Failure behavior and energy release of Zr-based amorphous alloy under dynamic compression

-

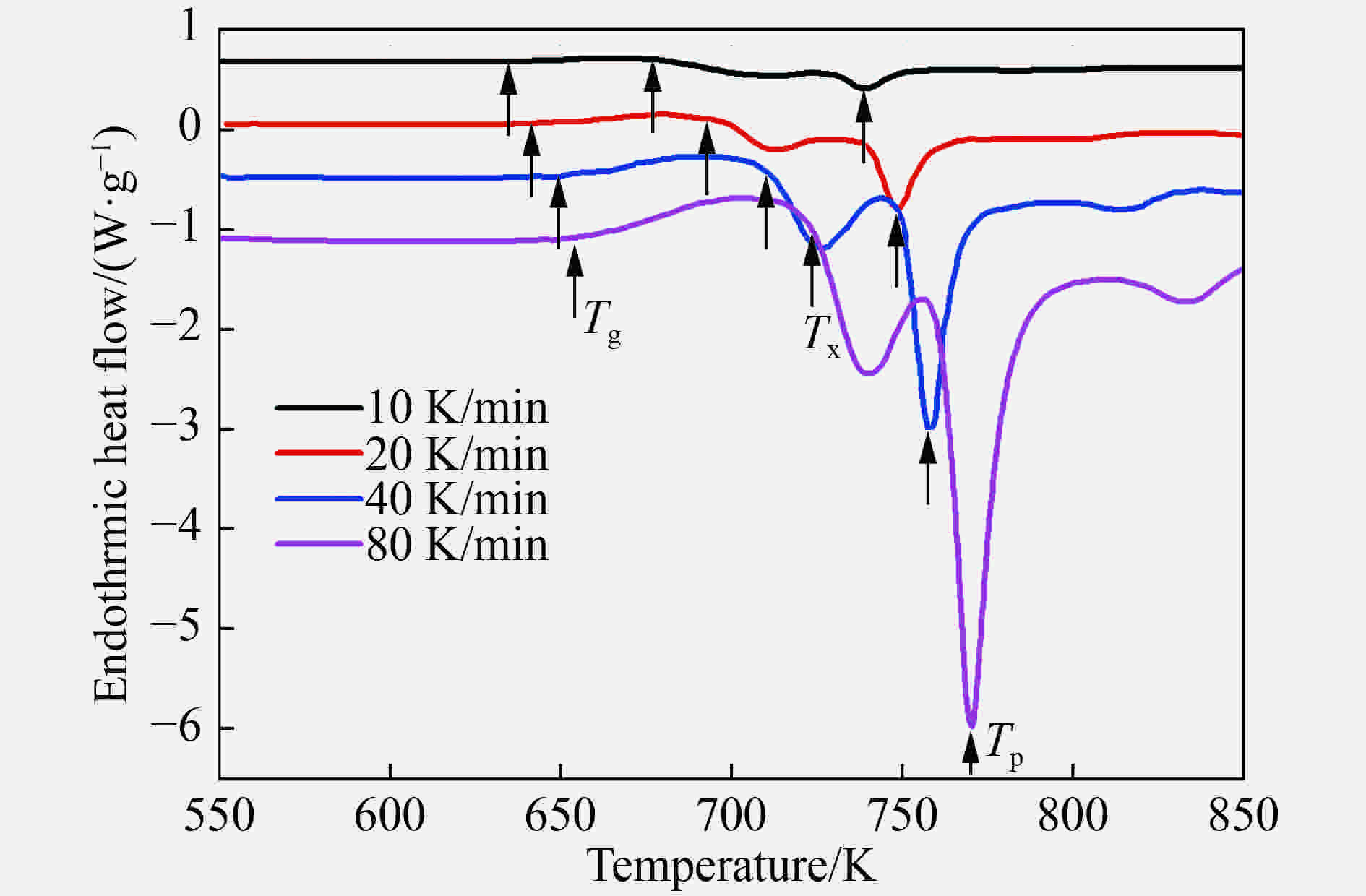

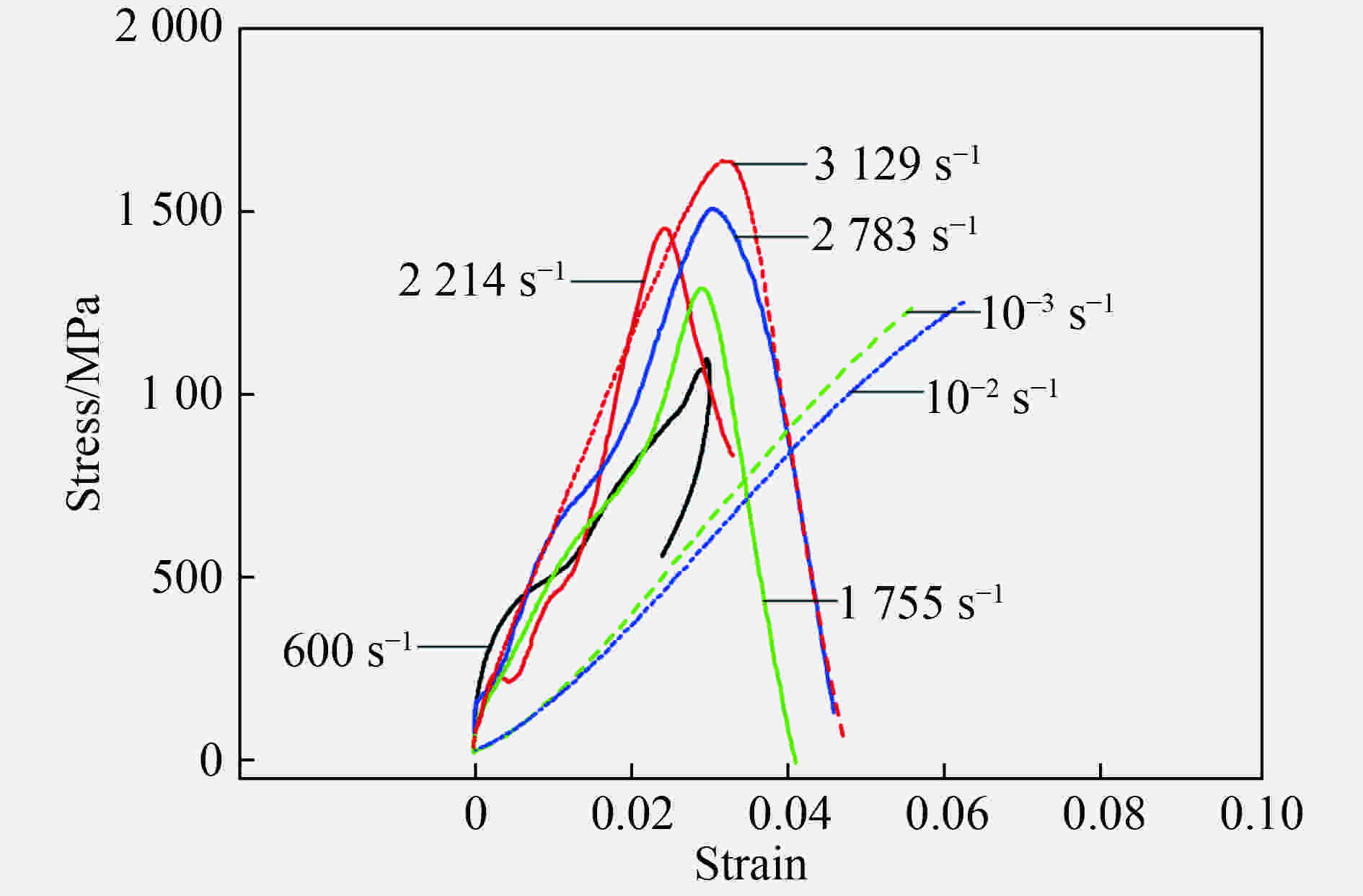

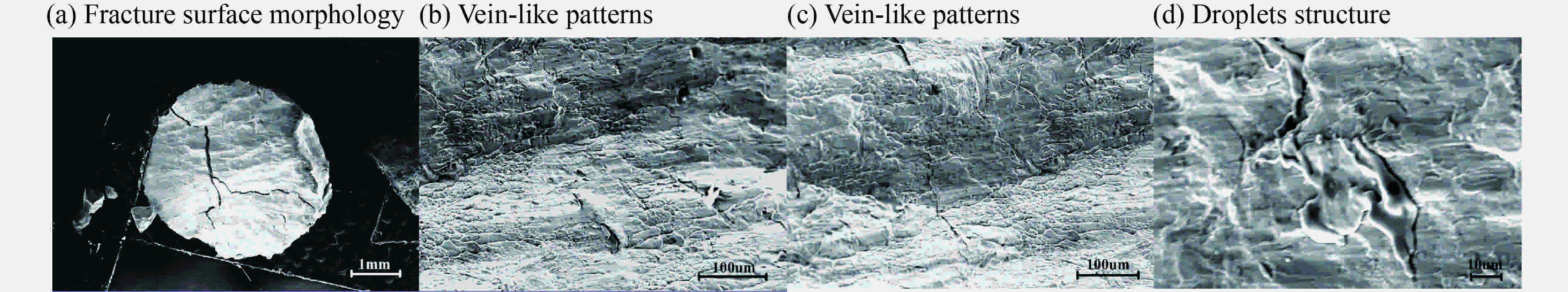

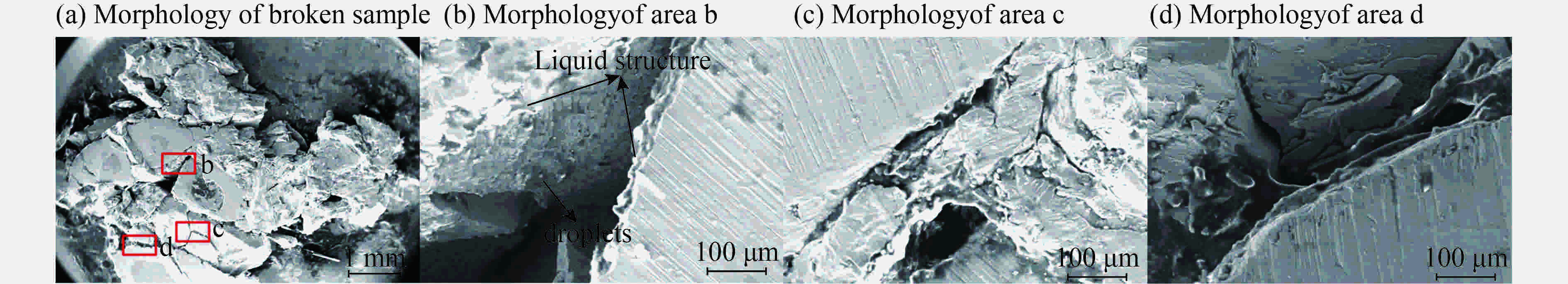

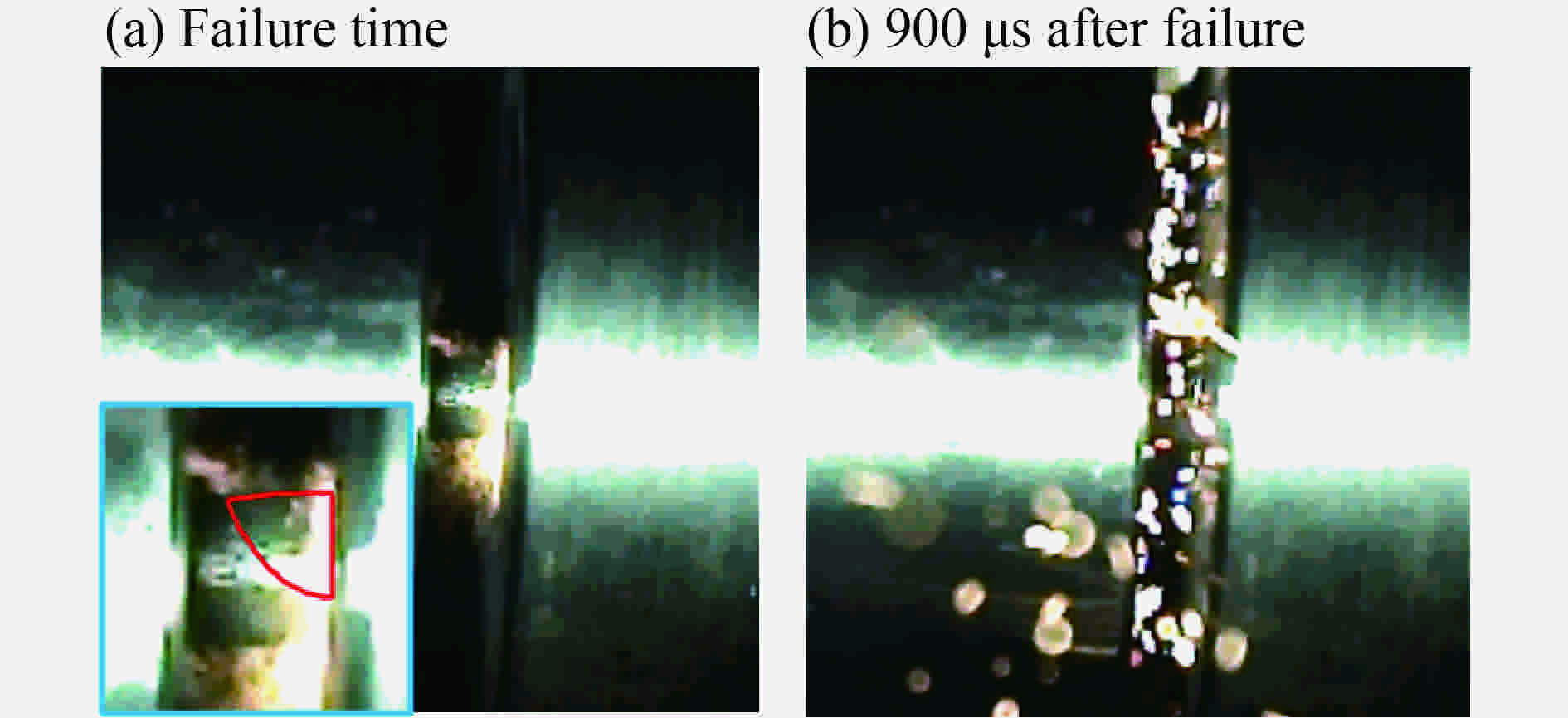

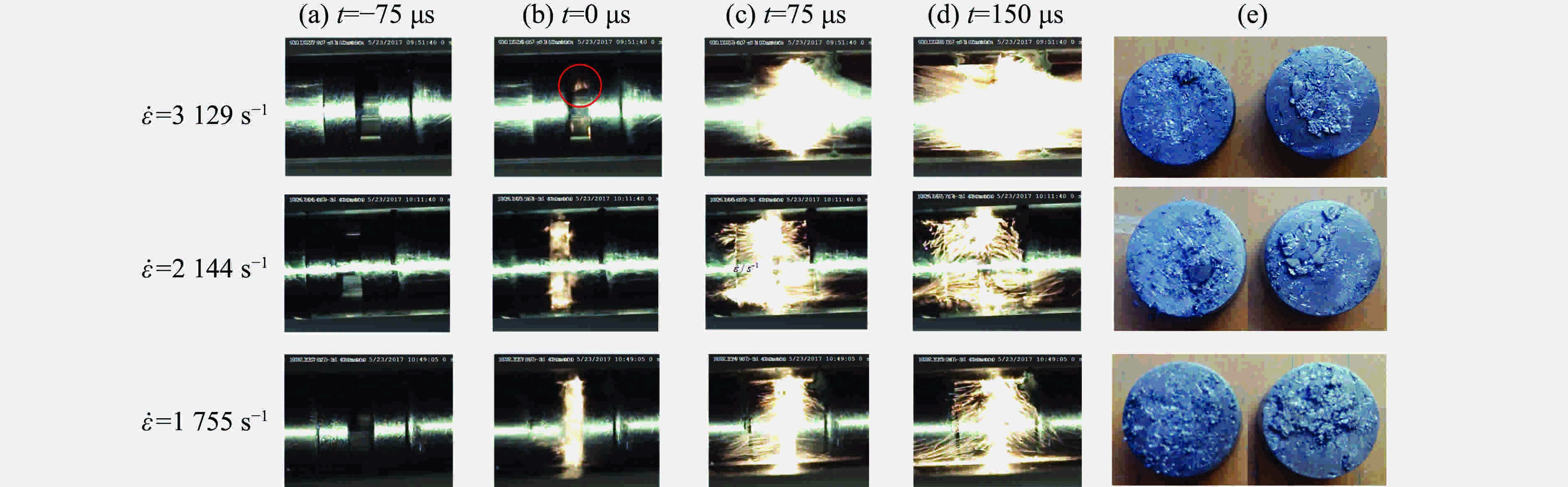

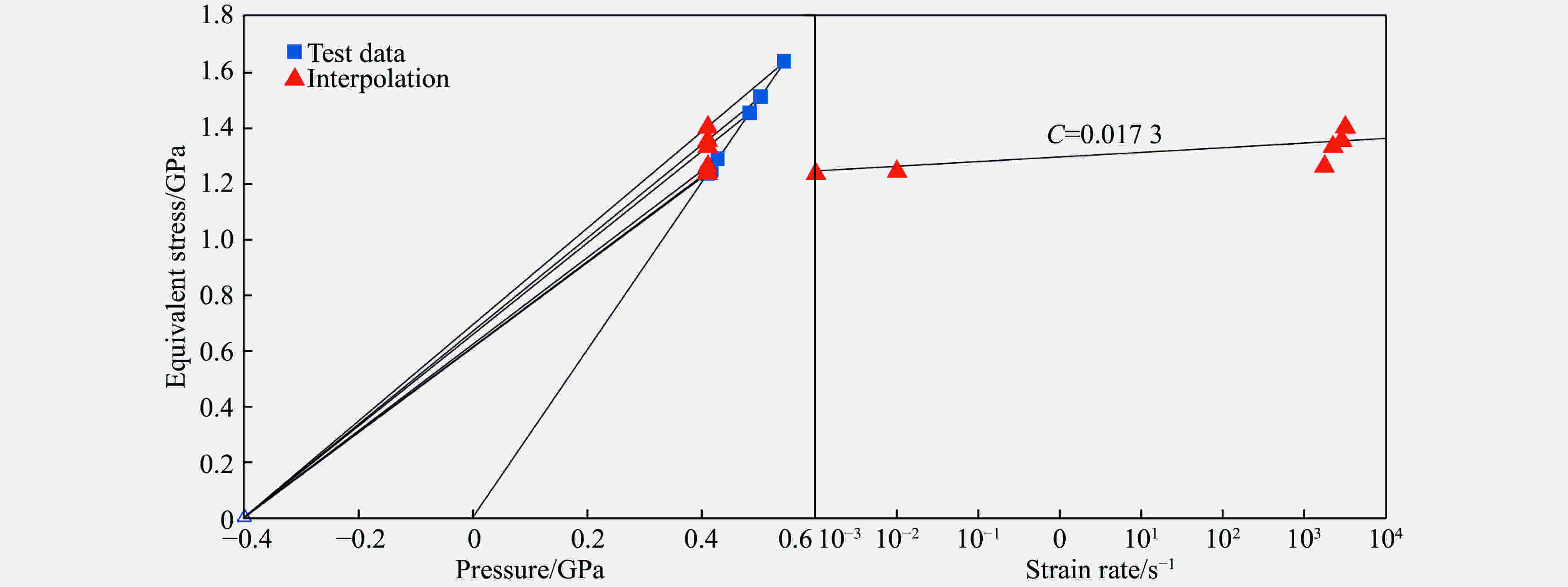

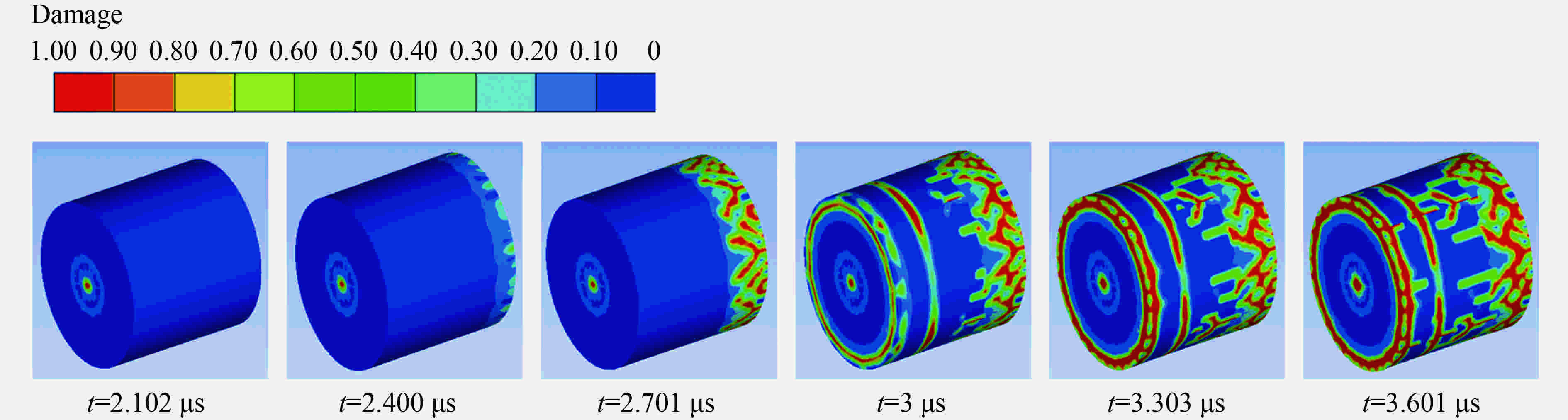

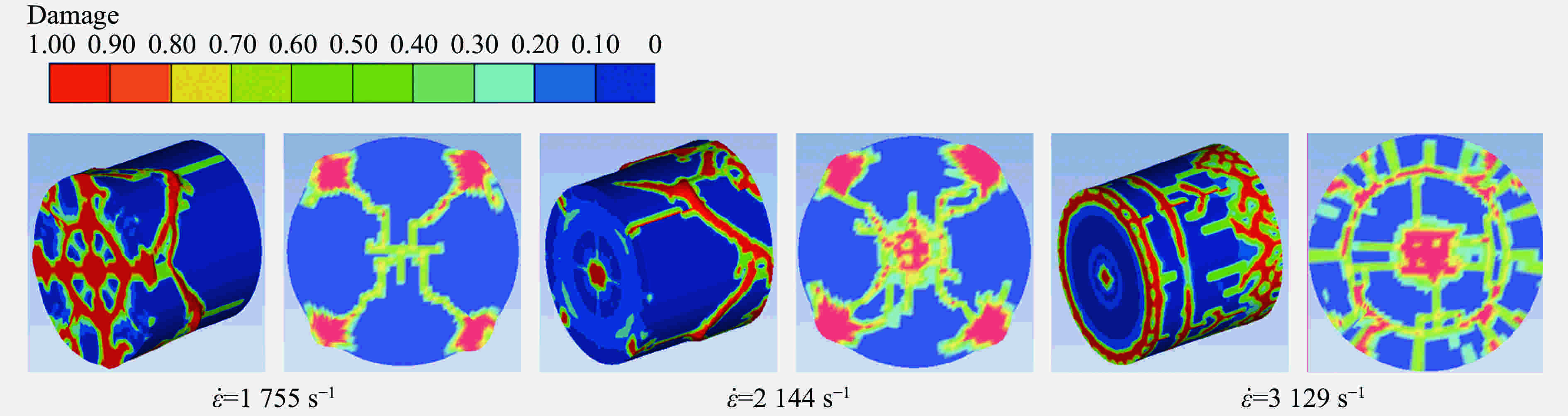

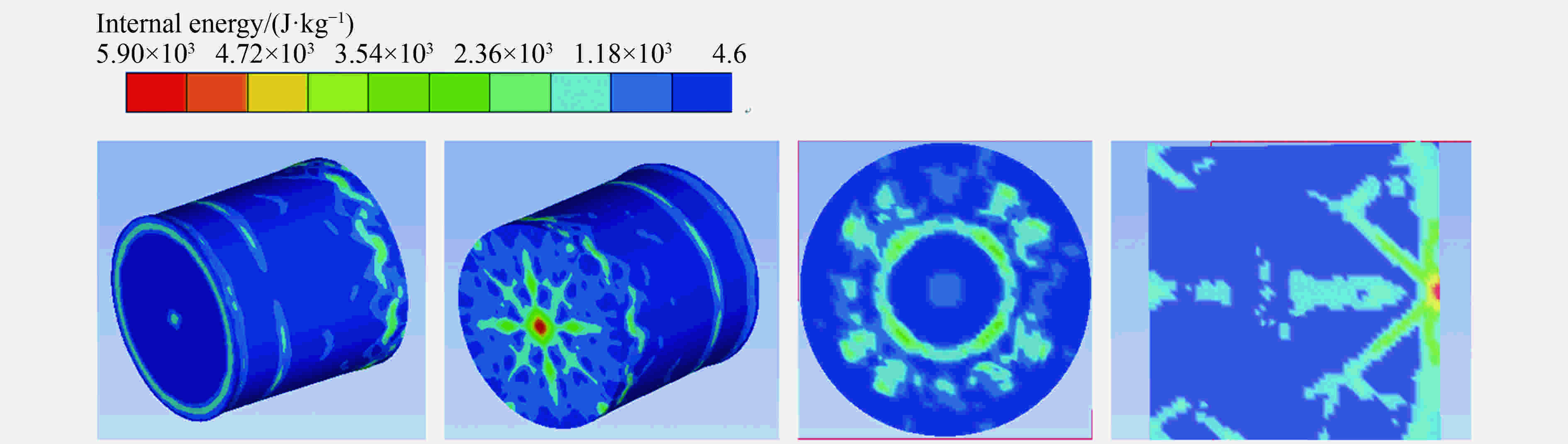

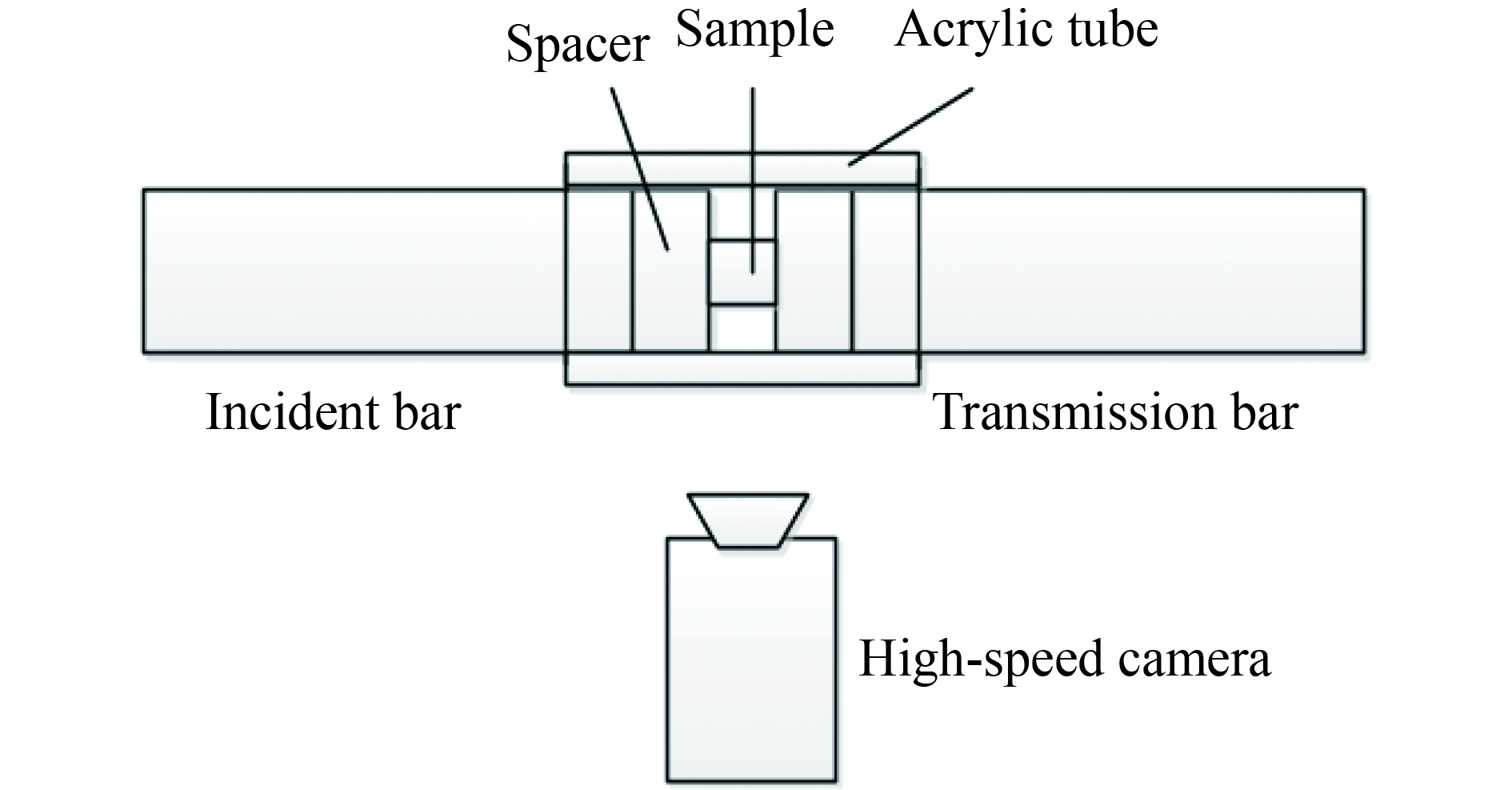

摘要: 为研究Zr基非晶合金动态压缩条件下的失效释能机理,采用力学试验机、霍普金森杆、高速摄影、差示扫描量热分析(differential scanning calorimetry, DSC)、扫描电镜(scanning electron microscope,SEM)等,得到了材料应力应变曲线、高速摄影图像、失效式样微观形貌及DSC曲线,根据实验数据计算了材料的晶化激活能,并拟合了材料的JH-2(Johnson-Holmquist II)模型,对材料动态失效过程进行有限元数值模拟。实验结果表明,压缩条件下材料为脆性断裂,断口处观察到典型的脉状纹样及液滴状结构,材料失效过程伴随着释能现象;数值模拟结果表明,材料裂纹局部的瞬时内能大于材料晶化激活能。动态压缩下材料的失效释能机理即为材料破碎释放储存的弹性势能,并导致材料局部晶化释能,释能强度与应变率成正相关。Abstract: To study the mechanism of failure behavior and energy release mechanism of Zr-based amorphous alloys, Instron machine, split hopkinson bar, high-speed photography, DSC and SEM are used to achieve the stress-strain curves at low strain rate, stress-strain curves at high strain rate, failure processes, DSC curves and failure morphologies, respectively. The crystallization enthalpy is obtained from DSC curves. The stress-strain curves are fitted by the Johnson-Holmquist II model, and the finite element method using this model is executed to simulate the failure process of material under dynamic compression. The experimental results suggest that the material fractures brittle under compression. Typical vein-like pattern is observed at the fracture surface of the material. The energy releasing occurs simultaneously with the material failure. The simulation results reveal that the internal energy of local crack is higher than crystallization enthalpy of the material. The energy release of Zr-based amorphous alloys results in the elastic potential energy and crystallization energy released by the material with instantaneous crack. The strength of energy release is in direct proportion to strain rates.

-

Key words:

- Zr-based amorphous alloys /

- dynamic compression /

- failure /

- energy release /

- high-speed imaging

-

表 1 材料的JH-2材料模型参数

Table 1. JH-2 model constants of the material

材料 K1/GPa K2 /GPa K3/GPa D1 D2 ZrTiNiCuBe 114.3 268.5 1 386 0.21 1.75 材料 A B C M N ZrTiNiCuBe 1.162 0.258 0.017 3 0.59 0.829 -

[1] TOGO H, ZHANG Y, KAWAMURA Y, et al. Properties of Zr-based bulk metallic glass under shock compression [J]. Materials Science and Engineering A, 2007, 449–451: 264–268. DOI: 10.1016/j.msea.2006.02.431. [2] MATTERN N, KUHN U, HERMANN H, et al. Thermal behavior and glass transition of Zr-based bulk metallic glasses [J]. Materials Science and Engineering A, 2004, 375−377: 351–354. DOI: 10.1016/j.msea.2003.10.125. [3] QIAO J W, ZHANG Y, LI J H, et al. Strain rate response of a Zr-based composite fabricated by Bridgman solidification [J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(2): 214–219. DOI: 10.1007/s12613-010-0216-9. [4] ZHANG Q S, ZHANG W, XIE G Q, et al. Synthesis, structure and mechanical properties of Zr-Cu-based bulk metallic glass composites [J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(2): 208–213. DOI: 10.1007/s12613-010-0215-x. [5] LIU C, HEATHERLY L, HORTON J, et al. Test environments and mechanical properties of Zr-base bulk amorphous alloys [J]. Metallurgy Materials Transaction A, 1998, 29: 1811–1820. DOI: 10.1007/s11661-998-0004-6. [6] DAI L H, BAI Y L. Basic mechanical behaviors and mechanics of shear banding in BMGs [J]. International Journal of Impact Engineering, 2008, 35: 704–716. DOI: 10.1016/j.ijimpeng.2007.10.007. [7] BATTEZZATI L, BALDISSIN D. Quantitative evaluation of length scales for temperature rise in shear bands and for failure of metallic glasses [J]. Scripta Materialia, 2008, 59: 223–226. DOI: 10.1016/j.scriptamat.2008.03.016. [8] 潘念侨. Zr基非晶合金材料本构关系及其释能效应研究[D]. 南京: 南京理工大学, 2016: 53−71. [9] DAI L H, YAN M, LIU L F, et al. Adiabatic shear banding instability in bulk metallic glasses [J]. Applied Physics Letters, 2005, 87: 141916 -1–14916-32005. DOI: 10.1063/1.2067691. [10] JIANG M Q, LING Z, MENG J X, et al. Energy dissipation in fracture of bulk metallic glasses via inherent competition between local softening and quasi-cleavage [J]. Philosophical Magazine, 2008, 88(3): 407–426. DOI: 10.1080/14786430701864753. [11] JIANG W H, LIAO H H, LIU F X, et al. Rate-dependent temperature increases in shear bands of a bulk-metallic glass [J]. Metallurgical and Materials Transactions A, 2008, 39(8): 1822–1830. DOI: 10.1007/s11661-007-9321-4. [12] WANG J G, PAN Y, SONG S X, et al. How hot is a shear band in a metallic glass? [J]. Materials Science and Engineering A, 2016, 651: 321–331. DOI: 10.1016/j.msea.2015.10.125. [13] WRIGHT W J, BYER R R, GU X J. High-speed imaging of a bulk metallic glass during uniaxial compression [J]. Applied Physics Letters, 2013, 102: 241920. DOI: 10.1063/1.4811744. [14] 李刚. Zr基非晶合金激光熔覆与诱导自蔓延合成[D]. 大连: 大连理工大学, 2003: 11−15. [15] JIANG M Q, WEI Y P, WILDE G, et al. Explosive boiling of a metallic glass superheated by nanosecond pulse laser ablation [J]. Applied Physics Letters, 2015, 106: 021904–1. DOI: 10.1063/1.4905928. [16] WANG C T, HE Y, JI C, et al. Investigation on shock-induced reaction characteristics of a Zr-based metallic glass [J]. Intermatellics, 2018, 93: 383–388. DOI: 10.1016/j.intermet.2017.11.004. [17] FAN Z J, ZHENG Z Y, JIAO Z B. Compressive fracture characteristics of Zr-based bulk metallic glass [J]. Science China Physics, Mechanics and Astronomy, 2016, 53(5): 823–827. DOI: 10.1007/s11433-010-0154-6. [18] NOWAK S, OCHIN P, PASKO A, et al. Mechanical behavior of Zr-based bulk metallic glasses [J]. Strength of Materials, 2008, 40(1): 154–157. DOI: 10.1007/s11223-008-0040-x. [19] JOHNSON G R, HOLMQUIST T J. Response of boron carbide subjected to large strains, high strain rates, and high pressures [J]. Journal of Applied Physics, 1999, 85(12): 8060–8073. DOI: 10.1063/1.370643. [20] WANG W H, LI F Y, PAN M X, et al. Elastic property and its response to pressure in a typical bulk metallic glass [J]. Acta Materialia, 2004, 52: 715–719. DOI: 10.1016/j.actamat.2003.10.008. [21] WANG W H, WEN P, WANG L M, et al. Equation of state of bulk metallic glasses studied by an ultrasonic method [J]. Applied Physics Letters, 2004, 24: 3947–3949. DOI: 10.1063/1.1426272. [22] 石永相. 多元非晶合金含能材料药型罩应用研究[D]. 石家庄: 陆军工程大学, 2017: 35−46. [23] HOLMQUIST T J, TEMPLETON D W, BISHNOI K D. Constitutive modeling of aluminum nitride for large strain, high-strain rate, and high-pressure applications [J]. International Journal of Impact Engineering, 2001, 25: 211–231. DOI: 10.1016/S0734-743X(00)00046-4. -

下载:

下载: