Study on crashworthiness design criteria and method of tubular structures with power exponent distribution of thickness

-

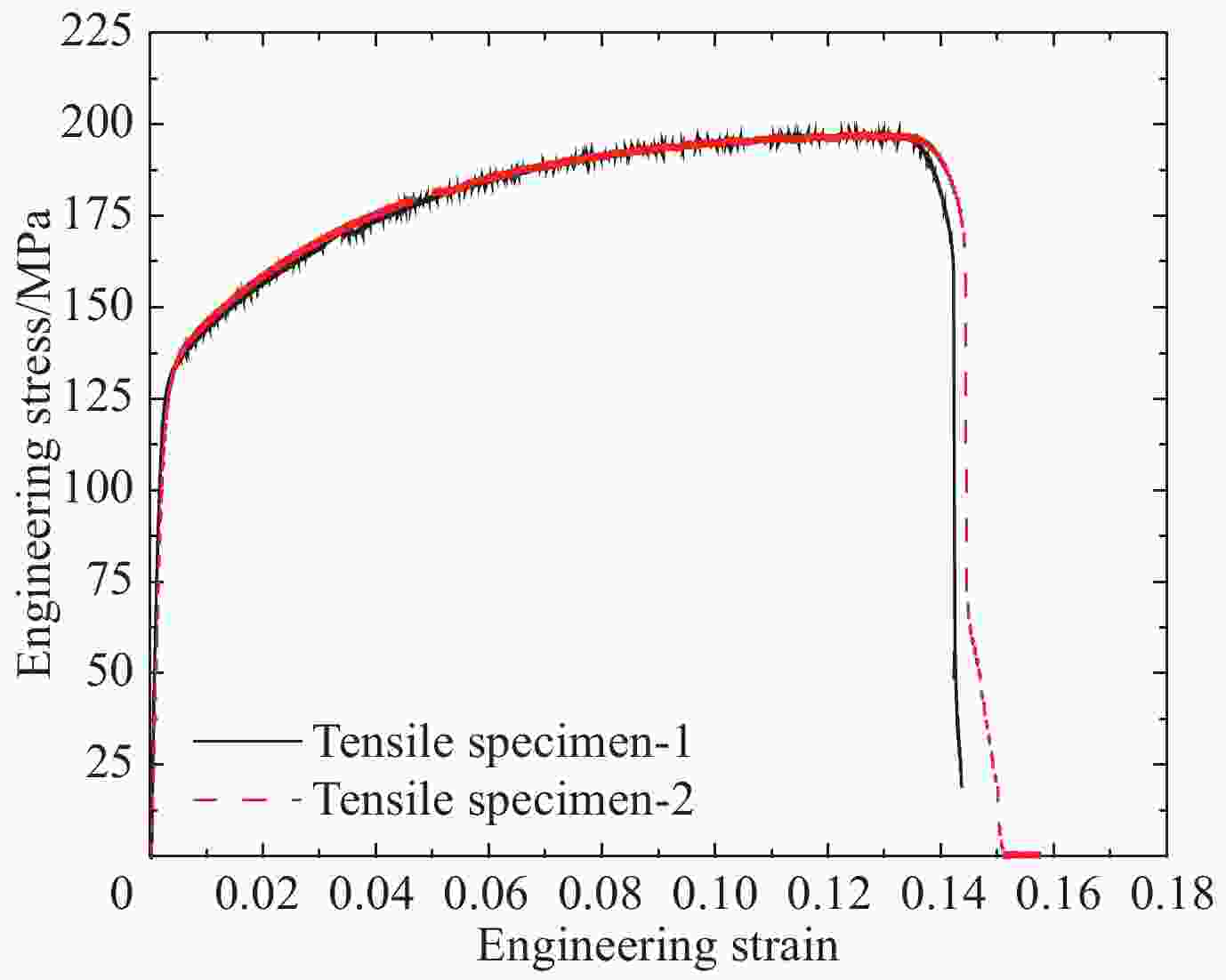

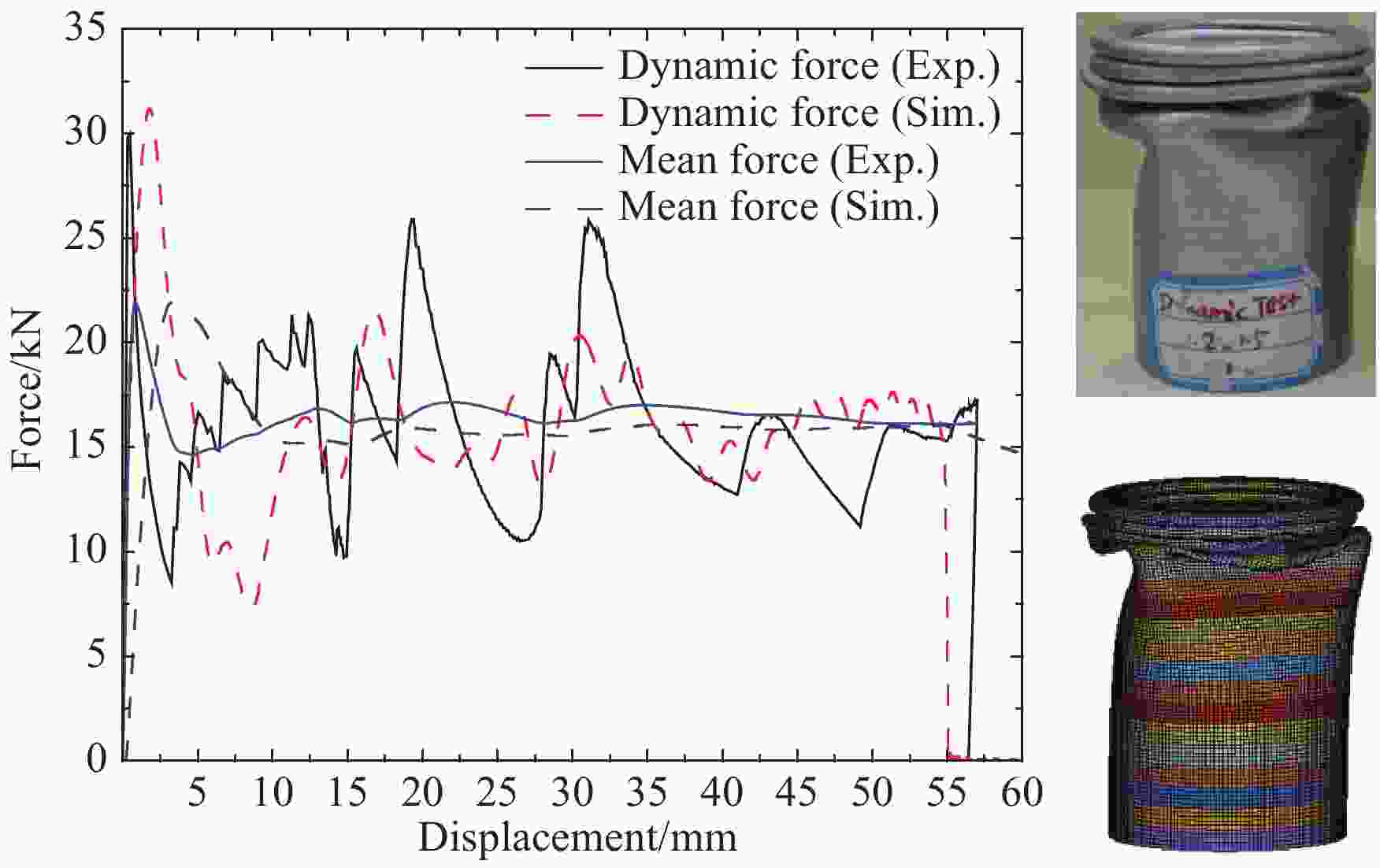

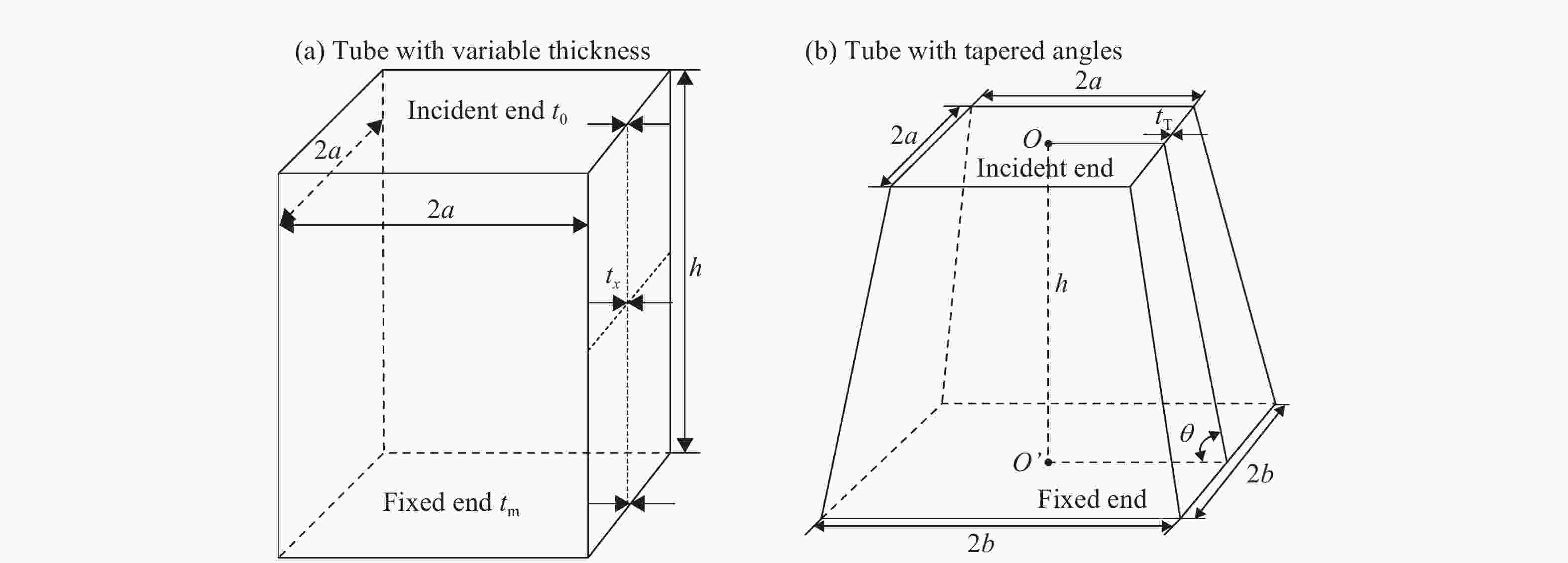

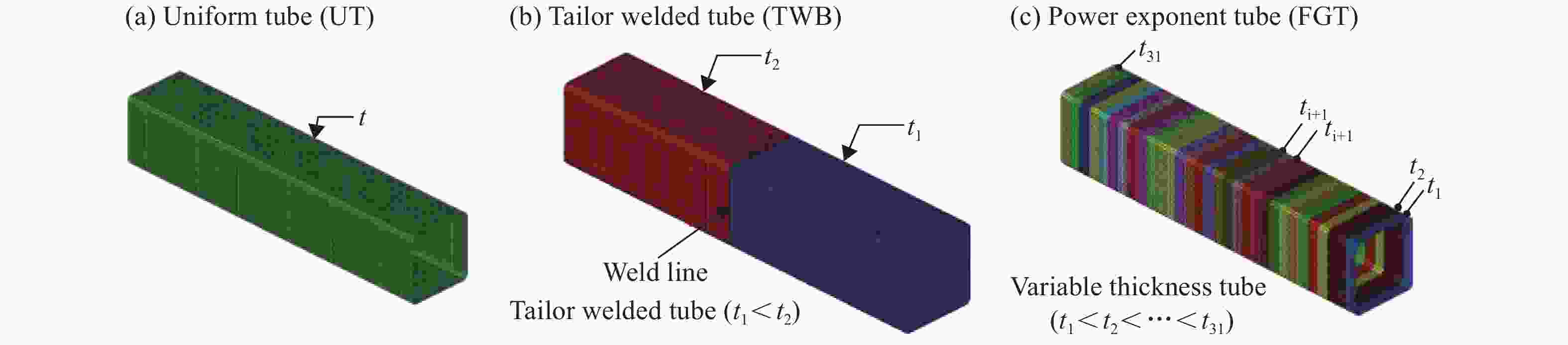

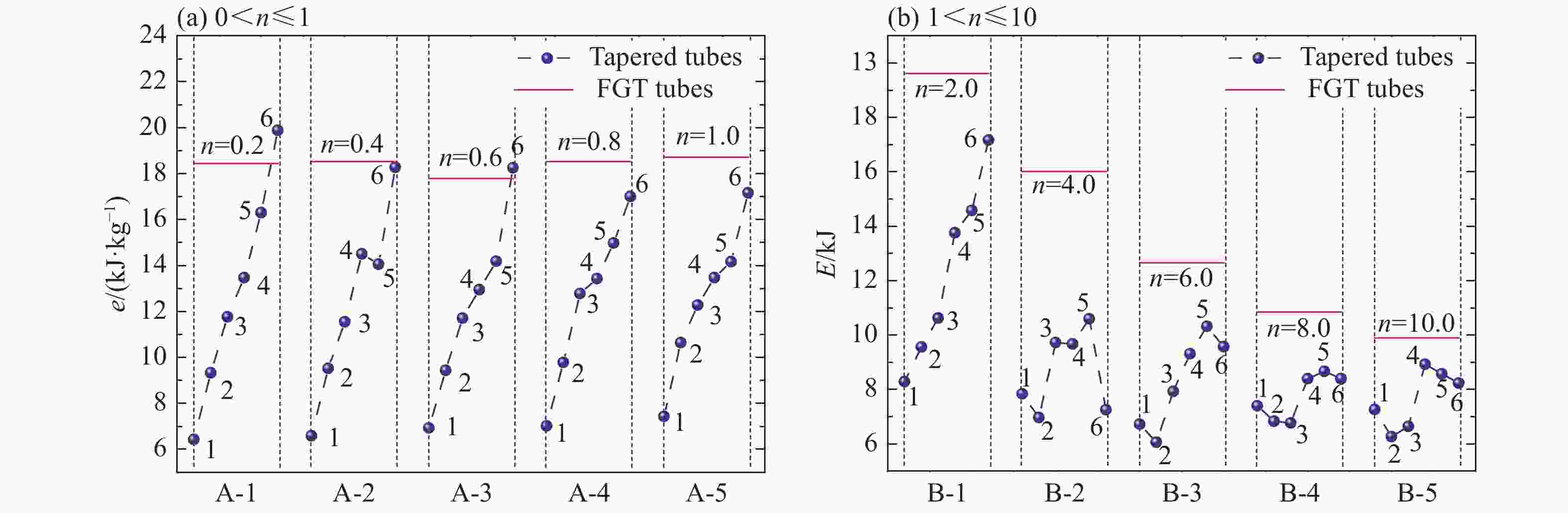

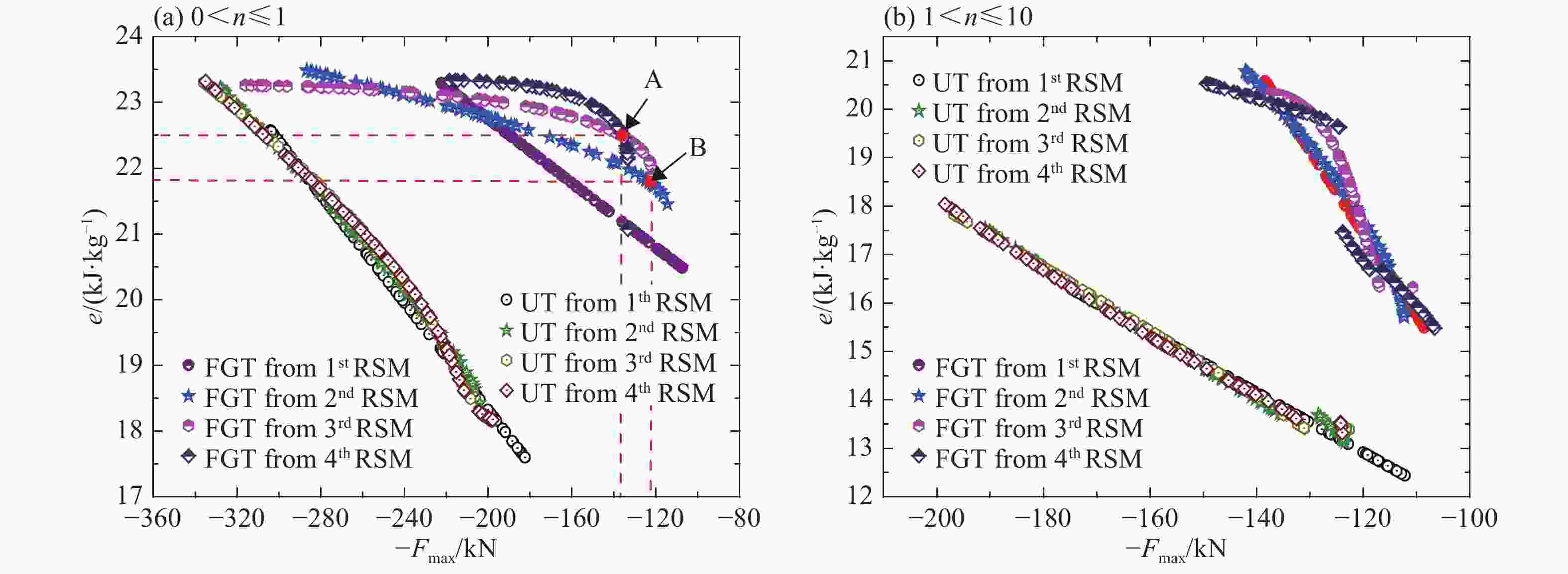

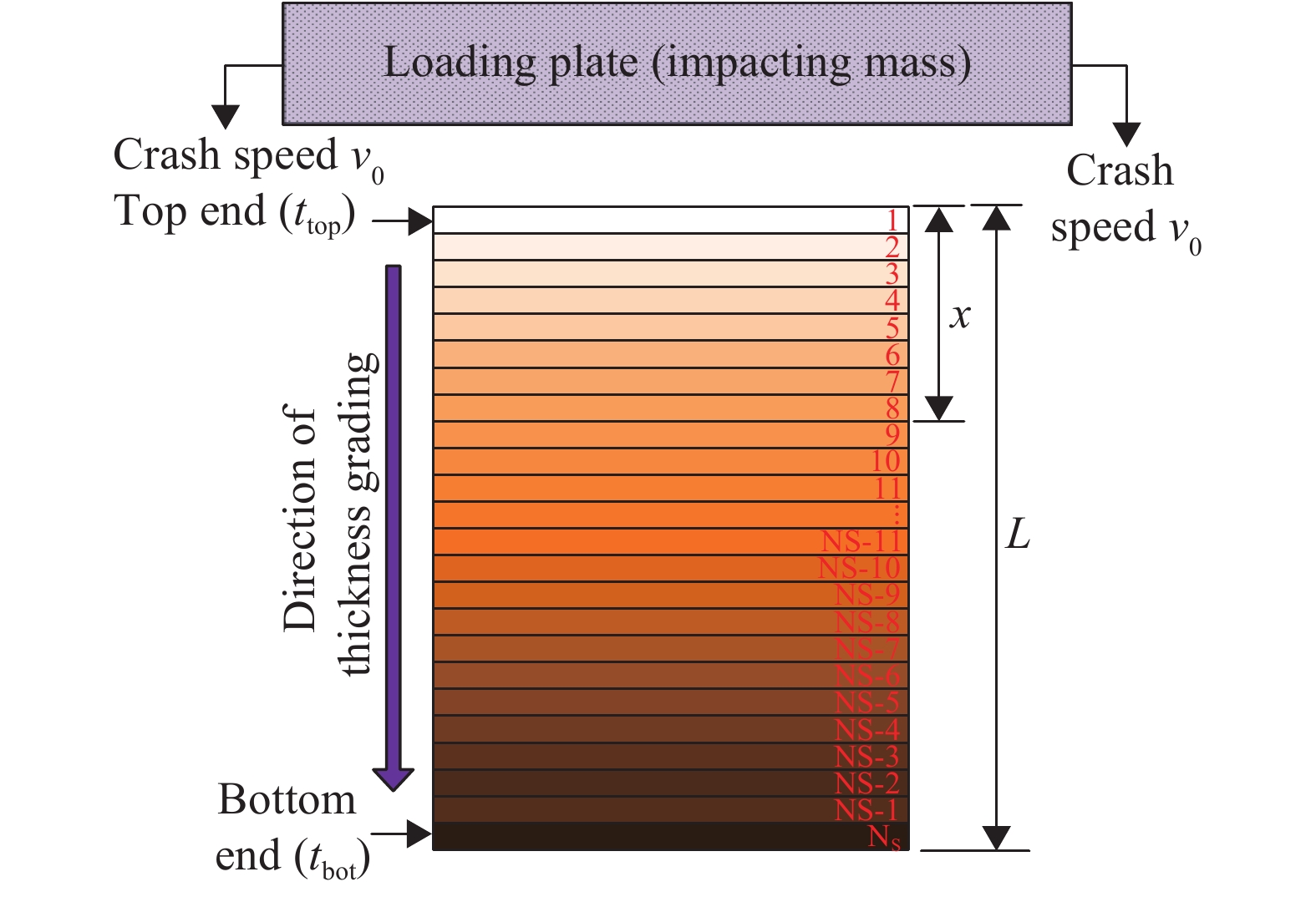

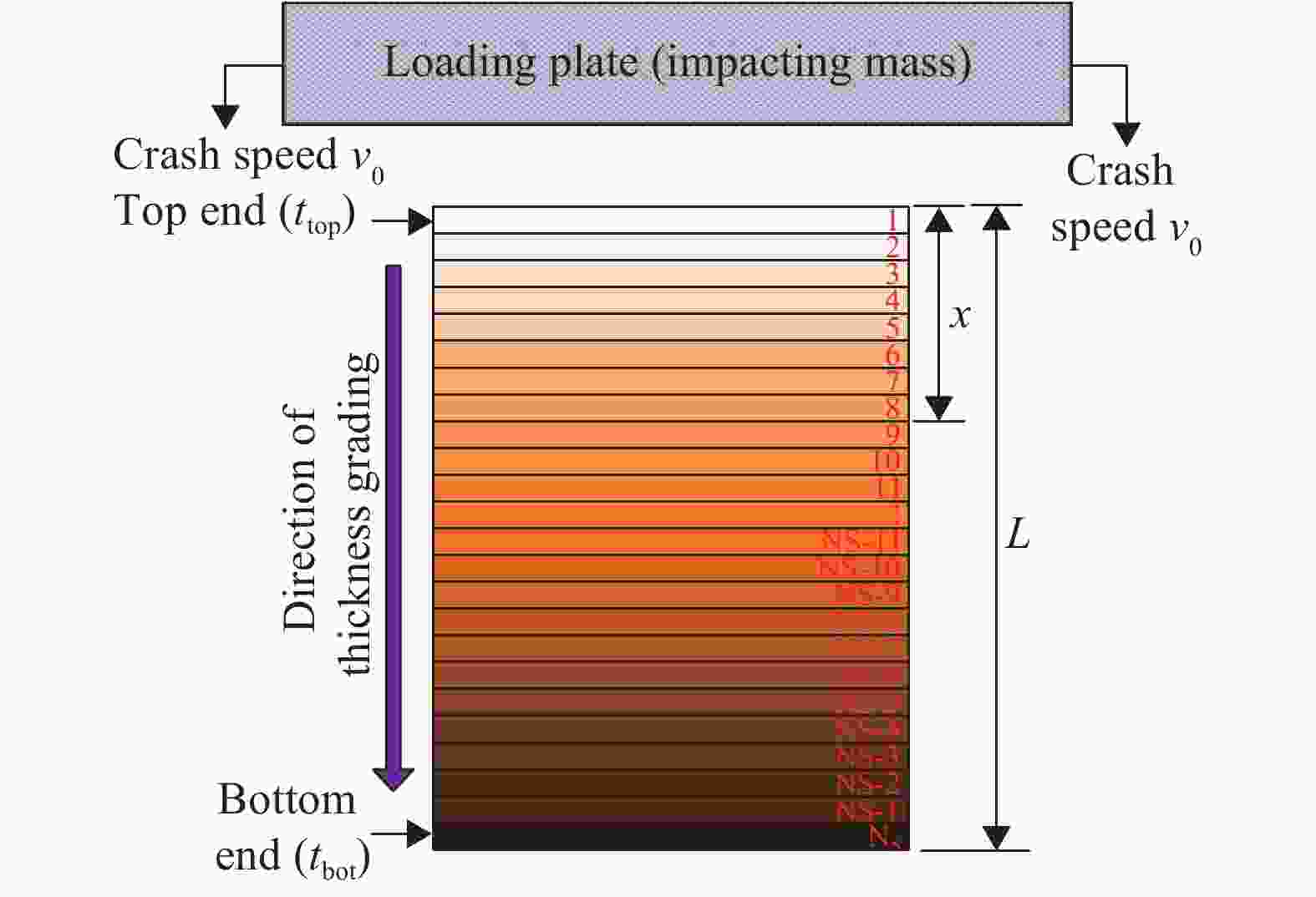

摘要: 厚度或质量连续分布技术对车身薄壁结构的轻量化和性能设计有着非常重要,甚至起到决定性的作用,从设计方法上研究连续变厚度结构在车身零部件中的耐撞性应用是安全性设计所需的主要工作。本文研究一种较新颖的薄壁吸能结构,其管壁厚度按照幂指数形式连续分布,根据此分布特点推导出了该薄壁结构在等质量条件下与其他管状结构(比如均匀管、拼焊管和锥管等)之间相关参数的定量解析关系,给出了前者的耐撞性设计准则,评估了不同梯度对幂指数管耐撞性能的影响。分析结果显示,该新颖管状结构比其他截面管具有更理想的耐撞特性。然后,在2个设计区间内对梯度指数分别采样并构造近似模型,采用遗传算法作为求解器得出了非劣解前沿,研究发现高阶响应面近似模型得到的设计结果不一定是最优的。Abstract: The property of continuous thickness or weight distributions plays an important even decisive role on the lightweight and performance design of an automotive body. The main study of safe design for continuous thickness components is to investigate on their crashworthiness in the crash process of automotive structures. We studied on a new energy-absorbed thin-walled structure with the thickness distributed according to the power exponent function. The analytical relationships of the relative parameters among the new structure, uniform thickness tubes, tailor welded tubes and taped tubes were obtained. And the crashworthiness design criteria was also carried out. The parametrical study shows that the crashworthiness of the new tube is superior to those of other cross-sectional tubes. Then, the crashworthiness design method of the new tube was performed. The graded exponent was given at two design regions and was sampled to construct reasonable approximate model. The compared results demonstrates that the optimal results of the higher model are not necessarily to be best. In addition, the crashworthiness of thethin-walled structures could be enhanced by reasonably designing the tube thickness.

-

表 1 三种管状结构在相同质量下的厚度分布

Table 1. Thickness distributions of three tubes with the same weight

n tU/mm t1/mm t2/mm n tU/mm t1/mm t2/mm 0.2 2.041 1.759 2.117 4 1.094 0.815 1.356 0.4 1.943 1.517 2.041 6 1.017 0.802 1.218 0.6 1.668 1.345 1.972 8 0.974 0.800 1.137 0.8 1.575 1.219 1.908 10 0.947 0.800 1.085 2 1.274 0.905 1.621 表 2 比吸能响应面近似模型的精度评估(0≤n≤1)

Table 2. Accuracy estimate of response surface model of SAE (0≤n≤1)

目标函数 阶数 R2 δavg δmax SAEG 1 0.952 96 0.151 60 0.750 46 2 0.953 35 0.148 30 0.752 92 3 0.953 94 0.149 12 0.745 72 4 0.954 96 0.146 50 0.740 61 SAEU 1 0.993 74 0.065 28 0.151 81 2 0.994 78 0.067 32 0.116 77 3 0.995 12 0.064 12 0.118 13 4 0.995 13 0.063 76 0.120 22 表 3 比吸能响应面近似模型的精度评估(1<n≤10)

Table 3. Accuracy estimate of response surface model of SAE (1<n≤10)

目标函数 阶数 R2 δavg δmax SAEG 1 0.987 45 0.072 09 0.295 03 2 0.991 13 0.062 97 0.252 97 3 0.993 73 0.054 78 0.186 99 4 0.995 25 0.059 80 0.190 98 SAEU 1 0.924 91 0.166 16 0.709 09 2 0.925 66 0.167 22 0.724 94 3 0.932 14 0.200 66 0.658 86 4 0.933 11 0.163 12 0.667 10 -

[1] 杜继涛, 甘屹, 齐从谦. TRB及其轧制应用关键技术 [J]. 汽车技术, 2007(7): 45–48 doi: 10.3969/j.issn.1000-3703.2007.07.013DU Jitao, GAN Yi, QI Congqian. Tailor rolled blanks and keys technologies in its rolling applications [J]. Automobile Technology, 2007(7): 45–48 doi: 10.3969/j.issn.1000-3703.2007.07.013 [2] 何安瑞, 邵健, 孙文权, 等. 冷轧无取向硅钢横向厚差控制 [J]. 机械工程学报, 2011, 47(10): 25–30HE Anrui, SHAO Jian, SUN Wenquan, et al. Transverse thickness deviation control of non-oriented silicon steel during cold rolling [J]. Journal of Mechanical Engineering, 2011, 47(10): 25–30 [3] 赵春璋, 余海东, 王皓, 等. 基于绝对节点坐标法的变截面梁动力学建模与运动变形分析 [J]. 机械工程学报, 2014, 50(17): 38–45ZHAO Chunzhang, YU Haidong, WANG Hao, et al. Dynamic modeling and kinematic behavior of variable cross-section beam based on the absolute nodal coordinate formulation [J]. Journal of Mechanical Engineering, 2014, 50(17): 38–45 [4] 杜继涛, 齐从谦. 变截面薄板在车身制造中的应用研究 [J]. 锻压技术, 2005, 30(S1): 39–43 doi: 10.3969/j.issn.1000-3940.2005.z1.011DU Jitao, QI Congqian. Research on applications of variable section blanks in the auto-body manufacturing [J]. Forging & Tamping Technology, 2005, 30(S1): 39–43 doi: 10.3969/j.issn.1000-3940.2005.z1.011 [5] 徐春国, 任广升, 袁相勇, 等. 轴类件的柔性辊轧成形工艺与实验研究 [J]. 塑性工程学报, 2008, 15(2): 100–104XU Chunguo, REN Guangsheng, YUAN Xiangyong, et al. The research on the process of flexible rolling for shaft forgings and experiment [J]. Journal of Plasticity Engineering, 2008, 15(2): 100–104 [6] 袁相勇, 徐春国, 任广升. 轴向辊轧轧件与轧轮接触面理论分析 [J]. 锻压技术, 2005, 30(S1): 156–159 doi: 10.3969/j.issn.1000-3940.2005.z1.046YUAN Xiangyong, XU Chunguo, REN Guangsheng. Theoretic analysis of contact surfaces between workpiece and roller of axial feed bar rolling [J]. Forging & Stamping Technology,, 2005, 30(S1): 156–159 doi: 10.3969/j.issn.1000-3940.2005.z1.046 [7] 袁海伦, 王泽武, 曾青, 等. 异形截面环件虚拟轧制及其工艺优化 [J]. 塑性工程学报, 2006, 13(6): 15–18 doi: 10.3969/j.issn.1007-2012.2006.06.004YUAN Hailun, WANG Zewu, ZENG Qing, et al. Virtual ring rolling and the process optimization of profile ring [J]. Journal of Plasticity Engineering, 2006, 13(6): 15–18 doi: 10.3969/j.issn.1007-2012.2006.06.004 [8] 王宏雁, 君毅. 汽车车身轻量化结构与轻质材料 [M]. 北京: 北京大学出版社, 2009.WANG Hongyan, JUN Yi. Lightweight structures and mateiral of automotive body [M]. Beijing: Beijing Univeristy Press, 2009. [9] KOPP R, WIEDNER C, MEYER A. Flexibly rolled sheet metal and its use in sheet metal forming [J]. Sheet Metal, 2005, 6-8: 81–92. [10] KOPP R, WIEDNER C, MEYER A. Flexible rolling for load-adapted blanks [J]. International Sheet Metal Review, 2005, 4: 20–24. [11] 包向军. 变截面薄板弯曲成形回弹的试验研究和数值模拟: [D]. 上海: 上海交通大学, 2003.BAO Xiangjun. Experimental and numerical study on springback of tailor rolled blanks in rotary bending [D]. Shanghai: Shanghai jiaotong University, 2003. [12] 任灏宇, 杜继涛. 连续变截面板的轧制控制 [J]. 机械制造与自动化, 2008, 37(2): 143–144 doi: 10.3969/j.issn.1671-5276.2008.02.050REN Haoyu, DU Jitao. Roll control of tailor rolled Blanks [J]. Machine Building & Automation, 2008, 37(2): 143–144 doi: 10.3969/j.issn.1671-5276.2008.02.050 [13] 姜银方, 方雷, 李志飞, 等. 连续变截面板及其应用中存在的关键问题 [J]. 制造技术与机床, 2011(1): 144–148 doi: 10.3969/j.issn.1005-2402.2011.01.043JIANG Yinfang, FANG Lei, LI Zhifei, et al. The key technologies in tailor rolled blanks and its application [J]. Manufacturing Technology & Machine Tool, 2011(1): 144–148 doi: 10.3969/j.issn.1005-2402.2011.01.043 [14] CHUANG C, YANG R, LI G, et al. Multidisciplinary design optimization on vehicle tailor rolled blank design [J]. Structural and Multidisciplinary Optimization, 2008, 35(6): 551–560. doi: 10.1007/s00158-007-0152-0 [15] YANG R J, FU Y, LI G. Application of tailor rolled blank in vehicle front end for frontal impact [J]. SAE Technical Paper, 2007 [16] 兰凤崇, 李佳光, 马芳武, 等. 连续变截面板(TRB 板)在汽车前纵梁中的应用及优化分析 [J]. 机械设计与制造, 2014(1): 25–28, 32 doi: 10.3969/j.issn.1001-3997.2014.01.008LAN Fengchong, LI Jiaguang, MA Fangwu, et al. The application and optimization analysis of tailor rolled board on automotive front rail structure [J]. Machinery Design & Manufacture, 2014(1): 25–28, 32 doi: 10.3969/j.issn.1001-3997.2014.01.008 [17] ZHANG X, ZHANG H. Optimal design of functionally graded foam material under impact loading [J]. International Journal of Mechanical Sciences, 2013, 68: 199–211. doi: 10.1016/j.ijmecsci.2013.01.016 [18] YIN H, WEN G, HOU S, et al. Crushing analysis and multiobjective crashworthiness optimization of honeycomb-filled single and bitubular polygonal tubes [J]. Materials & Design, 2011, 32(8−9): 4449–4460. -

下载:

下载: