Analysis of mass abrasion of high-speed penetrator influenced by aggregate in concrete target

-

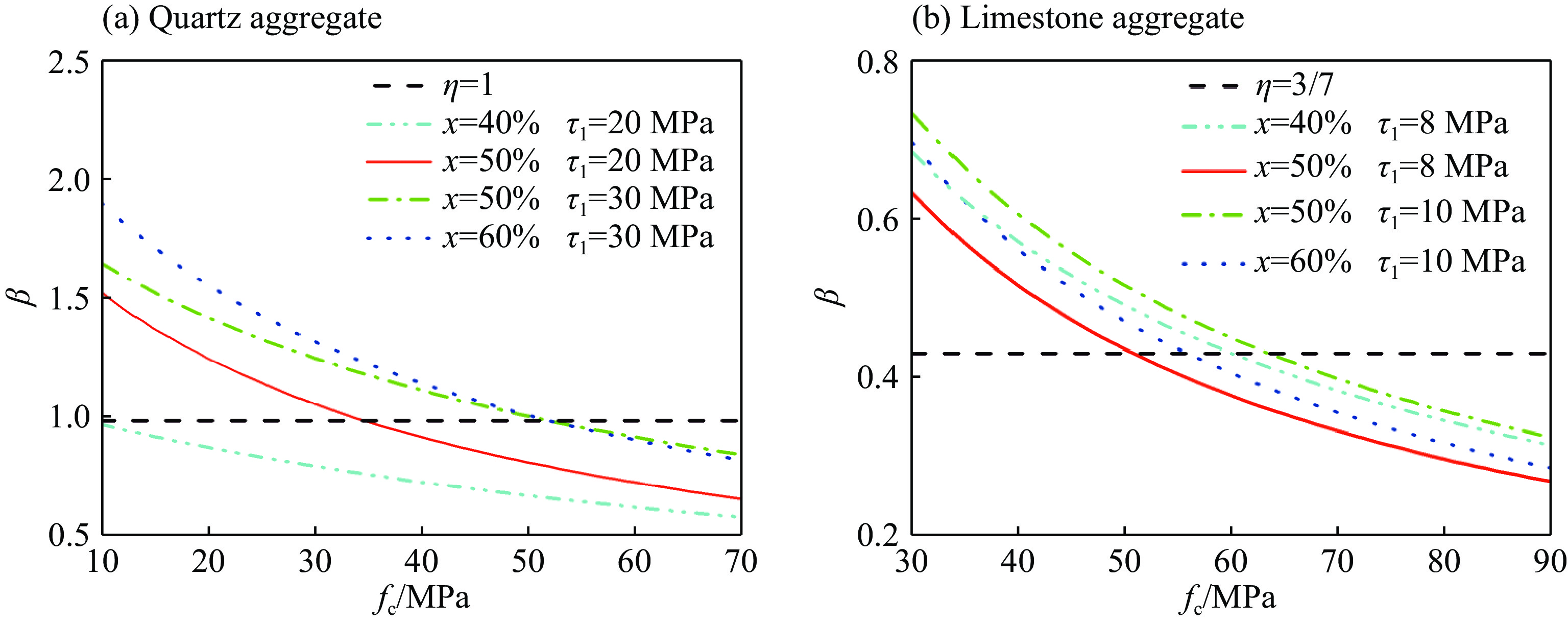

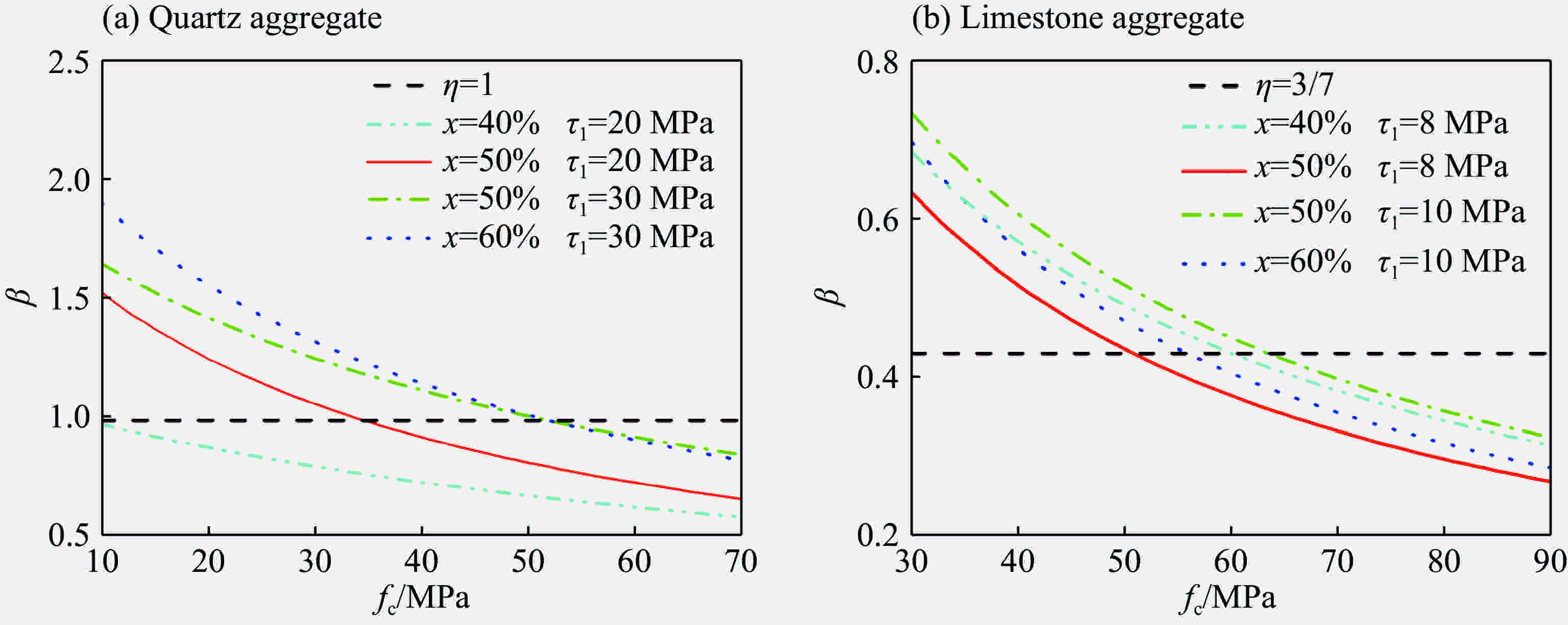

摘要: 高速侵彻时,弹靶之间发生强烈的局部作用,引起弹体头部发生质量侵蚀,从而影响弹体的侵彻性能。在弹体侵彻过程中,混凝土中的骨料对弹体的质量侵蚀有显著影响。本文通过对高速侵彻混凝土弹体的质量侵蚀实验数据进行分析,进一步分析讨论了混凝土骨料对弹体质量侵蚀的影响。将混凝土靶体视为骨料和砂浆基质混合的二相复合材料,引入混凝土骨料的体积分数χ和骨料的剪切强度τ1代替骨料的莫氏硬度H,给出无量纲骨料修正因子β,建立了修正的弹体质量损失工程模型。模型预测结果与现有的实验数据符合得很好,更准确地表征了混凝土骨料对弹体质量损失的影响。Abstract: The extreme local interaction between the projectile and target will cause mass erosion of the projectile during high-speed penetrating, and then decreases penetration performance of the penetrator. Aggregates in the concrete target will affect mass loss of the projectile obviously. Analysis about the experimental data is conducted to further discuss the effect of concrete aggregate on mass loss of the residual projectile after high speed penetration into concrete target. By assuming the concrete as a two-phase composite composed of mortar and aggregate and introducing the volume fraction and shear strength of aggregate instead of the aggregate Moh’s hardness, a modified engineering model is presented to predict the mass loss of projectile by giving a dimensionless modified factor β affected by aggregate. The modified model is in good agreement with available experimental data and can better characterize the effect of aggregate on the mass abrasion of penetrator into concrete target.

-

Key words:

- high speed penetration /

- mass abrasion /

- aggregate /

- volume fraction /

- shear strength

-

表 1 实验弹靶参数

Table 1. Parameters of targets and projectiles

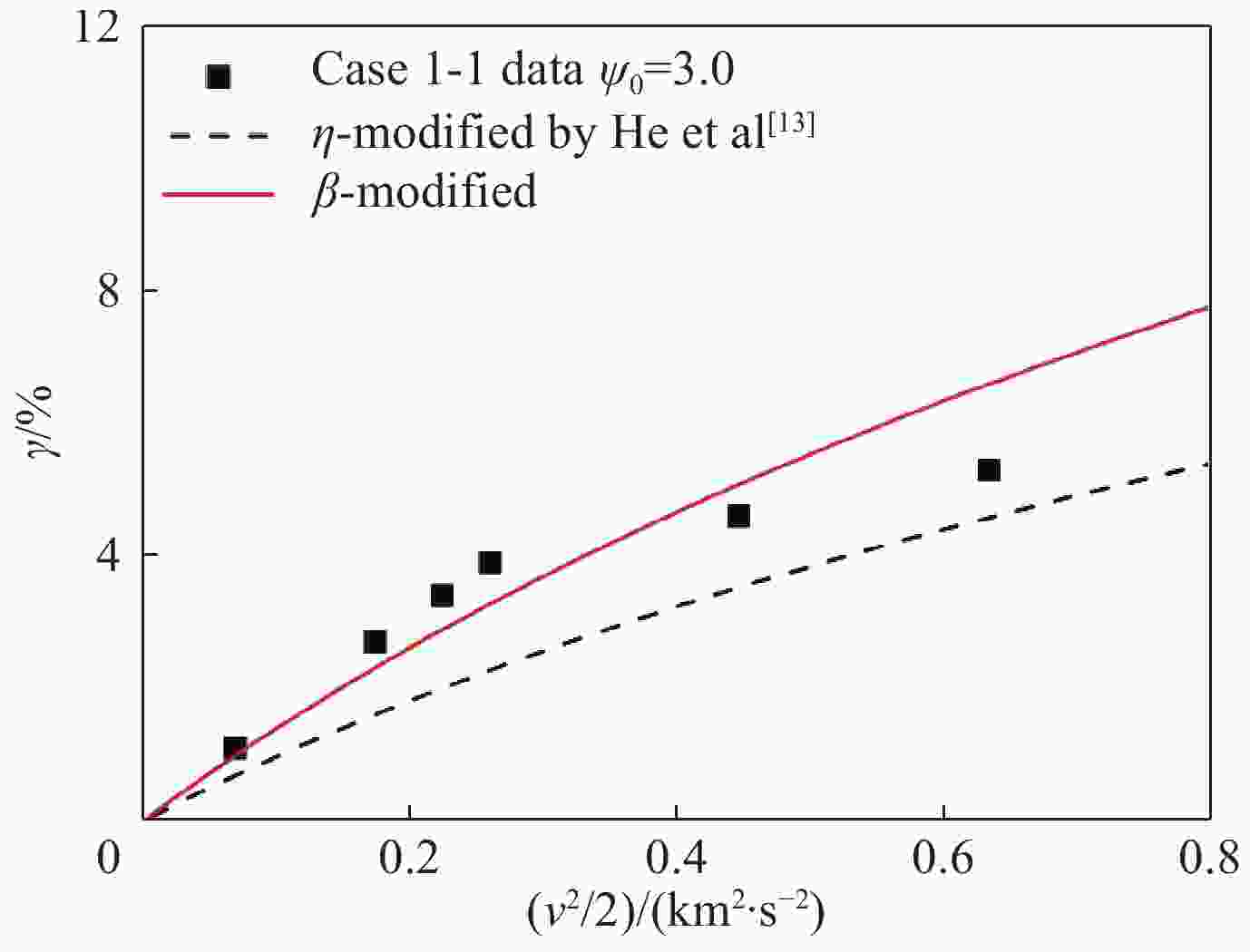

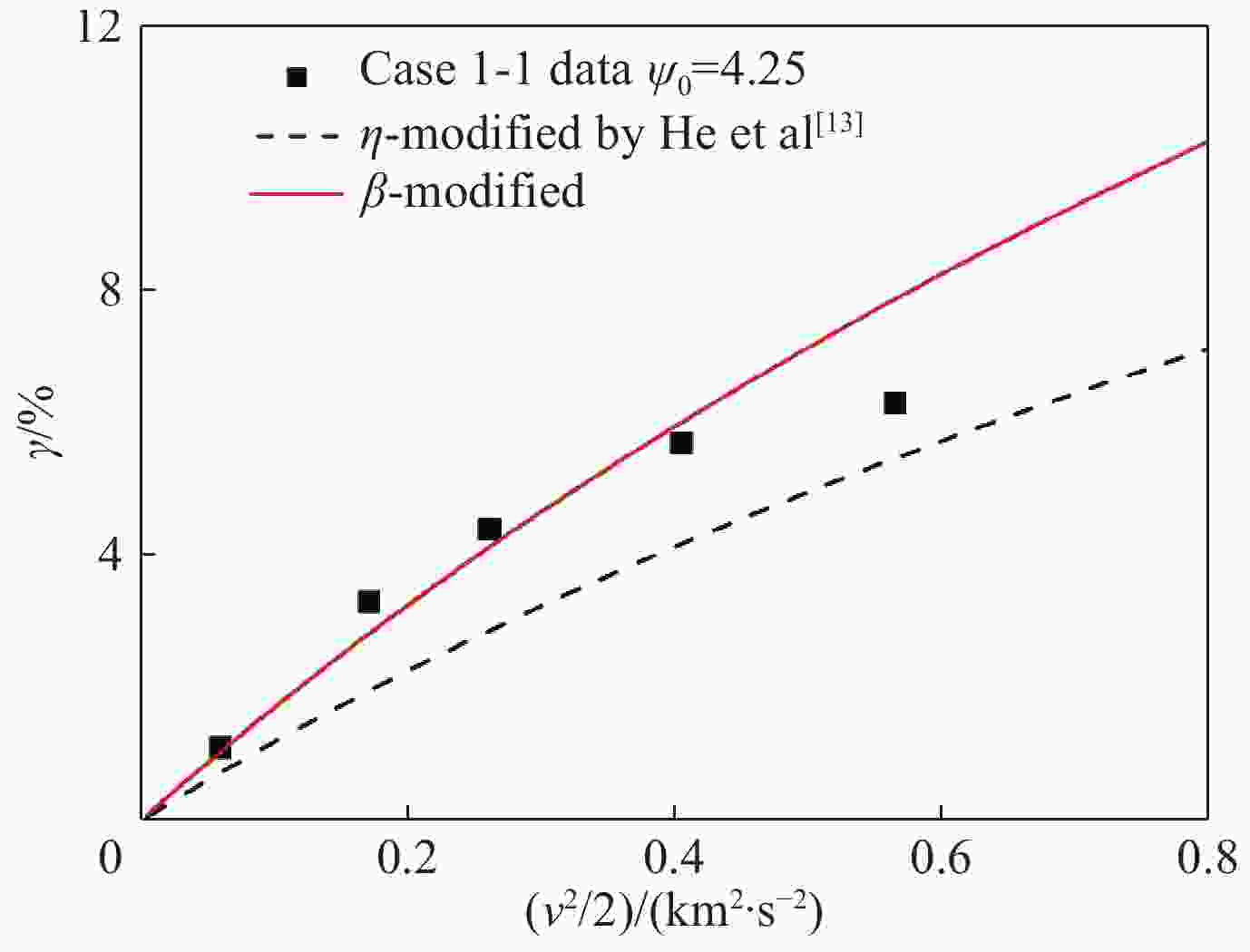

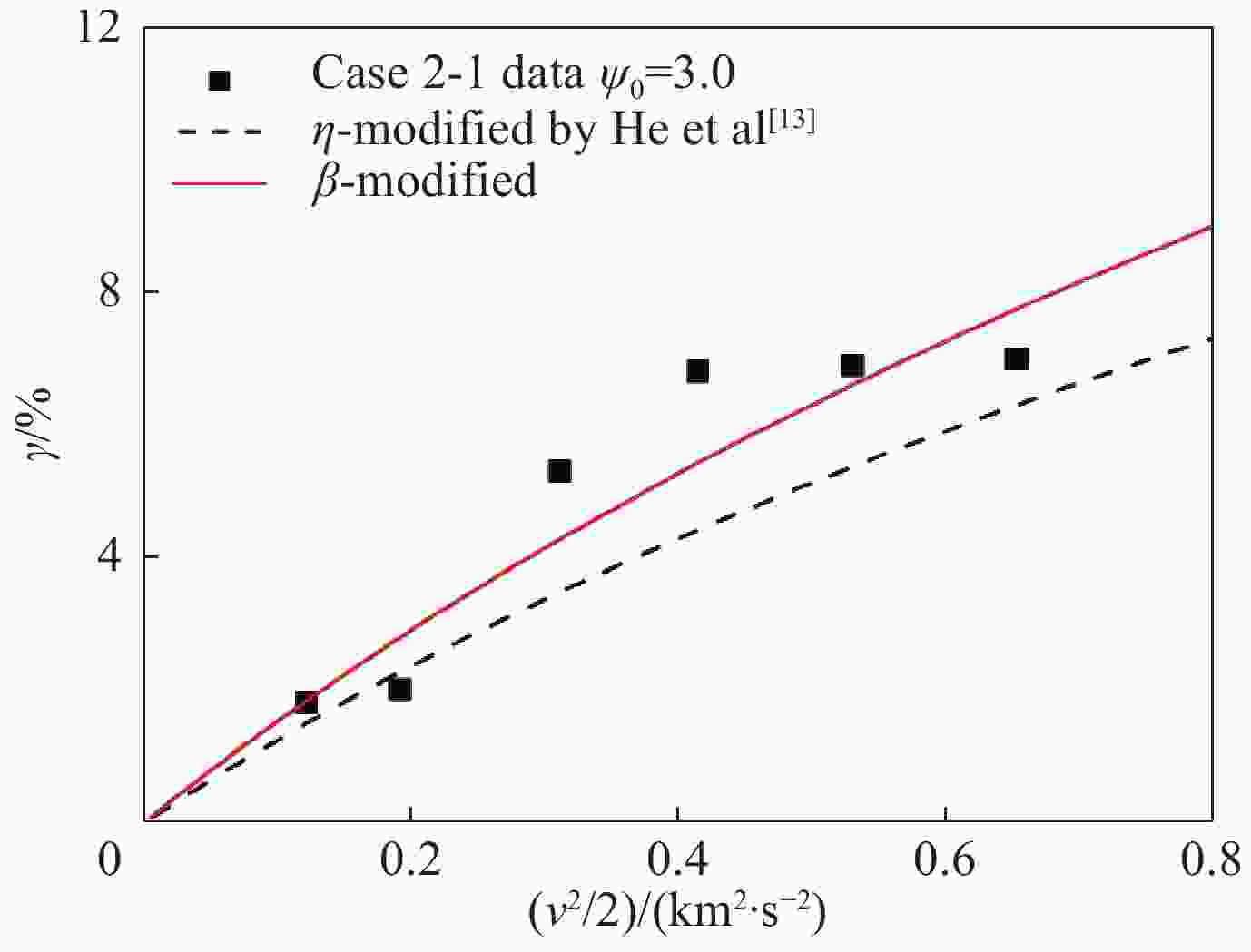

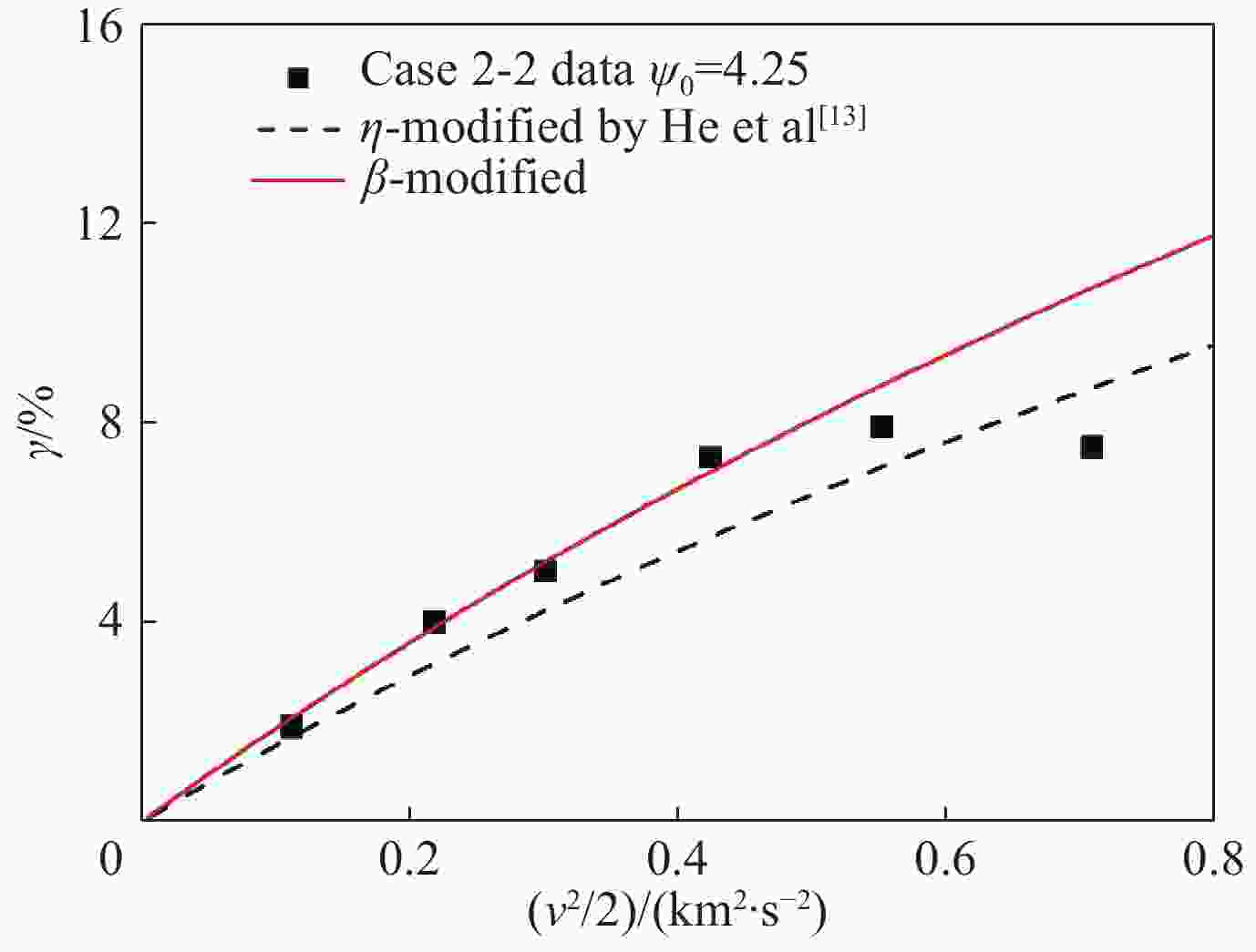

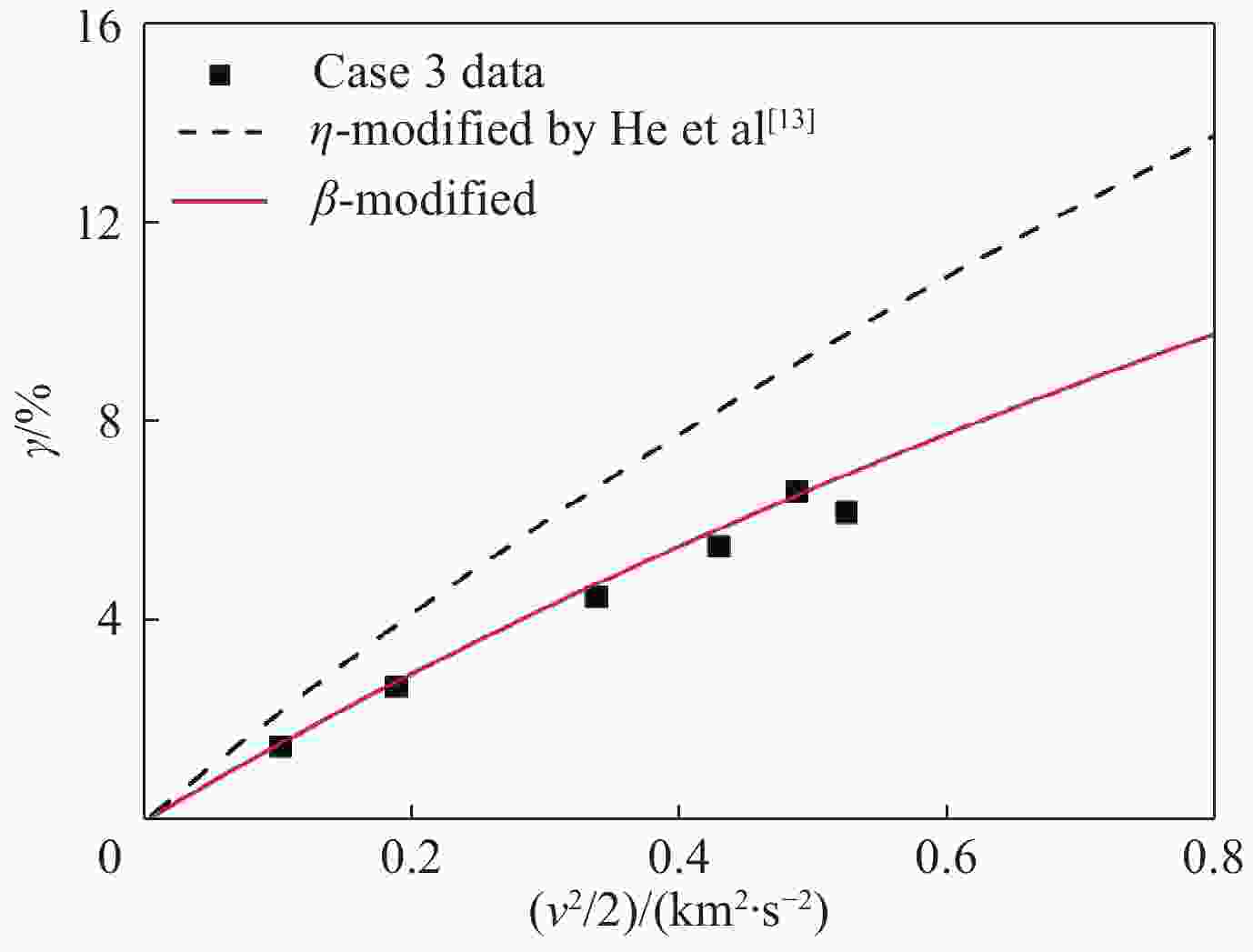

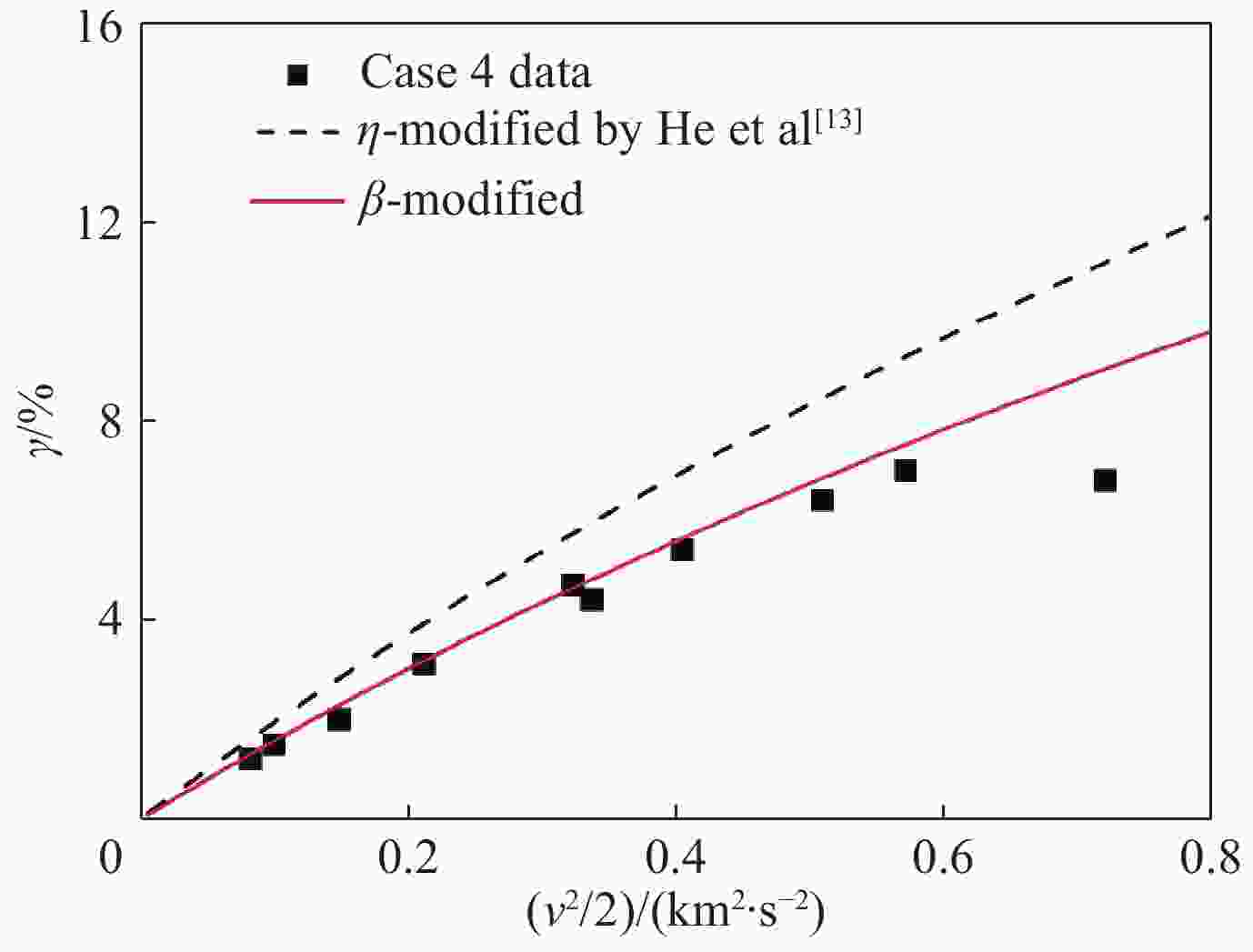

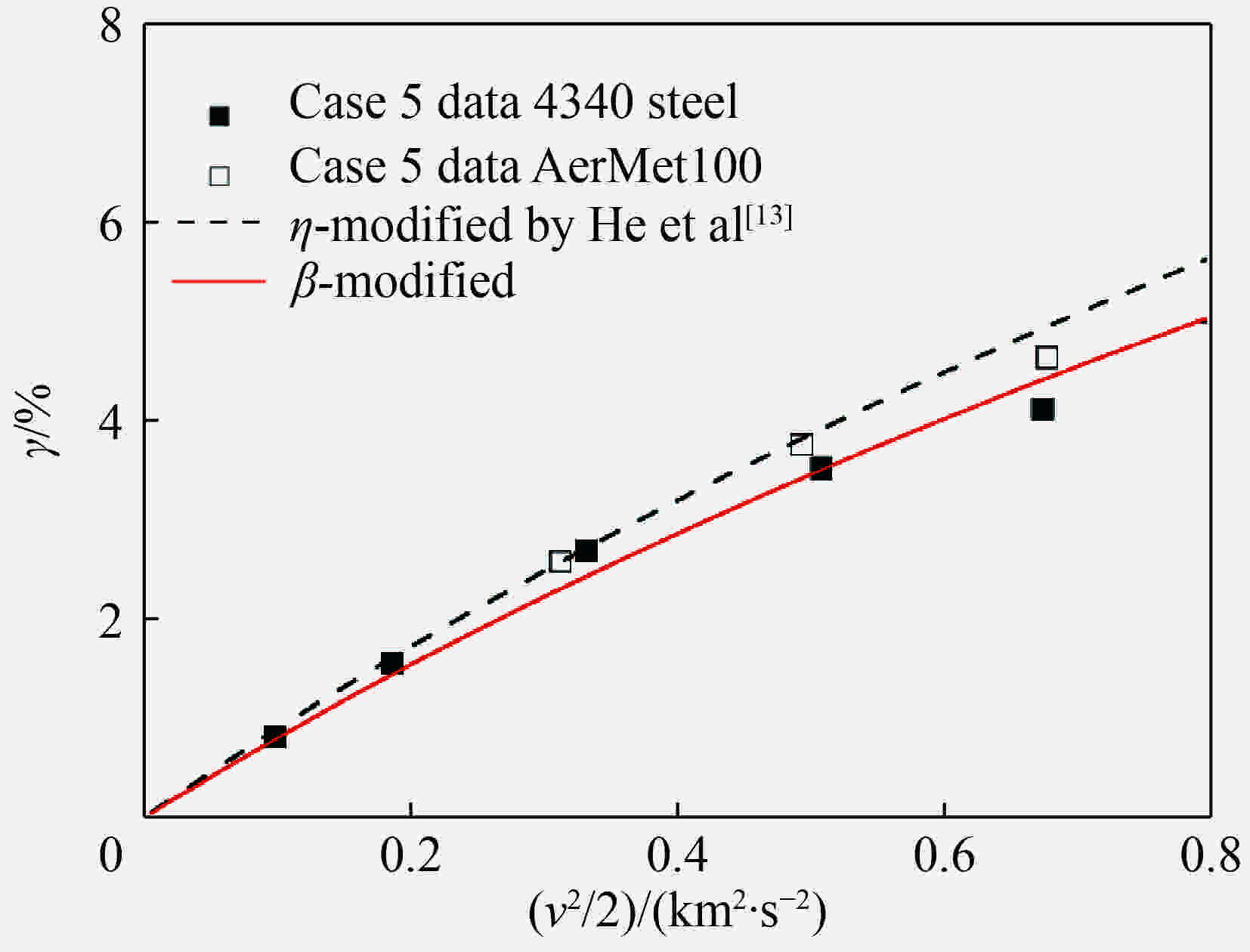

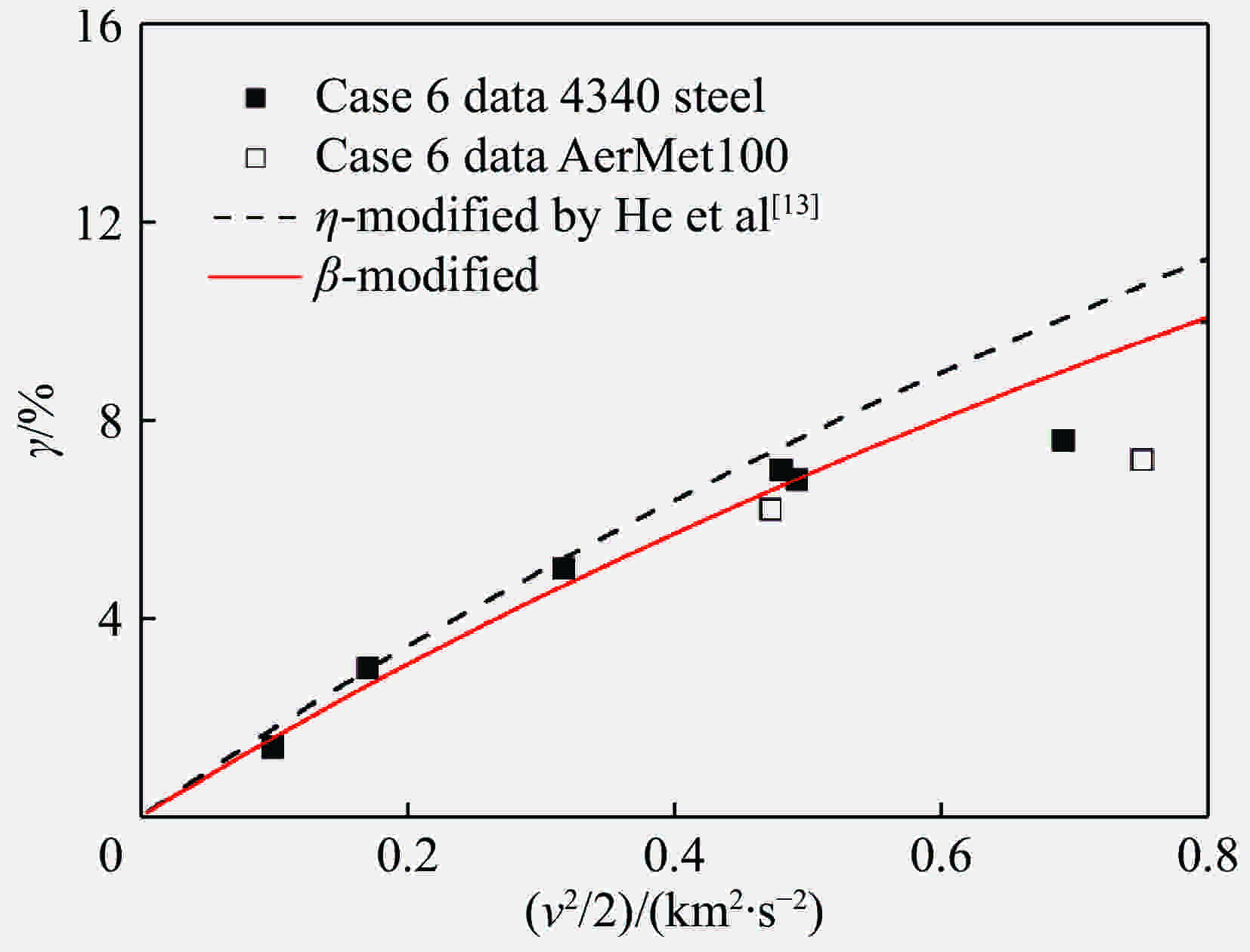

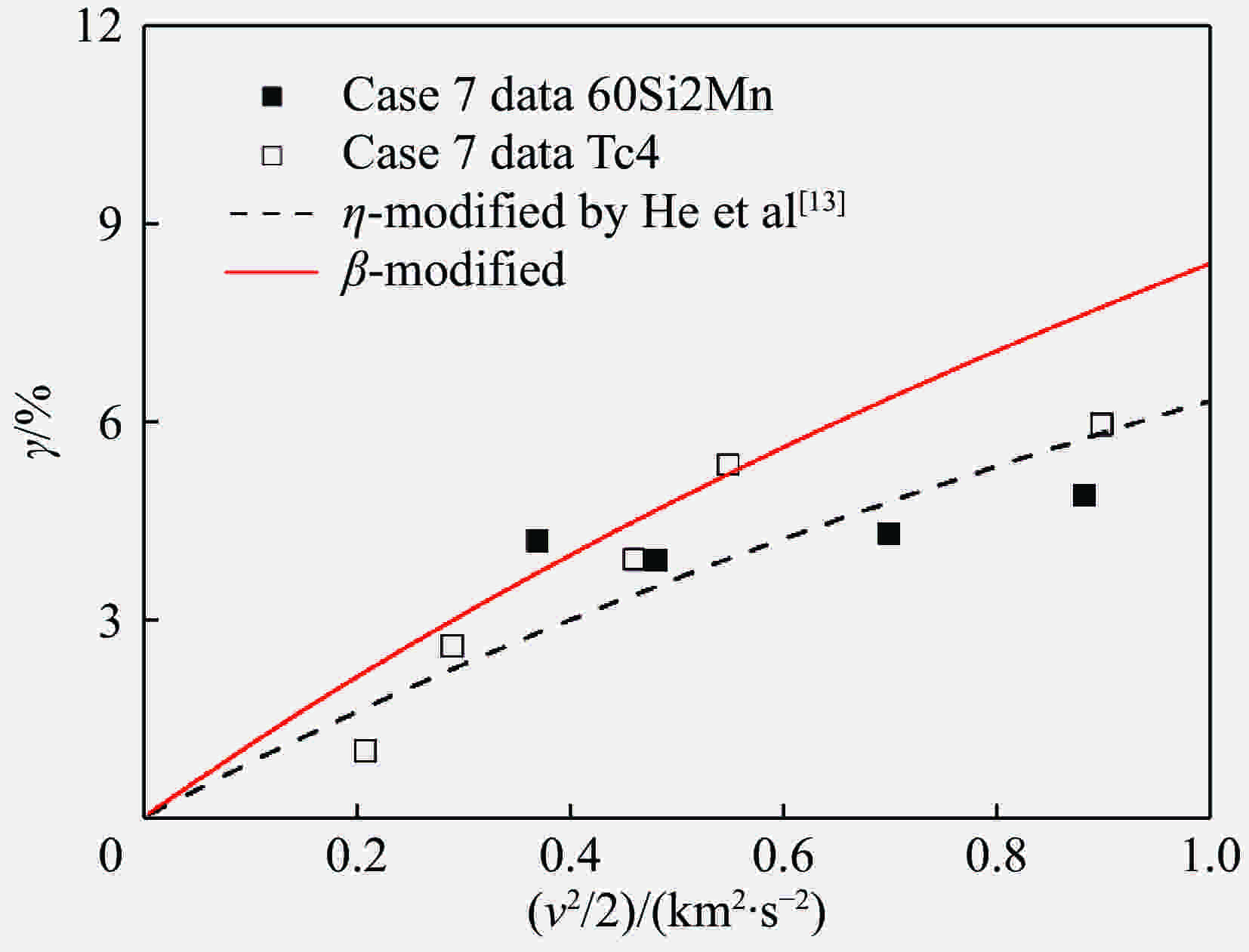

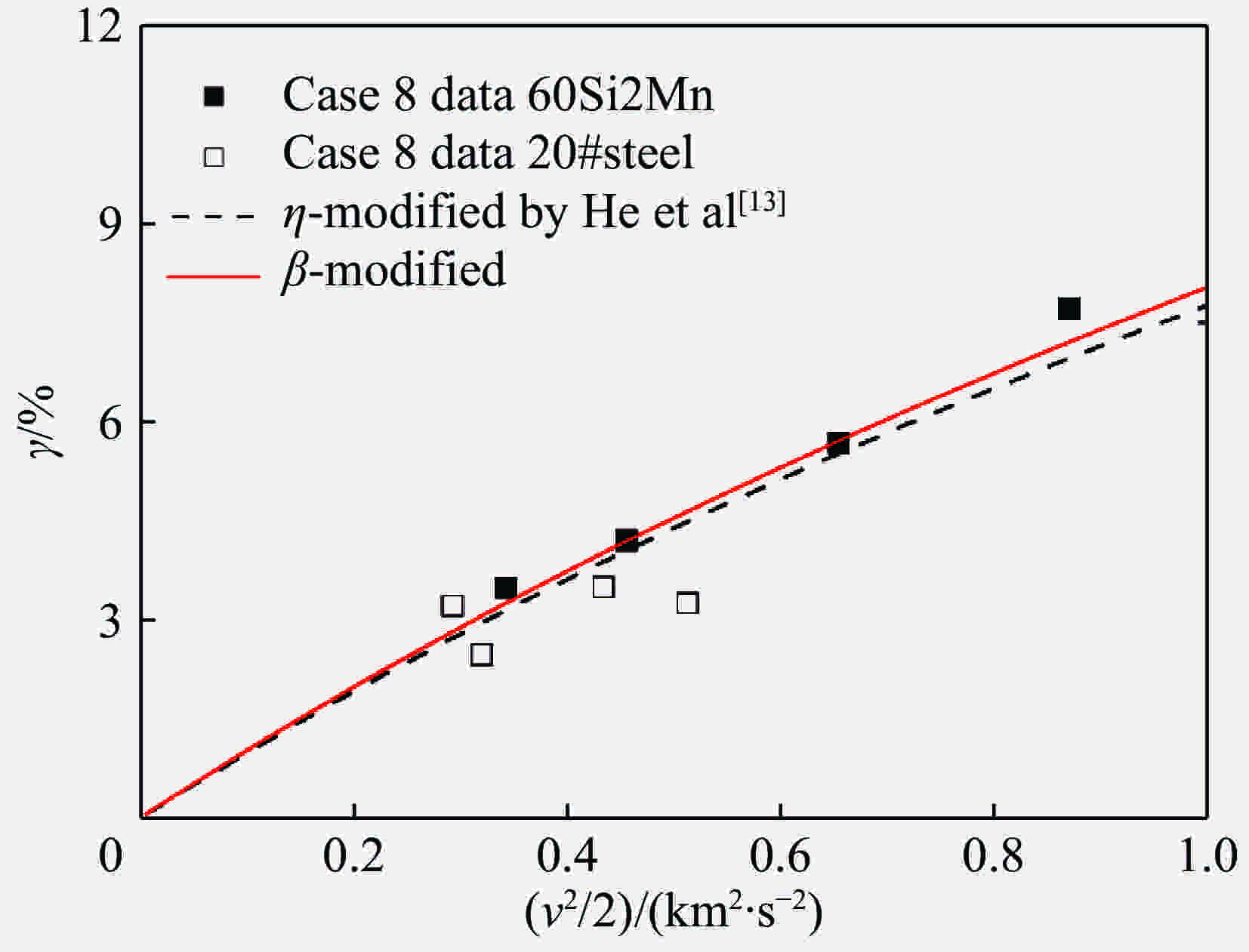

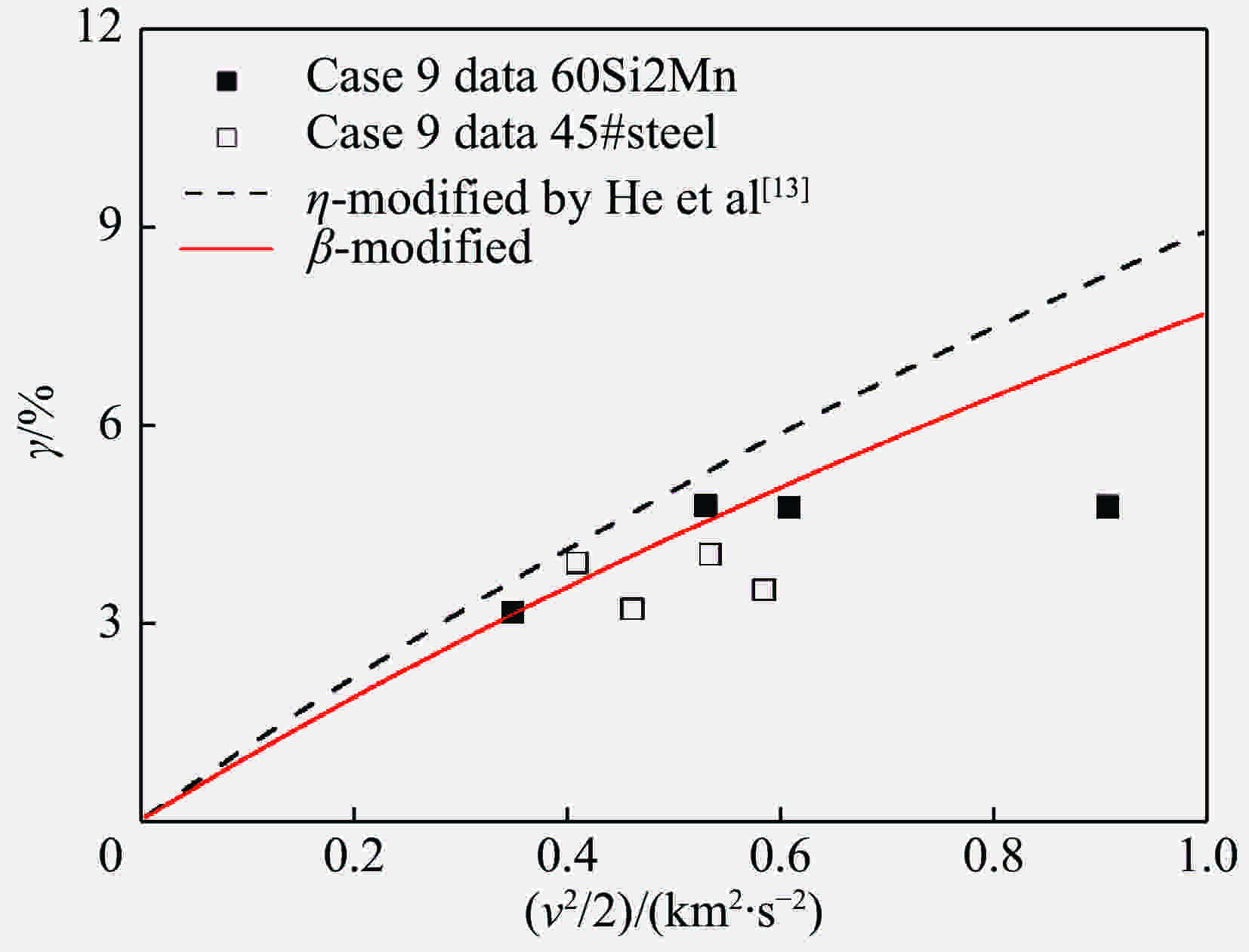

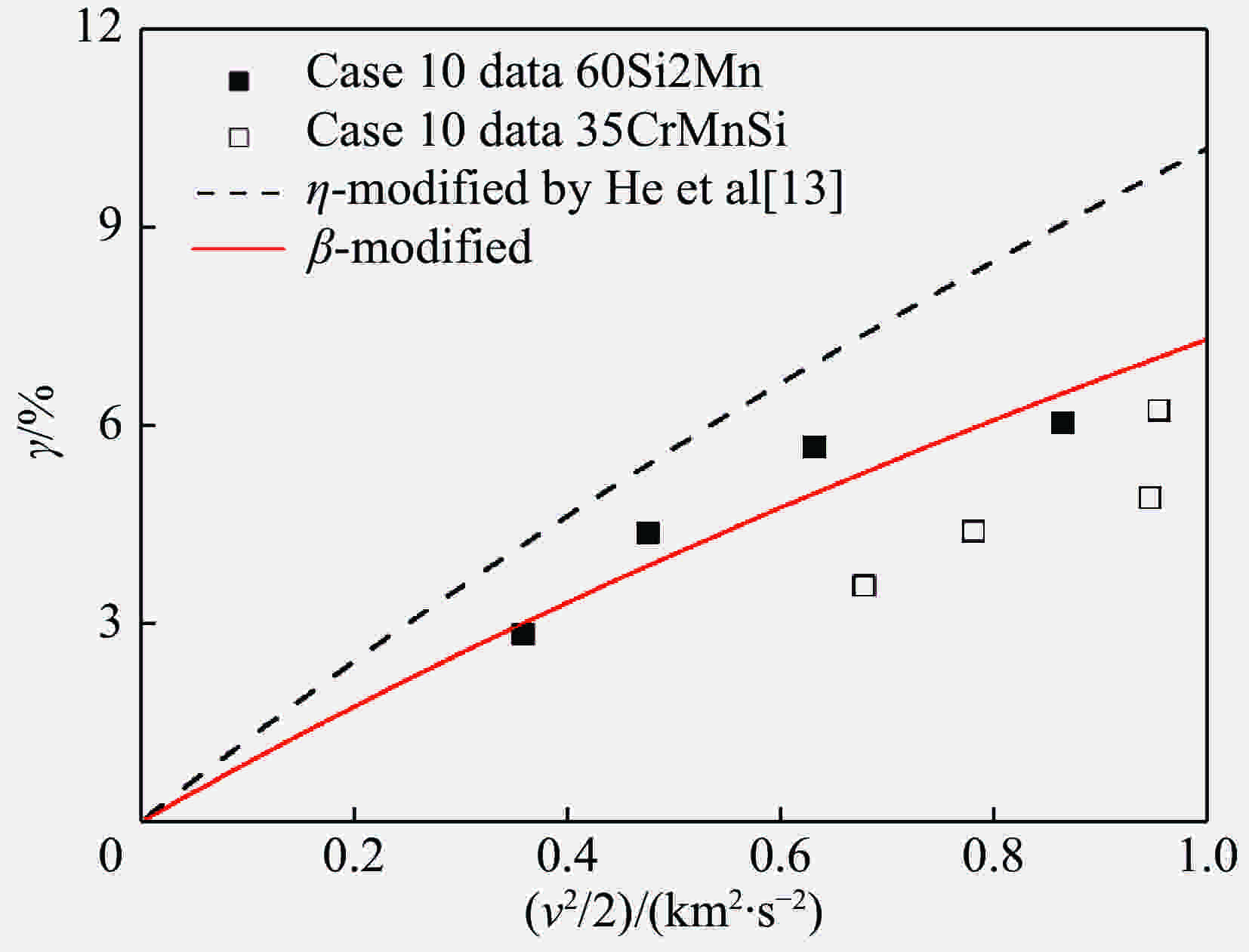

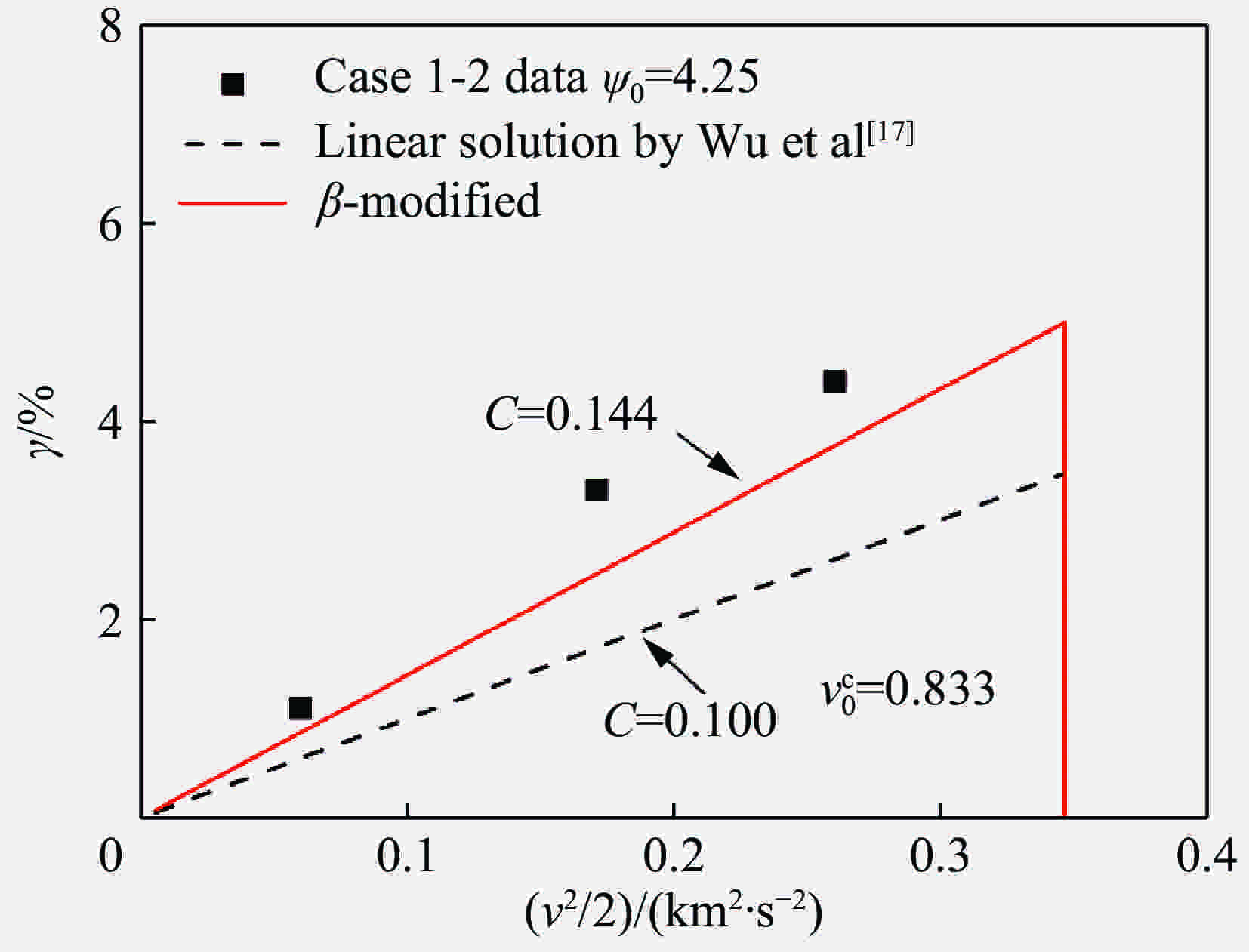

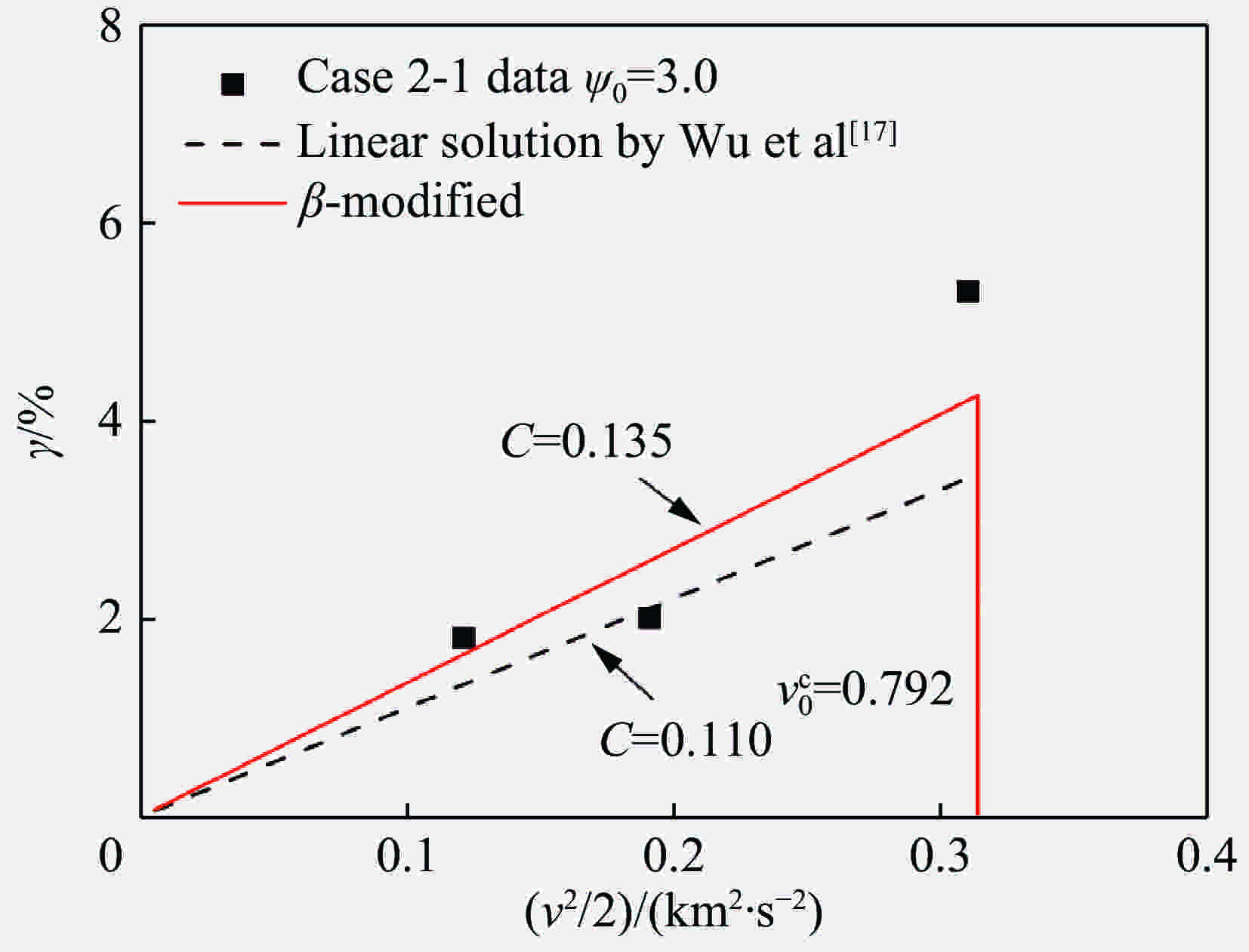

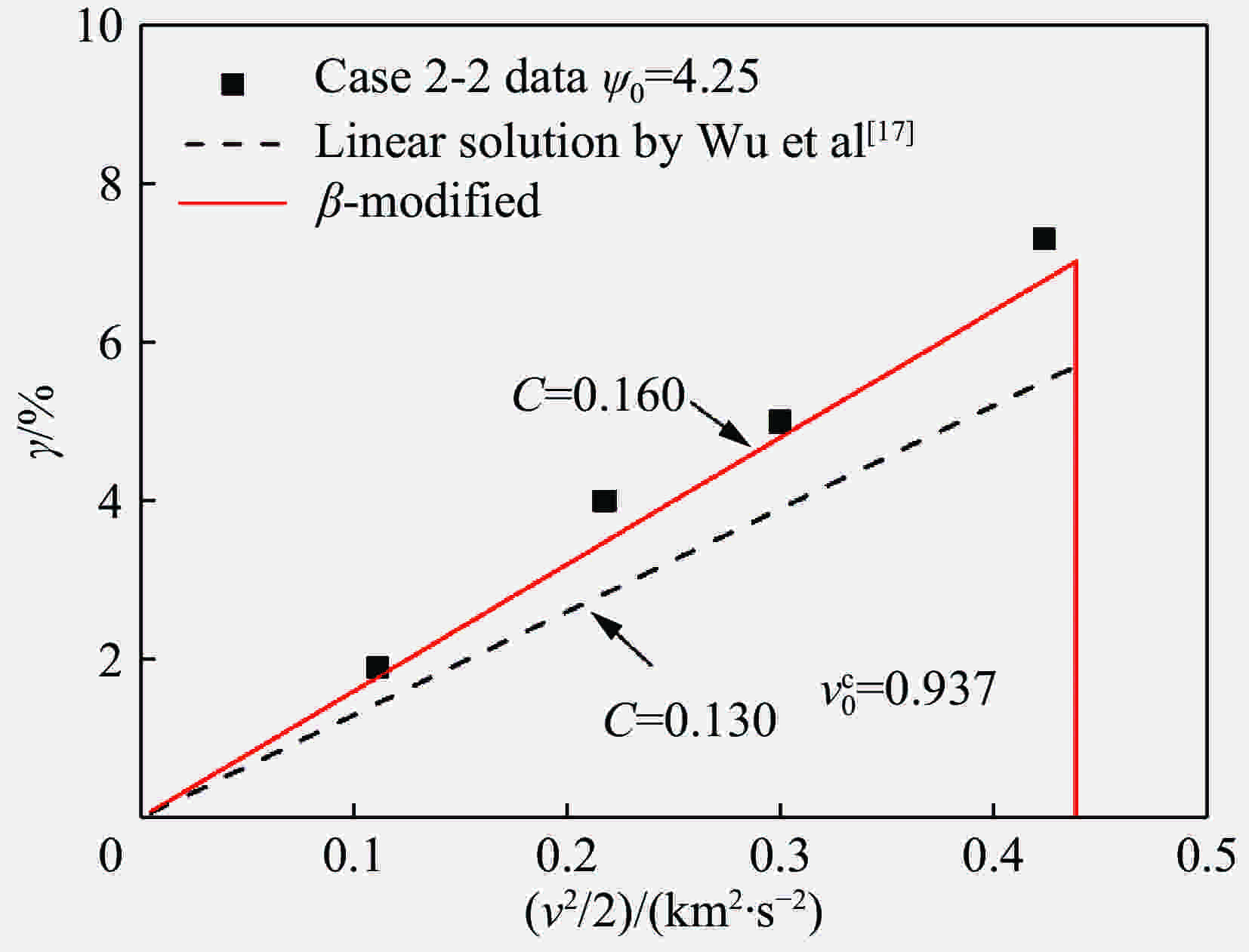

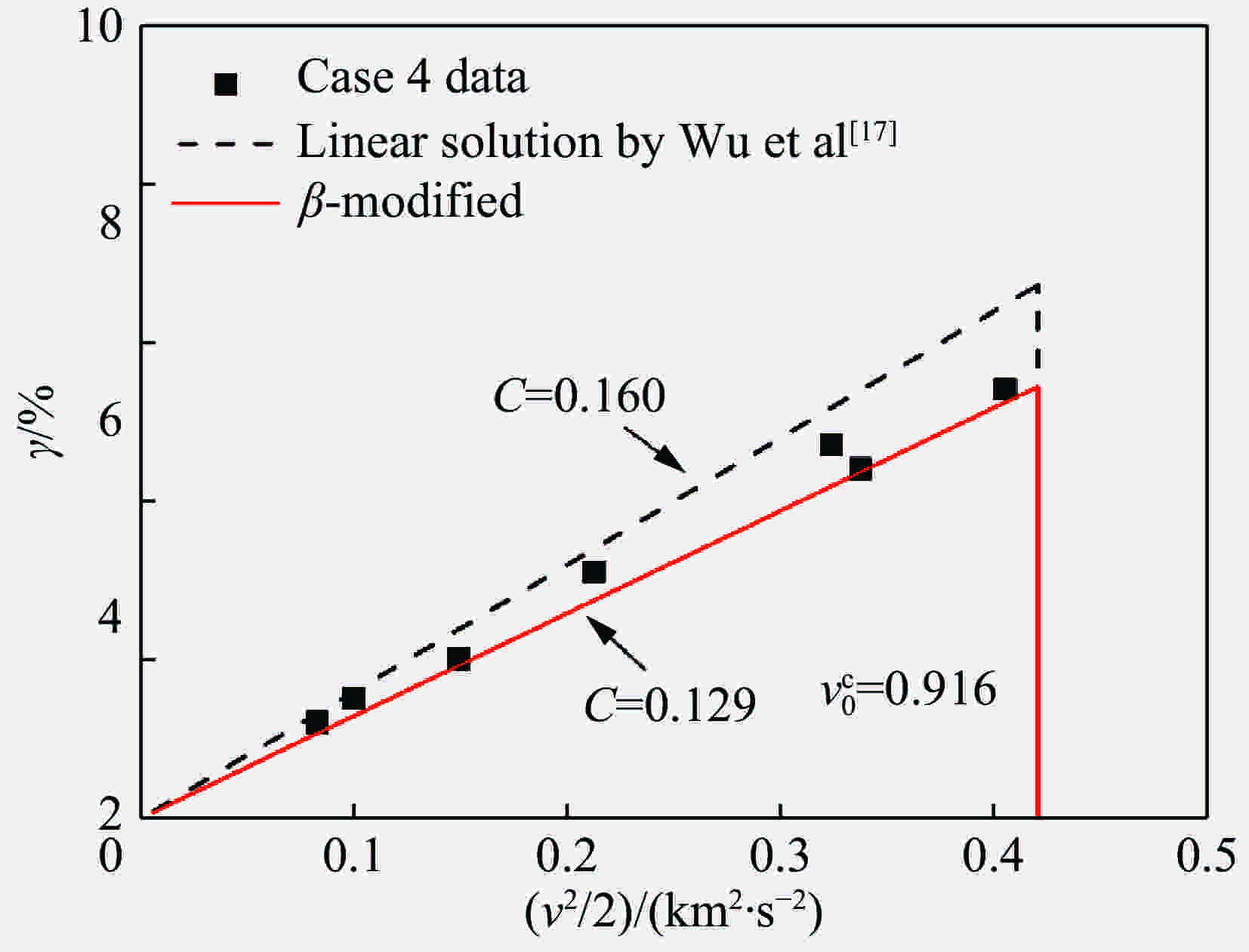

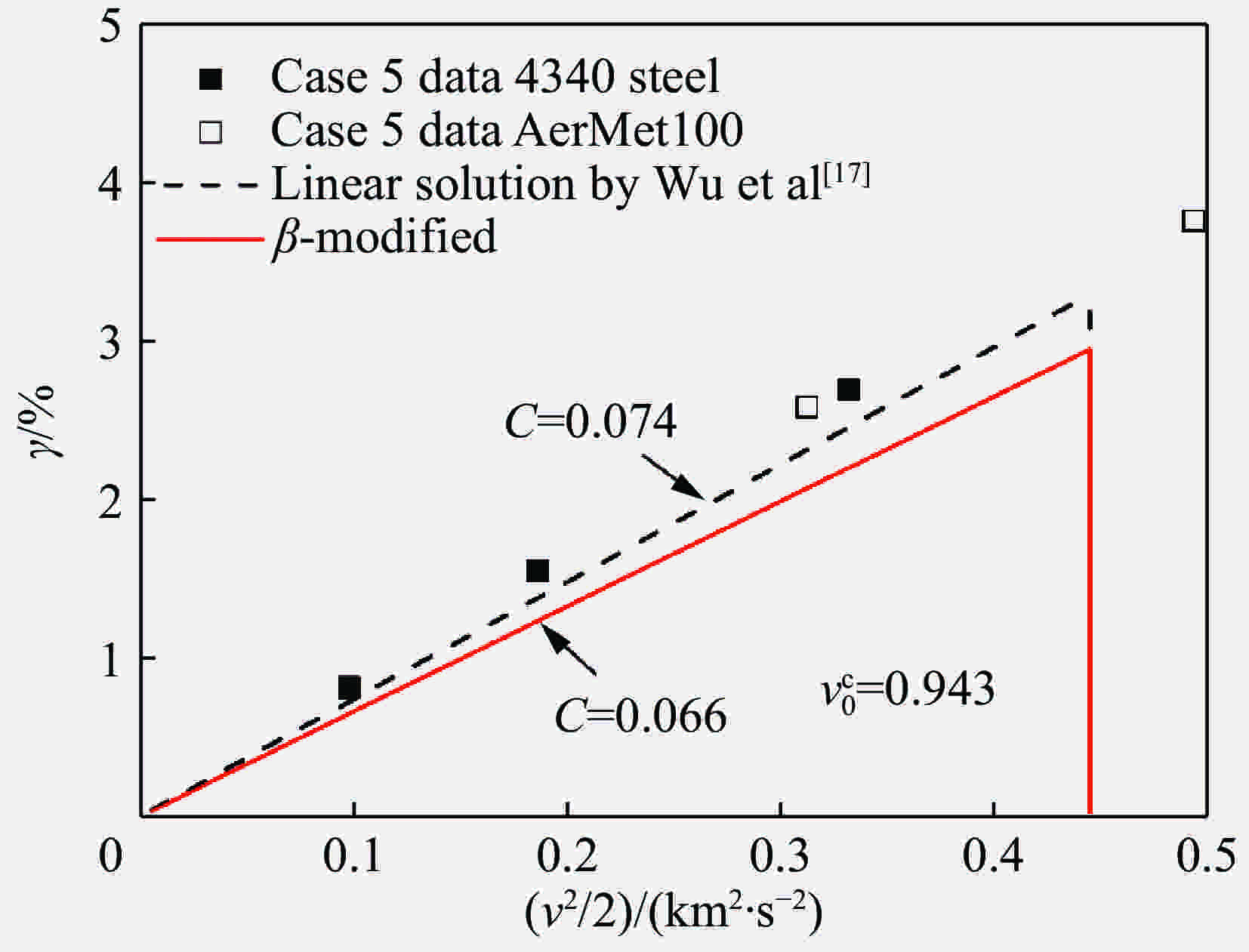

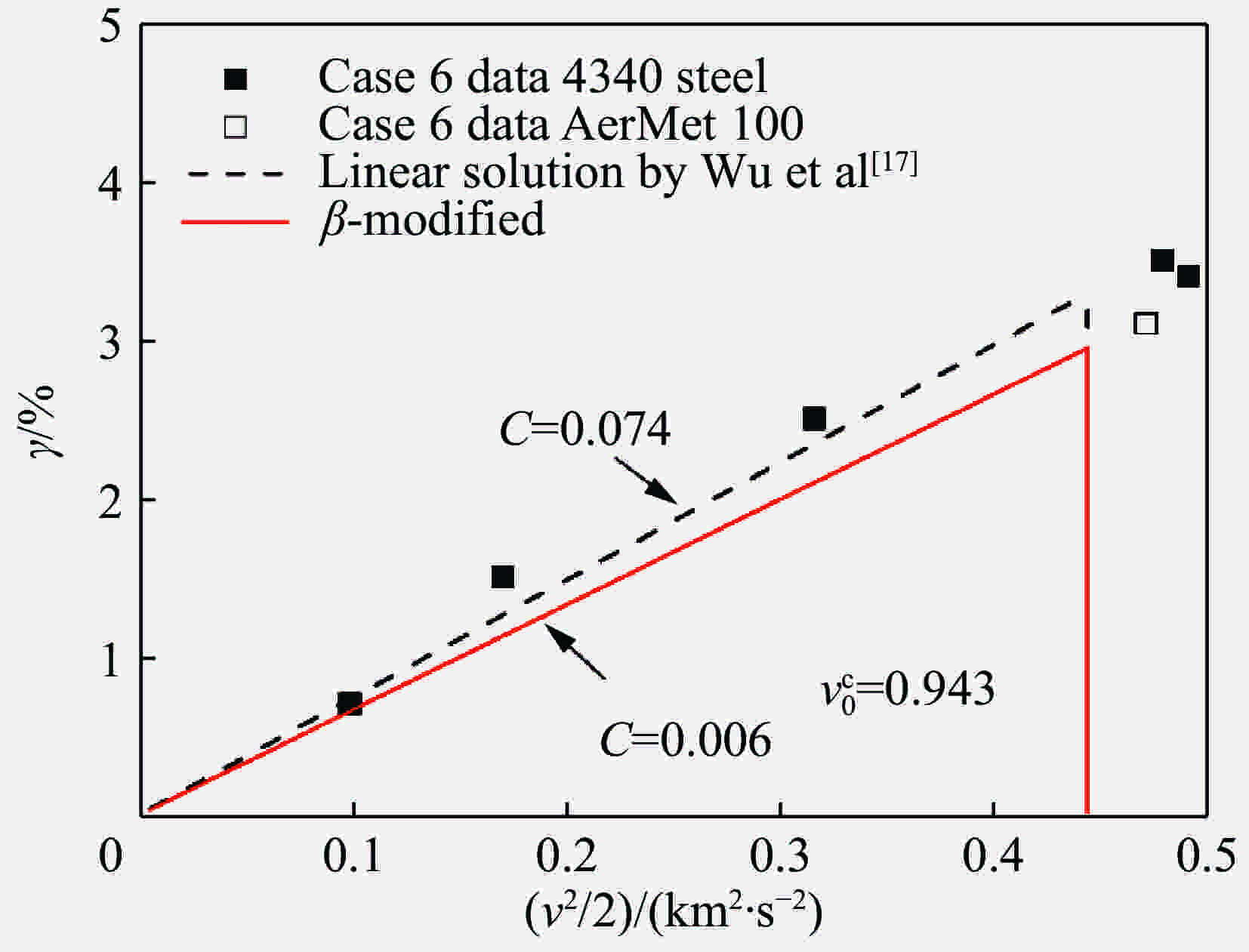

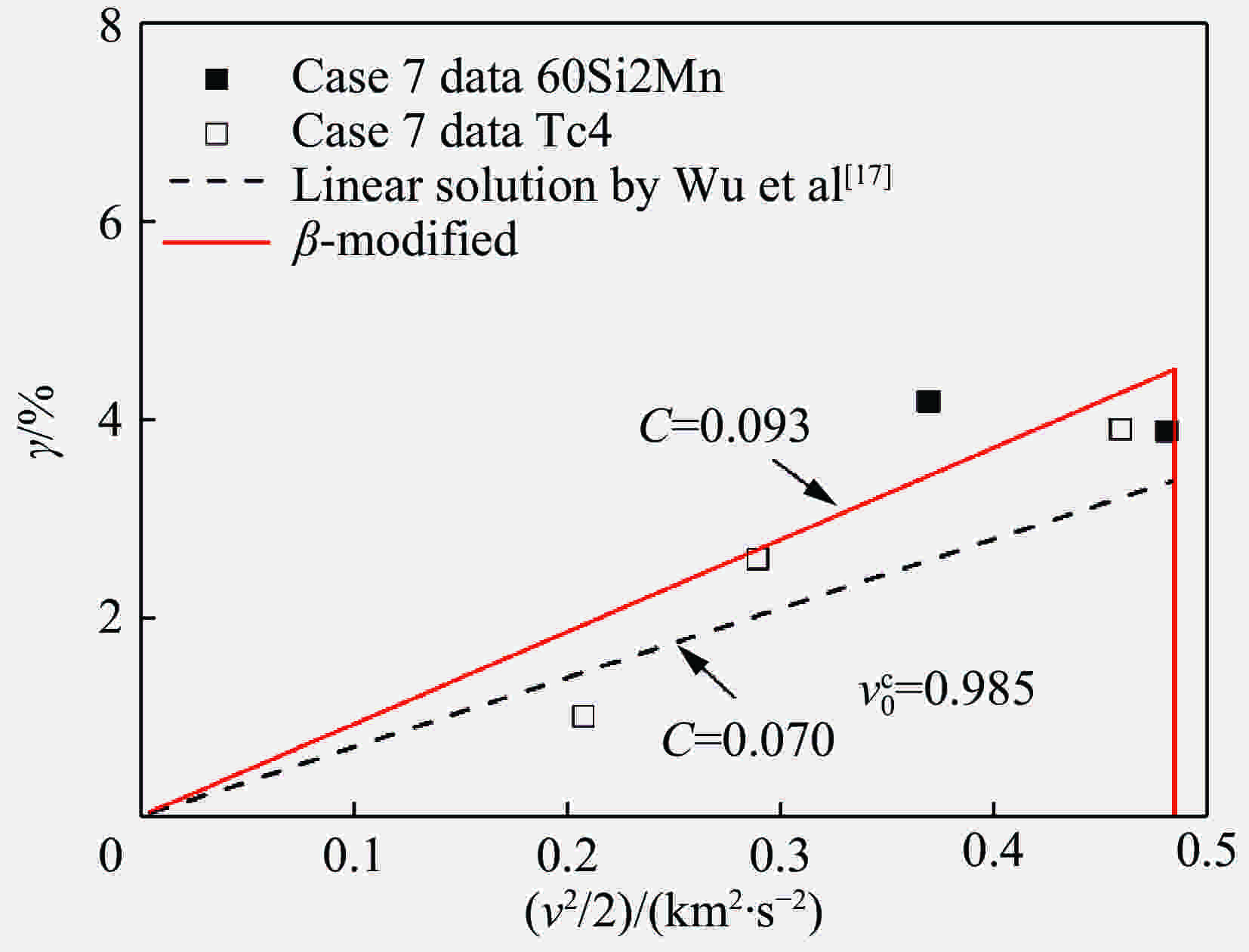

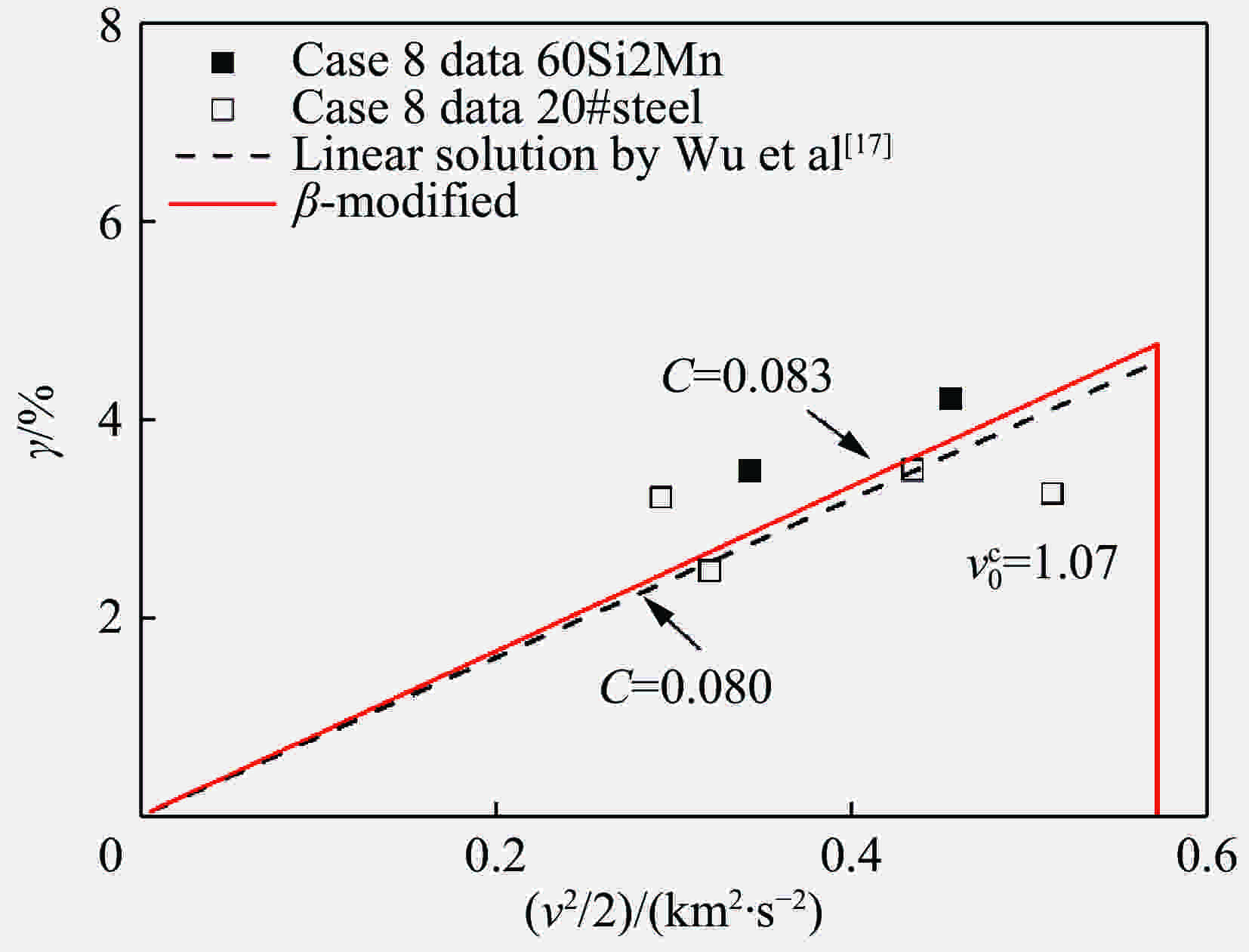

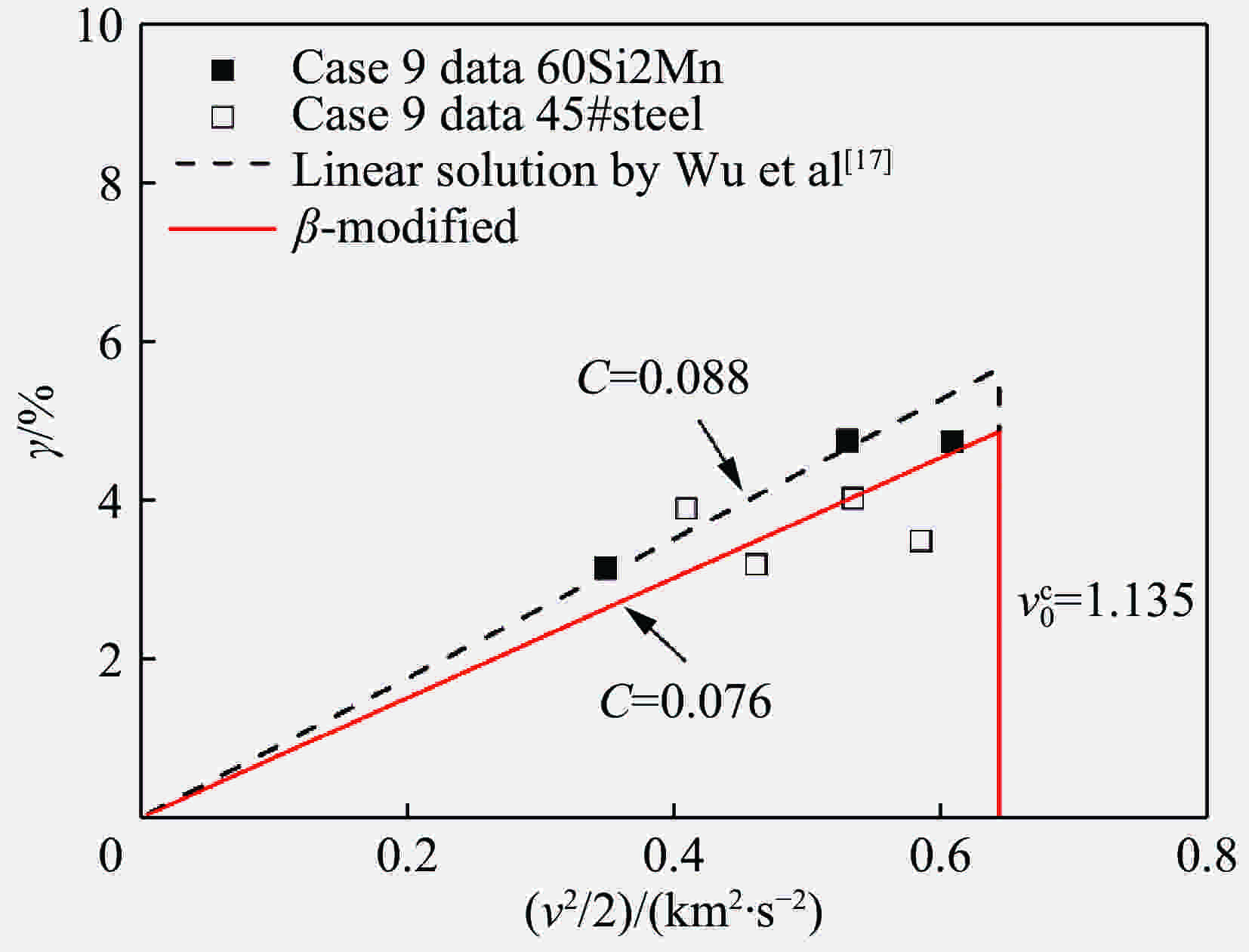

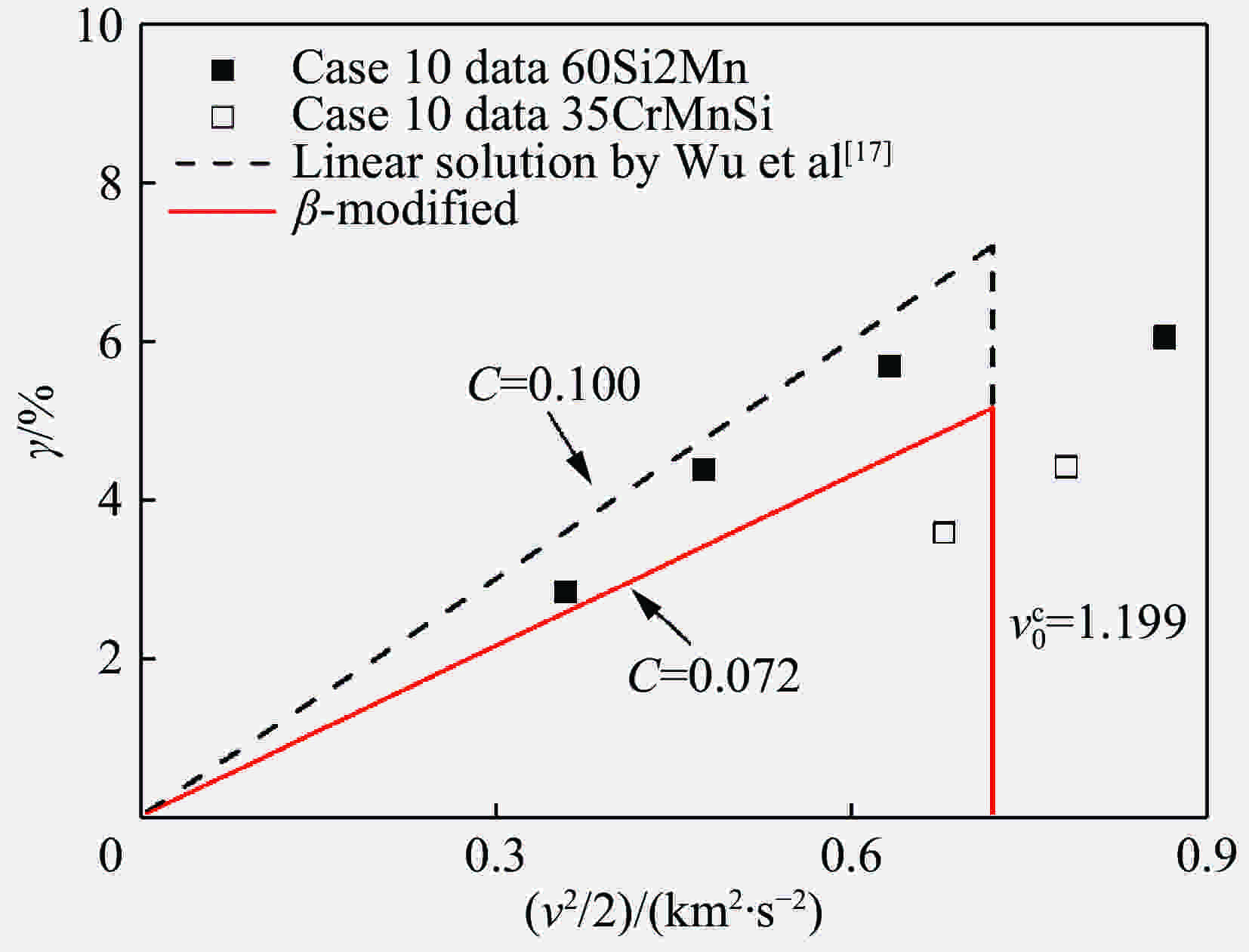

工况 fc/MPa ρt/(kg·m−3) 骨料 H 弹体材料 Yp/MPa ρp/(kg·m−3) m0/kg d/mm L/d ψ0 1-1 13.5 2 000 石英石 7 4340 钢 1 481 7 850 0.064 12.9 6.88 3 1-2 13.5 2 000 0.064 12.9 6.88 4.25 2-1 21.6 2 000 0.064 12.9 6.88 3 2-2 21.6 2 000 0.064 12.9 6.88 4.25 3 62.8 2 300 0.478 20.3 10 3 4 51.0 2 300 1.6 30.5 10 10 5 58.4 2 320 石灰石 3 4340 钢/AerMet100 1 481/1 820 7 850 0.478 20.3 10 3 6 58.4 2 320 4340 钢/AerMet100 1 481/1 820 1.62 30.5 3 7 34.8 2 300 60Si2 Mn/Tc4 1 300/1 030 0.155 14 4.25 8 48.6 2 300 60Si2 Mn/20#钢 1 300/450 0.155 14 4.25 9 61.3 2 300 60Si2 Mn/45#钢 1 300/680 0.155 14 4.25 10 76.4 2 300 60Si2 Mn/35CrMnSi 1 300/1 540 0.155 14 4.25 表 2 无量纲骨料修正因子η和β

Table 2. Dimensionless modified factors η and β

fc/MPa 骨料类型 η β fc/MPa 骨料类型 η β fc/MPa 骨料类型 η β 13.5 石英石 1 1.44 62.8 石英石 1 0.71 58.4 石灰石 0.43 0.38 21.6 石英石 1 1.23 34.8 石灰石 0.43 0.57 61.3 石灰石 0.43 0.37 51 石英石 1 0.81 48.6 石灰石 0.43 0.44 76.4 石灰石 0.43 0.31 表 3 工况1-2的模拟结果与实验对比

Table 3. Comparison of experimental and simulation results at case 1-2

工况1-2弹速/(m·s−1) 345 585 722 900 1 063 He等[13]模型误差 −33% −41% −35% −27% −13% 本文模型误差 −5% −15% −7% 6% 25% 表 4 工况10的模拟结果与实验对比

Table 4. Comparison of experimental and simulation results at case 10

工况10弹速/(m·s−1) 847 975 1 124 1 165 1 250 1 315 1 376 1 382 He等[13]模型误差 46% 23% 21% 102% 88% 49% 98% 57% 本文模型误差 5% −11% −12% 45% 35% 7% 42% 13% -

[1] FORRESTAL M J, ALTMAN B S, CARGILE J D, et al. An empirical equation for penetration depth of ogive-nose projectiles into concrete targets [J]. International Journal of Impact Engineering, 1994, 15(4): 395–405. DOI: 10.1016/0734-743X(94)80024-4. [2] FORRESTAL M J, FREW D J, HANCHAK S J, et al. Penetration of grout and concrete targets with ogive-nose steel projectiles [J]. International Journal of Impact Engineering, 1996, 18(5): 465–476. DOI: 10.1016/0734-743X(95)00048-F. [3] 孔祥振, 方秦, 吴昊, 等. 弹体高速侵彻混凝土靶质量损失和头形钝化的数值模拟研究 [J]. 固体力学学报, 2015, 36(S1): 65–73.KONG Xiangzhen, FANG qin, WU Hao, et al. Numerical study on mass loss and nose-blunting for the projectile during the high-speed penetration on concrete target [J]. Chinse Journal of Solid Mechanics, 2015, 36(S1): 65–73. [4] 刘志林, 王晓鸣, 李文彬, 等. 考虑侵蚀效应的卵形弹丸侵彻混凝土介质模型研究 [J]. 弹道学报, 2017, 29(2): 19–25. doi: 10.3969/j.issn.1004-499X.2017.02.004LIU Zhilin, WANG Xiaoming, LI Wenbin, et al. Model of ogive-nose projectile penetrating concrete target considering effect of mass loss and nose blunting [J]. Journal of Ballistics, 2017, 29(2): 19–25. doi: 10.3969/j.issn.1004-499X.2017.02.004 [5] 何翔, 徐翔云, 孙桂娟, 等. 弹体高速侵彻混凝土效应的实验研究 [J]. 爆炸与冲击, 2010, 30(1): 1–6. DOI: 10.11883/1001-1455(2010)01-0001-06.HE Xiang, XU Xiangyun, SUN Guijuan, et al. Experimental investigation on projectiles’ high-velocity penetration into concrete targets [J]. Explosion and Shock Waves, 2010, 30(1): 1–6. DOI: 10.11883/1001-1455(2010)01-0001-06. [6] 杨建超, 何翔, 金栋梁. 弹体高速侵彻混凝土质量侵蚀特性试验研究 [J]. 防护工程, 2010, 32(1): 6–10.YANG Jianchao, HE Xiang, JIN Dongliang. Experimental investigation into mass loss of projectiles that penetrate concrete targets at high velocity [J]. Protective Engineering, 2010, 32(1): 6–10. [7] FREW D J, HANCHAK S J, GREEN M L, et al. Penetration of concrete targets with ogive-nose steel rods [J]. International Journal of Impact Engineering, 1998, 21(6): 489–497. DOI: 10.1016/S0734-743X(98)00008-6. [8] MU Z C, ZHANG W. An investigation on mass loss of ogival projectiles penetrating concrete targets [J]. International Journal of Impact Engineering, 2011, 38(8−9): 770–778. DOI: 10.1016/j.ijimpeng.2011.04.002. [9] SILLING S A, FORRESTAL M J. Mass loss from abrasion on ogive-nose steel projectiles that penetrate concrete targets [J]. International Journal of Impact Engineering, 2007, 34(11): 1814–1820. DOI: 10.1016/j.ijimpeng.2006.10.008. [10] CHEN X W, HE L L, YANG S Q. Modeling on mass abrasion of kinetic energy penetrator [J]. European Journal of Mechanics A/Solids, 2010, 29(1): 7–17. DOI: 10.1016/j.euromechsol.2009.07.006. [11] 陈小伟, 杨世全, 何丽灵. 动能侵彻弹体的质量侵蚀模型分析 [J]. 力学学报, 2009, 41(5): 739–747. DOI: 10.3321/j.issn:0459-1879.2009.05.017.CHEN Xiaowei, YANG Shiquan, HE Liling. Modeling on mass abrasion of kinetic energy penetrator [J]. Chinese Journal of Theoretical and Applied Mechanics, 2009, 41(5): 739–747. DOI: 10.3321/j.issn:0459-1879.2009.05.017. [12] JONES S E, FOSTER J C, TONESS O A, et al. An estimate for mass loss from high velocity steel penetrators [C] // Pressure Vessels and Piping Conference. New York: ASME, 2002: 227−237. DOI: 10.1115/PVP2002-1149. [13] HE L L, CHEN X W, HE X. Parametric study on mass loss of penetrators [J]. Acta Mechanica Sinica, 2010, 26(4): 585–597. DOI: 10.1007/s10409-010-0341-8. [14] CHEN X W. Dynamics of metallic and reinforced concrete targets subjected to projectile impact [D]. Singapore: Nanyang Technological University, 2003: 1−62. [15] LI Q M, CHEN X W. Dimensionless formulae for penetration depth of concrete target impacted by a non-deformable projectile [J]. International Journal of Impact Engineering, 2003, 28(1): 93–116. DOI: 10.1016/S0734-743X(02)00037-4. [16] HILL R. Elastic properties of reinforced solids: Some theoretical principles [J]. Journal of the Mechanics and Physics of Solids, 1963, 11(5): 357–372. DOI: 10.1016/0022-5096(63)90036-X. [17] WU H, CHEN X W, HE L L, et al. Stability analyses of the mass abrasive projectile high-speed penetrating into concrete target, Part I: engineering model for the mass loss and nose-blunting of ogive-nosed projectiles [J]. Acta Mechanica Sinica, 2014, 30(6): 933–942. DOI: 10.1007/s10409-014-0090-1. -

下载:

下载: