Fluid-solid coupling model of micro-jet impact from acoustic cavitation bubble collapses near a wall and pit inversion analysis

-

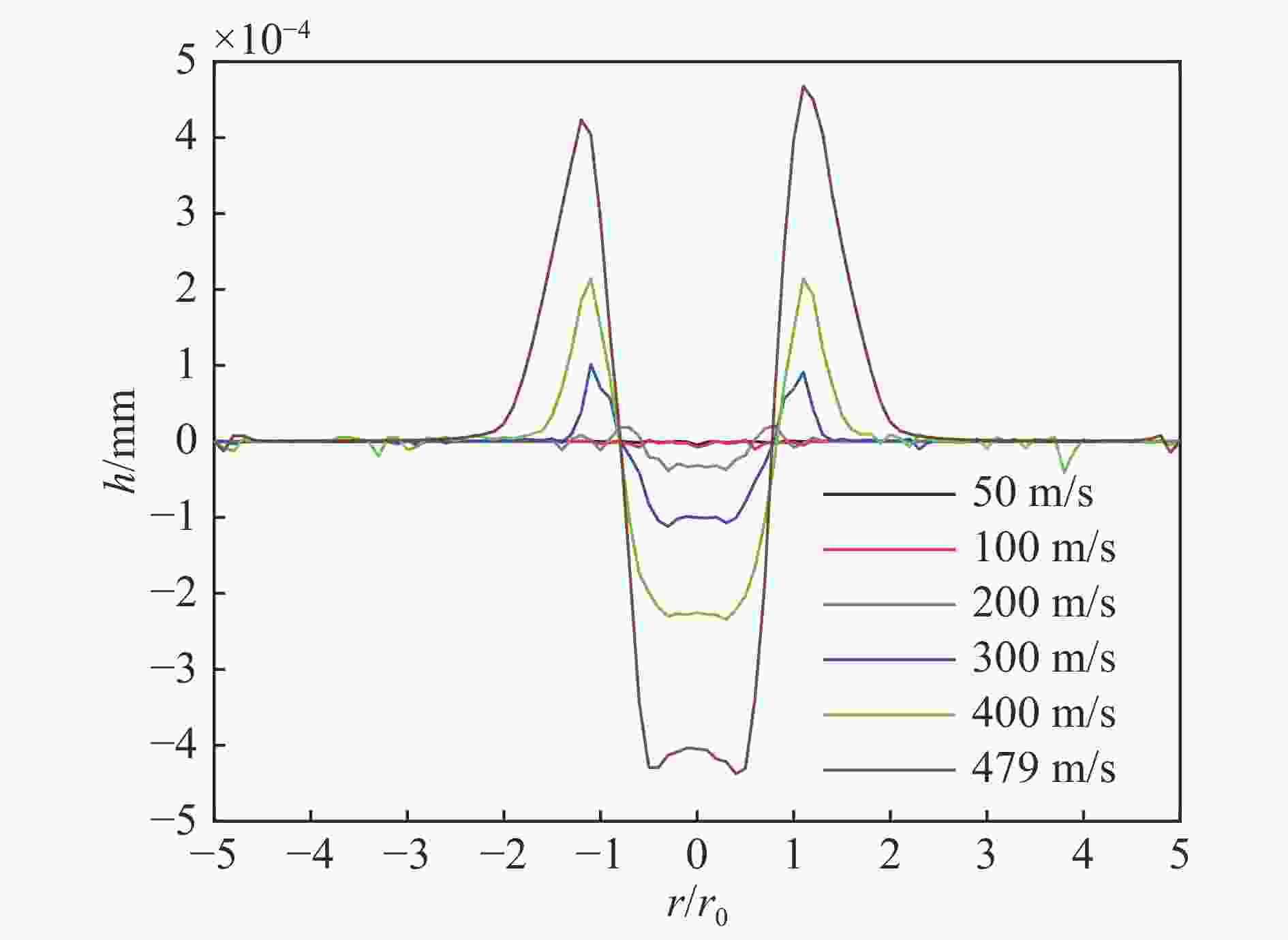

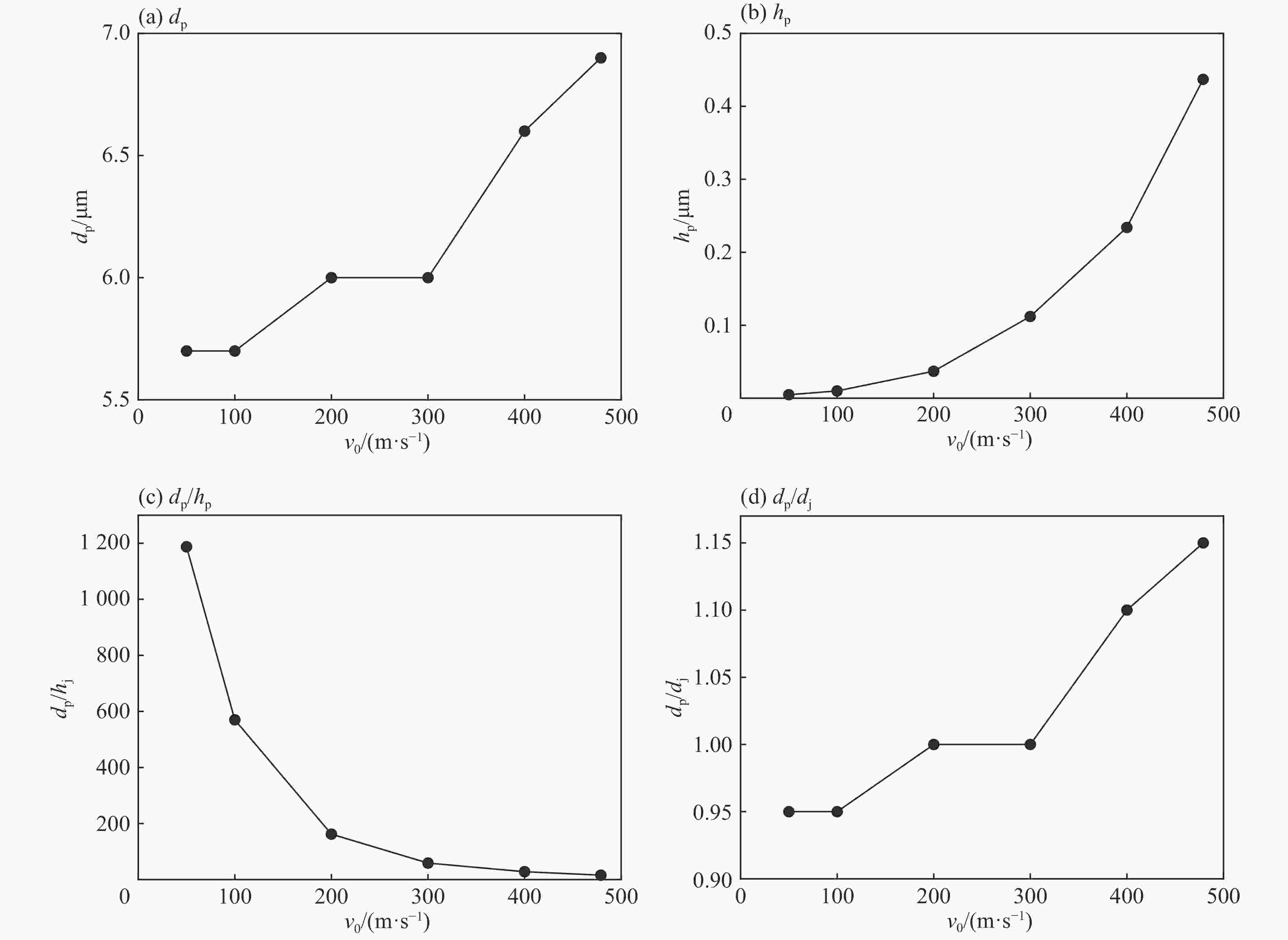

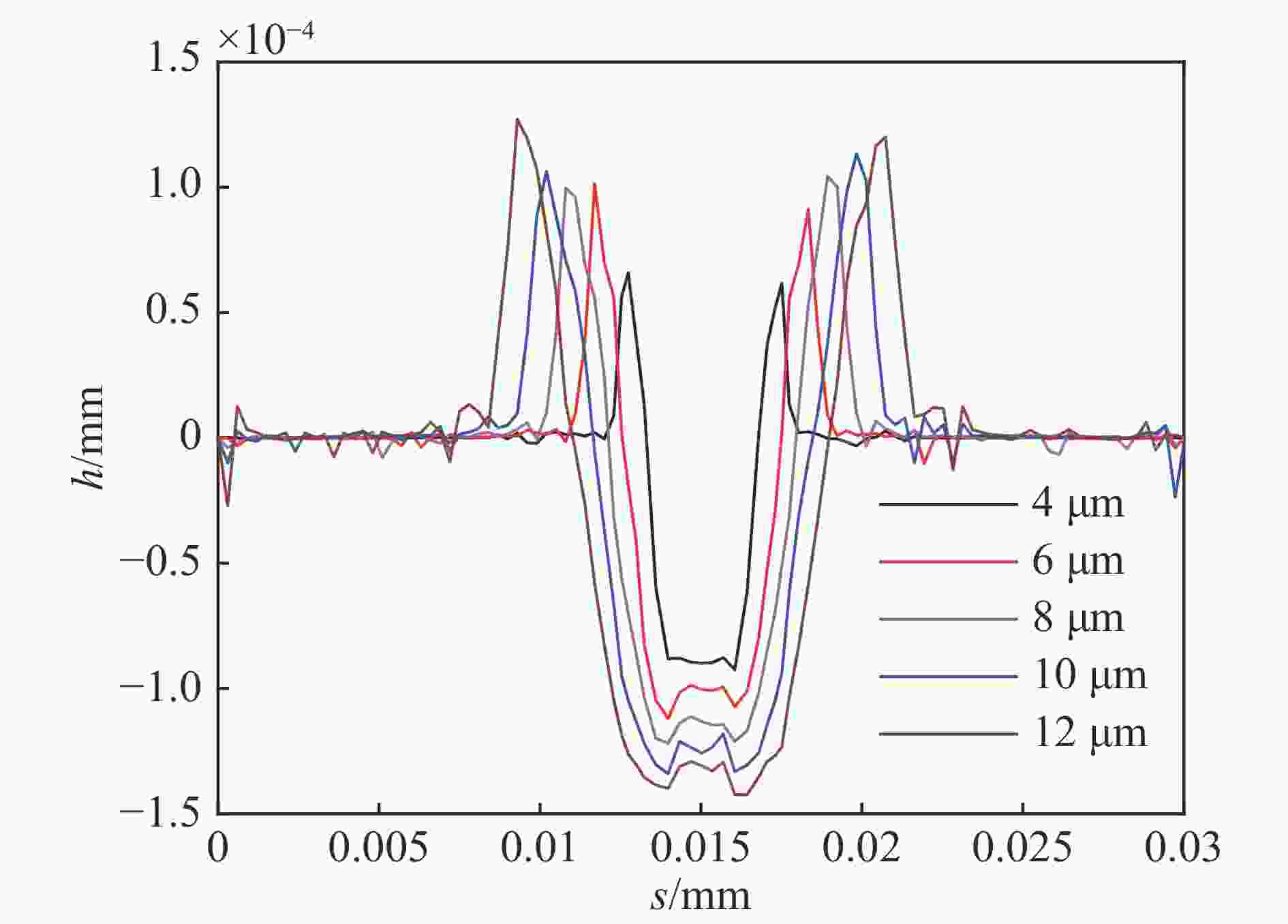

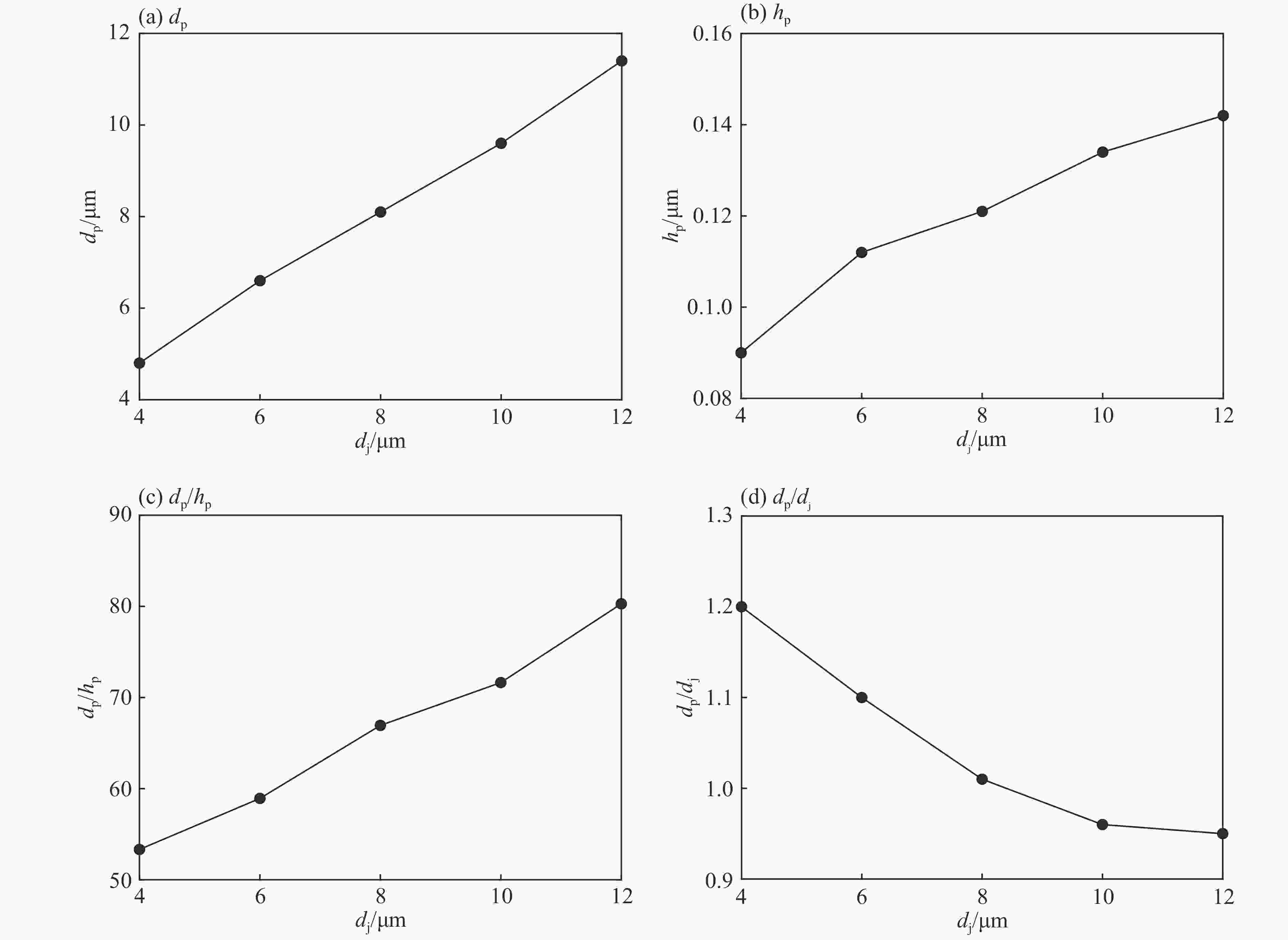

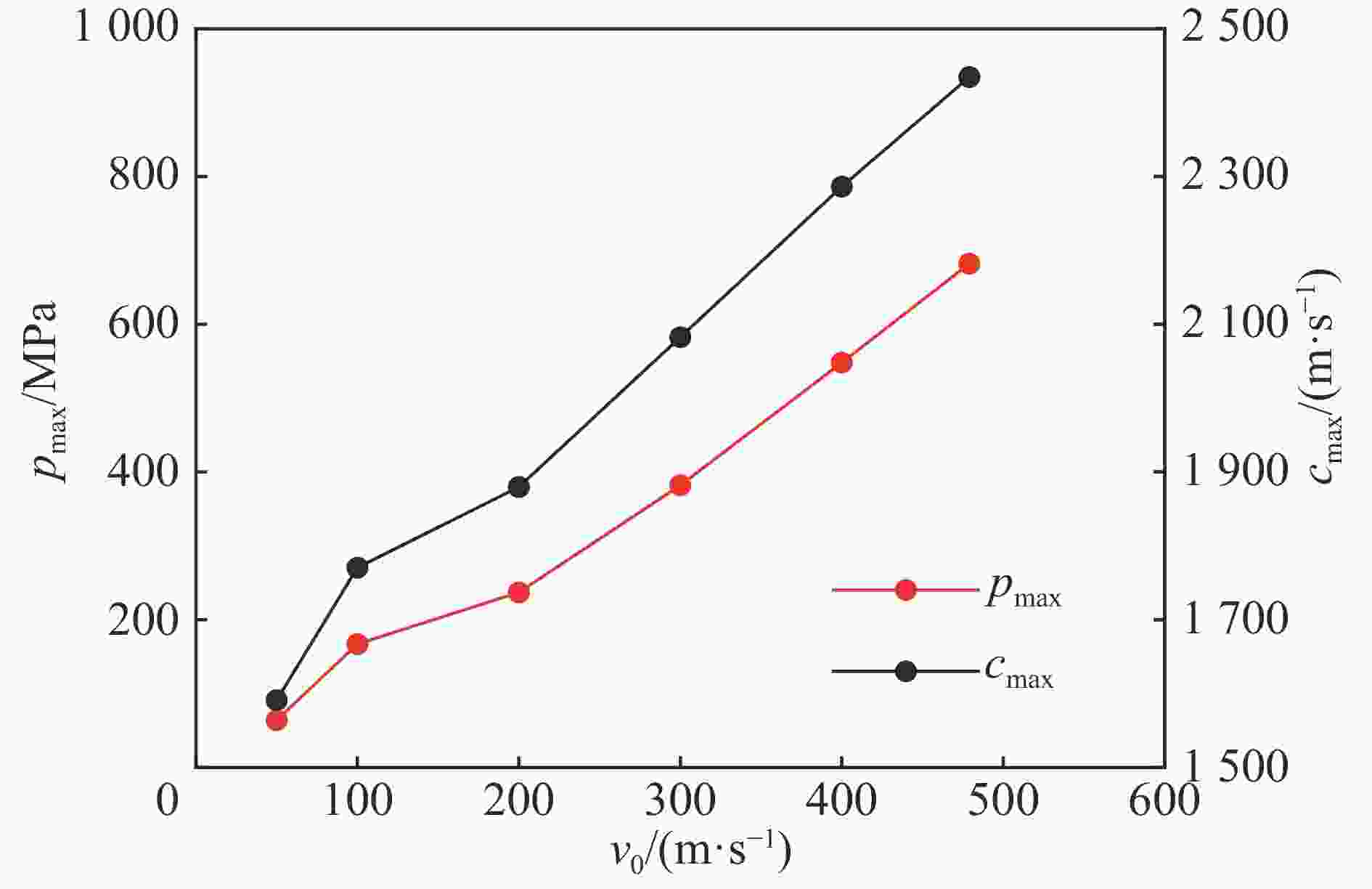

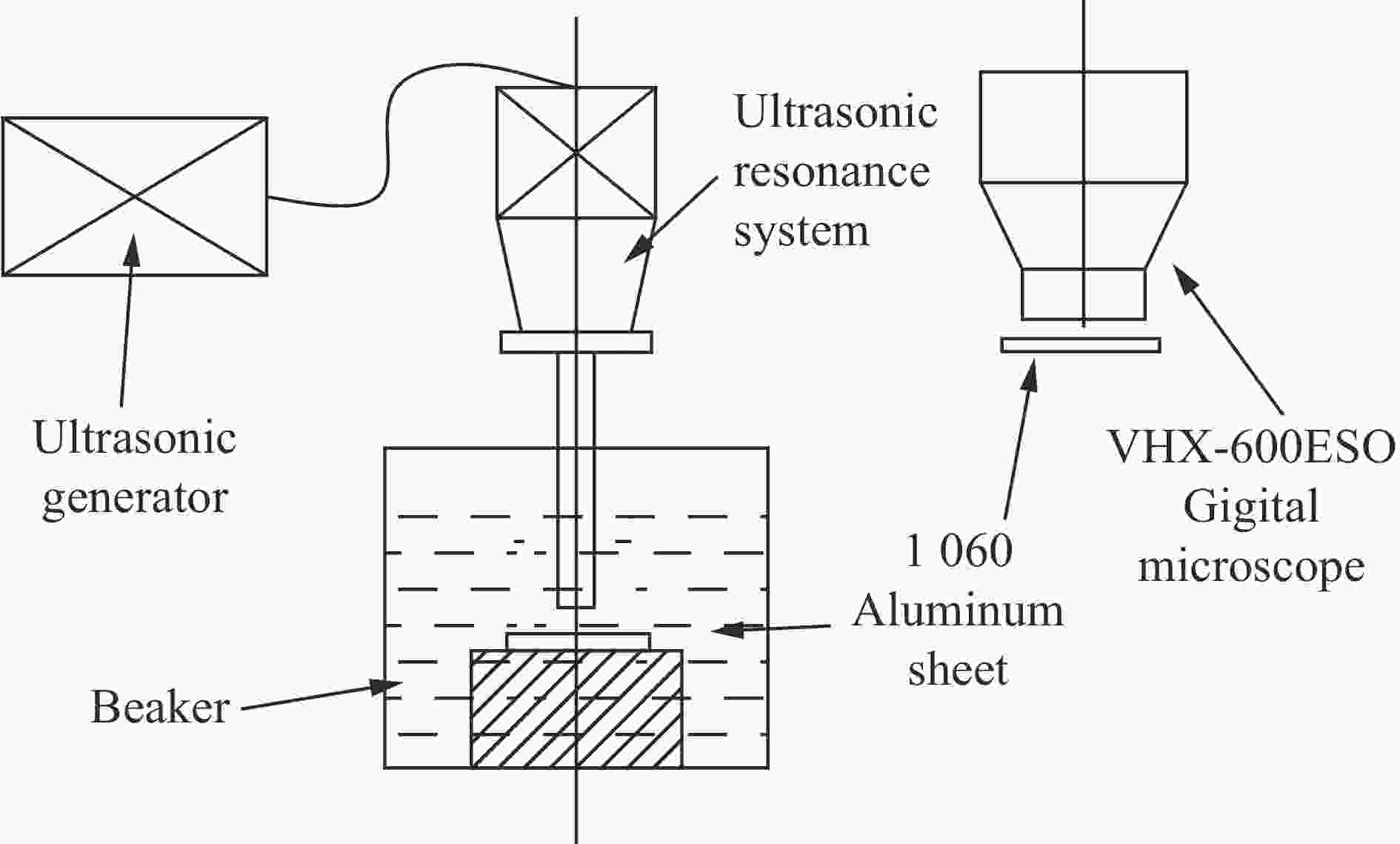

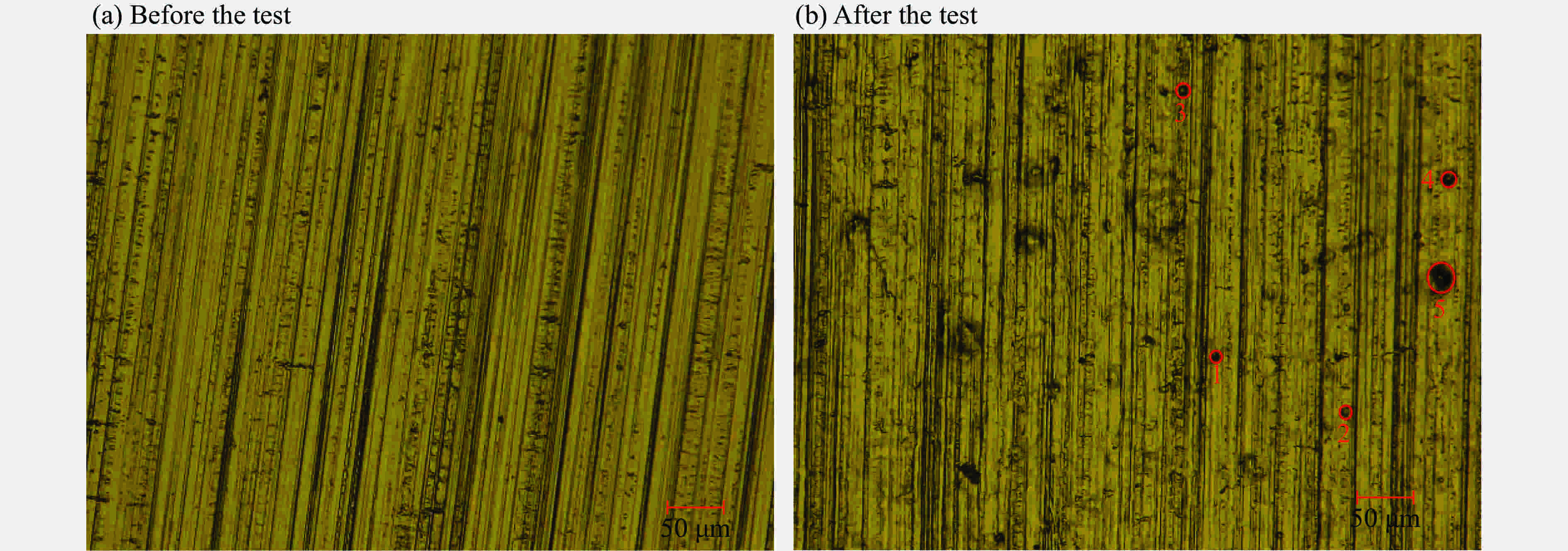

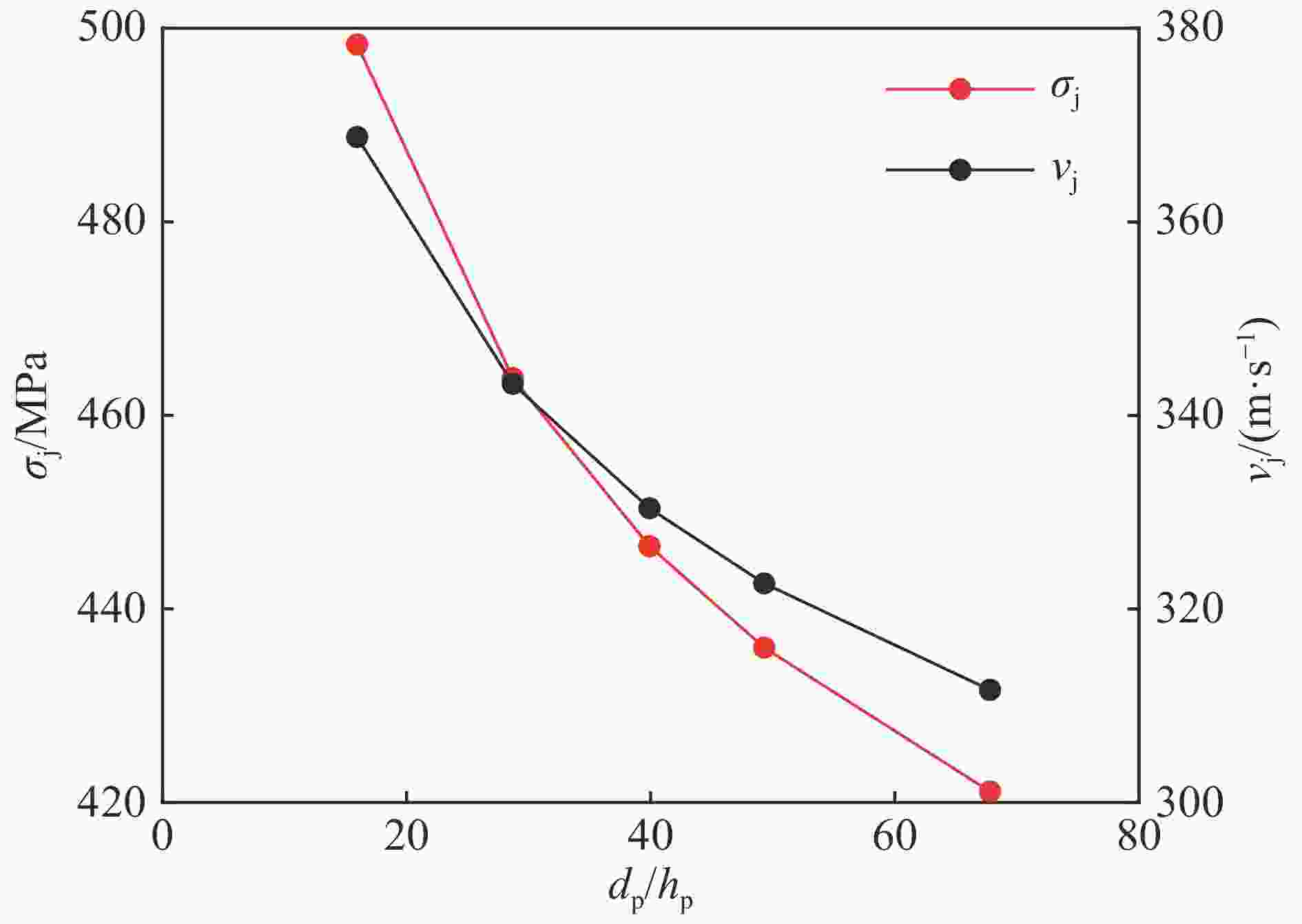

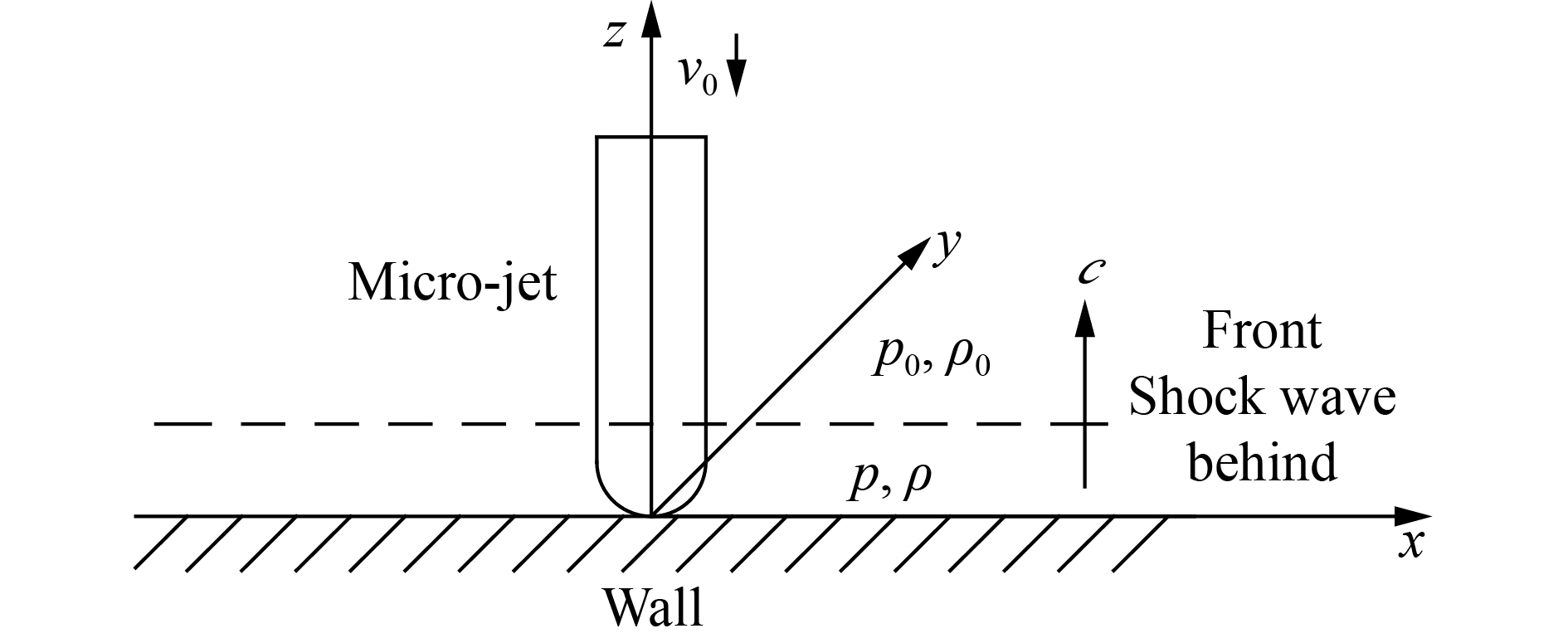

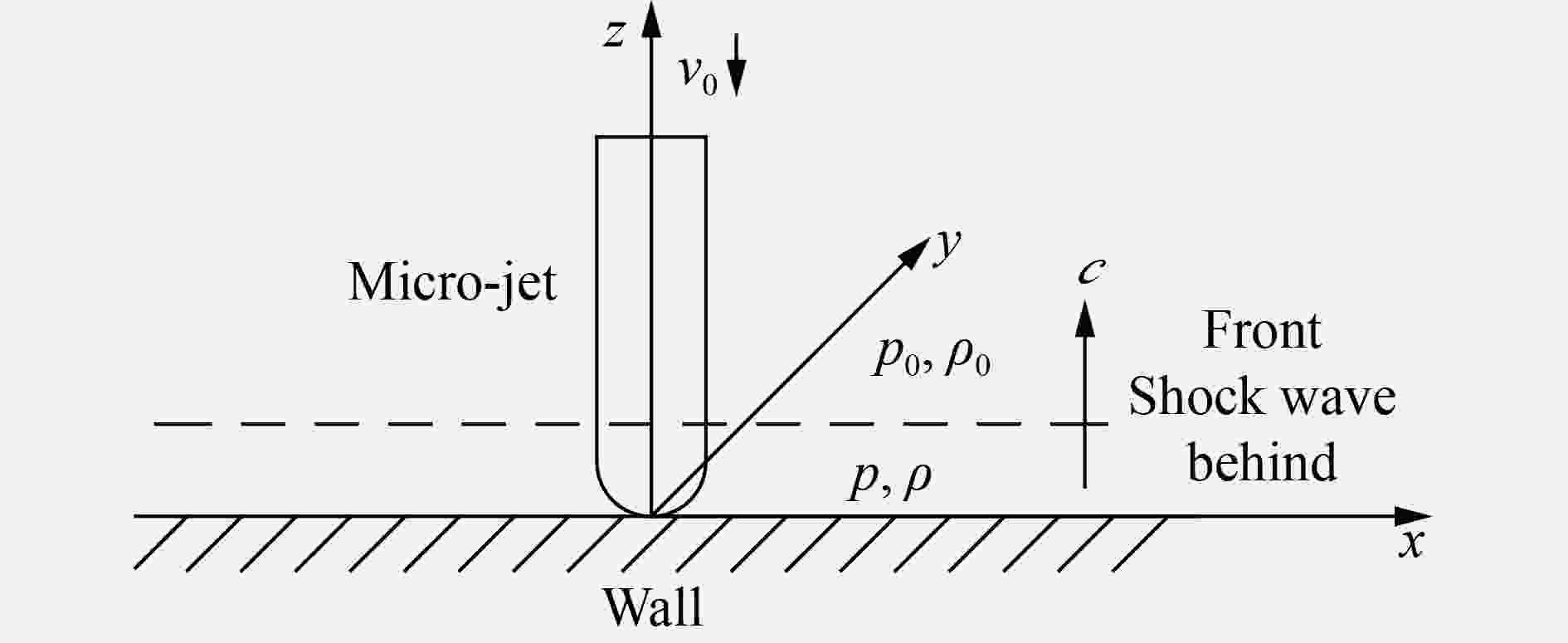

摘要: 超声场下液体环境中近壁空泡溃灭会产生强烈的微射流,为探究微射流冲击壁面流固耦合效应,利用流体力学及冲击动力学,考虑了率相关的J-C材料本构模型,建立并分析了微射流冲击壁面流固耦合三维模型,并通过超声空化试验和基于球形压痕试验理论的反演分析进行了验证。结果表明:微射流冲击下材料表面出现微型凹坑,凹坑深度由微射流速度和微射流直径共同决定且随其增大而增大,凹坑直径主要与微射流直径正相关,而凹坑径深比则主要与微射流速度负相关;壁面压强基本呈对称分布且最大压强出现在微射流冲击边缘;超声空化试验验证了微射流冲击下材料表面出现的微型凹坑,反演分析方法表明,在16~18的径深比下,微射流冲击强度为420~500 MPa,对应的微射流速度为310~370 m/s。试验及反演分析结果与理论分析结果相符,验证了流固耦合模型及反演分析方法的合理性及准确性,为后续工程应用中空化强度、微射流速度等的控制提供了理论参考。Abstract: Bubble collapse near a wall will generate strong micro-jet in a liquid environment under ultrasonic field. To explore the fluid-solid coupling effect of micro-jet impinging on a wall, hydrodynamics and impact dynamics were employed, and the J-C rate correlation material constitutive model was applied, then a three-dimensional fluid-solid coupling model of micro-jet impact on a wall was established and analyzed numerically based on the Euler-Lagrange coupling method. Finally, an ultrasonic cavitation test and inversion analysis based on the theory of the spherical indentation test were conducted for validation. Pit depth is decided jointly by micro-jet velocity and micro-jet diameter, and increases with their increases, while the ratio of diameter to depth of a pit is negatively correlated with the micro-jet velocity. Wall pressure distribution is mostly symmetric and the maximum pressure appears on the edge of micro-jet impinging. The maximum wall pressure clearly increases with the micro-jet velocity. The increase of the pressure can lead to the increase of the shock wave intensity and velocity in liquid, which can reach 682 MPa and 2 435 m/s, respectively, when the micro-jet velocity is 479 m/s. Micropits appearing on the material surface impacted by micro-jet were demonstrated by ultrasonic cavitation test, and the pits’ ratio of diameter to depth vary from 16 to 68. Inversion analysis results indicate that equivalent stress, equivalent strain of the pit and impact strength, velocity of the micro-jet are closely related with the ratio of diameter to depth of the pit. When it is 16−68, the micro-jet impingement strength is 420−500 MPa, and the corresponding micro-jet velocity is 310−370 m/s. Test and inversion analysis results are consistent with the theoretical analysis, which verifies the rationality and accuracy of a fluid-solid coupling model considering the J-C rate correlation material constitutive model and inversion analysis method. This work provides a theoretical reference for the control of cavitation intensity and micro-jet velocity in the following engineering applications.

-

Key words:

- ultrasonic cavitation /

- micro-jet impact /

- fluid-solid coupling /

- inversion analysis

-

表 1 Al 1060材料参数

Table 1. Material parameters of Al1060

ρs/(kg·m−3) cs/(m·s−1) σ0/MPa B/MPa n1 C ${\dot \varepsilon _{{}_0}}$ 2 707 5 000 66.562 108.853 0.23 0.029 1 表 2 凹坑几何参数

Table 2. Pit geometry parameters

凹坑 直径/μm 深度/μm 径深比 1 4.07 0.06 67.8 2 5.43 0.11 49.3 3 6.79 0.17 39.9 4 7.76 0.27 28.7 5 14.04 0.88 15.95 -

[1] 向文英, 李晓红, 卢义玉, 等. 空化射流效应的实验研究 [J]. 中国机械工程, 2006, 17(13): 1388–1391. DOI: 10.3321/j.issn:1004-132X.2006.13.016.XIANG Wenying, LI Xiaohong, LU Yiyu, et al. Experimental study of domino effect on cavitating water jet [J]. China Mechanical Engineering, 2006, 17(13): 1388–1391. DOI: 10.3321/j.issn:1004-132X.2006.13.016. [2] 张阿漫, 姚熊亮. 近边界三维水下爆炸气泡动态特性研究 [J]. 爆炸与冲击, 2008, 28(2): 124–130. DOI: 10.11883/1001-1455(2008)02-0124-07.ZHANG Aman, YAO Xiongliang. On dynamics of an underwater explosion bubble near a boundary [J]. Explosion and Shock Waves, 2008, 28(2): 124–130. DOI: 10.11883/1001-1455(2008)02-0124-07. [3] 张阿漫, 姚熊亮. 近自由面水下爆炸气泡的运动规律研究 [J]. 物理学报, 2008, 57(1): 339–353. DOI: 10.3321/j.issn:1000-3290.2008.01.054.ZHANG Aman, YAO Xiongliang. Law of the underwater explosion bubble motion near free surface [J]. Acta Physica Sinica, 2008, 57(1): 339–353. DOI: 10.3321/j.issn:1000-3290.2008.01.054. [4] 李健, 黄红生, 林贤坤, 等. 基于VOF法的近自由面水下爆炸气泡运动数值模拟 [J]. 北京理工大学学报, 2016, 36(2): 122–127. DOI: 10.15918/j.tbit1001-0645.2016.02.003.LI Jian, HUANG Hongsheng, LIN Xiankun, et al. Numerical study on bubble motion by underwater explosion near free surface based on VOF [J]. Transactions of Beijing Institute of Technology, 2016, 36(2): 122–127. DOI: 10.15918/j.tbit1001-0645.2016.02.003. [5] 郭娅, 唐文勇, 郑绍文, 等. 水下近场爆炸冲击波与射流载荷联合作用分析方法 [J]. 振动与冲击, 2014, 33(20): 26–30. DOI: 10.13465/j.cnki.jvs.2014.20.006.GUO Ya, TANG Wenyong, ZHENG Shaowen, et al. Simulation method for the combined effect of underwater near-field shock wave and jet load [J]. Journal of Vibration and Shock, 2014, 33(20): 26–30. DOI: 10.13465/j.cnki.jvs.2014.20.006. [6] 沈壮志, 林书玉. 声场中水力空化泡的动力学特性 [J]. 物理学报, 2011, 60(08): 385–394. DOI: 10.7498/aps.60.084302.SHEN Zhuangzhi, LIN Shuyu. Dynamical behaviors of hydrodynamic cavitation bubble under ultrasound field [J]. Acta Physica Sinica, 2011, 60(08): 385–394. DOI: 10.7498/aps.60.084302. [7] 郭策, 祝锡晶, 王建青, 等. 超声场下刚性界面附近溃灭空化气泡的速度分析 [J]. 物理学报, 2016, 65(4): 180–187. DOI: 10.7498/aps.65.044304.GUO Ce, ZHU Xijing, WANG Jianqing, et al. Velocity analysis for collapsing cavitation bubble near a rigid wall under an ultrasound field [J]. Acta Physica Sinica, 2016, 65(4): 180–187. DOI: 10.7498/aps.65.044304. [8] TAKAKUWA O, NISHIKAWA M, SOYAMA H. Estimation of the depth of surface modification layer induced by cavitation peening [J]. Journal of Materials Processing Technology, 2012, 212(8): 1716–1722. DOI: 10.1016/j.jmatprotec.2012.03.010. [9] FRANC J P, RIONDET M, KARIMI A, et al. Material and velocity effects on cavitation erosion pitting [J]. Wear, 2012, 274: 248–259. DOI: 10.1016/j.wear.2011.09.006. [10] KORNFELD M, SUVOROV L. On the destructive action of cavitation [J]. Journal of Applied Physics, 1944, 15(6): 495–506. DOI: 10.1063/1.1707461. [11] GREGORČIČ P, PETKOVŠEK R, MOŽINA J. Investigation of a cavitation bubble between a rigid boundary and a free surface [J]. Journal of Applied Physics, 2007, 102(9): 21–23. DOI: 10.1063/1.2805645. [12] PLESSET M S, CHAPMAN R B. Collapse of an initially spherical vapour cavity in the neighbourhood of a solid boundary [J]. Journal of Fluid Mechanics, 1971, 47(2): 283–290. DOI: 10.1017/S0022112071001058. [13] DULAR M. Hydrodynamic cavitation damage in water at elevated temperatures [J]. Wear, 2016, s346–347: 78–86. DOI: 10.1016/j.wear.2015.11.007. [14] TZANAKIS I, ESKIN D G, GEORGOULAS A, et al. Incubation pit analysis and calculation of the hydrodynamic impact pressure from the implosion of an acoustic cavitation bubble [J]. Ultrasonics Sonochemistry, 2014, 21(2): 866–878. DOI: 10.1016/j.ultsonch.2013.10.003. [15] REUTER F, METTIN R. Mechanisms of single bubble cleaning [J]. Ultrasonics Sonochemistry, 2015, 29: 550–562. DOI: 10.1016/j.ultsonch.2015.06.017. [16] SOYAMA H, TAKEO F. Comparison between cavitation peening and shot peening for extending the fatigue life of a duralumin plate with a hole [J]. Journal of Materials Processing Technology, 2016, 227: 80–87. DOI: 10.1016/j.jmatprotec.2015.08.012. [17] DULAR M, STOFFEL B, ŠIROK B. Development of a cavitation erosion model [J]. Wear, 2006, 261(5–6): 642–655. DOI: 10.1016/j.wear.2006.01.020. [18] LI R, NINOKATA H, MORI M. A numerical study of impact force caused by liquid droplet impingement onto a rigid wall [J]. Progress in Nuclear Energy, 2011, 53(7): 881–885. DOI: 10.1016/j.pnucene.2011.03.002. [19] LI N, ZHOU Q, CHEN X, et al. Liquid drop impact on solid surface with application to water drop erosion on turbine blades, Part I: Nonlinear wave model and solution of one-dimensional impact [J]. International Journal of Mechanical Sciences, 2008, 50(10): 1526–1542. DOI: 10.1016/j.ijmecsci.2008.08.001. [20] CARNELLI D, KARIMI A, FRANC J P. Evaluation of the hydrodynamic pressure of cavitation impacts from stress–strain analysis and geometry of individual pits [J]. Wear, 2012, 289(5): 104–111. DOI: 10.1016/j.wear.2012.04.009. [21] 王艳辉. 1060铝搅拌摩擦焊温度场数值模拟 [D]. 苏州: 江苏科技大学, 2012: 24−25. [22] CARNELLI D, KARIMI A, FRANC J P. Application of spherical nanoindentation to determine the pressure of cavitation impacts from pitting tests [J]. Journal of Materials Research, 2012, 27(1): 91–99. DOI: 10.1557/jmr.2011.259. [23] ROY S C, FRANC J P, PELLONE C, et al. Determination of cavitation load spectra – Part 1: Static finite element approach [J]. Wear, 2015, s 344–345: 110–119. DOI: 10.1016/j.wear.2015.09.006. [24] FRANCIS H A. Phenomenological analysis of plastic spherical indentation [J]. Journal of Engineering Materials and Technology Transactions of the Asme, 1976, 98(3): 272–281. DOI: 10.1115/1.3443378. [25] GRANT M M, LUSH P A. Liquid impact on a bilinear elastic-plastic solid and its role in cavitation erosion [J]. Journal of Fluid Mechanics, 2006, 176: 237–252. DOI: 10.1017/S0022112087000648. [26] CHEN H, LI J, CHEN D, et al. Damages on steel surface at the incubation stage of the vibration cavitation erosion in water [J]. Wear, 2008, 265(5–6): 692–698. DOI: 10.1016/j.wear.2007.12.011. [27] PETKOVSEK R, GREGORCIC P. A laser probe measurement of cavitation bubble dynamics improved by shock wave detection and compared to shadow photography [J]. Journal of Applied Physics, 2007, 102(4): 044909–044909. DOI: 10.1063/1.2774000. [28] ROBERTO G A S, SONG C, CLAUS-DIETER O. Fast transient microjets induced by hemispherical cavitation bubbles [J]. Journal of Fluid Mechanics, 2015, 767: 31–51. DOI: 10.1017/jfm.2015.33. [29] FUTAKAWA M, NAOE T, KOGAWA H, et al. Micro-impact damage caused by mercury bubble collapse [J]. JSME International Journal, 2005, 48(4): 234–239. DOI: 10.1299/jsmea.48.234. -

下载:

下载: