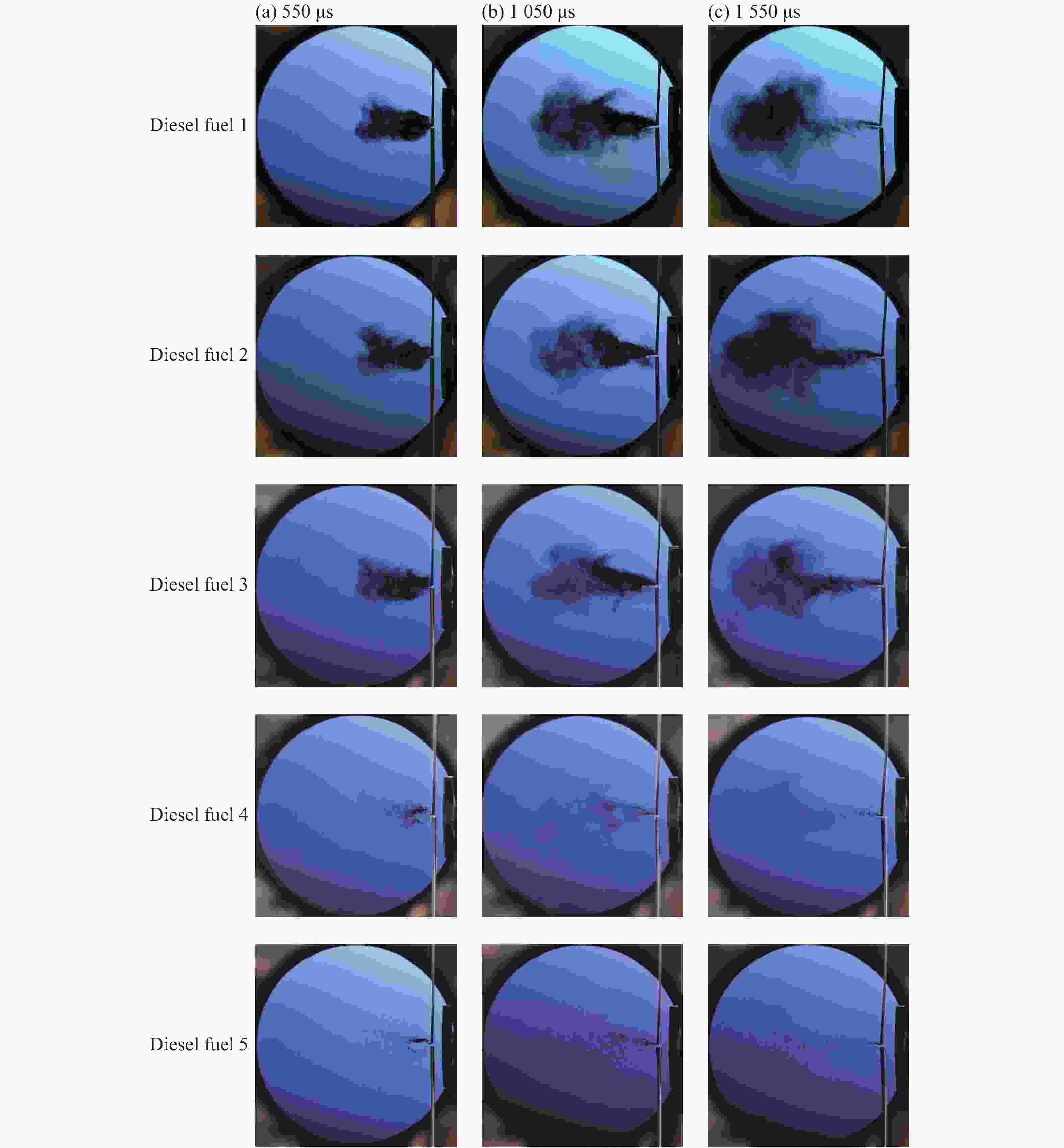

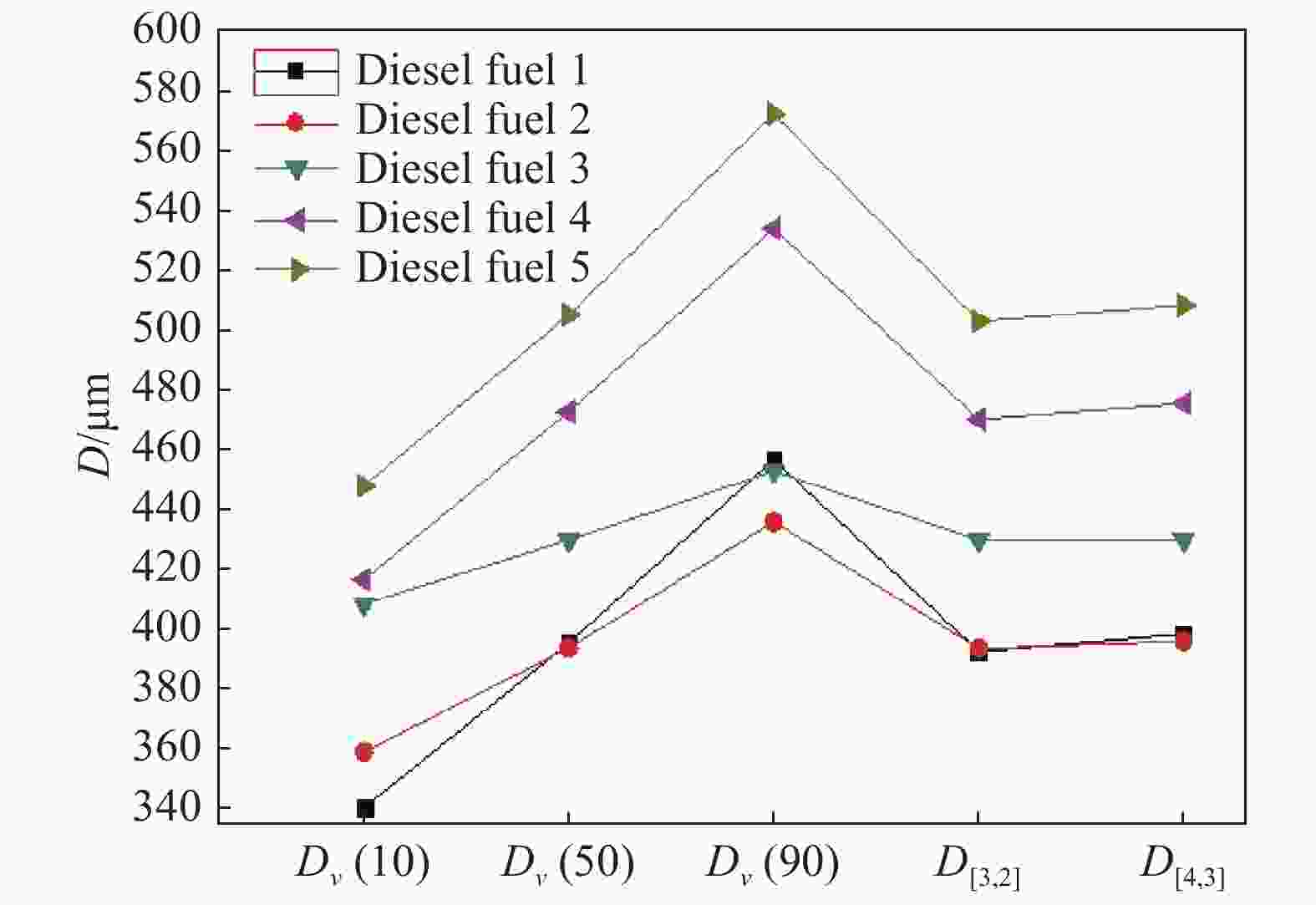

摘要: 为掌握新型微乳化柴油的抑爆性能和机理,开展了−10#柴油、普通微乳化柴油和新型微乳化柴油抛撒和云雾爆炸实验。采用灰色关联分析法,对柴油样品云雾爆炸火球的表面最高温度时的平均温度、高温(高于1 273.15 K)持续时间、火球最大截面积、火球辐射度等特征参数进行定量计算并评估其爆炸威力,又运用液体燃料抛撒和成像系统,研究柴油样品在激波及其高速气流作用下的抛撒雾化现象及其抑爆机理。结果表明:新型微乳化柴油的抛撒云雾径向扩展半径和云雾爆炸火球特征参数均明显小于−10#柴油、普通微乳化柴油,如在含水质量分数为5%的乳化柴油中分别添加质量分数为0.2%和0.4%的高分子聚合物防雾剂,形成的新型微乳化柴油的火球表面最高平均温度比−10#柴油分别低 296.90 和 336.90 K,高温持续时间比−10#柴油分别少 94 和 234 ms;火球最大截面积也分别只有−10#柴油的60.10%、53.53%;新型微乳化柴油的爆炸威力最小,抑爆性能最好,其次是普通微乳化柴油和−10#柴油;微乳化柴油的水分质量分数在15%以下时,多增加10%的水与添加0.2%防雾剂的抑爆效果相当;新型微乳化柴油抑爆性能较好的主要原因是柴油中添加防雾剂使其液滴黏弹性增大,在高速气流剪切作用不易破碎、雾化,液滴分散效果差。Abstract: To find out about the explosion suppression performance and mechanism of a new micro-emulsified diesel fuel, we carried out experiments on the dispersal and cloud explosion of −10# diesel fuel, ordinary micro-emulsified diesel fuel and new micro-emulsified diesel fuel. We calculated the average temperature at the maximum surface temperature, the high temperature duration (longer than 1 273.15 K), the maximum cross-sectional area and the radiant emittance of the cloud explosion fireballs of diesel fuel samples and evaluated them using the grey correlation analysis method and studied the dispersal atomization phenomena and explosion suppression mechanisms of the diesel fuel samples under the shock wave and high-speed airflow using the liquid fuel dispersal and imaging system. The results showed that the cloud radial expansion radius and the characteristic parameters of the explosion fireball of the new micro-emulsified diesel fuel were obviously lower than those of −10# diesel fuel and ordinary micro-emulsified diesel fuel. For example, the maximum surface mean temperatures of the fireballs of the new micro-emulsified diesel fuel samples made up by mixing 0.2% or 0.4% high polymer antifogging agents into the fuel containing 5% water were 296.90 and 336.90 K lower than those of −10# diesel fuel. Their high temperature duration is shorter by 94 and 234 ms respectively. The maximum cross-sectional areas of their fireballs were only 60.10% and 53.53% that of −10# diesel fuel respectively. The explosion power of the new micro-emulsified diesel fuel was the lowest and the explosion suppression performance was the best, followed by ordinary micro-emulsified diesel fuel and −10# diesel fuel. When the water mass fraction of the micro-emulsified diesel fuel was less than 15%, the explosion suppression effect of the micro-emulsified diesel fuel with an addition of 10% water was equivalent to that with an addition of 0.2% antifogging agents. The key for this better explosion suppression performance was that the viscosity and elasticity of the droplets increased due to the addition of antifogging agents to the diesel fuel, and that the droplets were not apt to be broken and atomized under the shearing action of high-speed airflow, and the dispersion of the droplets was not effective.

-

表 1 柴油样品的组成和理化性能

Table 1. Component and physical & chemical properties of diesel fuel samples

柴油 φ/% φhmp/10−3 密度/

(kg·m−3)运动黏度/

(10−6 m−2·s−1)黏度系数/

(10−3 kg·m−1·s−1)表面张力/

(10−3 N·m−1)−10# 微乳化剂 水 1 100 0 0 0 794.1 3.934 3.124 31.64 2 84.27 10.73 5 0 803.8 6.477 5.206 32.53 3 73.00 12.00 15 0 849.8 10.208 8.675 31.44 4 84.27 10.73 5 2 843.5 12.011 10.131 32.11 5 84.27 10.73 5 4 832.4 22.240 18.513 33.48 注:φ为未加入聚合物时各组分的质量分数,φhmp为所加入高分子聚合物的质量分数。 表 2 柴油云雾爆炸火球特征参数

Table 2. Characteristic parameters of diesel fuel cloud explosion fireball

柴油 Tm/K T0/K Δt/ms S/m2 T1/K J*/(104 W·m−2) 873.15~1 073.15 K 1 073.15~1 273.15 K 1 273.15 K以上 1 1 692.45 1 103.85 203 109 234 14.46 1 103.85 8.42 2 1 317.75 876.55 125 140 94 12.27 883.65 3.46 3 1 728.65 811.55 62 125 203 8.17 814.95 2.50 4 1 605.95 806.95 125 33 140 8.69 806.95 2.41 5 985.75 766.95 203 0 0 7.74 766.95 1.96 表 3 规范化后的指标值

Table 3. Normalized index values

柴油 T0 Δt S J* 1 0.694 8 0 0.535 3 0.232 8 2 0.900 7 0.598 3 0.686 8 0.821 9 3 0.959 6 0.132 5 0.970 3 0.935 9 4 0.963 8 0.401 7 0.934 3 0.946 6 5 1 1 1 1 注:上方横线表示为规范化后的物理量。 -

[1] 黄勇, 解立峰, 鲁长波, 等. 微乳化柴油池火焰蔓延特性研究 [J]. 常州大学学报(自然科学版), 2016, 28(5): 87−92. DOI: 10.3969/j.issn.2095-0411.2016.05.016.HUANG Yong, XIE Lifeng, LU Changbo, et al. Study on pool flame spread characteristics of microemulsion diesel fuel [J]. Journal of Changzhou University (Natural Science Edition), 2016, 28(5): 87−92. DOI: 10.3969/j.issn.2095-0411.2016.05.016. [2] DOWELL B. Researchers developing fire-resistant fuel [J]. Power and Energy, 2009, 7–9: 6–9. [3] 林璐. 俄军" 不燃烧”柴油研制概括 [J]. 军需物资油料, 2006(2): 63–64LIN Lu. Development process of " no combustion” diesel oil of Russian Army [J]. Supplies of oil, 2006(2): 63–64 [4] LU C B, AN G J, XIONG C H, et al. Progress on fire and explosion suppression technologies for light petroleum fuel [J]. Procedia Engineering, 2014, 84: 384–393. doi: 10.1016/j.proeng.2014.10.448 [5] 鲁长波, 安高军, 熊春华, 等. 主动式液体燃料安全技术研究—阻燃抑爆柴油研究 [C]//中国化工学会2013年学术年会. 南京, 2013: 300−301. [6] ZABELKA R J, SMITH L H. Explosively dispersed liquids: AD- 863268 [R]. 1969. [7] 丁珏, 刘家骢. 液体燃料云团形成过程的数值仿真 [J]. 兵工学报, 2001, 22(4): 481–484 doi: 10.3321/j.issn:1000-1093.2001.04.013DING Jue, LIU Jiacong. Numerical simulation for the formation of liquid fuel air cloud [J]. Acta Armamentarii, 2001, 22(4): 481–484 doi: 10.3321/j.issn:1000-1093.2001.04.013 [8] 张奇, 覃彬, 白春华, 等. 中心装药对FAE燃料成雾特性影响的试验分析 [J]. 含能材料, 2007, 15(5): 447–450 doi: 10.3969/j.issn.1006-9941.2007.05.002ZHANG Qi, QIN Bin, BAI Chunhua, et al. Effect of total energy of center explosive charge on fuel dispersal characteristic feature [J]. Chinese Journal of Energetic Materials, 2007, 15(5): 447–450 doi: 10.3969/j.issn.1006-9941.2007.05.002 [9] ZHANG F, FROST D L, THIBAULT P A, et al. Explosive dispersal of solid particles [J]. Shock Waves, 2001, 10(6): 431–443. doi: 10.1007/PL00004050 [10] 张陶, 於津, 惠君明. 爆炸抛撒方式对FAE云雾爆轰特性及威力影响的实验研究 [J]. 弹箭与制导学报, 2010, 30(1): 137–140 doi: 10.3969/j.issn.1673-9728.2010.01.042ZHANG Tao, YU Jin, HUI Junming. Experimental study of explosive dispersion form of the influence on FAE of cloud explosion characteristic and power [J]. Journal of Projectiles, Rockers, Missiles and Guidance, 2010, 30(1): 137–140 doi: 10.3969/j.issn.1673-9728.2010.01.042 [11] 郭学永. 云爆战斗部基础技术研究 [D]. 南京: 南京理工大学, 2006: 29−30.GUO Xueyong. Basic technical research on fuel air explosive warhead [D]. Nanjing: Nanjing University of Science and Technology, 2006: 29−30. [12] 苗常青, 张奇, 白春华, 等. FAE装置炸高对爆炸压力场影响的实验研究 [J]. 火炸药学报, 2002(3): 9–10 doi: 10.3969/j.issn.1007-7812.2002.03.004MIAO Changqing, ZHANG Qi, BAI Chunhua, et al. Investigation of bursting height of FAE influences blast pressure measuring [J]. Chinese Journal of Explosives & Propellants, 2002(3): 9–10 doi: 10.3969/j.issn.1007-7812.2002.03.004 [13] 范维澄, 王清安, 姜冯辉, 等. 火灾学简明教程 [M]. 合肥: 中国科学技术大学出版社, 1995: 92−93. [14] 杜栋, 庞庆华. 现代综合评价方法与案例精选 [M]. 北京: 清华大学出版社, 2005: 111−119. [15] MATTHYS E F. Heat transfer, drag reduction, and fluid characterization for turbulent flow of polymer solutions: recent results and research needs [J]. Journal of Non-Newtonian Fluid Mechanics, 1991, 38(2−3): 313–342. doi: 10.1016/0377-0257(91)83010-2 [16] PTASINSKI P K, BOERSMA B J, NIEUWSTADT F T M, et al. Turbulent channel flow near maximum drag reduction: simulations, experiments and mechanisms [J]. Journal of Fluid Mechanics, 2003, 490(490): 251–291. [17] ANNA S L, MCKINLEY G H. Elasto-capillary thinning and breakup of model elastic liquids [J]. Journal of Rheology, 2001, 45(1): 115–138. doi: 10.1122/1.1332389 [18] CHAO K K, CHILD C A, GRENS E A, et al. Antimisting action of polymeric additives in jet fuels [J]. American Institute of Chemical Engineers Journal, 1984, 30(1): 111–120. doi: 10.1002/(ISSN)1547-5905 [19] CHRISTANTI Y, WALKER L M. Effect of fluid relaxation time of dilute polymer solutions on jet breakup due to a forced disturbance [J]. Journal of Rheology, 2002, 46(3): 733–748. doi: 10.1122/1.1463418 -

下载:

下载: