Strain growth of flange bolts of the spherical explosive vessel

-

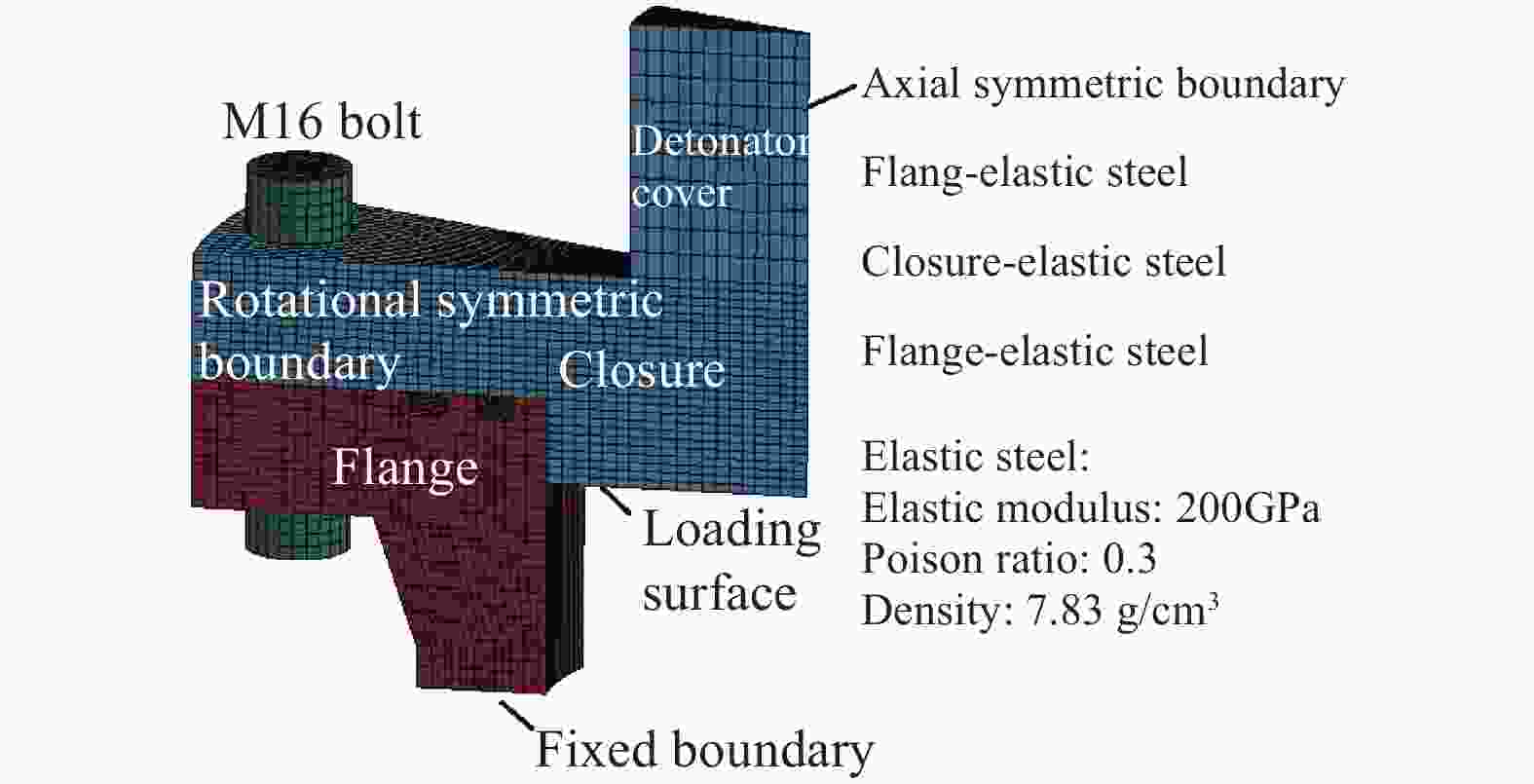

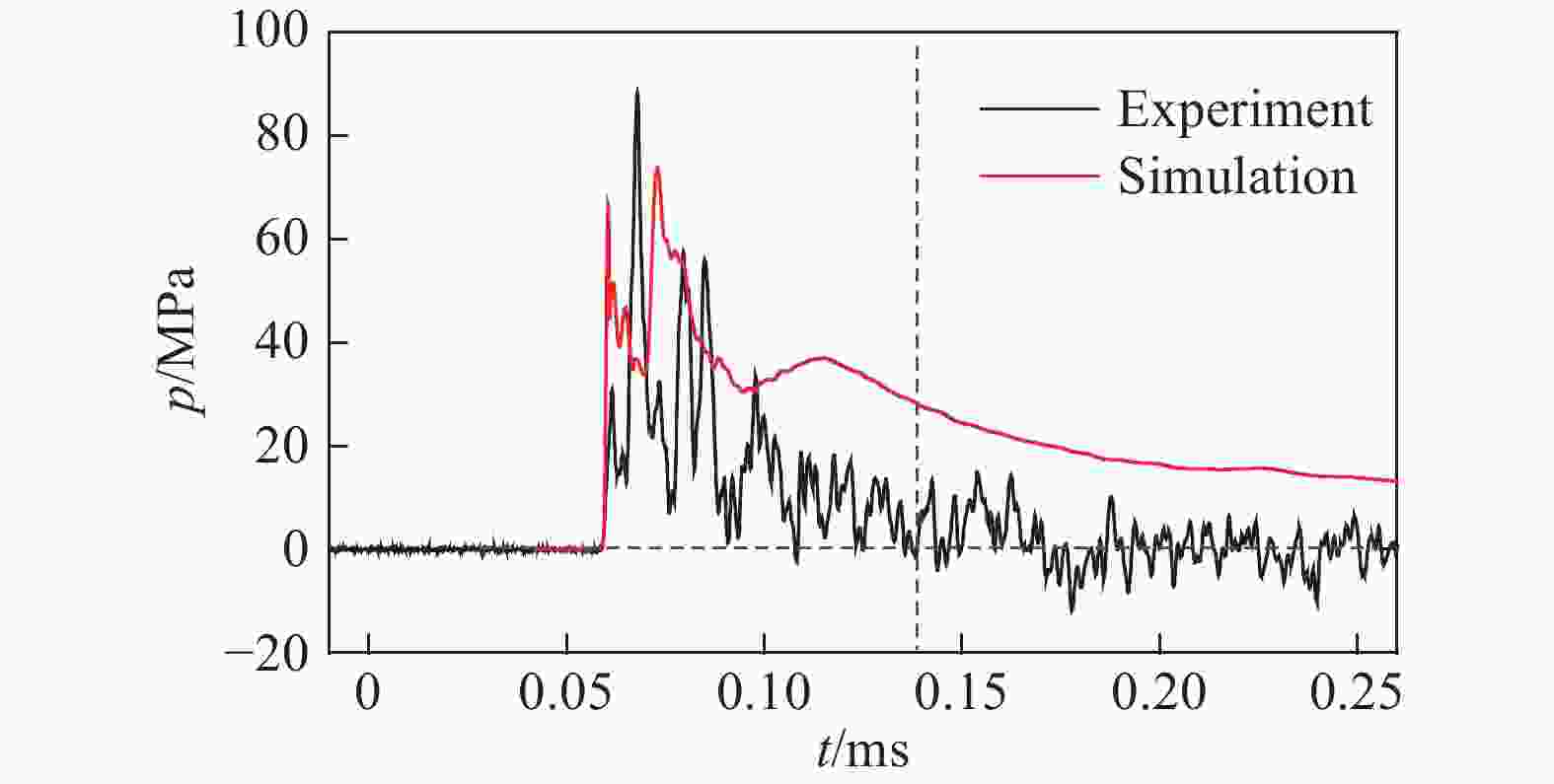

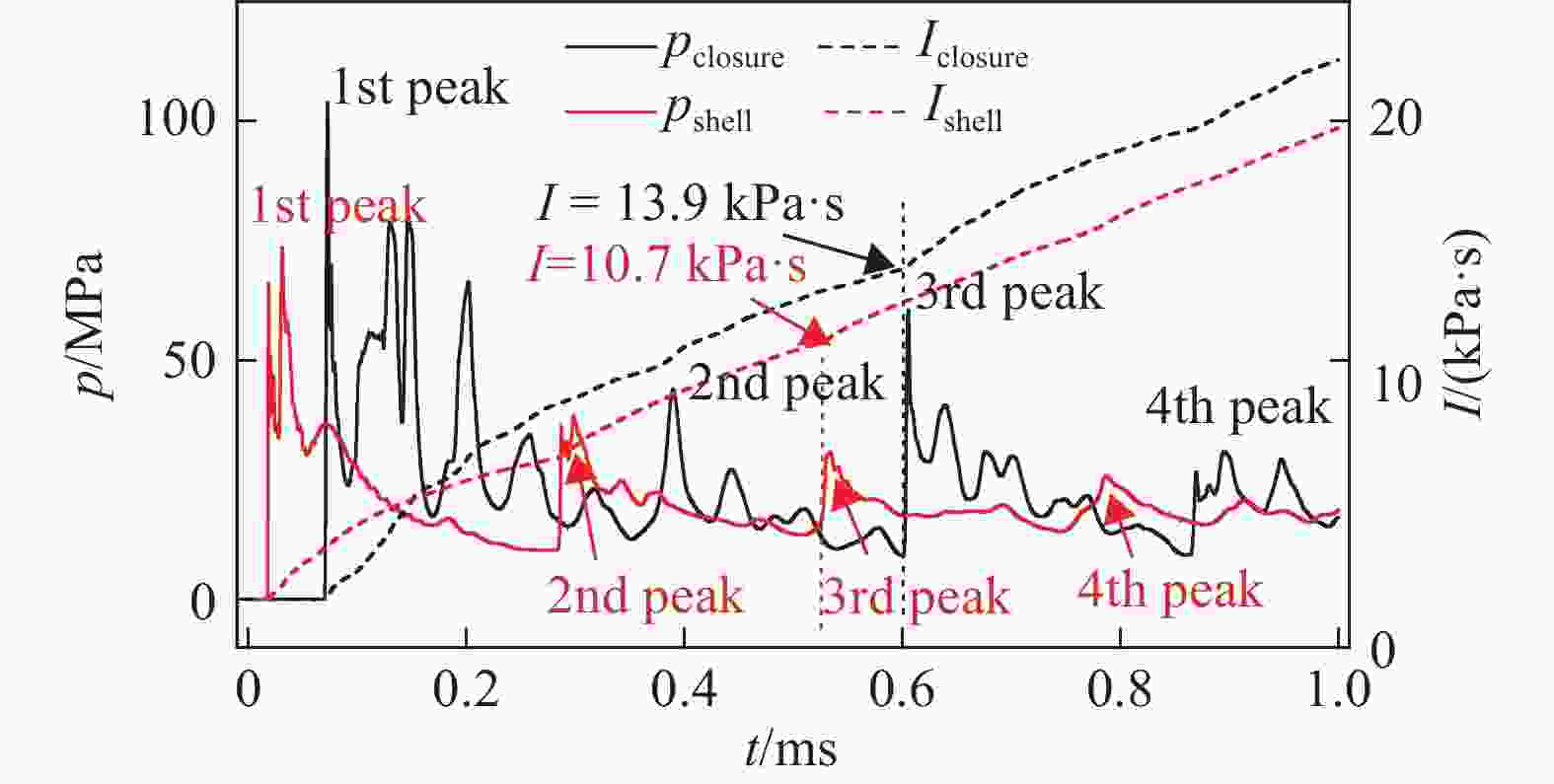

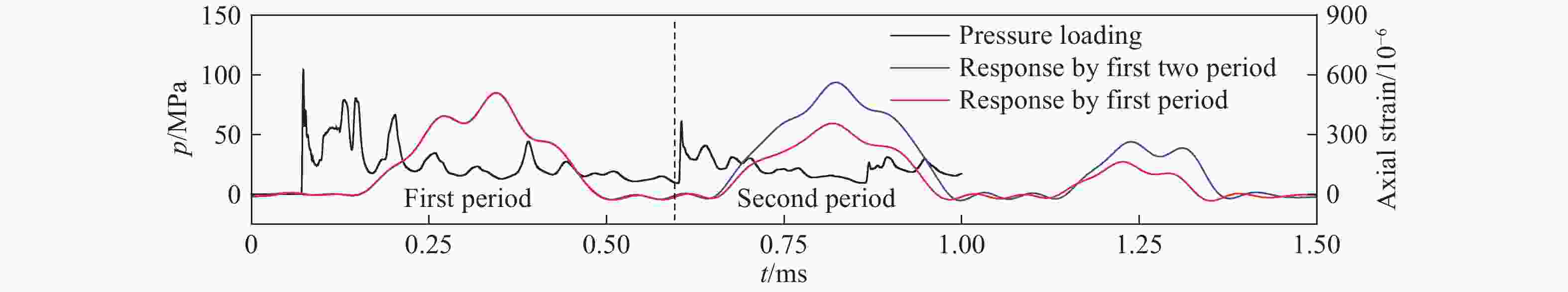

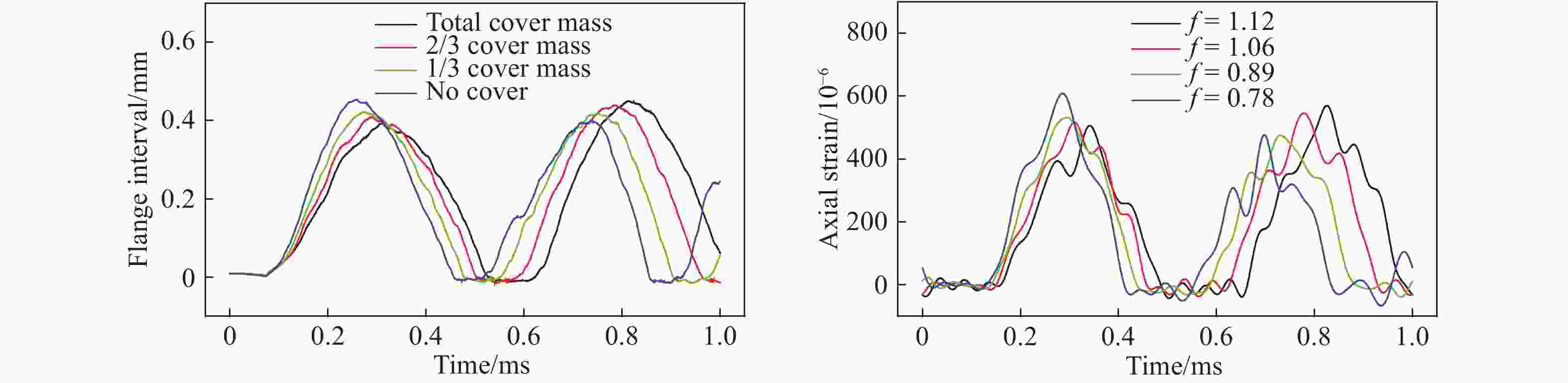

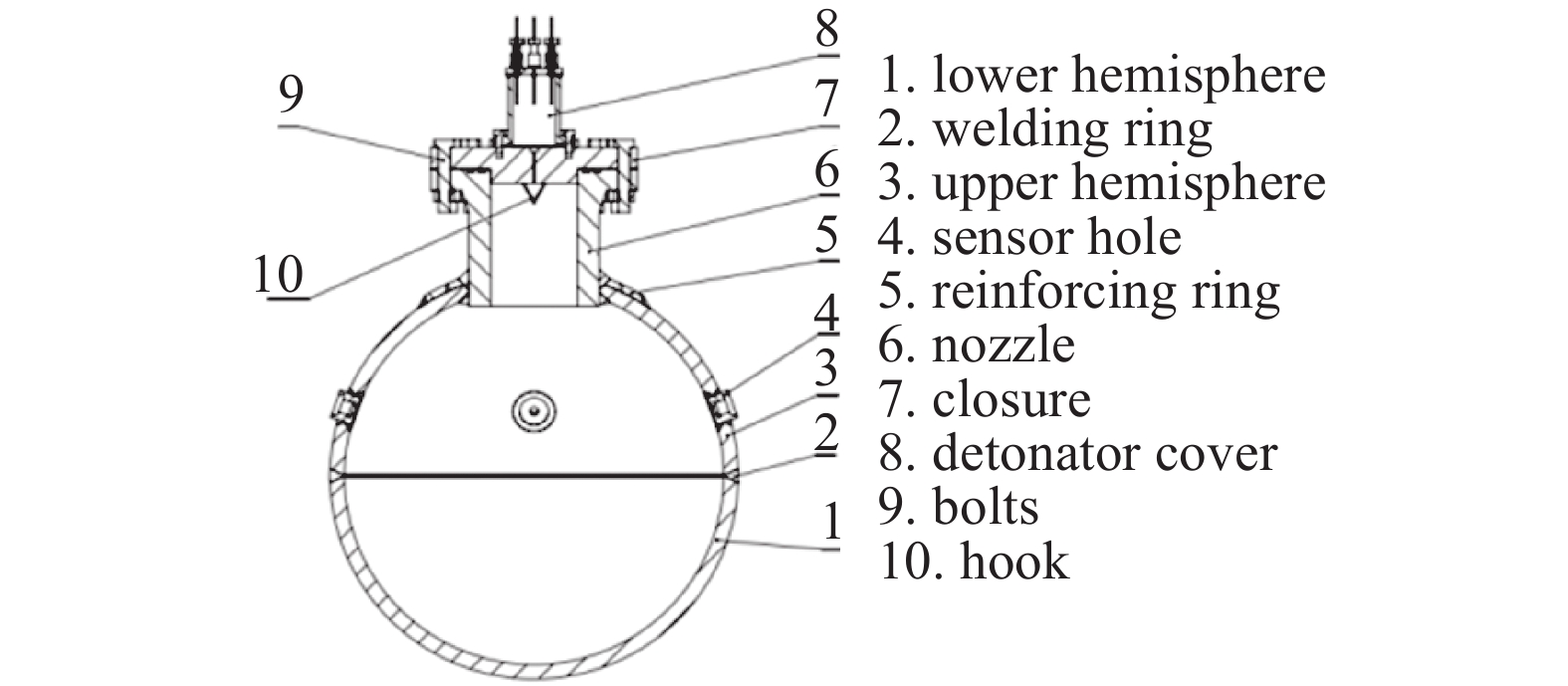

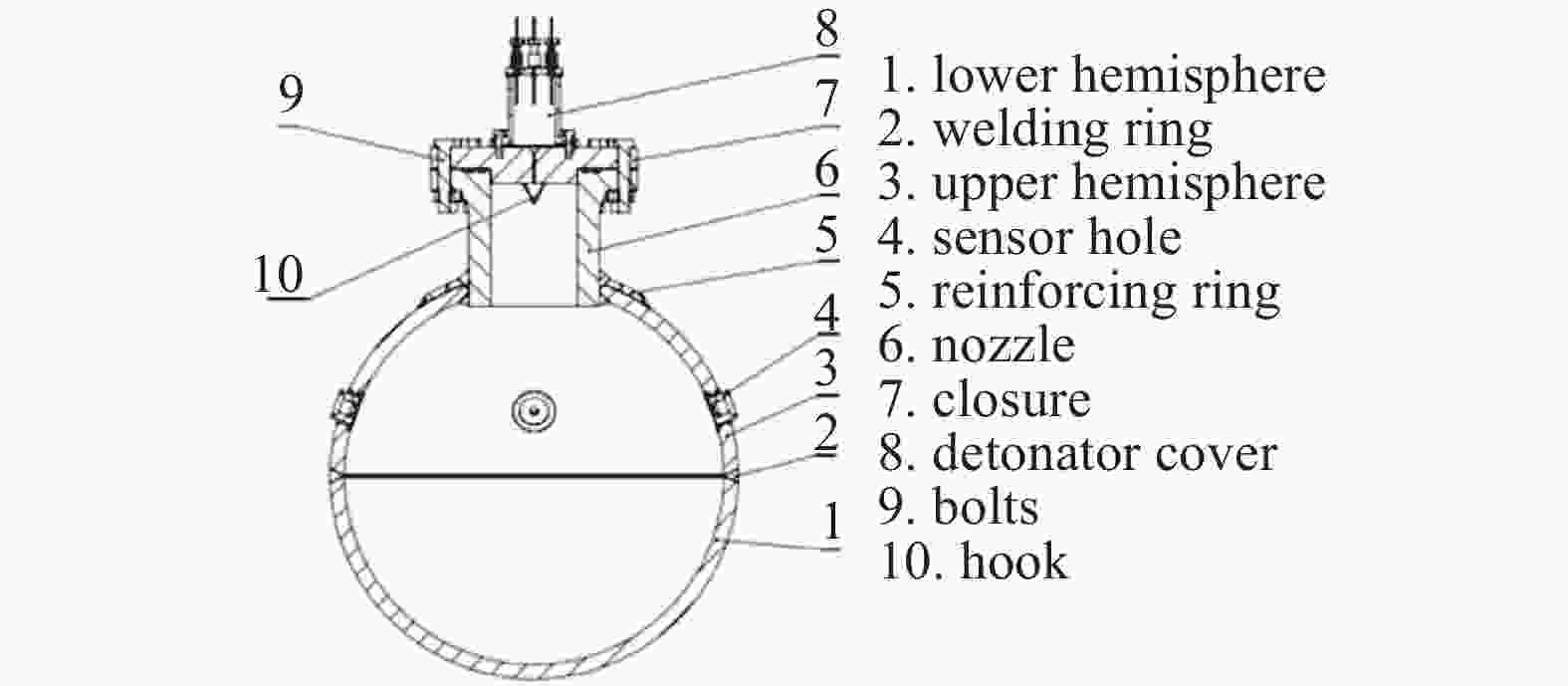

摘要: 本文在球形爆炸容器法兰连接螺栓的动态响应实验研究中,发现了法兰螺栓的应变增长现象。以实验数据为基础,通过数值模拟对螺栓发生应变增长的原因进行分析。研究结果表明:受到开口结构的影响,端盖螺栓受到的压力载荷强度较容器内壁大幅增强。螺栓的应变增长是被增强压力载荷的前2个周期与结构响应形成共振时引发的,通过改变端盖质量、预紧力大小可以避免螺栓发生应变增长。Abstract: In this paper, the strain growth of the flange bolts was observed in the experimental study of the dynamic response of the end cap and the bolts on the spherical explosive vessel. Numerical simulation based on the experiment was then carried out to detect the cause of this phenomenon. The results showed that the intensity of the pressure loading applied on the end cap and the bolts was much higher than that of the spherical vessel shell due to the strengthing effect of the opening’s structure. The resonance between the strengthened pressure loading and the periodical dynamic response of the end cap and bolts was the dominating cause for the bolt strain growth, which could be avoided by modulating the closure mass and the bolt preload.

-

Key words:

- explosive vessel /

- strain growth /

- bolt /

- preload

-

表 1 螺栓应变统计

Table 1. Statics of bolt strain

编号 第1应变峰值/10−6 第2应变峰值/10−6 应变增长系数 内侧 中轴线 内侧 中轴线 内侧 中轴线 1 762 373 1 391 691 1.83 1.85 2 900 371 1 357 692 1.51 1.87 3 1 057 610 1 148 615 1.09 1.01 4 869 329 1 367 690 1.57 2.10 平均 897 421 1 316 672 1.47 1.60 表 2 JWL状态方程参数

Table 2. Parameters in JWL Equation of State

ρ0/(kg∙m−3) e0/(J∙kg−1) D/(m∙s−1) pCJ/GPa A/GPa B/GPa R1 R2 ω' 1 630 4.26×106 6 930 21 371.2 3.231 4.15 0.95 0.3 -

[1] DUFFEY T A, ROMERO C. Strain growth in spherical explosive chambers subjected to internal blast loading [J]. International Journal of Impact Engineering, 2003, 28(9): 967–983. doi: 10.1016/S0734-743X(02)00169-0 [2] DONG Q, LI Q M, ZHENG J Y. Interactive mechanisms between the internal blast loading and the dynamic elastic response of spherical containment vessels [J]. International Journal of Impact Engineering, 2009: 1–10. doi: 10.1016/j.ijimpeng.2009.10.004 [3] 刘文祥, 张庆明, 钟方平, 等. 球壳塑性变形下的应变增长现象 [J]. 爆炸与冲击, 2017, 37(5): 893–898 doi: 10.11883/1001-1455(2017)05-0893-0LIU Wenxiang, ZHANG Qingming, ZHONG Fangping, et al. Strain growth of spherical shell subjected to internal blast loading during plastic response [J]. Explosion and Shock Waves, 2017, 37(5): 893–898 doi: 10.11883/1001-1455(2017)05-0893-0 [4] KARPP R R, DUFFEY T A, NEAL T R. Response of containment vessels to explosive blast loading [J]. Journal of Pressure Vessel Technology, 1980, 105(1): 23–27. doi: 10.1115/1.3264234 [5] 刘文祥, 张庆明, 谭书舜, 等. 球形爆炸容器的应变增长现象 [J]. 爆炸与冲击, 2013, 33(S1): 99–104LIU Wenxiang, ZHANG Qingming, TAN Shushun, et al. Strain growth in spherical explosion vessels subjected to internal blast loading [J]. Explosion and Shock Waves, 2013, 33(S1): 99–104 [6] DONG Q, LI Q M, ZHENG J Y. Further study on strain growth in spherical containment vessels subjected to internal blast loading [J]. International Journal of Impact Engineering, 2010, 37: 196–206. doi: 10.1016/j.ijimpeng.2009.09.001 [7] LIU W X, ZHANG Q M, ZHONG F P, et al. Further research on mechanism of strain growth caused by superposition of different vibration modes [J]. International Journal of Impact Engineering, 2017, 104: 1–12. doi: 10.1016/j.ijimpeng.2017.01.025 [8] DUFFEY T A. Optimal bolt preload For dynamic loading [J]. International Journal of Mechanical Science, 1993, 3(35): 257–265. doi: 10.1016/0020-7403(93)90080-e [9] DUFFEY T A, LEWIS B B, BOWERS S M. Bolt preload selection for pulsed-loaded vessel closures [C]// ASME PVP Conference, 1995. [10] 闻邦椿. 机械设计手册: 第二册 [M]. 北京: 机械工业出版社, 2012. [11] AUTODYN user’s manual 4.3 [M]. Century Dynamics, 2001. [12] LS-DYNA keyword user’s manual 971 [M]. Livermore Software Technology Corporation, 2010. [13] 李会勋, 胡迎春, 张建中. 利用ANSYS模拟螺栓预紧力的研究 [J]. 山东科技大学学报, 2006, 25(1): 57–59 doi: 10.16452/j.cnki.sdkjzk.2006.01.017LI Huixun, HU Yingchun, ZHANG Jianzhong. Study on simulating bolt pretension by using ANSYS [J]. Journal of Shandong University of Science and Technology, 2006, 25(1): 57–59 doi: 10.16452/j.cnki.sdkjzk.2006.01.017 -

下载:

下载: