Dynamic tensile fracture and the decay of elastic precursor wave in shocked pure vanadium

-

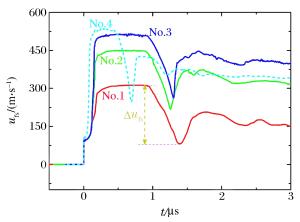

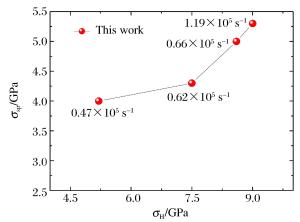

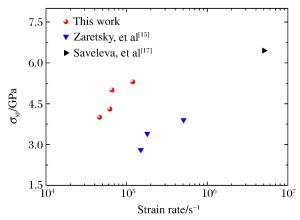

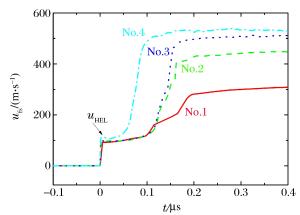

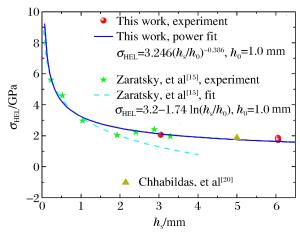

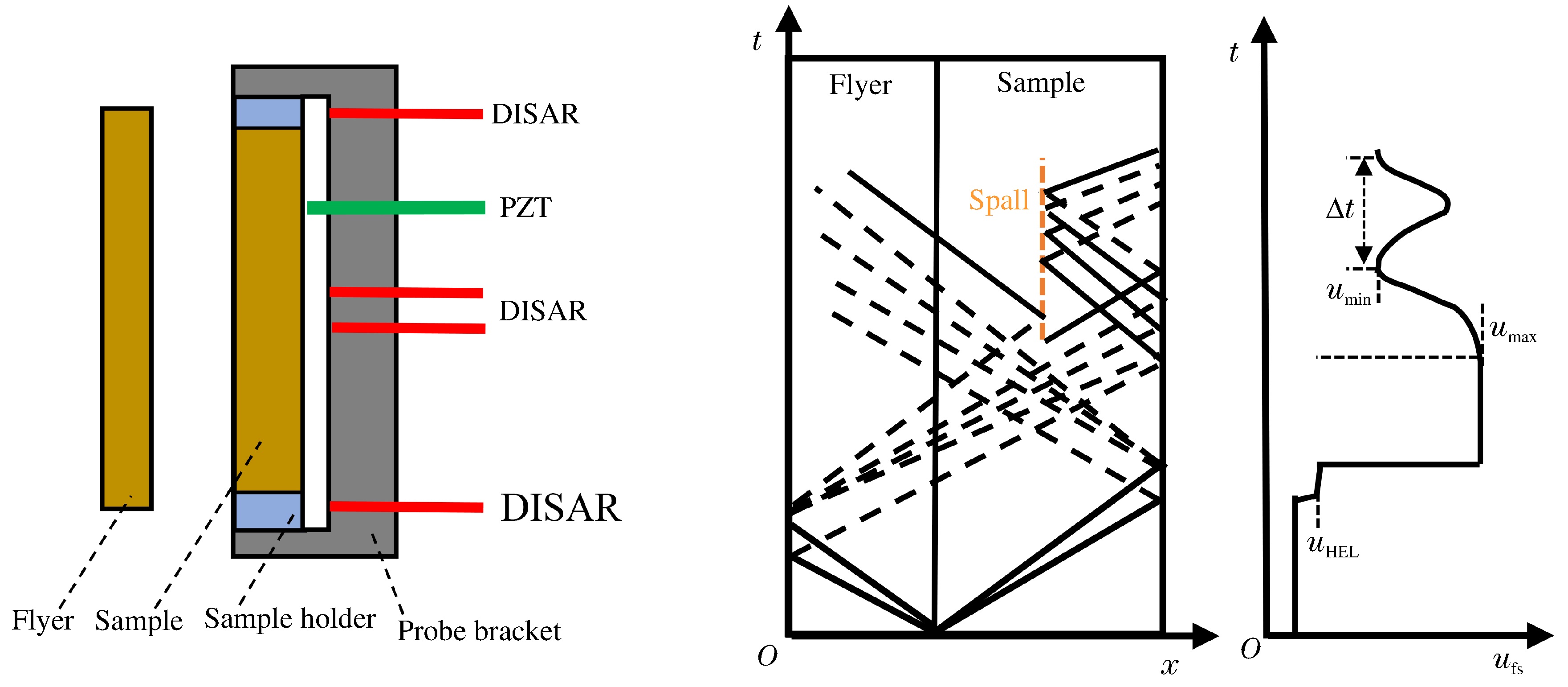

摘要: 利用平板撞击和激光干涉测速技术,实验研究了国产热等静压纯钒在压力5.2~9.0 GPa、拉伸应变率0.47×105~1.19×105 s-1冲击加载下的层裂特性。结果表明:国产热等静压纯钒具有较强的抗动态拉伸断裂能力,其层裂强度在4.0~5.3 GPa范围,明显高于相似加载条件下文献给出的熔炼钒结果,这主要与热等静压加工工艺下纯钒杂质含量更低、内缺陷更少有关;同时,纯钒层裂强度对冲击压力和拉伸应变率均比较敏感。此外,对弹塑性加载速度剖面的分析发现:在6 mm样品厚度范围,纯钒的弹性波幅值随样品厚度增大而减小,雨贡纽弹性极限随样品厚度的衰减规律较好地满足指数关系σHEL=3.246(hs/h0)-0.386,h0为单位长度。Abstract: By using plate impact and velocity interferometry, the dynamic tensile fracture (spall) of shocked pure vanadium was studied in the pressure range of 5.2-9.0 GPa, where the average tensile strain rate was in the range of 0.47×105-1.19×105 s-1. All the vanadium samples used here were made by the hot isostatic pressing (HIP) method. Our results show that the HIP vanadium has a higher spall strength than those given in literatures, which lies in the range of 4.0-5.3 GPa, and increases with both the shock pressure and tensile strain rate. The higher spall strength of the HIP vanadium can be ascribed to the higher purity and fewer initial defects in material than those made by the remelting method. Additionally, the analysis on elastic precursor wave in vanadium indicates a power decay of Hugoniot elastic limit (σHEL) with the dimensionless thickness of the sample (hs/h0), where h0 is a unit length. The coefficient and exponent of the power function best fitting the experimental data are 3.246 and -0.386, respectively, when the vanadium sample's thickness hs is no greater than 6 mm.

-

Key words:

- pure vanadium /

- spall strength /

- decay of elastic precursor /

- hot isostatic pressing /

- tensile fracture

-

表 1 HIP纯钒的主要杂质成分

Table 1. The main impurities of HIP vanadium

杂质元素a) C N O Al Fe Cr Si 质量分数/% 0.005 2 0.002 6 0.020 0.016 <0.005 <0.005 0.018 注:a)除Al和Si外,其余杂质含量均优于GB4310-84≪钒≫中V-1牌号熔炼钒的指标。 表 2 纯钒对称碰撞层裂实验参数及结果

Table 2. Summary of experimental parameters

实验编号 wf/(m·s-1) hf/mm hs/mm σH /GPa σsp/GPaa) ${{\bar {\dot \varepsilon} }_{\rm{s}}}$/s-1 σHEL/GPa Y/GPa No.1 321 3.051 6.055 5.2 4.0(3.6) 0.47×105 1.7 0.7 No.2 460 3.050 6.051 7.5 4.3(3.6) 0.62×105 1.8 0.8 No.3 525 3.064 6.055 8.6 5.0(3.9) 0.66×105 1.8 0.8 No.4 540 1.457 3.045 9.0 5.3(4.4) 1.19×105 2.0 0.9 注:a)括号内的值为不考虑回跳速度修正得到的层裂强度。 -

[1] SMITH D L, CHUNG H M, LOOMIS B A. Development of vanadium-base alloys for fusion first-wall-blanket applications[J]. Fusion Engineering and Design, 1995, 29:399-410. DOI: 10.1016/0920-3796(95)80046-Z. [2] CHUNG H M, LOOMIS B A, SMITH D L. Development and testing of vanadium alloys for fusion applications[J]. Journal of Nuclear Materials, 1996, 239:139-156. DOI: 10.1016/S0022-3115(96)00676-9. [3] FUKUMOTO K, MATSUI H, TSAI H, et al. Mechanical behavior and microstructural evolution of vanadium alloys irradiated in ATR-A1[J]. Journal of Nuclear Materials, 2000, 283-287(part 1):492-497. DOI: 10.1016/S0022-3115(00)00310-X. [4] TAKAHASHI H, OHNUKI S, KINOSHITA H, et al. The effects of damage structures on mechanical properties of neutron irradiated vanadium[J]. Journal of Nuclear Materials, 1988, 155-157(part 2):982-986. DOI: 10.1016/0022-3115(88)90453-9. [5] EPOV G A. Void evolution simulation in neutron-irradiated vanadium[J]. Journal of Nuclear Materials, 1996, 230(1):84-90. DOI: 10.1016/0022-3115(95)00156-5. [6] 冷邦义, 鲜晓斌, 庞晓轩, 等.纯钒的高温力学性能及断口特征[J].稀有金属材料与工程, 2011, 40(8):1470-1472. DOI: 10.3103/S1067821211040110.LENG Bangyi, XIAN Xiaobin, PANG Xiaoxuan, et al. High temperature mechanical properties and fracture characteristics of pure vanadium[J]. Rare Metal Materials and Engineering, 2011, 40(8):1470-1472. DOI: 10.3103/S1067821211040110. [7] 鲜晓斌, 叶林森, 冷邦义, 等.纯钒制备及其性能[J].稀有金属材料与工程, 2010, 39(5):928-931. DOI: 10.3321/j.issn:1002-185X.2010.05.039.XIAN Xiaobin, YE Linsen, LENG Bangyi, et al. Study on preparation and properties of pure vanadium[J]. Rare Metal Materials and Engineering, 2010, 39(5):928-931. DOI: 10.3321/j.issn:1002-185X.2010.05.039. [8] 叶林森, 鲜晓斌, 迟永刚, 等.热等静压纯钒性能研究[C]//中国材料研讨会.长沙, 2012: 1-5. [9] 谢若泽, 胡文军, 黄西成, 等.纯钒的动态压缩力学性能实验研究[J].中国测试, 2016, 42(10):40-44. DOI: 10.11857/j.issn.1674-5124.2016.10.008.XIE Ruoze, HU Wenjun, HUANG Xicheng, et al. Experimental study on dynamic compressive mechanical properties of pure vanadium[J]. China Measurement and Test, 2016, 42(10):40-44. DOI: 10.11857/j.issn.1674-5124.2016.10.008. [10] LENNON A M, RAMESH K T. A technique for measuring the dynamic behavior of materials at high temperatures[J]. International Journal of Plasticity, 1998, 14(12):1279-1292. DOI: 10.1016/S0749-6419(98)00056-4. [11] NEMAT-NASSER S, GUO Weiguo. High strain-rate response of commercially pure vanadium[J]. Mechanics of Materials, 2000, 32(4):243-260. DOI: 10.1016/S0167-6636(99)00056-3. [12] FLORANDO J N, JIAO T, GRANSCHEL S E, et al. High rate plasticity under pressure using a windowed pressure-shear impact experiment: LLNL-PROC-417930[R]. USA: LLNL, 2009. [13] YU Yuying, TAN Ye, DAI Chengda, et al. Phase transition and strength of vanadium under shock compression up to 88GPa[J]. Applied Physics Letters, 2014, 105(20):201910. DOI: 10.1063/1.4902374. [14] 俞宇颖, 谭叶, 戴诚达, 等.钒的高压声速测量[J].物理学报, 2014, 63(2):026202. DOI: 10.7498/aps.63.026202.YU Yuying, TAN Ye, DAI Chengda, et al. Sound velocities of vanadium under shock compression[J]. Acta Physica Sinica, 2014, 63(2):026202. DOI: 10.7498/aps.63.026202. [15] ZARETSKY E B, KANEL G I. Tantalum and vanadium response to shock-wave loading at normal and elevated temperatures:Non-monotonous decay of the elastic wave in vanadium[J]. Journal of Applied Physics, 2014, 115(24):243502. DOI: 10.1063/1.4885047. [16] KANEL G I, RAZORENOV S V, GARKUSHIN G V, et al. Stress relaxation in vanadium under shock and shockless dynamic compression[J]. Journal of Applied Physics, 2015, 118(4):045901. DOI: 10.1063/1.4927613. [17] SAVELEVA N V, BAYANDIN Y V, SAVINYKH A S, et al. Peculiarities of the elastic-plastic transition and failure in polycrystalline vanadium under shock wave loading conditions[J]. Technical Physics Letters, 2015, 41(6):579-582. DOI: 10.1134/S1063785015060292. [18] ASHITKAV S I, KOMAROV P S, STRULEVA E V, et al. Mechanical and optical properties of vanadium under shock picosecond loads[J]. JETP Letters, 2015, 101(4):276-281. DOI: 10.1134/S0021364015040049. [19] WENG Jidong, TAN Hua, HU Shaolou. New all-fiber velocimeter[J]. Review of Scientific Instrumentss, 2005, 76(9):93301. DOI: 10.1063/1.2008989. [20] CHHABILDAS L C, HILLS C R. Dynamic shock studies of vanadium: SAND-85-0322C[R]. USA: SNL, 1985. [21] ANTOUN T, SEAMAN L, CURRAN D R, et al. Spall fracture[M]. New York:Springer-Verlag, 2003:95-99. -

下载:

下载: